Professional Documents

Culture Documents

ECMs How To Write Electrical Specs

ECMs How To Write Electrical Specs

Uploaded by

FernandoCrespoMon0 ratings0% found this document useful (0 votes)

13 views99 pagesOriginal Title

ECMs How to write Electrical specs

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views99 pagesECMs How To Write Electrical Specs

ECMs How To Write Electrical Specs

Uploaded by

FernandoCrespoMonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 99

E. Q®2\AS

Reprinted from May 1969 issue ELECTRICAL CONSTRUCTION AND MAINTENANCE

© Copyright 1969 McGraw Hil, Ine—All rights reserved.

~Flectrical engineers

talk about specs

Toadda lively, stimulating note of personal attitudes

on spec writing, we surveyed a small, selected number from

our thousands of electrical-iesign-engineer readers across

the country to get a roundup of ideas and opinions about

various details of writing electrical specifications.

We chose wide geographicai coverage and asked them several

general questions about spec writing to reveal general trends

on important considerations. Within this report on spec

writing, we present the questions and summaries of the answers

from these experts. The contributors to this roundtable

of ideas about specs are all competent electrical design

engineers who have candidly expressed their convictions,

preferences and practices in writing electrical specs.

EC&M thanks them publicly for taking the time to present

their views. We are sure you will find this interesting.

‘THE CONTRIBUTORS ARI

4. R. Chester tian 4. Heraiger ‘Wali T. Boeddeor

Chie Electrical Engineer President Engineer

ers & Reaves, Ine. erage Lut, Ine Wilism T. Boeddeher & Asse,

Memphis, Tenn. wake, Ws Gincinna, Ohio

2.8. Downing Robert G. oSutvan 4. Bate Thompson

Partner Pipa Electrical Engineer Present

Downing & Ries Engineers

Portland, Oe

QUESTION 1: What type of equipment re-

Aires the most detail in electrical specs? How

about: a. wire and cable, blighting, ¢ racensps,

4. wiring devices, «. panels and switchboaree?

© Equipment which is unusual pr is kely to be

unfamiliar to the contractor should be described

in more detail than items such as wire, conduit

and panelboards. I would include én the “inusval

or unfamiliar” category such items as televi-

sion antenna systems, emergency generators and

nurse-call systems,

© Equipment requiring the most detail are those

items not installed on every electrical job; fr

instance, high-voltage switchgear, elaborate con

‘trol and control panel arrangements, involved

Sound systems, telemetering, supervisory and

computer interphasing.

© Grounding should always be carefully specified

as well as detailed on plans.

© Lighting fixtures require detail when a specific

‘manufacturer is not allowed.

Conduit fittings outdoors often rust unless #

broper type is selected. Cable trays require care-

£4 specs on loadings, type of dropouts, type of

connections, spacing of ladder rungs to prevent

cable sagging, rigidity, strength for men to stand

on, free from burrs which tear cable,

Battery chargers, inverters require good per-

formance requirements, tolerance, freedom from

voltage fluctuations,

In general, the specifier must be aware of the

ratings (voltage, current, BIL) and features

available that meet the requirements of his instal.

Burns & Roe Ine.

stead, N.Y. Seattle, Wash

Marvin €. King, J

Presicont

(het Electrical Engineer

Asifcated Consultants, Ine,

Minneapolis, Minn, ‘t Loui, Mo.

Look for Questions 2, 3,4 and 5 as you go through this report...

‘Tompson, Miler & Lyons Enginoers, ne

Water 6. Bayne

Electrical Engineer

Watt Hecick Enginering Corp. ‘Bayh, Weir & Frat, Ine,

Heuston, Texas [8 Francisco, Cai

Avert 8. ¢. Chong LT. Vivien,

Preigent Part Owner

‘bere Chong Associates Licien T. Vivien, se, & Asse.

enol, Haws New Orteans, ta,

David. Sebi RH. Ateisson

Chief Electrical Engineer

Fruco & Associates, Ine-

lation, to satisty any special needs and functions.

© Wire and cable require the most detail, Panels

and switchboards must also be carefully specified

© In our specifications, which are written for

new power plants, and expansion of existing mu-

nicipal power plauls, we emphasize and give more

detail on produets rather than on method. Our

specifications for electrical products are “most

descriptive on switchgear which contains relay-

ing, instrumentation and control. High-voltage

conductors complete with their terminations

would be next in importance, followed by misce>

Jancous items such as raceways, building wiring,

wiring devices, ete.

© Panels and switehboards, we feel, require the

most detail. Conduit and fittings are second.

© We strongly advise the use of “Equipment

Schedules” in listing equipment, and we list the

equipment either on the drawing or in the specifi-

cations. This enables the specification writer, in

assembling his specifications, to either attach the

“Equipment Schedule” as an Appendix to the

specifications or type (or print by hand) the

“Equipment Schedule” right on the drawing. The

latter does make sure that i is always on hand

for those doing the installation work,

© The most spec detail should be given to special

lighting fixtures, motor control centers, switeh-

boards, sound systems, signals and fire alarms

© We give greatest detail to panels, switch-

boards, raceways and lighting.

HE General Conditions section of project specif-

cations normally consists of a selected group of

considerations and regulations that apply to all sub-

divisions of the project and henee all contractors in-

volved. This may be presented as a standard AIA

form or a variation thereof. Mechanical and electrical

specifications normally contain a reference to the

General Conditions noting that these shall govern

the subcontractor work and shall be considered a part

of the subcontract specification,

‘Special conditions relating to the olectrical installa

tion ean be included as Supplementary General Con-

ditions in the electrical specifications. These may

cover certain considerations, such as seope of work,

te,, that must be tailored to the specific installation.

Depending on size, type and complexity of the project.

these additions may involve a few concise paragraphs

Cover these planning,

organization and management

aspects of the job...

GENERAL

CONDITIONS

of several pages of detailed instructions to bidders

and installing contractors.

The following outline presents discussion and pro-

totype specification clauses of selected typical subjects,

that normally are included in a set of General Condi-

tions or Supplementary General Conditions.

DESCRIPTION OF PROJECT AND WORK

General description of the property, building lay-

out, construction, height, type of occupaney, boundary

Jines, and relevant descriptive material.

Scope of work should list all systems and work to

be included in the contract and detailed in subsequent

pages of the specification. This section also should

spell out what electrical work is not included; what

electrical equipment items are to be furnished by

QUICK-REFERENCE CHECKLIST

1 Bids, contract—documents

1 Bonds—pertormance

D Changes—plans and specifications, addenda

5 Cutting, patching and repairs

1D Definitions —contract and specification terms

1 Description ofthe project

1D Drawings—working, shop, detailed

in this contract

not included i contract

by others

Electrical work, scope of

Examination of site and other drawings

Field office and storage areas

Guarantee

Inspections

Insuranee, indemnity

Interference with other trades

Labor and supervision

Licenses, permits, fees

cO0000000

1 Materiats

—type and quality

—furnished and installed by this contractor

—furnished by others but installed by this contractor

{urished and installed by others, but connected

by this contractor

Payments—when, iow made and on what basis:

Protection—to lite and property, watchman, ete.

