Professional Documents

Culture Documents

L9 Metals

L9 Metals

Uploaded by

Carlo EstoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L9 Metals

L9 Metals

Uploaded by

Carlo EstoleCopyright:

Available Formats

106

Unit 3 – The Chemistry of Engineering

Materials

Metals

LEARNING OBJECTIVES

• Describe the occurrence and abundance of metals in the Earth’s crust.

• Explain the processes involve

in the metallurgy of iron and steel

making.

• Explain the concept of the Band Theory of Electrical Conductivity

• Discuss the periodic trends of some metals and their reactivity.

1.0 OCCURRENCE OF METALS

A mineral where most metals come from, is a naturally occurring substance with a

range of chemical composition. A mineral deposit concentrated enough to allow economical

recovery of a desired metal is known as ore. Thus, an ore is a deposit in Earth’s crust of one

or more valuable minerals. Table 1 has the lists of principal types of minerals.

Aluminum, iron, calcium, magnesium, sodium, potassium, titanium and manganese

are the most abundant metals which exists as minerals in the Earth’s crust. Seawater is a rich

source of some metal ions, such as 𝑁𝑎N , 𝑀𝑔!N , 𝑎𝑛𝑑 𝐶𝑎!N . Moreover, vast areas of the ocean

floor are covered with manganese nodules which are made up mostly of manganese, along

with iron, nickel, copper, and cobalt in a chemically combine state. Manganese nodules are

combinations of rock on the sea bottom which is composed of concentric layers of iron and

manganese hydroxides around a core.

Table 1. Principal Types of Minerals (Chang & Goldsby, 2017)

Type Minerals

Uncombined 𝐴𝑔, 𝐴𝑢, 𝐵𝑖, 𝐶𝑢, 𝑃𝑑, 𝑃𝑡

metals

Carbonates 𝐵𝑎𝐶𝑂+ (witherite), 𝐶𝑎𝐶𝑂+ (calcite, limestone), 𝑀𝑔𝐶𝑂3

SCI 401 –GENERAL CHEMISTRY

107

(magnesite), 𝐶𝑎𝐶𝑂+ ∙ 𝑀𝑔𝐶𝑂+ (dolomite), 𝑃𝑏𝐶𝑂+ (cerussite), 𝑍𝑛𝐶𝑂+

(smithsonite)

Halides 𝐶𝑎𝐹! (fluorite), 𝑁𝑎𝐶𝑙 (halite), 𝐾𝐶𝑙 (sylvite), 𝑁𝑎+ 𝐴𝑙𝐹5 (cryolite)

Oxides 𝐴𝑙! 𝑂+ ∙ 2𝐻! 𝑂 (bauxite), 𝐴𝑙! 𝑂+ (corundum), 𝐹𝑒! 𝑂+ (hematite),

𝐹𝑒+ 𝑂$ (magnetite), 𝐶𝑢! 𝑂 (cuprite),

𝑀𝑛𝑂! (pyrolusite), 𝑆𝑛𝑂! (cassiterite), 𝑇𝑖𝑂! (rutile), 𝑍𝑛𝑂 (zincite)

Phosphates 𝐶𝑎+ (𝑃𝑂$ )! (phosphate rock), 𝐶𝑎# (𝑃𝑂$ )+ 𝑂𝐻 (hydroxyapatite)

Silicates 𝐵𝑒+ 𝐴𝑙! 𝑆𝑖5 𝑂(8 (beryl), 𝑍𝑟𝑆𝑖𝑂$ (zircon), 𝑁𝑎𝐴𝑙𝑆𝑖+ 𝑂8 (albite),

𝑀𝑔+ (𝑆𝑖$ 𝑂(0 )(𝑂𝐻)! (talc)

Sulfides 𝐴𝑔! 𝑆 (argentite), 𝐶𝑑𝑆 (greenockite), 𝐶𝑢! 𝑆 (chalcocite), 𝐹𝑒𝑆! (pyrite),

𝐻𝑔𝑆 (cinnabar), 𝑃𝑏𝑆 (galena), 𝑍𝑛𝑆 (sphalerite)

Sulfates 𝐵𝑎𝑆𝑂$ (barite), 𝐶𝑎𝑆𝑂$ (anhydrite), 𝑃𝑏𝑆𝑂$ (anglesite),

𝑆𝑟𝑆𝑂$ (celestite), 𝑀𝑔𝑆𝑂$ ∙ 7𝐻! 𝑂 (epsomite)

2.0 METALLURGICAL PROCESSES

The science and technology of separating metals from their ores and of compounding

alloys is called metallurgical process. An alloy is a solid solution either of two or more

metals, or of a metal or metals with one or more nonmetals. The three principal steps in the

recovery of a metal from its ore are (1) preparation of the ore, (2) production of the metal,

and (3) purification of the metal.

Preparation of the Ore

In ore prior treatment, the desired mineral is separated from waste materials that is

usually clay and silicate minerals which are collectively called the gangue. Flotation is a very

useful process for carrying out this separation. In this process, the ore is finely ground and

added to water containing oil and detergent. The liquid mixture is then beaten or blown to

form a froth. The oil preferentially wets the mineral particles, which are then carried to the

top in the froth, while the gangue settles to the bottom. The froth is skimmed off, allowed to

collapse, and dried to recover the mineral particles.

Another physical separation process makes use of the magnetic properties of certain

minerals. Ferromagnetic metals are strongly attracted to magnets. The mineral magnetite

(𝐹𝑒3𝑂4), in particular, can be separated from the gangue by using a strong electromagnet.

Cobalt is another ferromagnetic metal.

Mercury forms amalgams with a number of metals. An amalgam is an alloy of

mercury with another metal or metals. Mercury can therefore be used to extract metal from

ore. Mercury dissolves the silver and gold in an ore to form a liquid amalgam, which is easily

separated from the remaining ore. The gold or silver is recovered by distilling off mercury.

MACALALAD – GAYETA - BASILAN | BATSTATEU

108

Production of Metals

Because metals in their combined forms always have positive oxidation numbers, the

production of a free metal is a reduction process. Preliminary operations may be necessary

to convert the ore to a chemical state more suitable for reduction. For example, an ore may

be roasted to drive off volatile impurities and at the same time to convert the carbonates and

sulfides to the corresponding oxides, which can be reduced more conveniently to yield the

pure metals:

𝐶𝑎𝐶𝑂+ (𝑠) → 𝐶𝑎𝑂(𝑠) + 𝐶𝑂! (𝑔)

2𝑃𝑏𝑆(𝑠) + 3𝑂! (𝑔) → 2𝑃𝑏𝑂(𝑠) + 2𝑆𝑂! (𝑔)

This last equation points out the fact that the conversion of sulfides to oxides is a

major source of sulfur dioxide, a notorious air pollutant. Most major metallurgical processes

now in use involve pyrometallurgy, procedures carried out at high temperatures.

Chemical Reduction

We can use a more electropositive metal as a reducing agent to separate a less

electropositive metal from its compound at high temperatures:

𝑉! 𝑂# (𝑠) + 5𝐶𝑎(𝑙) → 2𝑉(𝑙) + 5𝐶𝑎𝑂(𝑠)

𝑇𝑖𝐶𝑙$ (𝑔) + 2𝑀𝑔(𝑙) → 𝑇𝑖(𝑠) + 2𝑀𝑔𝐶𝑙! (𝑙)

𝐶𝑟2𝑂3(𝑠) + 2𝐴𝑙(𝑠) → 2𝐶𝑟(𝑙) + 𝐴𝑙2𝑂3(𝑠)

3𝑀𝑛+ 𝑂$ (𝑠) + 8𝐴𝑙(𝑠) → 9𝑀𝑛(𝑙) + 4𝐴𝑙2𝑂3(𝑠)

In some cases, even molecular hydrogen can be used as a reducing agent, as in the

preparation of tungsten (used as filaments in lightbulbs) from tungsten(VI) oxide:

𝑊𝑂3(𝑠) + 3𝐻2(𝑔) → 𝑊(𝑠) + 3𝐻2𝑂(𝑔)

