Professional Documents

Culture Documents

371881083-Wankhede-Pdf (Dragged)

Uploaded by

Anish Pariani0 ratings0% found this document useful (0 votes)

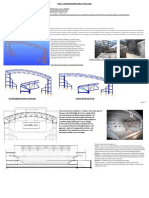

15 views1 pageThe document summarizes the key features and design aspects of renovating and expanding a sports stadium. Some of the main elements discussed include strengthening the existing foundations using fiber reinforced composites, designing high mast lighting supports, installing an aesthetically appealing steel roof structure with 45 trusses and compression rings, and addressing transportation and erection challenges with the large steel components. The redesign focused on improving the spectator experience through improved sightlines, seating capacity, and amenities while meeting tight construction timelines.

Original Description:

Original Title

371881083-wankhede-pdf (dragged)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the key features and design aspects of renovating and expanding a sports stadium. Some of the main elements discussed include strengthening the existing foundations using fiber reinforced composites, designing high mast lighting supports, installing an aesthetically appealing steel roof structure with 45 trusses and compression rings, and addressing transportation and erection challenges with the large steel components. The redesign focused on improving the spectator experience through improved sightlines, seating capacity, and amenities while meeting tight construction timelines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 page371881083-Wankhede-Pdf (Dragged)

Uploaded by

Anish ParianiThe document summarizes the key features and design aspects of renovating and expanding a sports stadium. Some of the main elements discussed include strengthening the existing foundations using fiber reinforced composites, designing high mast lighting supports, installing an aesthetically appealing steel roof structure with 45 trusses and compression rings, and addressing transportation and erection challenges with the large steel components. The redesign focused on improving the spectator experience through improved sightlines, seating capacity, and amenities while meeting tight construction timelines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Cover Story

Salient Features Project Management Consultants. After rounds

of discussions with the agencies for evaluating

North and South stands are newly constructed. The structure rests on piles and on footing in few their capability to carry out the job successfully,

areas. The RCC elements comprises of raft, retaining walls, pile caps, footings, columns, inclined deck Shrikhande Consultants were selected for the

beam and slabs etc. PMC work.

In case of East and West stands, area admeasures approx. 3500 sq mtrs. Existing foundations and

supporting columns were strengthened for chair seating arrangement without any alteration in the Designing the Game Plan

seating capacity and stadium profile in view of its close vicinity to the Western Railway track. The To achieve a sense of closeness between players

strengthening was done using fiber reinforced Kevlar by introducing composite columns. and spectators during the game is the central idea

of the design for the stadium. To achieve unity

Design of foundation for a 70 meter high mast, four in numbers, resting over pile foundation for and oneness in the architecture and structure,

lightening the ground during nights. inspite of many functional divisions and

The stadium is covered with aesthetically appealing and elegantly spaced structural steel roofing. The variations in the spatial quality of spaces within

challenge was to design a 22 meter cantilever and its supporting system using bent tubular hollow the stadium, was the objective. An innate

steel sections fabricated out of plates of different thicknesses and of varied diameters. The steel aesthetic quality of spaces has been achieved

roofing comprises of 45 trusses connected by compression rings. through the use of distinct colours, which are

seen and experienced inside and outside from the

The total tonnage of structural steel consumed was approx. 4000 MT. Handling of these massive steel field. Attention has also been paid to provide

columns and cantilevers were an uphill task. Thus, the complex and intricate design involved interesting experiences in all the spaces in

detailing, bending, fabricating, transporting, lifting and erection of steel components of various sizes transition, entrances, accesses, avenues and

to provide intended look to the roofing. passages, through distinct lighting, colours and

Due to the space constraint, the steel truss members were fabricated out of Mumbai, transported to flooring.

site and then erected using high capacity crawler mounted cranes with varying (125-250T) booms

lengths. In totality, there were 370 such truss members. A series of 90 compression rings fabricated A good proportion of quality public

using 350mm dia tubular hollow sections are connected to the roof trusses, with outer radius of the conveniences have ensured spectators comfort

rings being approx. 80 meters. and dignity. Large numbers and well-distributed

designed toilets, drinking water and hospitality

Construction of a stadium with huge quantum of concrete was just impossible in a relatively short counters add to the spectator’s joy. Seven

duration, without sizable quantities of shuttering, scaffolding, staging material for RCC works and entrance gates, twenty staircases, eighteen lifts,

massive temporary supporting arrangements for holding the trusses till the compression ring was and thirty-five emergency exits, ensures faster

complete. movement and high standard of safety. The 25-

The structural design is carried out taking into account the composite action of the columns for meter cantilevered roof is the most interesting

earthquake resistance. feature of the stadium. It completely opens up the

stands, as no pillars or supports come in the way

The entire structural steel roofing was covered with PTFE coated glass tensile fabric. A special team of the spectator’s view. Designs, drawings and

was flown to Sri Lanka for testing the fabric material and approving its quality. execution details were produced at breakneck

Heavy columns sections extending beyond the top edge of the stadium and each unit weighing in speed to match the schedule. Over 650 drawings

tonnes were fabricated out of three tubular hollow pipes in a triangular profile fabricated out of were prepared to ensure that every detail,

various diameter MS pipes. Designing of the 22 meter cantilever and its supporting system was a real including the interiors, was available to the

challenge. contractors on time.