Removal of rubbish, etc.

Rules and regulations—todes; ordinances, etc.

satety

Signs—protective, advertising, ete

Sleeves, slots, chases and openings

‘Specifications—intent and precedence

Substitutions—material and equipment, how handled

Taxes—including sales taxes, where applicable

Temporary facilities

—ight, neat, power, water

—who is to supply and pay for each

Temporary work

Termination of work

oo000gg0uun

others, but installed by this contractor; what clec-

trical equipment is to be furnished and installed by

others, but connected by this contractor. Typical spec-

ification clauses are presented in quotes,

Work included

“the work covered by this specification shall in-

clude furnishing all labor, material, equipment and

services to construct and install the complete electri-

cal system as shown on the accompanying plans and

specified herein. This work shall includ

“A. Outdoor high-voltage switching station

Underground feeders from switching station

to unit substations in plant,

“C. Unit substations including primary disconne

facilities, transformer, and secondary switchgear.

“D. Complete distribution system for lighting in

cluding the necessary transformers, feeders, distr'-

bution panelboards, branch circuits, lighting fixtures,

control switches and receptacles. ! :

“E, Complete distribution system for power inelue

ing busway feeders, branch-circuit plug-in type dis-

connects, and cable drop edhnections to motors.

“F. Underfloor duct distribution syatem, first floor,

office area.

“G. Cellular floor distribution aystem, second and

third floor, office building,

“H. Empty raceways and cabinets for the telephons

system.

“I. Clock system, including provision of clocks and

regulators,

“J. Paging equipment including fire alarm and se.

curity systems, ‘

“K, Outdoor lightins—building and parking areas

“L. Receiving, handling, setting and connecting

‘motors and controls.”

Work not included

“The following equipment items and work shall be

the responsibility of others,

“A. Motors and controls listed below shall be fur-

nished by the owner but shall be moved, installed and

connected by the electrical contractor as indicated on

the electrical plans. (List items.)

“B, Telephone system wires, cables, equipment and

instruments—furnished and installed by Tele-

phone Compan;

“C, levator signal and control wiring beyond ser-

vice feeder noted on plans—by others.

“D. Controls for motors on mechanical equipment

listed below will be furnished by others but shall be

installed and wired by the electrical contractor, (Pro-

vide a list of items.)”

BIDS AND CONTRACTS

Clearly state the procedures involved in submission

of bids and subsequent awarding of contracts,

Submission of bids

“Bid proposals shall be made on forms provided

yee Proposed prices shall be

indicated both in figures and in writing, Proposals

shall be signed by the bidder or his duly authorized

representative, with his address, firm name, title, ete.

Bidder’s bond shall be executed on the form attached

to the proposal form,

“All bids shall be presented under sealed cover

plainly identified as a proposal for the work bid upon

and shall have enclosed therewith a cashier’s or cer-

tified check for §...... (am amount equal to .....%

of the proposed bid) and made payable ta

The right is reserved to reject any or all proposals

or to award the contract to the responsible bidder

with the lowest proposal complying with all pre-

scribed requirements

Award of contract

“The contract award, if approved, will be made

within days after opening of sealed bids.

Within days after bid opening, the owner

or his representative will return the proposal guar-

antes accompanying proposals not to be considered

in the award of the contract.

“The successful bidder shall sign the contract in

duplicate counterpart and return it, with the contract,

bond, within ...... days after receipt of contract

award notice. The contractor shall also sign a set of

plans and specifications for filing with the contract.”

Include clauses relevant to:

Time schedules, work program, layout of work,

Inspection, supervision, approvals,

Extra work

“For any extra electrical work the (architect,

engineer, owner) may propose, this contractor shall

farnish to the (architect, engineer, owner) an esti-

mate of the cost (lump sum) (material, labor and

insurance cost plus .....% for overhead and profit)

of such work. The electrical contractor shall proceed

only after receiving a written order from the (archi-

tect, engineer, owner) establishing the agreed price

and describing the work to be done.”

Method of payment

“‘The contractor shall be paid monthly, as the work

progresses, an amount equal to the cast of the work

installed that month less .....% of the indicated

cost as a retained percentage. Monthly payments

‘shall be based upon the contractor's written statement

of equipment and materials installed and labor ex-

pended for that month, Verification by the engineer

will be required before certificates of payment are

fssued. No payments will be authorized until any de-

fective work and materials have been removed, re-

placed and made good.

“Within ...... days after completion of the work

by the contractor and its acceptanee, in writing, by

‘the (engineer, architect, owner), the unpaid balance

of the contract price will be paid under a cortificate

issued by the (engineer, architect, owner).””

Periodic payments may be based on prefixed dates,

progress reports, progress photographs, payroll, ma-

‘terials invoices, or other appropriate established

methods of payment.

Other financial considerations include:

Insurance coverage for fire, theft, public liability,

workman's compensation,

Bond for evidence of financial responsibility,

Local fees related to securing all required permits,

certificates,

Social Security withholding tax from payroll.

Liens.

Responsibility for taxes,

GOVERNING CONDITIONS

‘This section should include specification clauses

covering:

Codes, regulations, safety orders, building laws

and ordinances, such’as the NE Code, American In-

stitute of Architects’ contract for construction of

buildings, State Industrial Accident Commission

orders, plus any other national, state, munieipal, util-

ity or company directives relating to the contemplated

type of work.

Code rulings and interpretations—by whom ren-

dered in event of question.

Procedence of design features outlined in specifi-

cations and drawings, if they are over and above re-

quirements of relevant codes.

Arbitration of errors or eon‘licts—how handled,

Responsibility, status and definition of owner,

architect, engineer and contractor.

Cutting and patching.

Excavation and backfill,

Installation of sleeves, chases and openings.

Repair and maintenance,

Removal of debris from premises during and after

completion of work.

On-site signs, notiess and advertisements.

Use of installation photographs for commercial pur-

poses,

PLANS, DRAWINGS

List the plans and drawings related to the specifi-

cations. Also: note which ones are to be considered

“working drawings"; give instructions relating to

“shop drawings" to be supplied by the contractor and

equipment suppliers; addition to plans or changes

Afctated by local and Installation conditions; mnstrue-

tions relating to preparation and submission of “as

installed” drawings after job is completed, A typical

specifications clause is:

“The (architect's, engineer's) drawings, which eon

stitute an integral part of this contraet, shall serve

ett EST on welt

et See

co kat

SHOP DRAWINGS submitted by the electrical contractor on

the projector the equipment manufacturer ossure proper de-

sign and instolation method,

6

fas the working drawings. They indicate the eneral

layout of the complete electrical system: arrange-

ment of feeders, circuits, outlets, switches, controls,

panelboards, unit substations, service equipment, £-

tures, and other work.

“Field verification of seale dimensions on plans is

directed since actual locations, distances and levels

will be governed by actual field conditions.

“The electrical contractor shall cheek architectural,

structural, plumbing, heating and ventilating plans

to avert possible installation confiets, Should dras-

tic changes from original plans be necessary to re-

solve such conflicts, this contractor shall notify the

(architect, engineer, ete.), and secnre written ap-

proval and agreement on necessary adjustments be-

fore the installation is started

“Discrepancies shown on different plans, or between

plans and actual field conditions, or between plans

land specifications, shall promptly be brought to the

attention of the inspector, engineer, architect, etc.,

for a decision.