Electrolytic Reduction

Electrolytic reduction is suitable for very electropositive metals, such as sodium,

magnesium, and aluminum. The process is usually carried out on the anhydrous molten

oxide or halide of the metal:

2𝑀𝑂(𝑙) → 2𝑀 (𝑎𝑡 𝑐𝑎𝑡ℎ𝑜𝑑𝑒) + 𝑂2 (𝑎𝑡 𝑎𝑛𝑜𝑑𝑒)

2𝑀𝐶𝑙(𝑙) → 2𝑀 (𝑎𝑡 𝑐𝑎𝑡ℎ𝑜𝑑𝑒) + 𝐶𝑙2 (𝑎𝑡 𝑎𝑛𝑜𝑑𝑒)

The Metallurgy of Iron

Iron exists in Earth’s crust in many different minerals, such as iron pyrite (𝐹𝑒𝑆2),

siderite (𝐹𝑒𝐶𝑂3), hematite (𝐹𝑒2𝑂3), and magnetite (𝐹𝑒3𝑂4, often represented as 𝐹𝑒𝑂 ∙

𝐹𝑒2𝑂3). Hematite and magnetite are predominantly suitable for the extraction of iron. The

metallurgical processing of iron involves the chemical reduction of the minerals by carbon

(in the form of coke) in a blast furnace (Figure 1). The concentrated iron ore, limestone

(𝐶𝑎𝐶𝑂3), and coke are feed into the furnace from the top. A blast of hot air is forced up the

SCI 401 –GENERAL CHEMISTRY

109

furnace from the bottom, that’s why it is called a blast furnace. The oxygen gas reacts with

the carbon in the coke to form mostly carbon monoxide and some carbon dioxide. These

reactions are highly exothermic, and as the hot 𝐶𝑂 𝑎𝑛𝑑 𝐶𝑂2 gases rise, they react with the

iron oxides in different temperature zones, as shown in Figure 1. The key steps in the

extraction of iron are:

3𝐹𝑒2𝑂3(𝑠) + 𝐶𝑂(𝑔) → 2𝐹𝑒3𝑂4(𝑠) + 𝐶𝑂2(𝑔)

𝐹𝑒3𝑂4(𝑠) + 𝐶𝑂(𝑔) → 3𝐹𝑒𝑂(𝑠) + 𝐶𝑂2(𝑔)

𝐹𝑒𝑂(𝑠) + 𝐶𝑂(𝑔) → 𝐹𝑒(𝑙) + 𝐶𝑂2(𝑔)

The decomposition of limestone in the furnace is shown the equation below:

𝐶𝑎𝐶𝑂3(𝑠) → 𝐶𝑎𝑂(𝑠) + 𝐶𝑂2(𝑔)

The calcium oxide then reacts with the impurities in the iron, which are mostly sand

(𝑆𝑖𝑂2) and aluminum oxide (𝐴𝑙2𝑂3):

𝐶𝑎𝑂(𝑠) + 𝑆𝑖𝑂2(𝑠) → 𝐶𝑎𝑆𝑖𝑂3(𝑙)

𝐶𝑎𝑂(𝑠) + 𝐴𝑙2𝑂3(𝑠) → 𝐶𝑎(𝐴𝑙𝑂2)2(𝑙)

A mixture of calcium silicate and calcium aluminate that remains molten at the

furnace temperature is known as slag.

By the time the ore works its way down to the bottom of the furnace, most of it has

already been reduced to iron.

Figure 1. A blast furnace. Iron ore, limestone,

and coke are introduced at the top of the

furnace. Iron is obtained from the ore by

reduction with carbon (Chang & Goldsby,

2017).

Iron extracted in this way contains many impurities and is called pig iron; it may

contain up to 5 percent carbon and some silicon, phosphorus, manganese, and sulfur. Some

MACALALAD – GAYETA - BASILAN | BATSTATEU

110

of the impurities stem from the silicate and phosphate minerals, while carbon and sulfur

come from coke. Pig iron is granular and brittle. It has a relatively low melting point (about

1180°𝐶), so it can be cast in various forms; for this reason it is also called cast iron.

Steelmaking

Steel is an iron alloy that contains from 0.03 to 1.4 percent carbon plus various

amounts of other elements. The wide range of useful mechanical properties associated with

steel is primarily a function of chemical composition and heat treatment of a particular type

of steel.

The conversion of iron to steel is essentially an oxidation process in which the

unwanted impurities are removed from the iron by reaction with oxygen gas. One of several

methods used in steelmaking is the basic oxygen process.

Figure 2 shows the basic oxygen process. Molten iron from the blast furnace is poured

into an upright cylindrical vessel. Pressurized oxygen gas is introduced via a water-cooled

tube above the molten metal. Under these conditions, manganese, phosphorus, and silicon,

as well as excess carbon, react with oxygen to form oxides. These oxides are then reacted

with the appropriate fluxes (for example, CaO or SiO2) to form slag. If the main impurities

are silicon and phosphorus, a basic flux such as CaO is added to the iron:

𝑆𝑖𝑂2(𝑠) + 𝐶𝑎𝑂(𝑠) → 𝐶𝑎𝑆𝑖𝑂3(𝑙)

𝑃4𝑂10(𝑙) + 6𝐶𝑎𝑂(𝑠) → 2𝐶𝑎3(𝑃𝑂4)2(𝑙)

Figure 2. The basic oxygen process of

steelmaking. The capacity of a typical

vessel is 100 tons of cast iron (Chang

& Goldsby, 2017).

On the other hand, if manganese is the main impurity, then an acidic flux such as

𝑆𝑖𝑂2 is needed to form the slag:

𝑀𝑛𝑂(𝑠) + 𝑆𝑖𝑂2(𝑠) → 𝑀𝑛𝑆𝑖𝑂3(𝑙)

SCI 401 –GENERAL CHEMISTRY

111

The properties of steel depend not only on its chemical composition but also on the

heat treatment. At high temperatures, iron and carbon in steel combine to form iron carbide,

𝐹𝑒3𝐶, called cementite:

3𝐹𝑒(𝑠) + 𝐶(𝑠) ⟺ 𝐹𝑒3𝐶(𝑠)

The forward reaction is endothermic, so that the formation of cementite is favored at

high temperatures. When steel containing cementite is cooled slowly, the preceding

equilibrium shifts to the left, and the carbon separates as small particles of graphite, which

give the steel a gray color. (Very slow decomposition of cementite also takes place at room

temperature). If the steel is cooled rapidly, equilibrium is not attained and the carbon

remains largely in the form of cementite, 𝐹𝑒3𝐶. Steel containing cementite is light in color,

and it is harder and more brittle than that containing graphite.

Heating the steel to some appropriate temperature for a short time and then cooling

it rapidly in order to give it the desired mechanical properties is known as “tempering.” In

this way, the ratio of carbon present as graphite and as cementite can be varied within rather

wide limits. Table 2 shows the properties, composition and uses of various types of steels

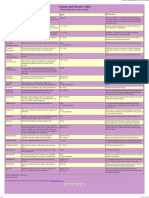

Table 2. The properties and uses of various types of steel.

Composition (Percent by Mass)

Type C Mn P S Si Ni Cr Others Uses

Plain 1.35 1.65 0.04 0.05 0.06 - - Cu(0.2- Sheet products,

0.6) tools

High- 0.25 1.65 0.04 0.05 0.15- 0.4- 0.3- Cu(0.01- Construction, steam

strength 0.9 1.0 1.3 0.08 turbines

Stainless 0.03- 1.0- 0.04- 0.03 1-3 1- 4.0- - Kitchen utensils,

1.2 10 0.06 22 27 razor blades

3.0 Purification of Metals

Metals prepared by reduction usually need further treatment to remove impurities.

The extent of purification, of course, depends on how the metal will be used. Three common

purification procedures are distillation, electrolysis, and zone refining.

