Professional Documents

Culture Documents

Product Specifications

Uploaded by

Tushar Mohta0 ratings0% found this document useful (0 votes)

8 views20 pagesOriginal Title

PD5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views20 pagesProduct Specifications

Uploaded by

Tushar MohtaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

Product Specifications

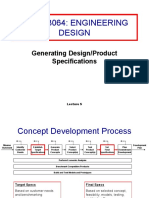

Concept Development Process

Mission Development

Statement Identify Establish Generate Select Test Set Plan Plan

Customer Target Product Product Product Final Downstream

Needs Specifications Concepts Concept(s) Concept(s) Specifications Development

Perform Economic Analysis

Benchmark Competitive Products

Build and Test Models and Prototypes

Target Specs Final Specs

Based on customer needs Based on selected concept,

and benchmarking feasibility, models, testing,

and trade-offs

Product Specifications Example:

Mountain Bike Suspension Fork

Challenges

‘Specialized Bicycle Components’ after assembling a

list of customer needs faced the following challenges:

• How could the relatively subjective customer needs be

translated into precise targets for the remaining

development effort?

• How could the team & its senior management agree on

what would constitute success or failure of the resulting

product design?

• How could the team develop confidence that its intended

product would garner a substantial share of the

suspension fork market?

• How could the team resolve the inevitable trade-offs

among product characteristics like cost & weight?

Start with the Customer Needs

The Product Specs Process

• Prepare the list of metrics

• Collect competitive benchmarking information

• Set ideal & marginally acceptable target values

• Reflect on the Results and the Process

Establish Metrics and Units

Link Metrics to Needs

Guidelines for forming the metrics

• Metrics should be complete

• Metrics should be dependent variables

• Metrics should be practical

• Some needs are not quantifiable

• The metrics should include popular criteria for

comparison in the marketplace

Benchmark on Customer Needs

Benchmark on Metrics

Assign Marginal and Ideal Values

Concept Development Process

Mission Development

Statement Identify Establish Generate Select Test Set Plan Plan

Customer Target Product Product Product Final Downstream

Needs Specifications Concepts Concept(s) Concept(s) Specifications Development

Perform Economic Analysis

Benchmark Competitive Products

Build and Test Models and Prototypes

Target Specs Final Specs

Based on customer needs Based on selected concept,

and benchmarking feasibility, models, testing,

and trade-offs

Setting the Final Spec.

The Process:

1. Develop technical models of the product

2. Develop a cost model of the product

3. Refine the spec., making trade-offs where

necessary

4. Flow down the spec. as appropriate

5. Reflect on results & the process

Component Qty/ High Low High Total Low Total

Fork ($ pu) ($ pu) ($/fork) ($/fork)

Steer Tube 1 2.5 2 2.5 2

Crown 1 4 3 4 3

Boot 2 1 0.75 2 1.5

Lower Tube 2 3 2 6 4

Lower Tube top cover 2 2 1.5 4 3

Main lip seal 2 1.5 1.4 3 2.8

Slide bushing 4 0.2 0.18 0.8 0.72

Slide bushing spacer 2 0.5 0.4 1 0.8

Lower tube plug 2 0.5 0.35 1 0.7

Upper tube 2 5.5 4 11 8

Upper tube top cap 2 3 2.5 6 5

Upper tube adjustment knob 2 2 1.75 4 3.5

Adjustment shaft 2 4 3 8 6

Spring 2 3 2.5 6 5

Upper tube orifice cap 1 3 2.25 3 2.25

Orifice springs 4 0.5 0.4 2 1.6

Brake studs 2 0.4 0.35 0.8 0.7

Brake brace bolt 2 0.25 0.2 0.5 0.4

Brake brace 1 5 3.5 5 3.5

Oil (l) 0.1 2.5 2 0.25 0.2

Misc. snap rings, o-rings 10 0.15 0.1 1.5 1

Decals 4 0.25 0.15 1 0.6

Assembly at $20/hr. 30 min 20 min 10 6.67

Overhead at 25% of direct cost 20.84 15.74

Total 104.19 78.68

Set Final Specifications

Reflect on the Results & Process

1. Is the product a winner?

2. How much uncertainty is there in the

technical & cost models?

