Professional Documents

Culture Documents

Flange Facing

Uploaded by

Chiller PartyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Facing

Uploaded by

Chiller PartyCopyright:

Available Formats

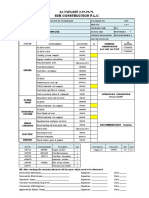

VICTORY LUMINAIRES WORKS 2

OPERATOR JOB CARD

(IN PROCESS INSPECTION REPORT / PRODUCTION REPORT / PREVENTIVE & PREDICTIVE MAINTENANCE CHECKSHEET / TOOL LIFE RECORD)

PART DESCRIPTION :- Filter head PART NO. 000016210P04 OPERATION FLANGE FACING

NO.

M/C NUMBER M/C NAME DATE :- Shift

Time From Time To OPERATOR NAME DIE CODE

Measuring

FOC READING IN PROCESS INSPECTION

Dimension Sign After 4 After 8 After 12

PARAMETER DESCRIPTION Inst to be TIME - Sign - Sign - Sign -

& Tolerance Hours Hours Hours

used

1 2 3 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

TOTAL THICKNES OF FILTER FACE 18.0±0.3 HEIGHT GAUGE

SURFACE FINISH 3.2 Ra comparator

PRODUCED QUANTITY REWORKED QUANTITY REJECTED QUANTITY

Machine Idle Time records Preventive & Predictive Maintenance Check points

Idle Cleaning (Chips Oiling - Air Filter & Checking Checking Over Drying of

N1 N2 N3 N4 N5 N6 N7 N8 N9

Removal from moving Spindle Checking

Code Tightness of sensing (Freq - Cooling of level of Excess heating of Electric tool clamp

parts, sensors, tool coolant & Taper of oil & air vibrations motor or

Idle Machine No dog of pallet change D)& fans sparking - / declamp

No No Fixture Inprocess Any Other magazine, pallet cleaning - leakage - of moving

Descriptio No Power Tool Setting Breakdow Requireme cycle - (Freq - D) Greasing - Cleaning - lubrication sliding (Freq - D) device -

Material Operator Setting Inspection Reason changing zone) - (Freq oil - (Freq (Freq - D) (Freq - D) parts - parts -

n n nt (Freq - W) (Freq - W) (Freq - W)

4 Hrs) - D) (Freq - D) (Freq - D)

TIME (in

minutes)

Job Set up Inspection Report (For nos. of equipments i.e. fixture no, tool no., etc, please refer control plan displayed at shop floor) Preventive & Predictive Maintenance Check

Fixture Tightness

Availability Value on Check as

Fixture locating Dirty oil in of nut

PARAMETER Fixture Clamp Hydraulic Fixture Fixture Working of of all tools Tool life Tool Tool offset extension Program per SOP

Fixture No. resting point pins / Tool No. oil tank - bolts or

DESCRIPTION condition

condition

blocks

pressure calibration offset pokayoke as per qty condition value (must be No. no. 11 -

(Freq - W) missing -

program zero) (Freq - D)

condition (Freq - D)

Ok (a) / Not ok (x)

Remark

Availability Availability Availability Checked By : Approved By :

Control Inprocess Availability Gauge

PARAMETER Program Offset value of marker Availability of of Hydraulic

SOP display plan report of rej / condition

DESCRIPTION edit key on in program for of gauges measuring identificati oil leakage

display availability rew bin & due date

marking of instrument on plates

Ok (a) / Not ok (x)

Remark

Frequency Codes - D - Daily, W - Weekly, N/A - No Activity, T - for Filling of Lubrication Oil, O - Weekly Off, H - Holiday. Tool replaced - R. Tool Regrind - G, Tool indexed - I

Note :- FOC (First operation check) should be conducted in following cases -1) Start of machine 2) Power failure 3) Operator Changed 4) Tool changed / indexed / ground 5) Fixture setting 6) Program parameters setting

IIR No. - H2 Filter headQC/QF/02-04(20.12.2016)

You might also like

- Side FacingDocument1 pageSide FacingChiller PartyNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- C13 Service Manual - 1Document180 pagesC13 Service Manual - 1mes100% (1)

- DET ReviewDocument2 pagesDET ReviewBasanta RoyNo ratings yet

- Failure Analysis ReportDocument9 pagesFailure Analysis ReportOka WansyahNo ratings yet