Distillation

Metals that have low boiling points, such as mercury, magnesium, and zinc, can be

separated from other metals by fractional distillation. One well-known method of fractional

distillation is the Mond process (named after Ludwig Mond, a British chemist of German

origin) for the purification of nickel. Carbon monoxide gas is passed over the impure nickel

MACALALAD – GAYETA - BASILAN | BATSTATEU

112

metal at about 70°𝐶 to form the volatile tetracarbonylnickel (𝑏. 𝑝. 43°𝐶), a highly toxic

substance, which is separated from the less volatile impurities by distillation:

𝑁𝑖(𝑠) + 4𝐶𝑂(𝑔) → 𝑁𝑖(𝐶𝑂)$ (𝑔)

Pure metallic nickel is recovered from 𝑁𝑖(𝐶𝑂)$ by heating the gas at 200°𝐶:

𝑁𝑖(𝐶𝑂)$ (𝑔) →→ 𝑁𝑖(𝑠) + 4𝐶𝑂(𝑔)

The carbon monoxide that is released is recycled back into the process.

Electrolysis

Another important purification technique is electrolysis. The copper metal obtained

by roasting copper sulfide usually contains impurities such as zinc, iron, silver, and gold. The

more electropositive metals are removed by an electrolysis process in which the impure

copper acts as the anode and pure copper acts as the cathode in a sulfuric acid solution

containing 𝐶𝑢!N ions (Figure 3). The reactions are:

𝐴𝑛𝑜𝑑𝑒(𝑜𝑥𝑖𝑑𝑎𝑡𝑖𝑜𝑛): 𝐶𝑢(𝑠) → 𝐶𝑢!N (𝑎𝑞) + 2𝑒 3

𝐶𝑎𝑡ℎ𝑜𝑑𝑒 (𝑟𝑒𝑑𝑢𝑐𝑡𝑖𝑜𝑛): 𝐶𝑢!N (𝑎𝑞) + 2𝑒 3 → 𝐶𝑢(𝑠)

Reactive metals in the copper anode, such as iron and zinc, are also oxidized at the

anode and enter the solution as 𝐹𝑒 !N and 𝑍𝑛!N ions. They are not reduced at the cathode,

however. The less electropositive metals, such as gold and silver, are not oxidized at the

anode. Eventually, as the copper anode dissolves, these metals fall to the bottom of the cell.

Thus, the net result of this electrolysis process is the transfer of copper from the anode to

the cathode.

Figure 3. Electrolytic purification of copper (Chang &

Goldsby, 2017).

Zone Refining

In this process, a metal rod containing a few impurities is drawn through an electrical

heating coil that melts the metal (Figure 4). Most impurities dissolve in the molten metal. As

the metal rod emerges from the heating coil, it cools and the pure metal crystallizes, leaving

SCI 401 –GENERAL CHEMISTRY

113

the impurities in the molten metal portion that is still in the heating coil. (This is analogous

to the freezing of seawater, in which the solid that separates is mostly pure solvent—water.

In zone refining, the liquid metal acts as the solvent and the impurities as the solutes.) When

the molten zone carrying the impurities, now at increased concentration, reaches the end of

the rod, it is allowed to cool and is then cut off.

Figure 4. Zone-refining technique for purifying metals. Top to bottom: An impure metal rod

is moved slowly through a heating coil. As the metal rod moves forward, the impurities

dissolve in the molten portion of the metal while pure metal crystallizes out in front of the

molten zone (Chang & Goldsby, 2017).

4.0 BAND THEORY OF ELECTRICAL CONDUCTIVITY

Band theory (a model use to study metallic bonding) states that delocalized electrons

move freely through “bands” formed by overlapping molecular orbitals. This theory can also

be applied to certain elements that are semiconductors.

Conductors

Metals are characterized by high electrical conductivity. For example, magnesium has

an electron configuration of [𝑁𝑒]3𝑠2, so each atom has two valence electrons in the 3s

orbital. In a metallic crystal, the atoms are packed closely together, so the energy levels of

each magnesium atom are affected by the immediate neighbors of the atom as a result of

orbital overlaps. The interaction between two atomic orbitals leads to the formation of a

bonding and an antibonding molecular orbital. Because the number of atoms in even a small

piece of magnesium is enormously large (on the order of 1020 atoms), the number of

molecular orbitals they form is also very large. These molecular orbitals are so closely spaced

on the energy scale that they are more appropriately described as a “band” (Figure 5). The

closely spaced filled energy levels make up the valence band. The upper half of the energy

levels corresponds to the empty, delocalized molecular orbitals formed by the overlap of the

3p orbitals. This set of closely spaced empty levels is called the conduction band.

MACALALAD – GAYETA - BASILAN | BATSTATEU

114

Figure 5. Formation of conduction bands in magnesium (Chang & Goldsby, 2017).

The electrons in the 1s, 2s, and 2p orbitals are localized on each Mg atom. However,

the 3s and 3p orbitals overlap to form delocalized molecular orbitals. Electrons in these

orbitals can travel throughout the metal, and this accounts for the electrical conductivity of

the metal.

The great cohesive force resulting from the delocalization is partly responsible for the

strength noted in most metals. Because the valence band and the conduction band are

adjacent to each other, the amount of energy needed to promote a valence electron to the

conduction band is negligible. There, the electron can travel freely through the metal,

because the conduction band is void of electrons. This freedom of movement accounts for

the fact that metals are good conductors, that is, they are capable of conducting electric

current.

Why don’t substances like wood and glass conduct electricity as metals do?

Basically, the electrical conductivity of a solid depends on the spacing and the state of

occupancy of the energy bands. In wood and glass, there is a gap between the valence band

and the conduction band is considerably greater than that in a metal. Consequently, much

more energy is needed to excite an electron into the conduction band. Lacking this energy,

electrons cannot move freely. Therefore, glass and wood are insulators, ineffective

conductors of electricity.

Semiconductors

Semiconductors normally are not conductors, but will conduct electricity at elevated

temperatures or when combined with a small amount of certain other elements (examples

are silicon and germanium from Group 4A elements). The use of semiconductors has

changed the electronic industry in recent decades, leading to increased miniaturization of

electric component. Transistors and solar cells are two examples of semiconductor’s

applications.

SCI 401 –GENERAL CHEMISTRY

115

If the energy needed to excite electrons from the valence band into the conduction

band is provided, the solid becomes a conductor. Note that this behavior is opposite that of

the metals. A metal’s ability to conduct electricity decreases with increasing temperature

because the enhanced vibration of atoms at higher temperatures tends to disrupt the flow of

electrons.

Enhancement of semiconductor’s ability to conduct electricity can be done, this is by

means of adding small amount of certain impurities to the element, this process is called

doping. Impurities of this type are known as donor impurities, because they provide

conduction electrons. Solids containing donor impurities are called n-type semiconductors,

where n stands for negative (the charge of the “extra” electron).

5.0 PERIODIC TRENDS IN METALLIC PROPERTIES

Figure 6 shows the positions of the representative metals and the Group 2B metals in

the periodic table. There is an increase of electronegativity of these metals from left to right

across a period and from bottom to top in a group. The metallic character of metals increases

in just the opposite directions, that is, from right to left across a period and from top to

bottom in a group. Low electronegativities of metals results to the formation of cations and

almost have positive oxidation numbers in their compounds. However, beryllium and

magnesium in Group 2A and metals in Group 3A and beyond also form covalent compounds.

Figure 6. Representative metals and Group 2B metals according to their positions in the

periodic table (Chang & Goldsby, 2017).

The Alkali Metals

The most electropositive or the least electronegative elements known are the alkali

metals (the Group 1A elements). These metals have a body-centered crystal structure with

low packing efficiency. They are also known because of their low melting point and soft

enough to be sliced with a knife. The lightest known metal is lithium and has great chemical

reactivity. Lithium never occur naturally in elemental form and they are found with halide,

sulfate, carbonate, and silicate ions. Other properties of alkali metals are shown in Table 3.

MACALALAD – GAYETA - BASILAN | BATSTATEU

116

This module will discuss the chemistry of the two most important element in this group;

sodium and potassium.