“The following drawings are part of this specifica

tion and contract:

Drawine No, Tree

Ba 96-68 ‘High-voltage switching

station

EQ 94-68 Underground distribu-

tion

58 9-15-68 Power - manufacturing

E4 915-68 Lighting-manufacturing

BS Office electrical — ist

floor

ES Office electrical — 2nd

floor

Eq Outdoor tighting

‘These drawings may be superseded by later re-

vised or detailed drawings or specification addenda

prepared by the (architect, engineer), and the con-

tzactor shall conform to all reasonable changes with-

out extra cost to the owner, AAI items not specifically

‘mentioned in the specifications or noted on the draw-

but which are obviously necessary to

complete working installation shall be included.”

Shop draws

"Br contentor shall suai o the (architec, eng

nor) detailed dimensioned shop drawings covering

0 tems of equipment and brochures of all lighting

fixtures. No equipment should be put into manufac:

ture (or ordered) until these shop drawings or bro-

chures have heen approved by the (architect, eng

ret).

“The following procedure shall be observed: The

contractor shall submit " prints of shop

‘drawings to the (architect, enginees) for comment

or correction. ‘The contractor’ shall then submit

cscrvses a6ts of prints of corrected shop draw

ings to the (arehitest, engineer) for Snal approval

‘The same procedure shall aply in making shop draw

i revisions

Also inchide specication clauses relevant to:

3ymbols and abbreviations.

Definitions.

carer

Em

a

Bone

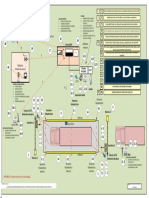

PLOT PLAN of simple electric! distribution system

ives overall picture of project; supplements specifi

Addenda, revisions, alternates,

Visit to site and examination of drawings of other

trades to verify dimensions, installation conditions

and conflicts, storage facilities, and the like.

Surveys for datum planes, elevations, benchmarks,

ete; how to request various information and who

should do it,

Order of precedence—specifications, plans, draw-

ings, ete.

TEMPORARY POWER

The electrical contractor shall furnish, install,

‘maintain, and remove after construction is completed,

asses amp, ....., volt, phase, .... wire

temporary power and lighting system as shown,

“The system shall consist of a service, distribution

system, panelboards, grounding, branch eireuits, and

20-amp duplex grounded type receptacle outlets as

shown on the drawing,

“Bach trade shall provide and pay for its own ex-

tensions for lights or power tools beyond the recep-

tacle outlets on the columns; and beyond the 3-phase

panelboard sub-mains in the case of S-phase power

tools :

“The general contractor shall pay all energy

charges for electric curvent used for temporary light

ing and power.”

Where the project is of sufficient size, it is advis-

able to list the number, size and location of the dis-

tribution panels that will be required for the tem

porary electric service during construction,

On large projects, call for temporary pole-line dis-

tribution systems,

Tt is good practice to list temporary power services

not included in the electrical bid but which, if re-

uired, shall be negotiated between the electrical con-

tractor and the trades requiring such service.

test

cations and other deowings relating to equipment

‘ond instllation specifies,

‘Typical specifications would be:

“The following services shall be part of the elee-

trical contractor’s bid. Where required, the cost of

such service shall be negotiated between the electrical

contractor and the contractor requesting such service:

‘A. Special circuits required by electric welders,

elevators, lifts, or other special equipment requiring

high amperage and/or special voltage service.

‘"B, Exterior lighting circuits for vandalism pro-

tection, public warning lights, advertising, ete.

“C. Overtime maintenance of temporary service fa-

cilities at the request of construction trade(s) or

contractor (s).”

MATERIALS

Definitive statements in the General Conditions

tion of the electrical specifications establish the means

of identifying the type and quality of materials and

equipment embodied in the system design and spect

fied in subsequent subsections.

On private projects, engineers “firm up” their ma-

terial specifications by listing one or more manufae-

turer's name(s), brand name(s), and catalog num-

er (s), plus reference to relevant industry standards

(NBMA, ete.). The bid is based on these items, Sub-

stitutions of equivalent quality materials normally

are permitted if they are submitted by the contractor

fas an alternate to the base bid and accepted by the

engineer.

Inclusion of these statements in the General Con-

ditions eliminates the necessity of repeating the “or

equal a8 approved” phrase in relevant specification

clauses, Without such reference in the General Con-

ditions, the “or equal as approved” phrases should be

uused to keep the specifications “open.”

The following prototype specification clauses indi-

cate how this subject can be handled,

Specification by brand name

“Where materials, equipment, apparatus or other

products are specified by manufacturer, brand name

type or catalog number, such designation is to estab-

lish standards of desired quality and style and shall

be the basis'of the bid. Materials so specified shall be

furnished under the contract, unless changed by mu-

tual agreement, Where two or more designations are

listed, choice shall be optional with the contractor.”

Material substitutions

“It is the intent of these specifications to establish

quality standards of materials and equipment. in-

stalled. Hence, specific itema are identified by manu-

facturer, trade name or eatalog designation,

“Should the contractor propose to furnish materials

‘and equipment other than those specified, as permit-

ted by the ‘or approved equal’ clauses, he shall sub-

mit a written request for any or all substitutions to

the (architect, engineer, owner), Such a request shall

be (an alternate to the original bid) (a separate pro-

posal) ; shall be accompanied with complete descrip:

tive (manufacturer, brand name, catalog number,

ete.) and technical Gata for all items; shall indicate

any addition or deduction to contract price.

“Where such substitutions alter the design or

space requirements indicated on the plans, the con-

tractor shall include all items of cost for the revised

design and construction including cost of all allied

trades involved.

“Acceptance or rejections of the proposed substitu-

tions shall be subject to approval of the (architect,

engineer, owner). If requested by the (architect,

engineer, owner), the electrical contractor shall sub-

mit for inspection samples uf both the specified ad

‘the proposed substitute items.

TEMPORARY POWER rcquirements should be included under

General Conditions, At lorge-ofec project shown above, pole

line distribution system provides temporory power while under-

ground system is being installed,

‘

“In ail cases where substitutions are permitted, the

contractor shall bear any extra cost of evaluating the

equality of the materials and equipment to be in-

stalled.”

‘The following also might be covered:

Quality of related hardware on the job.

Causes for rejection of materials or equipment,

Gauges of metal used in enclosures and boxes; wire

and cable sizes,

Point of delivery on jobsite of material and equip-

ment; on what dates,

‘Movement of material and equipment from jobsite

delivery point to installation point—by whom; how

protected against theft, damage, weather or other

deterioration,

LABOR

‘Where relevant, statements covering the following

tems can be included:

Governing labor laws, prevailing or acceptable wage

seales to be followed,

Specifications of labor fores, such as skill of me-

chanies, supervision ratio of foremen to journeymen

to apprentices, ete.

Clauses relating to antidiserimination, preference

to handicapped workers or veterans, senfority and

similar factors where applicable.