- F2be0681a F3a F3beDocument478 pagesF2be0681a F3a F3bejvega_534120100% (2)

- Maintenance Prescription: Analysis Integrated With Accuracy and MeaningDocument1 pageMaintenance Prescription: Analysis Integrated With Accuracy and MeaningVic AnaboNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

- F2be0685a F3ae0687a B CDocument552 pagesF2be0685a F3ae0687a B Cjvega_534120100% (1)

- Alignment & LevellingDocument4 pagesAlignment & LevellingyuwantoniNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- 66 FM-TRD-05 Tool History CardDocument2 pages66 FM-TRD-05 Tool History CardUttrakhand Vibes- OriginalNo ratings yet

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- Cursor 10-13 RMDocument338 pagesCursor 10-13 RMAminadavNo ratings yet

- Control Plan H.TDocument1 pageControl Plan H.TABHISHEK PANDEYNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Control (Quality) PlanDocument1 pageControl (Quality) PlanRabia ZulqarnainNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- OPRAF01 Service Activity Report V2Document1 pageOPRAF01 Service Activity Report V2BollywoodRevival SongsNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- Pm-Clinic Service: SEPD308400Document5 pagesPm-Clinic Service: SEPD308400Naughty VongNo ratings yet

- 故障分析报告 30112022Document15 pages故障分析报告 30112022Jimmy ManagaraNo ratings yet

- NEF ENGINES E Ed 01 - 2005Document788 pagesNEF ENGINES E Ed 01 - 2005Teknik Makina100% (3)

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- Process Flow ChartDocument11 pagesProcess Flow Chartsudar1477No ratings yet

- PM Clinic Pc200-8m0Document10 pagesPM Clinic Pc200-8m0phengNo ratings yet

- Cat D8R-T2Document1 pageCat D8R-T2Awet TesafyNo ratings yet

- Lube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Document21 pagesLube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Muhammad AbyNo ratings yet

- HIGH PRESSURE PUMP A To D MOTORDocument1 pageHIGH PRESSURE PUMP A To D MOTORprayogo kpjbNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz Aydin100% (1)

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Iveco Nef Engines F4ae Thru F4he Wshop ManualDocument788 pagesIveco Nef Engines F4ae Thru F4he Wshop ManualDarrell Nickels100% (19)

- PM Clinic 450-8Document7 pagesPM Clinic 450-8Naughty VongNo ratings yet

- 201.28-Mr1 Rutina de MantencionDocument8 pages201.28-Mr1 Rutina de MantencionNestor Serey LeivaNo ratings yet

- Test Record Form Kosong SatDocument10 pagesTest Record Form Kosong SatRangga SetaNo ratings yet

- Nom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Document8 pagesNom de Technicien Signature Durée D'intervention: Ordinary Maintenance 100 H For Forklift Fantuzzi (FDC250)Peix HichamNo ratings yet

- Iveco - Daily 2000my - Repair ManualDocument1,654 pagesIveco - Daily 2000my - Repair Manualjuan100% (2)

- Iveco Daily 2000Document13 pagesIveco Daily 2000Alberto Piosa OlivaresNo ratings yet

- 1 Paut ReportDocument1 page1 Paut ReportAhmedNo ratings yet

- 故障分析报告 30112022 - compressedDocument15 pages故障分析报告 30112022 - compressedJimmy ManagaraNo ratings yet

- Actividad de DurezaDocument7 pagesActividad de DurezaMartin Fibela EsparzaNo ratings yet

- Repair Manual EUROFIRE PDFDocument1,520 pagesRepair Manual EUROFIRE PDFREMZONANo ratings yet

- Samson 373X 5Document8 pagesSamson 373X 5Arun KumarNo ratings yet

- PPM Checklist - Air Circuit Breaker (Acb)Document1 pagePPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaNo ratings yet

- Lampiran Form TestDocument3 pagesLampiran Form TestRangga SetaNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- Designer's Handbook Instrmtn/Contr CircuitsFrom EverandDesigner's Handbook Instrmtn/Contr CircuitsRating: 5 out of 5 stars5/5 (1)

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- RDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Document124 pagesRDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Chiller PartyNo ratings yet

- RCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Document8 pagesRCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Chiller PartyNo ratings yet