Table 3. Properties of Alkali Metals (Chang & Goldsby, 2017)

Li Na K Rb Cs

( ( ( (

Valence electron 2𝑠 3𝑠 4𝑠 5𝑠 6𝑠(

configuration

Density (g/cm3) 0.534 0.97 0.86 1.53 1.87

Melting point 179 97.6 63 39 28

(°𝐶)

Boiling point 1317 892 770 688 678

(°𝐶)

Atomic radius 152 186 227 248 265

(pm)

Ionic radius (M+) 78 98 133 148 165

(pm)

Ionization 520 496 419 403 375

energy (kJ/mol)

Electronegativity 1.0 0.9 0.8 0.8 0.7

Sodium and Potassium

Electrolysis is the process where metallic sodium is ideally obtained from molten

sodium chloride. This compound (𝑁𝑎𝐶𝑙) has a high melting point (801°𝐶) where much

energy is needed to keep large amounts of the substance molten. Addition of 𝐶𝑎𝐶𝑙! , can

lower the melting point to about 600°𝐶 which is an ideal temperature for the electrolysis

process.

Metallic potassium is soluble to molten 𝐾𝐶𝑙, that’s why it cannot be prepared easily

by the electrolysis process. Moreover, it vaporizes readily at the operating temperatures,

creating hazardous conditions. Instead, it is usually obtained by the distillation of molten 𝐾𝐶𝑙

in the presence of sodium vapor at 892°𝐶. The reaction that takes place at this temperature

is

𝑁𝑎(𝑔) + 𝐾𝐶𝑙(𝑙) ⇔ 𝑁𝑎𝐶𝑙(𝑙) + 𝐾(𝑔)

Sodium and potassium are about equally abundant in nature. They occur in silicate

minerals such as albite (NaAlSi3O8) and orthoclase (KAlSi3O8). These elements are also both

extremely reactive, but potassium is the more reactive of the two. Both react with water to

form the corresponding hydroxides. In a limited supply of oxygen, sodium burns to form

sodium oxide (𝑁𝑎2𝑂). However, in the presence of excess oxygen, sodium forms the pale-

yellow peroxide:

SCI 401 –GENERAL CHEMISTRY

117

2𝑁𝑎(𝑠) + 𝑂2(𝑔) → 𝑁𝑎2𝑂2(𝑠)

Sodium peroxide reacts with water to give an alkaline solution and hydrogen

peroxide:

𝑁𝑎2𝑂2(𝑠) + 2𝐻2𝑂(𝑙) → 2𝑁𝑎𝑂𝐻(𝑎𝑞) + 𝐻2𝑂2(𝑎𝑞)

Like sodium, potassium forms the peroxide. In addition, potassium also forms the

superoxide when it burns in air:

𝐾(𝑠) + 𝑂2(𝑔) → 𝐾𝑂2(𝑠)

2𝐾𝑂2(𝑠) + 2𝐻2𝑂(𝑙) → 2𝐾𝑂𝐻(𝑎𝑞) + 𝑂2(𝑔) + 𝐻2𝑂2(𝑎𝑞)

This reaction is applied in breathing equipment. Exhaled air contains both moisture

and carbon dioxide. The moisture reacts with 𝐾𝑂2 in the apparatus to generate oxygen gas

as shown in the preceding equation. Furthermore, 𝐾𝑂2 also reacts with exhaled 𝐶𝑂2, which

produces more oxygen gas:

4𝐾𝑂2(𝑠) + 2𝐶𝑂2(𝑔) → 2𝐾2𝐶𝑂3(𝑠) + 3𝑂2(𝑔)

Sodium and potassium are essential elements of living matter. Sodium ions and

potassium ions are present in intracellular and extracellular fluids, and they are essential for

osmotic balance and enzyme functions.

Sodium Chloride

Sodium chloride (table salt) is a typical ionic compound, a brittle solid with a high

melting point (801°𝐶) that conducts electricity in the molten state and in aqueous solution.

Rock salt is one source of sodium chloride which can be found in subterranean deposits

where often hundreds of meters thick. It is also obtained from seawater or brine (a

concentrated NaCl solution) by solar evaporation. Sodium chloride also occurs in nature as

the mineral halite.

Sodium Carbonate

Sodium carbonate (called soda ash) is used in all kinds of industrial processes,

including water treatment and the manufacture of soaps, detergents, medicines, and food

additives. For many years 𝑁𝑎! 𝐶𝑂+ was produced by the Solvay process (named after Ernest

Solvay, a Belgian chemist), in which ammonia is first dissolved in a saturated solution of

sodium chloride. Bubbling carbon dioxide into the solution results in the precipitation of

sodium bicarbonate as follows:

𝑁𝐻+ (𝑎𝑞) + 𝑁𝑎𝐶𝑙(𝑎𝑞) + 𝐻! 𝐶𝑂+ (𝑎𝑞) → 𝑁𝑎𝐻𝐶𝑂+ (𝑠) + 𝑁𝐻$ 𝐶𝑙(𝑎𝑞)

Sodium bicarbonate is then separated from the solution and heated to give sodium

carbonate:

MACALALAD – GAYETA - BASILAN | BATSTATEU

118

2𝑁𝑎𝐻𝐶𝑂+ (𝑠) → 𝑁𝑎! 𝐶𝑂+ (𝑠) + 𝐶𝑂! (𝑔) + 𝐻! 𝑂(𝑔)

Sodium Hydroxide and Potassium Hydroxide

Sodium hydroxide and potassium hydroxide (has similar properties) are prepared by

the electrolysis of aqueous 𝑁𝑎𝐶𝑙 𝑎𝑛𝑑 𝐾𝐶𝑙 solutions; both hydroxides are strong bases and

very soluble in water. Sodium hydroxide is used in the manufacture of soap and many

organic and inorganic compounds. Potassium hydroxide is used as an electrolyte in some

storage batteries, and aqueous potassium hydroxide is used to remove carbon dioxide and

sulfur dioxide from air.

Sodium chloride (molten state), an ionic compound, can be electrolyzed to form

sodium metal and chlorine. The electrolytic cell contains a pair of electrodes connected to

the battery. The battery serves as an “electron pump,” driving electrons to the cathode,

where reduction occurs, and withdrawing electrons from the anode, where oxidation occurs.

The reactions at the electrodes are:

𝐴𝑛𝑜𝑑𝑒 (𝑜𝑥𝑖𝑑𝑎𝑡𝑖𝑜𝑛): 2𝐶𝑙 3 (𝑙) → 𝐶𝑙! (𝑔) + 2𝑒 3

𝐶𝑎𝑡ℎ𝑜𝑑𝑒(𝑟𝑒𝑑𝑢𝑐𝑡𝑖𝑜𝑛): 2𝑁𝑎N (𝑙) + 2𝑒 3 → 2𝑁𝑎(𝑙)

𝑂𝑣𝑒𝑟𝑎𝑙𝑙: 2𝑁𝑎N (𝑙) + 2𝐶𝑙 3 (𝑙) → 2𝑁𝑎(𝑙) + 𝐶𝑙! (𝑔)

This process is a major source of pure sodium metal and chlorine gas.

Sodium Nitrate and Potassium Nitrate

Sodium nitrate decomposes with the evolution of oxygen at about 500°𝐶:

2𝑁𝑎𝑁𝑂+ (𝑠) → 𝑁𝑎𝑁𝑂! (𝑠) + 𝑂! (𝑔)

Potassium nitrate is prepared beginning with the “reaction”

𝐾𝐶𝑙(𝑎𝑞) + 𝑁𝑎𝑁𝑂+ (𝑎𝑞) → 𝑁𝑎𝑁𝑂+ (𝑎𝑞) + 𝑁𝑎𝐶𝑙(𝑎𝑞)

Because 𝐾𝑁𝑂+ is the least soluble salt at room temperature, it is separated from the solution

by fractional crystallization. Like 𝑁𝑎𝑁𝑂3, 𝐾𝑁𝑂3 decomposes when heated ( a temperature

below 100°𝐶).

Gunpowder consists of potassium nitrate, wood charcoal, and sulfur in the

approximate proportions of 6:1:1 by mass. When gunpowder is heated, the reaction is

2𝐾𝑁𝑂+ (𝑠) + 𝑆(𝑙) + 3𝐶(𝑠) → 𝐾! 𝑆(𝑠) + 𝑁! (𝑔) + 3𝐶𝑂! (𝑔)

The sudden formation of hot expanding gases causes an explosion.