Reasons for dismiseal,

APPROVALS

Note procedures for obtaining necessary approvals,

Claims for extensions of deadlines, overtime pay.

Work suspension and related justification,

Field revisions of plang, substitution of materials,

departure from recommended installation procedures,

conflicts between plans and specifications, conflicts

with other trades,

“All electrical products used on this project shall

be as listed by Underwriters’ Laboratories, Ine., and/

or other agencies as approved.

“All electrical products used on this project shall

conform, unless, otherwise specifically noted, to ap-

plicable ‘standards of the National Blectrical Manu

facturers Assn. and/or the United States of America

Standards Institute.”

PROTECTION

Safety precautions

“The contractor shall furnish and place proper

suards for prevention of accidents. He shall provide

and maintain any other necessary construction re-

quired to secure safety of life or property, including

the maintenance of sufficient lights during all night

hours to secure such protection.”

Include instructions covering:

Enclosed storage areas, tool cribs, work sheds, field

offices, general headquarters.

Provision for watchman sexviee, fire extinguishers.

Guard rails around excavations or elevated work

areas, padlocks on enclosures, notices and warnings

pertaining to high voltage, protective guards on

power saws, drills and similar tools.

Approved tools, appliances, devices, scaffolds as well

as cranes and hoisting equipment to he utilized during

construction.

N ELECTRICAL service facility includes all the

conductors and equipment required to deliver

energy from @ utility supply line or system to the

wiring system of the individual premises being

served. The specifics of an electrical service will vary

with the size of the installation, voltages used, and

design criteria (overhead, underground, ete.). They

may range from a simple overhead service drop to

more complex arrangements of primary lines, under-

ground ducts, switching centers and transformer

installations.

Service-entranee systems may incorporate encloseé

busways, specially designed bus structures, inter-

locked armor cable, multiple conductors per phase

enclosed in parallel conduits or ducts, direct-burial

cables or conductors, multieonductor ‘cables, aerial

Don’t overlook these

considerations on...

SERVICE

ENTRANCE

EQUIPMENT

cables, or special insulations for open wiring. Also,

included are relevant equipment and accessory items

associated with power cutoff or interruption, eirouit

protection, primary (or secondary) metering and

grounding.

Definitive specification clauses should establish

quality and capacity levels of all items involved in

the service system. These clauses should note type,

size and number of cables; installation and support-

ing methods; location, rating, type and cironit pro-

tection features of disconnects and associnted items.

Where multiple services are indicated (power,

lighting, emergency, ete,), clearly note details of

such service sources in the specifications.

Emergency standby equipment (generators, bat-

tories, ete.) may be included with serviee-entrance

QUICK-REFERENCE CHECKLIST

Bus assembly or busway

—size, voltage, phase and number of conductors

1D Characteristics of service

‘volts, amperes, phase, number of wires

—primary (note specific vatages)

_—secondaty (nate specific voltages)

1D Conduetors

—type (insulation) and size

single conductor

—multiconductor assembly

direct burial

1D Connections

types of cable connectors to be used,

splicing instructions, etc.

10 Disconnecting means

service equipment

—primary—cireuit breakers, interrupter switches

—secondary—cireuit breakers, switches and fuses

0 Ducts

—conduit (metal, fiber, asbestos-cement, plastic,

tie, ete.)

1D Emergency service facilities See section on

Standby Power Facilities

1D Equipment—detals of service equipment (may be

covered in section on Transformers)

1 Grounding

‘methods and details of grounding service and

equipment

1D Location of service equipment

exact location on property or building

—point of attachment to utility lines

1D Multiple service requirements

—titferent voltages

1 Routing of service entrance

—overtead—pole line and service drop

—underground—trenching details and protection

1 Structures

details of switching and/or transformer structures

outdoor structures

indoor vaults

manholes for underground service

Cy Other items dictated by specific project

specifications or handled separately as indicated in the

section on Standby Power Facilities

Electrical specification sections relating to service

facilities and equipment may include any or all of the

items and prototype specification clauses. presented

below.

SERVICE DETAILS

Define the service characteristies—voltage, fre-

quency, phase, and number of wires. This informa

tion should also be noted on the relevant plans ac-

companying the specifications

Primary service

Specifically state what primary service work is to

be done by the electrical contractor, giving necessary

details on equipment locations and service facilities.

Generally this phase of the work is done by the ser

ving utility, but there are eases where part of it is

one by the electrical contractor. For example:

“The electrical contractor shall furnish and install

two primary ... kv underground ... in. fiber duct

systems encased in a... in, conerete envelope, as

shown on Drawing No. .... One duct line shall orig-

inate at the (utility) Company ... kv limes on

Street; the other at similar lines on .....

Street. Both ducts shall terminate at the (utility)

Company outdoor substation behind the plant boiler

house. The (utility) Company will furnish and ine

stall all ... kw cables in these ducts and do all wiring

for their transformers and switchgear concerned

with the ... ky system,

“The electrical contractor shal] (furnish and) ine

stall a... kv outdoor, metalclad switching center

consisting of (interrupter. switches and

fuses) (cireuit breakers) of capacities as noted on

Drawing No. .... This contractor shall furnish and

install the No. ..., ... insulated, ... kv eables,

Bround cable and conduit aystems between the in:

coming ... kv sections of the metalclad switchgear

and the secondary busses of the (utility) Company

substation, and make all connections to these busses.

INE DIAGRAM of an electrcol system design presents

Imple picture of service and mojor distribution facilities Basie

squlpment specifics are inluded, Accompanying specticetions

indicate type, quality and construction details ef items In

volved,

0

“This contractor shall furnish and install the nec

essary conduits and wiring between the metalclad

switchgear and the meter house as required by the

(utility) Company, also the ground rods and under~

ground cable system for equipment ground of the

outdoor metalclad switehgear and grounding of metal

fence around switchgear,

Tn an installation of this type, primary service

entrance can be considered to terminate at the out

door switchgear. From there on out, it is a primary

distribution system to the various unit substations

within the plant or building. Specifications for such

feeders can be added here, as included in the section

on Wire and Cable

Secondary service

“Power for distribution within the building will

be available from the secondary side of transformers

supplied by the (utility) Company. This service shall

be... amp, ... phase, ... wire, .../... volts, 60-

cycle, alternating current for normal power and light-

ing requirements. General arrangement of the trans-

former vault, switchgear room and connecting main

is shown on Drawing No. .... Conductor sizes and

enclosures shall be as noted on this drawing.

“The electrical contractor shall (furnish and) In-

stall all equipment items and connections to the see-

ondary side of the transformers and make all wiring

connections to the current transformers and tie

Dusses as shown. This contractor shall furnish and

install the tie busses, limiting lugs, terminals, ete.,

to make 2 complete connection in each ease. Bus

shall be (size), (type) conductor as noted on plans.

Terminals for secondary connections at the trans-

formers shall be supported independently trom the

transformers so that any transformer may be easily

removed.”