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Building Construction Project 2 ReportDocument20 pagesBuilding Construction Project 2 ReportCynthia Lee100% (1)

- Aviva StadiumDocument12 pagesAviva StadiumSakshi Bodkhe0% (1)

- PAPER IASS Geodesic Dome Cottonera Sports Hall MaltaDocument9 pagesPAPER IASS Geodesic Dome Cottonera Sports Hall MaltaistructeNo ratings yet

- London Olympic StadiumDocument3 pagesLondon Olympic StadiumPranav SamdadiyaNo ratings yet

- London Olympic StadiumDocument3 pagesLondon Olympic StadiumPranav SamdadiyaNo ratings yet

- Uttamansh: International Cricket Stadium Ghaziabad, Uttar PradeshDocument10 pagesUttamansh: International Cricket Stadium Ghaziabad, Uttar Pradeshfida parween100% (1)

- Ayush Patel - UG190253 - Mid Term AssignmentDocument34 pagesAyush Patel - UG190253 - Mid Term AssignmentAyush PatelNo ratings yet

- TOS PPT Marina BayDocument28 pagesTOS PPT Marina BayDakshata KoliNo ratings yet

- Kurilpa Bridge Case Study PDFDocument4 pagesKurilpa Bridge Case Study PDFkamomartNo ratings yet

- Benz StadiumDocument18 pagesBenz StadiumHARI NIVETHAN K G 20BAR0026No ratings yet

- TST40 Neo Bankside Case Study 04-2012Document4 pagesTST40 Neo Bankside Case Study 04-2012MisSquishyNo ratings yet

- Polyvalent Hall Multi-Functional Sports Hall Romania: Name - Shreya Balasaheb Padwal Class - Fr. Y. - BDocument8 pagesPolyvalent Hall Multi-Functional Sports Hall Romania: Name - Shreya Balasaheb Padwal Class - Fr. Y. - BShreya PadwalNo ratings yet

- Long Span Structure London VelodromeDocument20 pagesLong Span Structure London VelodromeArjun Nambiar67% (3)

- AAMI Park Case StudyDocument3 pagesAAMI Park Case StudyKennedy TuguinayNo ratings yet

- Precast ConcreteDocument69 pagesPrecast Concretejaffna100% (2)

- Kurilpa Bridge Case StudyDocument4 pagesKurilpa Bridge Case StudyTheomi BunburyNo ratings yet

- Marina Bay Sands HotelDocument26 pagesMarina Bay Sands HotelGilmar MazinhoroNo ratings yet

- One Shelley ST Case StudyDocument4 pagesOne Shelley ST Case Study上島瞬No ratings yet

- High Rise Structure ReportDocument32 pagesHigh Rise Structure ReportNazeeha NazneenNo ratings yet

- Project Presentation With GUETDocument22 pagesProject Presentation With GUEThavel keysanNo ratings yet

- Burj KhalifaDocument15 pagesBurj Khalifakavyareddy_17100% (1)

- Steel Structure-Study: Aditi ManojDocument7 pagesSteel Structure-Study: Aditi ManojAditi Manoj.S0% (1)

- Steel: Built To Last: Case Study No 3Document4 pagesSteel: Built To Last: Case Study No 3clam2014No ratings yet

- bt5 FinalDocument4 pagesbt5 FinalKimber Lee BaldozNo ratings yet

- Football Stadium Case StudyDocument9 pagesFootball Stadium Case StudyUrvashi Bagde100% (1)

- Case Study of Multi-Functional Sports Hall at RomaniaDocument4 pagesCase Study of Multi-Functional Sports Hall at Romaniadamandadino50% (2)

- EARTHQUAKE RESISTANT BUILDINGS: CASE STUDIES - Yokohama Landmark Tower, Burj Khalifa, Torre Mayor MexicoDocument23 pagesEARTHQUAKE RESISTANT BUILDINGS: CASE STUDIES - Yokohama Landmark Tower, Burj Khalifa, Torre Mayor Mexiconiki niks75% (12)

- Manchester City Stadium - Structural Case StudyDocument20 pagesManchester City Stadium - Structural Case StudyYuvan SethNo ratings yet

- NMBS Composite Slab Engineering CourseDocument72 pagesNMBS Composite Slab Engineering CourseDario P. YanezNo ratings yet