The Alkaline Earth Metals

The alkaline earth metals are considerably less electropositive and less reactive than

the alkali metals. Except for beryllium which resembles aluminum. The oxidation number of

SCI 401 –GENERAL CHEMISTRY

119

alkaline earth metals in the combined form is almost always +2. Table 4. lists some common

properties of these metals. Radium is not included in the list because all of its isotopes are

radioactive and the study of its chemistry is expensive as well.

Table 4. Properties of Alkaline Earth Metals

Be Mg Ca Sr Ba

! ! ! !

Valence electron 2𝑠 3𝑠 4𝑠 5𝑠 6𝑠 !

configuration

Density (g/cm3) 1.86 1.74 1.55 2.6 3.5

Melting point 1280 650 838 770 714

(°𝐶)

Boiling point 2770 1107 1484 1380 1640

(°𝐶)

Atomic radius 112 160 197 215 222

(pm)

Ionic radius 34 78 106 127 143

(M2+) (pm)

First ionization 899 738 590 548 502

energy (kJ/mol)

Second 1757 1450 1145 1058 958

ionization

energy

Electronegativity 1.5 1.2 1.0 1.0 0.9

Magnesium

Magnesium is the sixth most plentiful element in Earth’s crust (about 2.5 percent by

mass). Among the principal magnesium ores are brucite, Mg(OH)2; dolomite, 𝐶𝑎𝐶𝑂3 ∙

𝑀𝑔𝐶𝑂3; and epsomite, 𝑀𝑔𝑆𝑂4 ∙ 7𝐻2𝑂. Seawater is a good source of magnesium and there

are about 1.3 g of magnesium in each kilogram of seawater. Metallic magnesium is obtained

by electrolysis from molten chloride, 𝑀𝑔𝐶𝑙2.

The chemistry of magnesium is intermediate between that of beryllium and the

heavier Group 2A elements. Magnesium does not react with cold water but does react slowly

with steam:

Mg(s) + H2O(g) → MgO(s) + H2(g)

It burns in air to produce magnesium oxide and magnesium nitride:

2Mg(s) + O2(g) → 2MgO(s)

3Mg(s) + N2(g) → Mg3N2(s)

MACALALAD – GAYETA - BASILAN | BATSTATEU

120

This property makes magnesium (in the form of thin ribbons or fibers) useful in flash

photography and flares.

Magnesium oxide reacts very slowly with water to form magnesium hydroxide, a

white solid suspension called milk of magnesia, which is used to treat acid indigestion:

MgO(s) + H2O(l) → Mg(OH)2(s)

Calcium

Calcium is about 3.4% by mas in the Earth’s crust. Calcium can be found in limestone,

calcite, chalk, and marble as 𝐶𝑎𝐶𝑂3; in dolomite as 𝐶𝑎𝐶𝑂3 ∙ 𝑀𝑔𝐶𝑂3; in gypsum as 𝐶𝑎𝑆𝑂4 ∙

2𝐻2𝑂; and in fluorite as 𝐶𝑎𝐹2. Metallic calcium is best prepared by the electrolysis of molten

calcium chloride (𝐶𝑎𝐶𝑙2).

Calcium (like strontium and barium) reacts with cold water to produce the

corresponding hydroxide, although the rate of reaction is much slower than those involving

the alkali metals:

𝐶𝑎(𝑠) + 2𝐻2𝑂(𝑙) → 𝐶𝑎(𝑂𝐻)2(𝑎𝑞) + 𝐻2(𝑔)

Calcium hydroxide [𝐶𝑎(𝑂𝐻)2] is commonly known as slaked lime or hydrated lime. Lime

(CaO), which is also referred to as quicklime, is one of the oldest materials known to

mankind. Quicklime is produced by the thermal decomposition of calcium carbonate:

𝐶𝑎𝐶𝑂3(𝑠) → 𝐶𝑎𝑂(𝑠) + 𝐶𝑂2(𝑔)

while slaked lime is produced by the reaction between quicklime and water:

𝐶𝑎𝑂(𝑠) + 𝐻2𝑂(𝑙) → 𝐶𝑎(𝑂𝐻)2(𝑎𝑞)

Aluminum

Aluminum is the most abundant metal and the third most plentiful element in Earth’s

crust which is 7.5 percent by mass. The elemental form cannot be found in nature; its

principal ore is bauxite (𝐴𝑙2𝑂3 ∙ 2𝐻2𝑂). Other minerals containing aluminum are orthoclase

(𝐾𝐴𝑙𝑆𝑖3𝑂8), beryl (𝐵𝑒3𝐴𝑙2𝑆𝑖6𝑂18), cryolite (𝑁𝑎3𝐴𝑙𝐹6), and corundum (𝐴𝑙2𝑂3).

Aluminum is usually prepared from bauxite with silica (𝑆𝑖𝑂2), iron oxides, and

titanium(IV) oxide. The ore is first heated in sodium (𝑁𝑎𝑂𝐻) solution to convert the silica

into soluble silicates:

𝑆𝑖𝑂! (𝑠) + 2𝑂𝐻3 (𝑎𝑞) → 𝑆𝑖𝑂+!3 (𝑎𝑞) + 𝐻! 𝑂(𝑙)

Aluminum oxide is also converted to the aluminate ion (𝐴𝑙𝑂!3 ):

𝐴𝑙2𝑂3(𝑠) + 2𝑂𝐻3 (𝑎𝑞) → 2𝐴𝑙𝑂!3 (𝑎𝑞) + 𝐻2𝑂(𝑙)

Unaffected iron oxide and titanium oxide by this treatment are filtered off.

To precipitate the insoluble aluminum hydroxide, the solution is treated with acid.

𝐴𝑙𝑂!3 (𝑎𝑞) + 𝐻+ 𝑂N (𝑎𝑞) → 𝐴𝑙(𝑂𝐻)+ (𝑠)

SCI 401 –GENERAL CHEMISTRY

121

After filtration, the aluminum hydroxide is heated to obtain aluminum oxide:

2𝐴𝑙(𝑂𝐻)3(𝑠) → 𝐴𝑙2𝑂3(𝑠) + 3𝐻2𝑂(𝑔)

Anhydrous aluminum oxide, or corundum, is reduced to aluminum by the Hall process

(named after Charles Martin Hall, an American inventor). The cathode is also made of carbon

and constitutes the lining inside the cell. The key to the Hall process is the use of cryolite, or

𝑁𝑎+ 𝐴𝑙𝐹5 (melting point is 1000 °C), as the solvent for aluminum oxide (melting point is 2045

°C). The mixture is electrolyzed to produce aluminum and oxygen gas:

𝐴𝑛𝑜𝑑𝑒 (𝑜𝑥𝑖𝑑𝑎𝑡𝑖𝑜𝑛): 3[2𝑂!3 → 𝑂! (𝑔) + 4𝑒 3 ]

𝐶𝑎𝑡ℎ𝑜𝑑𝑒 (𝑟𝑒𝑑𝑢𝑐𝑡𝑖𝑜𝑛): 4[𝐴𝑙 +N + 3𝑒 3 → 𝐴𝑙(𝑙)]

𝑂𝑣𝑒𝑟𝑎𝑙𝑙: 2𝐴𝑙! 𝑂+ → 4𝐴𝑙(𝑙) + 3𝑂! (𝑔)

Oxygen gas reacts with the carbon anodes (at elevated temperatures) to form carbon

monoxide, which escapes as a gas. The liquid aluminum metal (melting point is 660.2 °C)

sinks to the bottom of the vessel, from which it can be drained from time to time during the

procedure.

Transition Metals

Transition metals typically have incompletely filled d subshells or readily give rise to

ions with incompletely filled d subshells. (The Group 2B metals—Zn, Cd, and Hg—do not

have this characteristic electron configuration and so, although they are sometimes called

transition metals, they really do not belong in this category.) This attribute is responsible for

several notable properties, including distinctive coloring, formation of paramagnetic

compounds, catalytic activity, and especially a great tendency to form complex ions. In this

section we focus on the first-row elements from scandium to copper, the most common

transition metals.