EQUIPMENT DETAILS

Service equipment may be listed and installed sepa-

rately or in combination with switching centers, dis

tribution switchgear, ete. Clearly indicate on the

rlans and in the specifications which type is intended

‘and include pertinent descriptive information,

State whether disconnect moans (main and branch)

are to be: circuit breakers (air or oil, mamually or

electrically operated, automatically tripped) ; inter-

mupter switches and fuses (high voltage) ; or switches

and fuses. Note ratings, characteristics, terminal

connection methods and construction details (where

necessary).

Primary equipment

a. Interrupter switches.

b. Cireuit breakers.

Indicate manufactarer’s name, type number or

other identifying designation; number of poles, volts,

amperes, interrupting capacity and type of operation

(manual) (automatic). Specify type and style of

enclosure (indoor or outdoor) and type of conduit

or cable entrance and exit fittings; pertinent data on

enclosed equipment,

‘A typical specification for

might read as follows:

“The electrical contractor shall furnish and install

interrupter switch

Tonsh see

eutrat

SPECIFICATION CLAUSE covering grounding of service equip

tment should call for grounding in accordance with the Ne

Code, local inspection cuthorties and the serving utlity com:

& Spole, 2-position Copen-close), sroup-operated,

fased air-interrapter switeh rated... amps with an

interrupting rating of ... amps at... kv. Switch

shall be Type ... as manufactured by Com

Pany, or approved equal; shall be mounted in a sui

able metal enclosure equipped with an interlock to

Permit access to fuses only when switch is in open

Position.

“Power fuses shail have an interrupting rating of

. amps rms, ... kva symmetrical at... volts

shall be Type ....as manufactured by ...... Com.

any, or approved equal.’

Secondary equipment

“A. Fused switch: The electrical contractor shall

furnish and install where shown on the plans @ ...

amp, ... volt, ... pole (solid neutral) fased switch

in a NEMA Type ... enclosure as a serviee entrance

disconnect. Switch shall he UL listed as suitable for

use as service equipment,

“Switch shall be of the positive-sction, quick-make,

guick-break type with interlocking cover that pre.

vents opening door when external handle is in “on”

Position. Switch shall be ...... Company, Type ...,

Catalog No. ..., or approved equal.”

In the 1200-amp to 6000-amp range, up to 600 volts,

ony. General errangement should be presented on © plan

Such 5 shown; connection methods ere shown on separate

drowns.

bolted pressure-contact switches are available as ser-

vice-entrance equipment. ‘They are used with high-

capacity current-limiting or noncurrent limiting

fuses (as required). When the design incorporates

equipment of this type, follow the above specification

Procedure noting: make, type, electrical rating, enclo-

sure (ventilated) ; also ‘make, type, rating and num.

ber of high-capacity fuses.

“B. Cireuit breaker disconnect: The electrical con-

tractor shall furnish and install where indicated on

the plans a... amp, ... volt, ... pole eireuit breaker

in a NEMA Type ... enclosure. Breaker shall be

manually operated, ttip-free and desigtied so that all

poles open simultaneously. Tripping mechanisms shall

be (thermally, magnetically) operated; shall open

instantaneously on short circuits and have time delay

on overloads; shall have effective sealing against tam

ering. Breaker shall be Type ..., Catalog No,

as manufactured by the ‘Company, or ‘sp

proved equal.””

Coordinated combinations of circuit breakers and

current-limiting fuses are available for use as high-

capacity secondary service equipment where fault

currents beyond the interrupting ratings of the

breakers will be encountered. The fuses interrupt the

high fautt currents and protect the breakers. Specifi-

“PROOF” TESTING of service ond distribution conductors is

becoming © common requirement on electrical construction

cation of this type of equipment should follow that

of conventions circuit breakers with attention di-

ected to specific characteristics of the selected fuses:

Recommendations of fuse manufacturers should be

closely followed when selecting and specifying fuses

for this type of application,

Where service-entrance disconnecting means is to

consist of two to six switches (circuit breakers) in

@ common enclosure, as permitted by Section 230-

70 (g) of the NE Code, clearly indicate this on the

plans and in the specifications. Indicate the voltage,

ampere rating and number of poles of each discon-

nect, fuse or overcurrent protection size, number and

size of main busbars and type of enclosure. If assem:

bly is standard catalog item, give manufacturer's

name and catalog designation, or approved equal; if

special assembly, show detailed drawings.

Circuit, protection

List the overcurrent and interrupting capacity rat-

ing for each disconnecting means,

A typical specification clause for a ofreuit breaker

might read

“The main circuit breaker shall be Com-

Pany, model (or type) ..., or approved equal,

Breaker shall be rated ... amps at ... volts ae, with

trip adjustable from... amps to... amps at

volts; shall have an interrupting rating of ... rms

amps at ... volts, Branch-circuit protective devices

shall be rated 2s shown on the (plans) (schedule).”

MULTIPLE SERVICES

‘When the system design calls for more than one

service entrance, specify and list each separately.

This may cover’ separate services for fire pumps,

2

projects. Specifications should define type of tests to be

‘mode, by whom and under whose supervision,

emergency lighting, different voltages, varied occu-

pancies and similar items.

Auxiliary services

Specify any suxiliary services required by the

system design—such as batteries, motor-generator

emergency sets, other voltages or frequencies, direct

current, and similar “special use" systems, Any “spe-

cial use” aystems should be clearly described and

specified.

‘Typical specifieation clauses for emergency standby

power sources appear in a later section on Standby

Power Facilities

CONDUCTORS

Include instructions and specification clauses relat-

ing to the number, size, voltage rating, type of insu

iation of all conductors and cables involved. Where

considered necessary, construction characteristics of

specific eables can be added. Specification clauses may

be included in the Serviee-ntrance Equipment sec-

tion, or separately in the Wire and Cable section of

the electrical specifications.

Cables

Where cables are to be of a special type (other

than the common building types listed in the NE

Code) or for use on high-voltage systems, definitive

clauses describing such cables should be included in

the specifications. Example:

“All cable for the ...-kv system shall be ... MCM,

-ky, single-conductor, shielded, with coated copper

cemduetors, butyl base insulation and neoprene base

jcket, Cable shall be (manufacturer), (trade name),

Specification No. ..., or approved equal, All such

cable shall be in accordance with, and conform to

the latest requirements of the Insulated Power Cable

Engineers Association.’

Fireproofing

“The electrical contractor ehall fireproof all high-

voltage cables, including splices, exposed in manholes

and cable closets. Fireproofing’ shall consist of two

wrappings of (manufacturer) (trade name) arc and

fireproofing tape No. ..., or approved equal. Tape

shall be ... in. wide. The first wrap shall be wourd

half-lapped, and installed with fabric side out. ‘The

Second wrap shall te installed slick side out, and

Wound butt-lapped. The fireproofing shall be hound

with Mone! wire at the ends of the tape and

‘at 24in, intervals along its entire length.

“All ducts from manhole to building shall be sealed

at the manhole end with (manufacturer) (trade

name) sealing compound.”

Color coding 5

‘Specifications should define the extent and method

of color coding of cireuit and phase conductors and

the proposed method of fdentification at terminal

points. Some engineers use a table to indicate colors

to be used for specific phases and voltages.