3. Is the concept chosen best suited to the

target market or could it be best applied

in another market?

4. Should the firm initiate a formal effort to

develop better technical models of some

aspect of the product’s performance for

future use?

You might also like

- 6 Product SpecificationsDocument32 pages6 Product Specificationssalladım TuttuNo ratings yet

- Ulrich 6 Product SpecificationsDocument60 pagesUlrich 6 Product SpecificationsFahim Faisal RaunaqNo ratings yet

- Mech 3064: Engineering Design: Generating Design/Product SpecificationsDocument28 pagesMech 3064: Engineering Design: Generating Design/Product SpecificationsYash maullooNo ratings yet

- Product Specifications: Teaching Materials To AccompanyDocument48 pagesProduct Specifications: Teaching Materials To AccompanySudarshanNo ratings yet

- Product Specifications: Teaching Materials To AccompanyDocument32 pagesProduct Specifications: Teaching Materials To AccompanyThiru MoorthyNo ratings yet

- Product Specifications: Teaching Materials To AccompanyDocument32 pagesProduct Specifications: Teaching Materials To AccompanyDebabrata PaulNo ratings yet

- Product SpecificationDocument36 pagesProduct SpecificationrvimalsamsinghNo ratings yet

- Product Design & Development: BITS PilaniDocument32 pagesProduct Design & Development: BITS PilaniShanmugasundaram RaghuramanNo ratings yet

- Lecture 5 PSEDocument29 pagesLecture 5 PSEJason RoyNo ratings yet

- Target CostingDocument56 pagesTarget CostingAnshul Chhabra100% (1)

- Product Specifications: Teaching Materials To AccompanyDocument32 pagesProduct Specifications: Teaching Materials To AccompanyThiru MoorthyNo ratings yet

- Product Design Issues: INDR 371 Fall 2020Document96 pagesProduct Design Issues: INDR 371 Fall 2020Uzma UzmaNo ratings yet

- ECE520.427 Class #4: Customer Needs and Target SpecificationsDocument51 pagesECE520.427 Class #4: Customer Needs and Target Specificationsnareshkumar menmulaNo ratings yet

- Module 4 - Customer Value PropositionDocument26 pagesModule 4 - Customer Value PropositionMirnal MungraNo ratings yet

- 6T Concept SelectionDocument23 pages6T Concept Selectionsai ashwindranNo ratings yet

- Babok Visual v3Document218 pagesBabok Visual v3thiquangdai100% (1)

- NPD L5 - Product Concept and Business Analysis - HandoutsDocument74 pagesNPD L5 - Product Concept and Business Analysis - HandoutsMaria S HarizanovaNo ratings yet

- AMED 01dDocument17 pagesAMED 01dAbenesh KumaresanNo ratings yet

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarNo ratings yet

- Erik Kolderup Standard 209 October 2018Document34 pagesErik Kolderup Standard 209 October 2018Hamed Houri JafariNo ratings yet

- Product Specification WrintingDocument27 pagesProduct Specification WrintingAbhay SinghNo ratings yet

- Iso Presentation Asq 1114 Dec 2010 HandoutDocument25 pagesIso Presentation Asq 1114 Dec 2010 HandoutHarish YadavNo ratings yet

- 4 Product SpecificationsDocument14 pages4 Product Specificationstemu temuNo ratings yet

- SQAM-2019 VolvoGroupDocument52 pagesSQAM-2019 VolvoGroupJanNo ratings yet

- Product Specifications: Teaching Materials To AccompanyDocument32 pagesProduct Specifications: Teaching Materials To AccompanySanket LandgeNo ratings yet

- Industrial Management 2: Six Sigma OverviewDocument17 pagesIndustrial Management 2: Six Sigma OverviewYagnik prajapatiNo ratings yet

- Development Processes and Organizations: Teaching Materials To AccompanyDocument15 pagesDevelopment Processes and Organizations: Teaching Materials To AccompanySudarshanNo ratings yet

- CH IV - Design of Goods and ServicesDocument42 pagesCH IV - Design of Goods and ServicesSanjay ThakurNo ratings yet

- BDA 40804 - Automatic Farm Fish FeederDocument148 pagesBDA 40804 - Automatic Farm Fish FeederAmin SanNo ratings yet

- ISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980Document21 pagesISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980ivanNo ratings yet

- Development Processes and Organizations: Teaching Materials To AccompanyDocument32 pagesDevelopment Processes and Organizations: Teaching Materials To AccompanyhansleyNo ratings yet

- ME 4054W: Senior Design Projects: Week 6 - Tuesday Concept ScreeningDocument30 pagesME 4054W: Senior Design Projects: Week 6 - Tuesday Concept ScreeningShiella Rose VitalisNo ratings yet

- Implementing Devops With Team Foundation Server 2015 Community Edition PDFDocument113 pagesImplementing Devops With Team Foundation Server 2015 Community Edition PDFcarajorspyNo ratings yet

- Iso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307Document21 pagesIso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307avinash_k007No ratings yet

- Quality Function DeploymentDocument6 pagesQuality Function DeploymentSuvash KumarNo ratings yet

- A Good Product Is The Result of A Good ProcessDocument34 pagesA Good Product Is The Result of A Good ProcessYash maullooNo ratings yet

- 1 Product Development ProcessDocument100 pages1 Product Development Processzaid zainol100% (1)

- Project Life CyclesDocument13 pagesProject Life CyclesNilushi FernandoNo ratings yet

- Advanced Operations Management CHP 3Document50 pagesAdvanced Operations Management CHP 3Mohsin AliNo ratings yet

- L08 Cellular ManufacturngDocument24 pagesL08 Cellular ManufacturngDr. Sandeep KautishNo ratings yet

- Product Design: Please Refer Chapter 5 in Your E-BookDocument29 pagesProduct Design: Please Refer Chapter 5 in Your E-BookIlyana NadhirahNo ratings yet

- Removing Bottleneck From A Manufacturing Unit: Binod TimilsinaDocument75 pagesRemoving Bottleneck From A Manufacturing Unit: Binod TimilsinakinfegetaNo ratings yet

- Product Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TDocument57 pagesProduct Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TKumar AbhishekNo ratings yet

- Design of Goods and ServicesDocument27 pagesDesign of Goods and ServicesAmir AhmadNo ratings yet

- Chapter 3 (New)Document50 pagesChapter 3 (New)2023418704No ratings yet

- EvtDocument104 pagesEvtsephirothNo ratings yet

- 1.0 Title: Mechanical Design For AssemblyDocument10 pages1.0 Title: Mechanical Design For Assemblybm100040No ratings yet

- Guide To Product OwnershipDocument298 pagesGuide To Product OwnershipMihaela M100% (1)

- Rubrics For Machine DesignDocument2 pagesRubrics For Machine DesignYoniNo ratings yet

- Concept SelectionDocument23 pagesConcept SelectionAshok DargarNo ratings yet

- Concept Selection: Teaching Materials To AccompanyDocument23 pagesConcept Selection: Teaching Materials To AccompanyhansleyNo ratings yet

- Guide To Product OwnershipDocument291 pagesGuide To Product OwnershipCristina Oprisa100% (2)

- FacilitiesPlanning Lecture2Document65 pagesFacilitiesPlanning Lecture2Yasser MohamedNo ratings yet

- LOB - Product DesignDocument50 pagesLOB - Product DesignahyaniluthfianasariNo ratings yet

- Chapter 1Document13 pagesChapter 1subashiniNo ratings yet

- Chap 5 - Product DesignDocument63 pagesChap 5 - Product DesignÁnh LêNo ratings yet

- QD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBDocument35 pagesQD 002 - Quality Manual 2022 - Feb22-Rev2.6 - RBAjibade SukuratNo ratings yet

- S4H - 491 BDC Questionnaire - R and D EngineeringDocument27 pagesS4H - 491 BDC Questionnaire - R and D EngineeringVigneshNo ratings yet

- RomerDocument6 pagesRomerTushar MohtaNo ratings yet

- Product DevelopmentDocument13 pagesProduct DevelopmentTushar MohtaNo ratings yet

- Conversion of Ideas To Product RealizationDocument16 pagesConversion of Ideas To Product RealizationTushar MohtaNo ratings yet

- Development Processes and OrganizationsDocument16 pagesDevelopment Processes and OrganizationsTushar MohtaNo ratings yet