- Steelwork in Action 11Document11 pagesSteelwork in Action 11bachNo ratings yet

- Cryolor Asia PasificDocument4 pagesCryolor Asia PasificJosh BiadnoNo ratings yet

- Large Span Structures - Arjun and JahanDocument51 pagesLarge Span Structures - Arjun and JahanJacob K Thomas100% (1)

- One World Trade CenterDocument31 pagesOne World Trade Centersakshi meherNo ratings yet

- Capitol Visitor Center..Document5 pagesCapitol Visitor Center..Tanasescu AlinNo ratings yet

- 003Document8 pages003Asad HassanNo ratings yet

- Olympiapark MunichDocument25 pagesOlympiapark MunichA-07 MIHIR BHUVANo ratings yet

- Central CCTV EstructuraDocument5 pagesCentral CCTV EstructuraMartín DalmazoNo ratings yet

- 1037 Steel Plate Shear Walls Efficient Structural Solution For Slender High Rise in ChinaDocument16 pages1037 Steel Plate Shear Walls Efficient Structural Solution For Slender High Rise in ChinasteadycoNo ratings yet

- 2003 05 AustinDocument5 pages2003 05 AustinDan A. DanielNo ratings yet

- Structural SystemDocument13 pagesStructural Systemlalit kadu100% (1)

- Building Tech Presentation Group ArcheologyDocument41 pagesBuilding Tech Presentation Group ArcheologyJude AwosikaNo ratings yet

- The Cloud, AucklandDocument7 pagesThe Cloud, AucklandShailvi ShahNo ratings yet

- Kharkopar STN Concept, Material, ServicesDocument6 pagesKharkopar STN Concept, Material, Serviceskomal100% (1)

- Sarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresDocument17 pagesSarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresMais Maher AldwaikNo ratings yet

- 1748 Nusha Rakhe As 2Document4 pages1748 Nusha Rakhe As 2nusha rakheNo ratings yet

- Waikato University Case Study 5Document4 pagesWaikato University Case Study 5clam2014No ratings yet

- Structural Steel Design Awards 2017Document28 pagesStructural Steel Design Awards 2017bachNo ratings yet

- Heydar Aliyev Center: by Zaha Hadid ArchitectsDocument11 pagesHeydar Aliyev Center: by Zaha Hadid ArchitectsDakshata KoliNo ratings yet

- Arch Pipe With Rod TensionDocument4 pagesArch Pipe With Rod Tensionahm_shaabanNo ratings yet

- Lacture 2 Special ConstructionDocument91 pagesLacture 2 Special ConstructionLau Jeh FarnNo ratings yet

- An Iconic Building and A Successful Stadium: Prof. Nichols St. Nooshin Ahmadi Yasaman Bagheri Farzad GolestaniradDocument29 pagesAn Iconic Building and A Successful Stadium: Prof. Nichols St. Nooshin Ahmadi Yasaman Bagheri Farzad Golestaniraddev dubeyNo ratings yet

- Design and Construction of The Fabian Way Bridge SuperstructureDocument10 pagesDesign and Construction of The Fabian Way Bridge SuperstructureMazhar ZamanNo ratings yet

- The Shard at London Bridge: Structure Case Study byDocument42 pagesThe Shard at London Bridge: Structure Case Study byJovita Chiara100% (1)

- Structural System 2Document2 pagesStructural System 2Steve B. BondocNo ratings yet

- Stadium - Eden GardensDocument19 pagesStadium - Eden Gardensanushree singhalNo ratings yet

- Bulk Active Structural SystemDocument30 pagesBulk Active Structural SystemRisky Manek100% (1)

- VME PRECAST Presentation PDFDocument134 pagesVME PRECAST Presentation PDFTri LeNo ratings yet

- Building Technology: Hearst TowerDocument15 pagesBuilding Technology: Hearst TowerAsavariNo ratings yet

- Twin TowerDocument21 pagesTwin TowerPETA DEVENDRANo ratings yet

- 371881083-Wankhede-Pdf (Dragged)Document1 page371881083-Wankhede-Pdf (Dragged)Anish ParianiNo ratings yet

- 371881083-Wankhede-Pdf (Dragged)Document1 page371881083-Wankhede-Pdf (Dragged)Anish ParianiNo ratings yet

- 371881083-Wankhede-Pdf (Dragged)Document1 page371881083-Wankhede-Pdf (Dragged)Anish ParianiNo ratings yet

- Sustainability-13-07944 (Dragged)Document1 pageSustainability-13-07944 (Dragged)Anish ParianiNo ratings yet

- Couttsetal.20122 (Dragged)Document1 pageCouttsetal.20122 (Dragged)Anish ParianiNo ratings yet

- Couttsetal.2012 1 (Dragged)Document1 pageCouttsetal.2012 1 (Dragged)Anish ParianiNo ratings yet