If conduits, raceways, or enclosures are to be

painted distinctive colors for identifying eystems, or

voltages, this item should be included in the specifi-

ions. If the electrical contractor is to be respon.

sible for such painting, the specification should clearly

state this,

Connections ’

Be specific about method of making conductor and

. One transformer section with a ... kva,

phase, 60-cycle, ... volt delta, .../... voit wye, air-

cooled type, natural draft, ...°C rise, with four

% full capacity taps (two above and two below

normal primary voltage), necessary insulated ... ky

bus, bare 600-volt bus and ground bus complete with

connections and support. Forced air-cooling equip-

ment facilities shall be provided to obtain ...9%

greater capacity. This equipment shall be automat

ically controlled from winding temperature devices.

“e. One main breaker section with stationary and

removable elements, primary diseonnecting devices

and mechanical interlocks eomplete with one main air

circuit breaker of proper capacity for substation

rating, and tie air circuit breaker of proper rating

for transfer of ... % of substation rating, each draw-

QUICK-REFERENCE CHECKLIST

1D Circuit and equipment characteristics

voltage

—phase

ampere toad

— interrupting capacity

1 Service-entrance equipment

Primary

circuit breakers

interrupter switches

Secondary

circuit breakers

—used switches

—bolted prossure-contact switches

combination circuit breakers and fuses

Ci Primary distribution center

interrupter switches, number and size

circuit breakers, number and size

—type of equipment enclosure

—associated wiring and connections

1 Unit substation

—primary and secondary disconnect

transformer type and rating

low-voltage section

number, type and size of units

substation construction

type and arrangement of enclosure

instrumentation

—bus and connection data

circuit te and interlocking

2 Controt center or switchboard

5 main disconnect

—type, size

branch-circut units

—number, type and size

construction

—type and arrangement of enclosure

‘—bus end connection data

—metering or instrumentation details, if any

Cl Paneltoards—power and lighting

size and arrangement of main bus

—number of branch-circuis devices

circuit breakers

—fuse and switch assembly

—size and number of poles of each

‘enclosing cabinet and trim, doors and locks

flush —aurface

1D High-frequency lighting panels—need for

detailed specification clauses

D Fuses

—size and type

—one time

—renewabie

—time delay

dual element

high interrupting capacity

high -current limitation

—number of spares

Other items dictated by specific project

WHEN WRITING specificotions for low-voltage svitehgeor,

such os shown above, consider special feotures that boost

performance and reliability. These include such items os eur

Fentlimiting circuit breckers, high-interrupting ‘capacity,

Shunt or undervoltage teps, remote operation and. ground:

feult protection,

SPLIT.BUS MAIN distribution panel how system design con-

cept for all-electric office structure ‘medemizotion.- Lower

fection. serves through-the-wall heating/cooling venting

nits. Subdistrbution ponels‘alzo ore spit-bur oeign. Clear,

contise ponelspecifcctons ore @ mut.

18

cout type, triple pole, single throw, electrically oper-

ated, rated 600 volts, ... rms amp interrupting

capacity respectively with three time-overeurrent and

instantaneous trip coils.

“One ammeter, one voltmeter, transfer switches,

potential and current transformers,

“iq, Two feeder-breaker sections with stationary

and removable elements, primary disconnecting de-

vices and mechanical interlocks complete with six (6)

air circuit breakers, draw-out type, triple pole, single

throw, manually operated, rated. amps, 600 volts

rms «mp interrupting eapacity with three time

overcurrent and instantaneous short-cireuit trip coils

land two spaces for future breakers

‘Substations shall be arranged in pairs and

equipped with secondary-selective devices to operate

as follows: Upon loss of bus voltage on one substa

tion, its main breaker shall open and its tie breaker

and the breaker of the second substation shail close

‘automatically, When bus voltage is restored, the main

breaker shall be closed manually, thereby opening

both tie breakers.”

CONTROL CENTERS

“The electrical contractor shall furnish and install

‘8 centralized control center of the self-supporting,

totally enclosed metal (steel, aluminum) type con:

sisting of standard modular dimension units as noted

on the plans.

“The complete control center shall contain main

disconnect, branch-cireuit breaker and combination

line starters, and cizeuit-breaker disconnects of size

and type and voltage noted on the drawings. Where

required, startstop and reset buttons shall be pro-

vided in'the cover of each motor starter section,

“Interior wiring shall be NEMA Class ..., Type

= (Class I, Type A, B, C) (Class TI, Type B)

(Class TIT, Type 0).

“Control center shall be furnished complete with

necessary pullboxes, wiring gutters, assembled cop-

per (or aluminum) bus connections, terminal blocks

and all additionally required control features

“All motor starters and branch-cireuit breakers

shall be (front, back-to-back) mounted and shall be

easily accessible for maintenance, repair or replace-

ment.

“Control centers shall be as manufactured by the

Company, or approved equal.”

‘Note that the above paragraphs refer to the plans

for specifie ratings of control devices, possibly in

detailed drawing or schedule. A more detailed speci-

feation could inelude this pertinent information as

well as more detailed data on physical size and con-

struction . 7

SWITCHBOARDS

‘The following prototype specification clauses can

be adapted, expanded or used as a guide to the devel-

opment of definitive switehboard specification. The

amount of detail included depends upon the sophis-

tieation of the desired equipment and is the pre~

rogative of the engineer.

“Furnish and install a dead-front type, completely

‘metal enclosed, self-supporting secondary power

switchboard consisting of (number) panels, or eu-

Dicles, containing circuit breakers (fusible switch

assemblies) of the number, rating and type noted

herein or shown on the drawings,

“a. Circuit breakers shall be (stationary-mounted)

(molded-case) (draw-out) type of capacities and

number of poles indicated,

“b. Fusible switch assemblies ... pole (or as

noted), quick-make, quick-break type mounted ina

‘metal enclosure with an externally operated handle

Which can be locked in “on” or “off” position. Urits

shall be of sizes listed and shall be removable from

the front of the board without disturbing adjacent

units or the swilchboard bus structure,

“c. Current-limiting circuit breakers shall combine

time-delay thermal-trip, instantaneous magnetic-trip,

and fault-current limiting protection in one complete

assembly. Units shall have ampere ratings as shown

and an interrupting rating of .. rms amps at

volts. Current-limiting fuses (protectors) shall be

‘mounted in a special housing with safoty-cover se-

cess from the front of the board i

“Switchboard main bus and connections to switeh-

ing devices shall be of (eopper) (aluminum) of suff

cient size to limit rated continuous current operating.

temperature rise to 80°C (50°C for cireuit-breaker

branches). All main bus and tap connections shell

be silver surfaced and tightly bolted for maximum

conductivity. Switchboard bus shall be braced for

short-circuit, stresses up to... rms amps (asym-

metrical)

“Switchboard shail be factory assembled, wired

and tested before delivery, and shall conform to UL

and NE Code standards, Individual-units. (eubieles)

shall be designed for bolting together at installation

PANELBOARD SPECIFICATIONS describe detcils such os

istrbution pane! (let ond type of overcurrent grote

site and shall be bonderized and painted in standard

finish as provided by manufacturer.

“Switchboard shall be as manufactured by

Company, or approved equal.”