- Product PlanningDocument28 pagesProduct PlanningTushar MohtaNo ratings yet

- Entrep Midterm 1-1Document4 pagesEntrep Midterm 1-1CHLOE ANNE CORDIALNo ratings yet

- SWOTDocument3 pagesSWOTJunaid SayedNo ratings yet

- Thelo Rolling Stock Leasing (Pty) LTD - Generic Media ReleaseDocument2 pagesThelo Rolling Stock Leasing (Pty) LTD - Generic Media ReleaseLCNo ratings yet

- QHSE Requiremnts TataDocument5 pagesQHSE Requiremnts TataparthaNo ratings yet

- 10.1 Thesis - FachiDocument85 pages10.1 Thesis - FachiMadalitso MukiwaNo ratings yet

- PaypalDocument20 pagesPaypalAnika VarkeyNo ratings yet

- PSFR Exam GuideDocument31 pagesPSFR Exam Guideathancox5837No ratings yet

- THREADLESSDocument3 pagesTHREADLESSMilan JoseNo ratings yet

- Management Accounting Objectives Sem VDocument14 pagesManagement Accounting Objectives Sem VytsNo ratings yet

- MPM722-2014-Topics 10 and 11Document30 pagesMPM722-2014-Topics 10 and 11RazA KhaTTaKNo ratings yet

- BBA 2019 2020 Project Work TitlesDocument20 pagesBBA 2019 2020 Project Work TitleszaqejiNo ratings yet

- Business Income Tax Guide FinalDocument40 pagesBusiness Income Tax Guide FinalOlaNo ratings yet

- PepsiDocument2 pagesPepsiJerhica ResurreccionNo ratings yet

- Supervisor Workplace Skills Series: DelegationDocument14 pagesSupervisor Workplace Skills Series: Delegationrossaniza RamlanNo ratings yet

- F6 Taxation (FA07) Course Slides BPPDocument295 pagesF6 Taxation (FA07) Course Slides BPPhrsh444No ratings yet

- How Leaders Drive Workforce PerformanceDocument20 pagesHow Leaders Drive Workforce PerformanceRight Management100% (1)

- Accounts ReceivableDocument6 pagesAccounts ReceivableNerish PlazaNo ratings yet

- Project Handover Form (ESCO V5) - G36Document1 pageProject Handover Form (ESCO V5) - G36Hamza KhanNo ratings yet

- Case Study 1 - Barings Bank, PLC. - EBF 301 - Global Finance For The Earth, Energy, and Materials IndustriesDocument3 pagesCase Study 1 - Barings Bank, PLC. - EBF 301 - Global Finance For The Earth, Energy, and Materials Industriescoseri5No ratings yet

- 1) Introduction: Currency ConvertibilityDocument34 pages1) Introduction: Currency ConvertibilityZeenat AnsariNo ratings yet

- QAV - 1.1. Report (Sup1)Document2 pagesQAV - 1.1. Report (Sup1)Rohit SoniNo ratings yet

- CHAPTER 3 Financial PlanningDocument7 pagesCHAPTER 3 Financial Planningflorabel parana0% (1)

- 7 Dividend Valuation ModelDocument11 pages7 Dividend Valuation ModelDayaan ANo ratings yet

- Maganjo Institute of Career Education: Unit ThreeDocument17 pagesMaganjo Institute of Career Education: Unit ThreewonueNo ratings yet

- Druk WangDocument24 pagesDruk WangSonam Peldon (Business) [Cohort2020 RTC]No ratings yet

- Application of Operation Reasearch in Hospital ManagementDocument3 pagesApplication of Operation Reasearch in Hospital ManagementBoobalan RNo ratings yet

- FoodpandaDocument10 pagesFoodpandaMd. Solaiman Khan ShafiNo ratings yet

- P&G - Colgate Final 1Document21 pagesP&G - Colgate Final 1Payal PatelNo ratings yet

- Operation Manual: Hermetic Sealing SystemDocument50 pagesOperation Manual: Hermetic Sealing SystemsunhuynhNo ratings yet

- Kj1010-6804-Man604-Man205 - Chapter 7Document16 pagesKj1010-6804-Man604-Man205 - Chapter 7ghalibNo ratings yet