As we read across any period from left to right, atomic numbers increase, electrons

are added to the outer shell, and the nuclear charge increases by the addition of protons. In

the third-period elements—sodium to argon—the outer electrons weakly shield one another

from the extra nuclear charge. Consequently, atomic radii decrease rapidly from sodium to

argon, and the electronegativities and ionization energies increase steadily.

For the transition metals, the trends are different. Looking at Table 5 we see that the

nuclear charge, of course, increases from scandium to copper, but electrons are being added

to the inner 3d subshell. These 3d electrons shield the 4s electrons from the increasing

nuclear charge somewhat more effectively than outer-shell electrons can shield one another,

so the atomic radii decrease less rapidly. For the same reason, electronegativities and

ionization energies increase only slightly from scandium across to copper compared with

the increases from sodium to argon.

MACALALAD – GAYETA - BASILAN | BATSTATEU

122

Although the transition metals are less electropositive (or more electronegative) than

the alkali and alkaline earth metals, the standard reduction potentials of the first-row

transition metals suggest that all of them except copper should react with strong acids such

as hydrochloric acid to produce hydrogen gas. However, most transition metals are inert

toward acids or react slowly with them because of a protective layer of oxide.

Table 5. Electron Configurations and Other Properties of the First Row Transition Metals

Sc Ti V Cr Mn Fe Co Ni Cu

Electron

Configuration

(M) 4𝑠 . 3𝑑/ 4𝑠 . 3𝑑. 4𝑠 . 3𝑑0 4𝑠/ 3𝑑1 4𝑠 . 3𝑑1 4𝑠 . 3𝑑2 4𝑠 . 3𝑑3 4𝑠 . 3𝑑4 4𝑠/ 3𝑑/5

(M2+) --- 3𝑑. 3𝑑0 3𝑑6 3𝑑1 3𝑑2 3𝑑3 3𝑑4 3𝑑7

(M3+) [Ar] 3𝑑/ 3𝑑. 3𝑑0 3𝑑6 3𝑑1 3𝑑2 3𝑑3 3𝑑4

Electronegativity 1.3 1.5 1.6 1.6 1.5 1.8 1.9 1.9 1.9

Ionization

energy (kJ/mol)

First 631 658 650 652 717 759 760 736 745

Second 1235 1309 1413 1591 1509 1561 1645 1751 1958

Third 2389 2650 2828 2986 3250 2956 3231 3393 3578

Radius (pm)

(M) 162 147 134 130 135 126 125 124 128

(M2+) --- 90 88 85 91 82 82 78 72

(M )

3+ 83 68 74 64 66 67 64 --- ---

General Physical Properties

Most of the transition metals have a close-packed structure in which each atom has a

coordination number of 12. Furthermore, these elements have relatively small atomic radii.

The combined effect of closest packing and small atomic size results in strong metallic bonds.

Therefore, transition metals have higher densities, higher melting points and boiling points,

and higher heats of fusion and vaporization than the Group 1A, 2A, and 2B metals.

Chemistry of Iron

After aluminum, iron is the most abundant metal in Earth’s crust (6.2 percent by

mass). It is found in many ores; some of the important ones are hematite, Fe2O3; siderite,

FeCO3; and magnetite, Fe3O4.

Pure iron is a gray metal and is not particularly hard. It is an essential element in living

systems.

Iron reacts with hydrochloric acid to give hydrogen gas:

Fe(s) + 2H1(aq) → Fe2+(aq) + H2(g)

Concentrated sulfuric acid oxidizes the metal to Fe3+, but concentrated nitric acid

renders the metal “passive” by forming a thin layer of Fe3O4 over the surface. One of the best-

known reactions of iron is rust formation. The two oxidation states of iron are +2 and +3.

SCI 401 –GENERAL CHEMISTRY

123

Iron(II) compounds include FeO (black), FeSO4 ∙ 7H2O (green), FeCl2 (yellow), and FeS

(black). In the presence of oxygen, Fe2+ ions in solution are readily oxidized to Fe3+ ions.

Iron(III) oxide is reddish brown, and iron(III) chloride is brownish black.

Chemistry of Copper

Copper, a rare element (6.8𝑥103+ percent of Earth’s crust by mass), is found in nature

in the uncombined state as well as in ores such as chalcopyrite, CuFeS2. The reddish-brown

metal is obtained by roasting the ore to give Cu2S and then metallic copper:

2CuFeS2(s) + 4O2(g) → Cu2S(s) + 2FeO(s) + 3SO2(g)

Cu2S(s) + O2(g) → 2Cu(l) + SO2(g)

Impure copper can be purified by electrolysis. After silver, which is too expensive for

large-scale use, copper has the highest electrical conductivity. It is also a good thermal

conductor. Copper is used in alloys, electrical cables, plumbing (pipes), and coins.

Copper reacts only with hot concentrated sulfuric acid and nitric acid. Its two

important oxidation states are +1 and +2. The +1 state is less stable and disproportionates

in solution:

2Cu+(aq) → Cu(s) + Cu2+(aq)

All compounds of Cu(I) are diamagnetic and colorless except for Cu2O, which is red.

The Cu(II) compounds are all paramagnetic and colored. The hydrated Cu2+ ion is blue. Some

important Cu(II) compounds are CuO (black), CuSO4 ∙ 5H2O (blue), and CuS (black).

LEARNING ENRICHMENT ACTIVITIES

Watch the videos to learn more about the topic

https://www.youtube.com/watch?v=7uIIq_Ofzgw

https://www.youtube.com/watch?v=mvDHeYI-a00

Refer to the link below to explore more understanding about the topic

https://chem.libretexts.org/Bookshelves/General_Chemistry/Map%3A_General_Chemistry_(Petrucc

i_et_al.)/12%3A_Intermolecular_Forces%3A_Liquids_And_Solids/12.6%3A_Crystal_Structures

MACALALAD – GAYETA - BASILAN | BATSTATEU

124

ASSESSMENT TASK

1. Define the following terms:

a) mineral

b) ore

c) metallurgy

2. List three metals that are usually found in an uncombined state in nature and

three metals that are always found in combined state in nature.

3. Write the chemical formulas for the following minerals:

a) calcite f) magnetite

b) dolomite g) beryl

c) fluorite h) galena

d) halite i) epsomite

e) corundum j) anhydrite

4. Describe the main step involved in the preparation of an ore.

5. Briefly discuss the steelmaking process.

6. Briefly discuss the nature of bonding in metals, insulators, and semiconducting

elements.

7. Briefly discuss the properties and characteristics of the following:

a) alkali metals

b) alkaline earth metals

c) aluminum

Reference:

Chang, Raymond and Kenneth A. Goldsby, (2017) Chemistry, (12th International Edition), New

York: McGraw-Hill]

SCI 401 –GENERAL CHEMISTRY

You might also like

- ISTA Senior Science Quiz Final Q&A 2018: Round 1Document4 pagesISTA Senior Science Quiz Final Q&A 2018: Round 1gopodNo ratings yet

- 3.30 Within A Cubic Unit Cell, Sketch The Following DirectionsDocument13 pages3.30 Within A Cubic Unit Cell, Sketch The Following DirectionsTrong LanNo ratings yet

- Quest Review 4 Electric Force, Magnetic Fields KEYDocument16 pagesQuest Review 4 Electric Force, Magnetic Fields KEYJ PNo ratings yet

- Afp Organization OkDocument31 pagesAfp Organization OkNiña Viaña Binay100% (2)

- Basic IntelligenceokDocument27 pagesBasic IntelligenceokNiña Viaña BinayNo ratings yet

- Solution Smuth Cap 5Document32 pagesSolution Smuth Cap 5Joyce Caroline Lima Nunes100% (1)

- Unit 3 - The Chemistry of Engineering Materials Engineered NanomaterialsDocument10 pagesUnit 3 - The Chemistry of Engineering Materials Engineered NanomaterialsNiña Viaña BinayNo ratings yet