PANELBOARDS

Power distribution

“Where shown on the plans, indicated in the riser

diagram, and listed in the panelboard schedule, fur

nish and install distribution and power panels of the

types and sizes noted. Panels shall be installed with

top of cabinet . . . ft, . .. in, above floor level

“a. Panelboards shall be of the combination switch

and fuse type with dead-front safety construction

incorporating (hinged-eover swing out; pull-out

Guick-make, quick-break, safety-interlocked, exter.

nally operable handle) branch-circuit units,

“Panel bus structure shall be for... vott,

Phase, . .. wire service and of sufficient capacity to

feed the (number) . . . pole, .. . wire branch-cireuit

units indicated. Mains shall be equipped with solder

less lugs. Branch-cireuit units shall be of sizes indi

cated,

‘Panelboard assembly shall be enclosed in a code-

gauge stee] cabinet with flush (surface type) trim

and ample wiring gutters on top, sides and bottom,

Cabinet doors shall be equipped ‘with spring (bar)

latohes (indicate whether locks are required and if

all shall be keyed alike and how many Keys are to be

Furnished).

‘Panelboards shall be Type .. . as manufactured

by the Company, or approved equal

rangement of split-bus power

in lighting. onal (eight

one es

asco

pti

masons pe ee

fst ere 9b

| Hs

US Te i or intg:

Inge St, Ego 00

et Es seston 20.

he, Tee an bear Ups

USS epic ser

Tg emp. Teste Tae pe

Sts ae 18. tr me ag

sie ely os tras o>

ne tle eo ey on

oe

ae

Sanda er hes re"

0, Reis ysl 496

Se sp tet Instn bt ay

IM be sled pr Cale Stan

‘Ho2ab. Tne ay ne 1 sete

24 00% of ating teal. Css

ated ne

= TSED an Uf ge “Prd

= Sindee ade

fies 1/1/8 eat"

Si ny Ci eae ce

‘eb

U5 060 an aes Carat

‘ie or KOON 0 sy

slr net ie fe

iy iret cogae wh

thr tec

27

CLASSIFICATION CHART of modern cortrdge fuses elds final selection end specification,

%, Distribution panelbosrda shall be of the dead:

front safety type equipped with thermal-magnetic

cireuit-breaker branches of sizes and types noted on

the drawings or indieated in the panelboard schedule.

Breakers shall provide instantaneous trip on short

circuits and éime-delay trip on overloads.

‘Panel bus structure shall be for .... volt, ...-

phase, .... wire service and of sufficient capacity to

feed the number of branch-eireuit breakers indicated.

Main busbars shall be equipped with solderless lugs.

“Panelboard assembly shall be enclosed in a code-

gauge steel cabinet with flush (surface type) trim

and ample wiring gutters on top, sides and bottom.

Cabinet doors shall be equipped with spring (bar)

latches (indicate whether locks are required and if all

shall be keyed alike and how many keys are to be

furnished with each panel)

“Panelboards shall be Type .

by the ...... Company, or approved equal.

= as manufactured

Lighting distribution

“All lighting branch-circuit panelboards shall be of

the (switch and fuse, eircuit-breaker) type of sizes

listed in the panelboard schedule or noted on the

drawings. Panels shall have mains only with solder-

Jess lugs on the main busbars and shall be arranged

for service on a .... volt, .... phase, .... wire

system.

“a, Branches shall have approved molded-block sin-

sle-pole snap-switch units with (Type S) plug fuse-

holders.

20

‘. Branches shall have aingle-pole, thermal-mag-

netic (noninterchangeahle) cireuit breakers of sizes

noted.

‘Cabinets for lighting panelboards shall be of code-

gauge steel with ample wiring gutters for all wires

‘and connections. Doors shall be the single type (unless

otherwise noted) with spring latches (note if locks

are required, if they should be keyed alike, and how

many Keys should be furnished for each panel). Panel

trim shall be furnished for flush (surface) mounting

as noted.

“Panelboards shall be Type .... as manufactured

by ..--., Company, or approved equal.”

When lighting panelboards are to be of the narrow,

single-row construction, so indieate on the plans and

in the specifications. Include the necessary pullbox

containing the neutral bar and required wiring duet

te connect column panel with pullbox above.

High-frequency lighting panels

Lighting distribution panels for high-frequency

lighting systems differ from conventional panels and

must be tailored to the specific type of system in-

stalled. Circuiting from the frequency converters have

definite bearing on panel arrangement. Until electri-

cal components for new distribution concepts, such as

this, become standard catalog items, it is advisable

to be more detailed and explanatory in specificatfon

clauses and to provide detailed drawings of compo-

nents.

‘A specification clause for a single high-frequency

lighting panelboard for a two-converter system might

read 8 follows:

“Furnish and install a (manufacturer's name) or

approved equal, two-section, .... circuit panelboard

for the .... cycle, .... volt lighting systam whsre

indicated on the plans. Panel shall be rated .... volts

line to ground, and .... cycles.

“The top section of the panel shall contain (num-

ber) .... amp, 2-pole, .... volts cireuit breakers w th

bus connections arranged so that each phase of the

S-phase, 6-wire, .... eyele feeder from one converter

feeds .... branch-cireuit breakers. Converter can,

ductors shall be connected to a terminal block at the

top of the panel,

{The bottom section of the panel shall be a dupli-

cate of the top section with terminal block at. the

bottom to receive conductors from the other con

verter.

“CA steel barrier shall separate the 2-panel sections,

‘Bach 2-pole branch-circuit breaker shall contro)

(number) high-frequency lighting fixtures as shown

on the plans,

“Panel shall be of the dtad-front, safety type with

& code-gauge shect metal eabinet and hinged door

with spring Isteh and lock.”

277-volt fuse panels

he development and availability of a line of 300-

volt (UL Type G) small dimension cartridge fuses

and recognition of same in Seetion 240-23(a) of the

1968 NE Code may lead to the development of prac.

Heal fuse-switeh panelbdards for 277-volt lighting

distribution systems. :

‘The following is a typical guide-form speciGeation

for this type of panel.

“Distribution panelboards for the 277-vlt lighting

avetem shall be of sizes (maina, number and size of

branch cireuits) noted on the plans or in the panel

board schedule, Panels shall contain fusible branch

switches that accept the smal! dimension, 300-volt

Type ... cartridge fuses, Switches shall be toggle

type, quick-make, quick-break with visual indication

ie Ena. WW 225 re

emg fos. nay SODA a

foe 4

Te emergency

‘gn pe

LOADCENTER substation drawing illustrates coordinated, unit-

Peckoge assembly of primary disconnect, transformer “ord

of a blown fuse for each pole. Switch mechanism and

fuse carriers shall have interlocking feature to pre-

‘ent fuse removal when switch is in the ‘on’ position,

Fuse carriers and bases shall have fuse-size limiting

feature to prevent over-fusing. Panelboards shall be

enclosed in a code-gauge galvanized steel cabinet with

minimum .... in. end gutters and .... in, side gut-

ters. Cabinet fronts are to be (flush) (surface) type

complete with door and flush chrome-plated pin-type

eylinder lock and catch and directory frames. Panel.

boards shall be UL listed; shall be ...,.. Company,

Type ... oF approved equal.”