- Sustainability-13-07946 (Dragged)Document1 pageSustainability-13-07946 (Dragged)Anish ParianiNo ratings yet

- Couttsetal11.2012 (Dragged)Document1 pageCouttsetal11.2012 (Dragged)Anish ParianiNo ratings yet

- Sustainability-13-07944 (Dragged)Document1 pageSustainability-13-07944 (Dragged)Anish ParianiNo ratings yet

- Sustainability-13-07945 (Dragged)Document1 pageSustainability-13-07945 (Dragged)Anish ParianiNo ratings yet

- Xyz 1Document2 pagesXyz 1Anish ParianiNo ratings yet

- Framecad ManualDocument141 pagesFramecad ManualAie Bantugan100% (2)

- 3 Loads Distribution MDocument45 pages3 Loads Distribution MRagheb IbrahimNo ratings yet

- General Notes: Proposed Bungalow HouseDocument1 pageGeneral Notes: Proposed Bungalow HouseRenvil PedernalNo ratings yet

- Chapter 4 Design of SlabsDocument43 pagesChapter 4 Design of SlabsiiMa stic100% (1)

- Technical ProposalDocument6 pagesTechnical ProposalMark Sinclair100% (1)

- Sheetpile Handbook ch2Document90 pagesSheetpile Handbook ch2Raihan Harun ArrasyidNo ratings yet

- 14 Soccobel Structural Plans v1.1Document11 pages14 Soccobel Structural Plans v1.1daylesford.worksNo ratings yet

- Master List of Drawings Nov 2019Document67 pagesMaster List of Drawings Nov 2019Kanhaiya Lal YadavNo ratings yet

- TRIO Stopend Form TS PDFDocument4 pagesTRIO Stopend Form TS PDFineboluuNo ratings yet

- Blended CementsDocument170 pagesBlended CementsShruti KonkaNo ratings yet

- Raft Technical ManualDocument24 pagesRaft Technical ManualTuroy100% (1)

- ReportDocument2 pagesReportRosallind daBombNo ratings yet

- Ruh8 2021 M-101 Ground Floor Hvac-M - 1 0 1Document1 pageRuh8 2021 M-101 Ground Floor Hvac-M - 1 0 1Ata AtefNo ratings yet

- Anchorbolt (318 08)Document26 pagesAnchorbolt (318 08)Anonymous 9MDGo2jNo ratings yet

- RC2 PDFDocument213 pagesRC2 PDFMARIO VARGAS100% (1)

- Waste Plastic in PaversDocument17 pagesWaste Plastic in PaversNabeel Inamdar50% (8)

- Bolted or Riveted Tension MembersDocument39 pagesBolted or Riveted Tension MembersKristin Brienne Leander-Renomeron88% (8)

- Prefabrication and Modular ConstructionDocument28 pagesPrefabrication and Modular ConstructionAmmaar RayedNo ratings yet

- DR Kumar Neeraj Jha July15 PDFDocument73 pagesDR Kumar Neeraj Jha July15 PDFShalom ArayaNo ratings yet

- 5 KL GLSR: SchemeDocument12 pages5 KL GLSR: SchemeVenkata Bhaskar DameraNo ratings yet

- Midas Civil Application in Box Girder LRT 3Document48 pagesMidas Civil Application in Box Girder LRT 3milkcNo ratings yet

- Combined Footing Design With Example and Types of Combined FootingDocument2 pagesCombined Footing Design With Example and Types of Combined FootingNick GeneseNo ratings yet

- Determination of Fracture Toughness and KIC CVN Correlations For API 5L X60 PipelineDocument9 pagesDetermination of Fracture Toughness and KIC CVN Correlations For API 5L X60 PipelineEfvan Adhe Putra PradanaNo ratings yet

- Principles of RCC 2Document3 pagesPrinciples of RCC 2prashmceNo ratings yet

- Notaton X Foreword X 1 Introducton 1: Istructe Manual For The Design of Concrete Building Structures To Eurocode 2Document7 pagesNotaton X Foreword X 1 Introducton 1: Istructe Manual For The Design of Concrete Building Structures To Eurocode 2Lim Wee BengNo ratings yet

- TR - Type - 2 - Box Shape - Hot - DryDocument17 pagesTR - Type - 2 - Box Shape - Hot - DryFreedom Love NabalNo ratings yet

- Structural Design Criteria and ConsiderationsDocument2 pagesStructural Design Criteria and ConsiderationsCj VillanuevaNo ratings yet

- RCC Bundled BarsDocument7 pagesRCC Bundled BarsVSMS8678No ratings yet

- Exercise No. 5Document7 pagesExercise No. 5Stanly Mark SantosNo ratings yet

- BridgeDocument9 pagesBridgeMuhammad Tajammul KhalidNo ratings yet