- Scorecard Mar 20Document3 pagesScorecard Mar 20Chiller PartyNo ratings yet

- Bosnax (Thailand) Co.,Ltd. ท บอสแนกซ (ประเทศไทย) จํ บริษั ากัดDocument24 pagesBosnax (Thailand) Co.,Ltd. ท บอสแนกซ (ประเทศไทย) จํ บริษั ากัดJesus SoberanesNo ratings yet

- MY Fire DampersDocument12 pagesMY Fire Dampersjames_chan2178No ratings yet

- Electricity Y3Document224 pagesElectricity Y3Ronaldo Paloma50% (6)

- Radial TCDocument3 pagesRadial TCArun SNo ratings yet

- González-Prieto2022 Article Finger-jointingOfGreenEucalyptDocument9 pagesGonzález-Prieto2022 Article Finger-jointingOfGreenEucalyptkulin_banNo ratings yet

- Fugato Full MetalDocument3 pagesFugato Full MetalDaniel KozoraNo ratings yet

- Poster ATExDocument1 pagePoster ATExmarius_brkt6284No ratings yet

- IFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic FlowmetersDocument44 pagesIFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic FlowmetersSalgado BonéNo ratings yet

- X210CR12 GradeDocument3 pagesX210CR12 GradekartsoftNo ratings yet

- TE Connectivity Raychem S01 03 R DatasheetDocument7 pagesTE Connectivity Raychem S01 03 R DatasheetРоман ДяченкоNo ratings yet

- Aurelia Ti 4030: Safety Data SheetDocument12 pagesAurelia Ti 4030: Safety Data SheetNibaldo KamelNo ratings yet

- Victaulic Zero-Flex Rigid Coupling Style 07: 1.0 Product DescriptionDocument5 pagesVictaulic Zero-Flex Rigid Coupling Style 07: 1.0 Product DescriptionWilfredo RamirezNo ratings yet

- Question and Answers For Introduction To TextilesDocument7 pagesQuestion and Answers For Introduction To TextilesProf Dr Md Saifur RahmanNo ratings yet

- Non-Clog Submersible Pump Non-Clog Submersible Pump DML DMLDocument6 pagesNon-Clog Submersible Pump Non-Clog Submersible Pump DML DMLAgus YohanesNo ratings yet

- AISC Seismic Design-ModuleUG-Brief OverviewDocument86 pagesAISC Seismic Design-ModuleUG-Brief OverviewDemçe Florjan100% (1)

- Cathodic Protection Systems Interim Technical GuideDocument10 pagesCathodic Protection Systems Interim Technical Guidemdc2013No ratings yet

- DS-K3H4410-120+Full+Height+Turnstile Datasheet V1.0 20200727Document4 pagesDS-K3H4410-120+Full+Height+Turnstile Datasheet V1.0 20200727mrangelNo ratings yet

- Esquema Hidráulico Trailla 631GDocument2 pagesEsquema Hidráulico Trailla 631GJose Carlos Annicchiarico BritoNo ratings yet

- EP Conveyor Belt Catalog PDFDocument104 pagesEP Conveyor Belt Catalog PDFKR123No ratings yet

- Module 3 B Solid Waste Management 4Document31 pagesModule 3 B Solid Waste Management 4PRAVIN GNo ratings yet

- Fashion For Functional NeedsDocument23 pagesFashion For Functional NeedsAnanta ChoureyNo ratings yet

- Futigue & CreepDocument20 pagesFutigue & CreepRamesh Jakkanagoudar100% (1)

- Info SorbitolDocument45 pagesInfo SorbitolSanti CarpNo ratings yet

- Flow Coeffi Cients: Catalog # 77-1006ADocument8 pagesFlow Coeffi Cients: Catalog # 77-1006AFelipe Gamboa GálvezNo ratings yet

- Chemicals Zetag DATA Powder Zetag 8125 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8125 - 0410PromagEnviro.comNo ratings yet

- SCA Kraftliner-Eng (PDF 700kB)Document3 pagesSCA Kraftliner-Eng (PDF 700kB)José António Cardoso RodriguesNo ratings yet

- Ishrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaDocument35 pagesIshrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaAnurag JoshiNo ratings yet

- Flexible Foam Buyers Guide.Document7 pagesFlexible Foam Buyers Guide.Yo GoldNo ratings yet

- Narrative ConcretingDocument3 pagesNarrative ConcretingJune Mark AwingNo ratings yet

- Pipe Sizing V2.3-ASPEDocument56 pagesPipe Sizing V2.3-ASPEAdnan AttishNo ratings yet