FUSES

As utility generating and distribution capacity in-

creases, 30 does the magnitude of fault currents avail

able at electrical system service points. Thus, in addi

tion to voltage, current rating and speed of response,

interrupting eapacity becomes a major consideration

in the selection and specification of fuses,

Where coordination with other fuse protective de-

vices and circuit breakers is required, investigate and

follow manufacturers’ (fuse and breaker)” recom-

‘mendations,

There is a wide range of fuses available with a

wide variety of protection characteristics. Hence it

is important that the electrical specifications clearly

indicate the specific type of fuse to be installed at

specific protection points. Otherwise, the incorrect

type of fuse may be ordered and applied with disrup-

tive and costly consequences,

One or more specification paragraphs or clauses

‘may be necessary to cover the complete fuse list, Each

should clearly indicate the type and pertinent char.

scleristics of the desired fuse. To avoid confusion and

misunderstanding, it is common practice to identify

items by listing one or more manufacturer's name,

trade name, type designation, ete,

‘Typical fuse specification ‘clauses might read as

follows.

208V/120 volte

_-—— lighting Gnd pone feeders

56,270 Shy naspeneaceled abe Tooley ToS

Secondary distribution system concept. Specifications provide

detalls cn component eatipment,

a1

Plug fuses

“Plog fuses shall be dual-clement, time-delay, Type

S of eapacities noted on the (plans) (switchboard,

panel, feeder schedules, etc.). Fuses shall be (trade

name) as manufactured by ...... Company, or ap-

proved equal.”

Cartridge fuses

“A—General

Cartridge fuses shall be ... volt (one-time) (re-

newable) of ampere ratings noted, Fuses shall be

(trade name) as manufactured by Company,

or approved equal.

“

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1591861190-ABB New+generation+ATS+solutionsDocument29 pages1591861190-ABB New+generation+ATS+solutionsFernandoCrespoMonNo ratings yet

- Nbd18a MVCDocument75 pagesNbd18a MVCFernandoCrespoMonNo ratings yet

- Scanned From Padre Xerox Multifunction PrinterDocument3 pagesScanned From Padre Xerox Multifunction PrinterFernandoCrespoMonNo ratings yet

- AISIKAI-SKT Series Automatic Transfer Switch Catalogue2022V1.0Document17 pagesAISIKAI-SKT Series Automatic Transfer Switch Catalogue2022V1.0FernandoCrespoMonNo ratings yet

- 4 Types of Motor Enclosures TMEIC - Reprint - 0621Document3 pages4 Types of Motor Enclosures TMEIC - Reprint - 0621FernandoCrespoMonNo ratings yet

- Led / CFL / Incandescent Slide Dimmer: Installation InstructionsDocument2 pagesLed / CFL / Incandescent Slide Dimmer: Installation InstructionsFernandoCrespoMonNo ratings yet

- Layers of Protection AnalysisDocument8 pagesLayers of Protection AnalysisFernandoCrespoMonNo ratings yet

- Approved, Listed, and Field Evaluated - Requirements For Low Voltage Electrical Equipment Used For Power Distribution and Motor ControlDocument7 pagesApproved, Listed, and Field Evaluated - Requirements For Low Voltage Electrical Equipment Used For Power Distribution and Motor ControlFernandoCrespoMonNo ratings yet

- DOE - Motor - and - Drive - Assessment - Leads - To - Energy - Savings - For - Power - Drive - SystemsDocument8 pagesDOE - Motor - and - Drive - Assessment - Leads - To - Energy - Savings - For - Power - Drive - SystemsFernandoCrespoMonNo ratings yet

- Iec 60243-1-2013Document58 pagesIec 60243-1-2013FernandoCrespoMon100% (1)

- Operator's Manual: Nirvana Cycling Refrigerated DryerDocument50 pagesOperator's Manual: Nirvana Cycling Refrigerated DryerFernandoCrespoMonNo ratings yet

- C Form 02Document72 pagesC Form 02FernandoCrespoMonNo ratings yet

- Ice 2005Document62 pagesIce 2005FernandoCrespoMonNo ratings yet

- GFCI Fact SheetDocument3 pagesGFCI Fact SheetFernandoCrespoMonNo ratings yet

- Notice 1 PageDocument2 pagesNotice 1 PageFernandoCrespoMonNo ratings yet

- Methods of Proving Triangle Congruent - MathBitsNotebook (Geo - CCSS Math)Document4 pagesMethods of Proving Triangle Congruent - MathBitsNotebook (Geo - CCSS Math)FernandoCrespoMonNo ratings yet

- Taking Medium-Voltage Motor Control Centers To New Levels of SafetyDocument10 pagesTaking Medium-Voltage Motor Control Centers To New Levels of SafetyFernandoCrespoMonNo ratings yet

- CCM - Modelo 6 - Arc - ResistantDocument5 pagesCCM - Modelo 6 - Arc - ResistantFernandoCrespoMonNo ratings yet

- Lighting Handbook INDALUX 2002 - Vebuka PDFDocument263 pagesLighting Handbook INDALUX 2002 - Vebuka PDFFernandoCrespoMonNo ratings yet

- 051109556894Document16 pages051109556894FernandoCrespoMonNo ratings yet

- GFCI Outlets and How They Keep You Safe - Raleigh Electricians Blog PDFDocument4 pagesGFCI Outlets and How They Keep You Safe - Raleigh Electricians Blog PDFFernandoCrespoMonNo ratings yet

- Dexson DXN25000Document1 pageDexson DXN25000FernandoCrespoMonNo ratings yet

- Opcion Sistema Automatizado Pesaje de CamionesDocument1 pageOpcion Sistema Automatizado Pesaje de CamionesFernandoCrespoMonNo ratings yet

- Challenges and Solutions of Protecting Variable Speed Drive MotorsDocument7 pagesChallenges and Solutions of Protecting Variable Speed Drive MotorsFernandoCrespoMonNo ratings yet

- Conexion de Un Sensor PNP-NPN A Un PLCDocument4 pagesConexion de Un Sensor PNP-NPN A Un PLCFernandoCrespoMonNo ratings yet

- SR-SB1029-5C InstructionDocument2 pagesSR-SB1029-5C InstructionFernandoCrespoMonNo ratings yet

- Digital - Transformation - of - Protection - and - Control - in - Industrial - Power - SystemsDocument2 pagesDigital - Transformation - of - Protection - and - Control - in - Industrial - Power - SystemsFernandoCrespoMonNo ratings yet

- Spear - Long Range 1080p 2MP 60 FPS License Plate Recognition (LPR) CameraDocument4 pagesSpear - Long Range 1080p 2MP 60 FPS License Plate Recognition (LPR) CameraFernandoCrespoMonNo ratings yet

- DM 6XXX Register MapDocument5 pagesDM 6XXX Register MapFernandoCrespoMonNo ratings yet

- SRP-2305-50CCT Instruction V1Document2 pagesSRP-2305-50CCT Instruction V1FernandoCrespoMonNo ratings yet