- Unit 3 - The Chemistry of Engineering Materials Basic Concepts of Crystal StructuresDocument17 pagesUnit 3 - The Chemistry of Engineering Materials Basic Concepts of Crystal StructuresNiña Viaña BinayNo ratings yet

- Lecture 1 Introduction, Laboratory Safety and Waste ManagementDocument21 pagesLecture 1 Introduction, Laboratory Safety and Waste ManagementNiña Viaña Binay100% (2)

- PowerDocument2 pagesPowerraymond baliteNo ratings yet

- Ode Assignment FinalllDocument14 pagesOde Assignment FinalllM shayan JavedNo ratings yet

- Simulab 3Document3 pagesSimulab 3Igho SilvaNo ratings yet

- Delta Check Calculation Guide 3Document13 pagesDelta Check Calculation Guide 3yousrazeidan1979No ratings yet

- CCAA Salinity T56Document22 pagesCCAA Salinity T56HTC1111No ratings yet

- Lattice VibrationsDocument10 pagesLattice VibrationsVarun GovindNo ratings yet

- Electrochemistry, PPT 3Document33 pagesElectrochemistry, PPT 3Ernest Nana Yaw AggreyNo ratings yet

- Legendre Equation ProblemsDocument2 pagesLegendre Equation ProblemsShahbaz AhmedNo ratings yet

- Semiconductor: Properties Materials Physics of SemiconductorsDocument9 pagesSemiconductor: Properties Materials Physics of SemiconductorsFelixNo ratings yet

- Electrical Property of Ceramic and PolymerDocument32 pagesElectrical Property of Ceramic and PolymerbawokeNo ratings yet

- Course Content: No. Title Slide NoDocument54 pagesCourse Content: No. Title Slide NoDilip YadavNo ratings yet

- Uses of MetalsDocument6 pagesUses of Metalsdan964No ratings yet

- Chapter 1 - Electric Charges and FieldsDocument26 pagesChapter 1 - Electric Charges and FieldsRavi Inder Singh SandhuNo ratings yet

- Chapter 5 Eigenvalues and EigenvectorsDocument50 pagesChapter 5 Eigenvalues and EigenvectorsJulius100% (1)

- Electro MagsDocument4 pagesElectro MagsVan Daryl C MonteNo ratings yet

- Electrical Measurement Lab (EEE-352)Document23 pagesElectrical Measurement Lab (EEE-352)DhinakarrajNo ratings yet

- Engineering ChemistryDocument2 pagesEngineering ChemistryssjatavNo ratings yet

- WYE (Y) and DELTA ( ) ConversionDocument12 pagesWYE (Y) and DELTA ( ) Conversionvamps sierNo ratings yet

- Chapter 13. Filter Inductor DesignDocument29 pagesChapter 13. Filter Inductor DesignNestor EspinozaNo ratings yet

- Review of Related LiteratureDocument5 pagesReview of Related LiteratureJay Ar GalangNo ratings yet

- Lebanese International University School of EngineeringDocument12 pagesLebanese International University School of EngineeringHassan RashedNo ratings yet

- SemiconductorsDocument5 pagesSemiconductorsdeep34No ratings yet

- Chapter 28 Atomic Physics: The Hydrogen Atom The Bohr Model Electron Waves in The AtomDocument64 pagesChapter 28 Atomic Physics: The Hydrogen Atom The Bohr Model Electron Waves in The Atomvivekrajbhilai5850No ratings yet

- Unit 4 - The Chemistry of The Environment: Learning ObjectivesDocument8 pagesUnit 4 - The Chemistry of The Environment: Learning ObjectivesNiña Viaña BinayNo ratings yet

- Resistance Electricity Class X Science Ncert Ncert Questions Science Class 10 Chapter 1 Ncert Notes Electrical ResistivityDocument2 pagesResistance Electricity Class X Science Ncert Ncert Questions Science Class 10 Chapter 1 Ncert Notes Electrical ResistivityPranavMehtaNo ratings yet

- Electromagnetism Lecture NotesDocument8 pagesElectromagnetism Lecture NotesoinkNo ratings yet

- Topic 1 - Electric CircuitsDocument70 pagesTopic 1 - Electric CircuitsKavinesh AnanthanNo ratings yet

- SheetDocument2 pagesSheetabosalah1223334444100% (1)

- HW07 PDFDocument117 pagesHW07 PDFAndri OdeNo ratings yet

- Structures of SolidsDocument53 pagesStructures of SolidsAndreas Vivaldi100% (1)

- CHM031 Module 1 ReviewerDocument8 pagesCHM031 Module 1 ReviewerrainNo ratings yet

- Energy Levels of Semiconductor, Conductors and InsulatorsDocument53 pagesEnergy Levels of Semiconductor, Conductors and InsulatorsTawki BakiNo ratings yet

- Density and UpthrustDocument20 pagesDensity and UpthrustRanjit SinghNo ratings yet

- Distribution & UtilizationDocument154 pagesDistribution & UtilizationganeshNo ratings yet

- Optical Fiber 2022Document12 pagesOptical Fiber 2022Nidhi R VassNo ratings yet

- CH 1 Semiconductor DiodesDocument6 pagesCH 1 Semiconductor DiodesJaysonSanGabrielNo ratings yet

- Superconductivity (New)Document9 pagesSuperconductivity (New)RshshNo ratings yet

- PQT Chapter 11 Applications and Processing of Metal AlloysDocument30 pagesPQT Chapter 11 Applications and Processing of Metal AlloysNguyễn Việt TiếnNo ratings yet

- Chapter 2Document18 pagesChapter 2api-3527095490% (1)

- Pioneer X-rsm400dv SMDocument69 pagesPioneer X-rsm400dv SMAlbertoNo ratings yet

- Liquid Drop Model and Bohr-Wheeler Theory of Nuclear FissionDocument6 pagesLiquid Drop Model and Bohr-Wheeler Theory of Nuclear FissionAmogh BorgaveNo ratings yet

- First Years Physics Lab ManualDocument186 pagesFirst Years Physics Lab ManualFestusNo ratings yet

- Efrida Firda Yani - EnglishDocument3 pagesEfrida Firda Yani - EnglishYUDI CANDRA100% (1)

- Basic Electrical Tools: OBJECTIVE: To Study Construction, Working and Application of Workshop Tools. Also Study TheoryDocument32 pagesBasic Electrical Tools: OBJECTIVE: To Study Construction, Working and Application of Workshop Tools. Also Study TheoryAditya KumarNo ratings yet

- Supplementary Problems Electrical CircuitsDocument2 pagesSupplementary Problems Electrical Circuitsmae50% (2)

- Unit 1 Ee2355 Machine DesignDocument21 pagesUnit 1 Ee2355 Machine DesignRamesh BabuNo ratings yet

- General Physics Lab Report: Faculty of Engineering and TechnologyDocument19 pagesGeneral Physics Lab Report: Faculty of Engineering and TechnologyIzaNo ratings yet

- Chapter 3: The Structure of Crystalline Solids: Issues To Address..Document37 pagesChapter 3: The Structure of Crystalline Solids: Issues To Address..يوسف عادل حسانينNo ratings yet

- Interpolation Direct MethodDocument16 pagesInterpolation Direct MethodSri Peni WijayantiNo ratings yet

- Capacitors PDFDocument84 pagesCapacitors PDFNaseerUddin100% (1)

- ELTR 270 - Diode Practice Problems and SolutionsDocument33 pagesELTR 270 - Diode Practice Problems and SolutionsKirk100% (1)

- Electrical Properties of SolidsDocument54 pagesElectrical Properties of SolidsAnthonio MJNo ratings yet

- MSE 227 HW9 F10 SolutionsDocument5 pagesMSE 227 HW9 F10 Solutionsputri nur shahidaNo ratings yet

- Wave Guids PDFDocument32 pagesWave Guids PDFlakshman donepudiNo ratings yet

- Materials Science Lec 04 Phase & Iron-Carbon DiagramDocument53 pagesMaterials Science Lec 04 Phase & Iron-Carbon DiagramKrishna SarkarNo ratings yet

- Conductors, Insulators and Semiconductors - GDLCDocument29 pagesConductors, Insulators and Semiconductors - GDLCAnonymous uspYoqE0% (1)

- Basic IntelligenceokDocument27 pagesBasic IntelligenceokNiña Viaña BinayNo ratings yet

- Legal Basis: Name of PresenterDocument24 pagesLegal Basis: Name of PresenterAzha Clarice VillanuevaNo ratings yet

- Basic Map ReadingOKDocument67 pagesBasic Map ReadingOKNiña Viaña Binay100% (1)

- Interior Guard Duty OkDocument34 pagesInterior Guard Duty OkNiña Viaña BinayNo ratings yet

- Human Rights OkDocument28 pagesHuman Rights OkNiña Viaña BinayNo ratings yet

- Basic Survival OkDocument24 pagesBasic Survival OkNiña Viaña Binay100% (1)

- Course-Overview MS 1Document14 pagesCourse-Overview MS 1Niña Viaña BinayNo ratings yet

- Sci 401pptDocument107 pagesSci 401pptNiña Viaña BinayNo ratings yet

- Sci 401 PDFDocument84 pagesSci 401 PDFNiña Viaña BinayNo ratings yet

- Basic Map ReadingOKDocument67 pagesBasic Map ReadingOKNiña Viaña Binay100% (1)

- Military Justice OkDocument32 pagesMilitary Justice OkNiña Viaña BinayNo ratings yet

- SCI 401 General Chemistry Syllabus RevDocument10 pagesSCI 401 General Chemistry Syllabus RevNiña Viaña BinayNo ratings yet

- Military Courtesy OkDocument34 pagesMilitary Courtesy OkNiña Viaña BinayNo ratings yet

- Unit 4 - Chemistry of The Environment The Soil Chemistry: Learning ObjectivesDocument17 pagesUnit 4 - Chemistry of The Environment The Soil Chemistry: Learning ObjectivesNiña Viaña BinayNo ratings yet

- Lecture 10 Engineered NanomaterialsDocument29 pagesLecture 10 Engineered NanomaterialsNiña Viaña BinayNo ratings yet

- Unit 2 - Matter and Energy Electrochemical Energy: Learning ObjectivesDocument8 pagesUnit 2 - Matter and Energy Electrochemical Energy: Learning ObjectivesNiña Viaña BinayNo ratings yet

- Chemistry For Engineers: Engr. Rosamia D. TuboDocument15 pagesChemistry For Engineers: Engr. Rosamia D. TuboNiña Viaña BinayNo ratings yet

- Unit 4 - The Chemistry of The Environment: Learning ObjectivesDocument8 pagesUnit 4 - The Chemistry of The Environment: Learning ObjectivesNiña Viaña BinayNo ratings yet

- Laboratory Safety Policies, Safety Data Sheet and Waste ManagementDocument35 pagesLaboratory Safety Policies, Safety Data Sheet and Waste ManagementNiña Viaña Binay100% (1)

- Lecture 3 Energy Changes in Chemical Reactions-1-17Document17 pagesLecture 3 Energy Changes in Chemical Reactions-1-17Niña Viaña Binay100% (1)

- Unit 3 - The Chemistry of Engineering Materials PolymersDocument12 pagesUnit 3 - The Chemistry of Engineering Materials PolymersNiña Viaña BinayNo ratings yet

- Unit 4 - Chemistry of The Environment The Chemistry of WaterDocument19 pagesUnit 4 - Chemistry of The Environment The Chemistry of WaterNiña Viaña BinayNo ratings yet

- Metals: Sci 401 Lecture 8Document54 pagesMetals: Sci 401 Lecture 8Niña Viaña BinayNo ratings yet

- Lecture 9 Polymers-With AnnotationsDocument21 pagesLecture 9 Polymers-With AnnotationsNiña Viaña BinayNo ratings yet

- Unit 2 - Matter and Energy Fuels: Learning ObjectivesDocument6 pagesUnit 2 - Matter and Energy Fuels: Learning ObjectivesNiña Viaña BinayNo ratings yet

- SQ Prove 100 - Analytical Procedures and Appendices 2017-07Document254 pagesSQ Prove 100 - Analytical Procedures and Appendices 2017-07PepeNo ratings yet

- Terapi Cairan Dan Elektrolit: RSUD AjibarangDocument42 pagesTerapi Cairan Dan Elektrolit: RSUD Ajibarangrifqi nurkamalNo ratings yet

- Clinical Management of DiabetesDocument13 pagesClinical Management of DiabetesMark TallyNo ratings yet

- Ntailianas 1963Document7 pagesNtailianas 1963Debraj Dhar PurkayasthaNo ratings yet

- AnuppurDocument16 pagesAnuppurshivseenu100% (1)

- Influence of Organic and Inorganic Fertilizers On Growth, Yield and Physio-Chemical Properties of PapayaDocument16 pagesInfluence of Organic and Inorganic Fertilizers On Growth, Yield and Physio-Chemical Properties of Papayamwah mwahNo ratings yet

- Pyrotenax Industrial Wiring Cable Termination Manual: For System 2000 and System 2200Document72 pagesPyrotenax Industrial Wiring Cable Termination Manual: For System 2000 and System 2200thanna9783No ratings yet

- Water ChemDocument11 pagesWater ChemAnjali KumbharNo ratings yet

- 1 Stoichiometry P1Document22 pages1 Stoichiometry P1mostafa barakatNo ratings yet

- Make Potassium Metal (Catalyzed Magnesium Reduction Method)Document6 pagesMake Potassium Metal (Catalyzed Magnesium Reduction Method)Imran FirdausNo ratings yet

- Free Shilajit Booklet Mountaindrop NewDocument48 pagesFree Shilajit Booklet Mountaindrop Newlistener.a50% (2)

- 2004 MRSM Without AnswerDocument49 pages2004 MRSM Without AnswerChoong Wen JianNo ratings yet

- Black Beauty AbrasiveDocument10 pagesBlack Beauty AbrasiveJesus De la RosaNo ratings yet

- Air Cells Using Negative Metal Electrodes Fabricated by Sintering Pastes With Base Metal Nanoparticles For Efficient Utilization of Solar EnergyDocument7 pagesAir Cells Using Negative Metal Electrodes Fabricated by Sintering Pastes With Base Metal Nanoparticles For Efficient Utilization of Solar EnergySEP-PublisherNo ratings yet

- Ga4325 00 - Calcium OcpDocument2 pagesGa4325 00 - Calcium OcpTrần Thanh ViệnNo ratings yet

- CH 7. Metallurgy (Chem +2)Document52 pagesCH 7. Metallurgy (Chem +2)Sajag GargNo ratings yet

- Chemistry: Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesChemistry: Cambridge International Examinations International General Certificate of Secondary EducationVarun PanickerNo ratings yet

- Evaluation of Drinking Water Quality of Navsari District (Gujarat)Document7 pagesEvaluation of Drinking Water Quality of Navsari District (Gujarat)ESSENCE - International Journal for Environmental Rehabilitation and ConservaionNo ratings yet

- Rate of Reaction Bwat SendiriDocument4 pagesRate of Reaction Bwat SendiriNor Ashikin IsmailNo ratings yet

- Nesrine-2021-2016 P4 QPDocument686 pagesNesrine-2021-2016 P4 QPMostafa HaithamNo ratings yet

- Anayytical Methods Section PDFDocument174 pagesAnayytical Methods Section PDFTatianaNo ratings yet

- Recommended Dietary Allowance (RDA) of NutrientsDocument8 pagesRecommended Dietary Allowance (RDA) of NutrientsDr. Asha DagarNo ratings yet

- The Elemental Analysis of Various Classes of Chemical Compounds Using CHNDocument6 pagesThe Elemental Analysis of Various Classes of Chemical Compounds Using CHNMariam IshtiaqNo ratings yet

- Metales Pesados Ph. Eur.Document4 pagesMetales Pesados Ph. Eur.sarasaNo ratings yet

- Vitamin and Mineral TABLEDocument1 pageVitamin and Mineral TABLEHibozoNo ratings yet

- Ts 1 5 Specific Feed Safety LimitsDocument87 pagesTs 1 5 Specific Feed Safety Limitsraed abujoudehNo ratings yet