Professional Documents

Culture Documents

pdf2728312790859111167

Uploaded by

Jim WhitehouseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pdf2728312790859111167

Uploaded by

Jim WhitehouseCopyright:

Available Formats

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference. REV 16c

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com 63262

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2016 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in Read this material before using this product.

any shape or form without the express written consent of Harbor Freight Tools. Failure to do so can result in serious injury.

Diagrams within this manual may not be drawn proportionally. Due to continuing SAVE THIS MANUAL.

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

Specifications

Maximum Spring Diameter 5/8"

Maximum Compressible Spring Length 10"

Maximum Strut Spring Outside Diameter 6"

Page 2 For technical questions, please call 1-888-866-5797. Item 63262

IMPORTANT SAFETY INFORMATION

1. Use as a pair only. Tighten and release evenly and 10. Wear ANSI-approved safety goggles and heavy-

slowly. Only use hand tools to tighten/release. duty work gloves during setup and use.

2. Secure spring in place with 11. Don’t overreach. Keep proper footing

locking pins before use. and balance at all times.

3. Keep work area clean. Cluttered areas invite injuries. 12. Maintain tools with care. Keep tools clean for

better and safer performance. Follow instructions

4. Consider work area conditions. Don’t use for lubricating and changing accessories. Keep

in damp, wet, or poorly lit locations. Don’t handles dry, clean, and free from oil and grease.

expose to rain. Keep work area well lit.

13. Stay alert. Watch what you are doing, use common

5. This product is not a toy. Do not allow sense. Don’t operate any tool when you are tired.

children to play with or near this item.

14. Inspect before every use; do not use

6. Store idle equipment. When not in use, tools should if parts are loose or damaged.

be locked up in a dry location to inhibit rust.

15. Replacement parts and accessories. When

7. Don’t force the machine or tool. It will servicing, use only identical replacement

do the job better and more safely at the parts. Only use accessories intended for

rate for which it was intended. use with this tool. Approved accessories

are available from Harbor Freight Tools.

8. Use as intended only.

16. Do not use when tired or when under the

9. Dress properly. Don’t wear loose clothing or

influence of alcohol, drugs or medication.

jewelry. They can be caught in moving parts.

Protective gloves and non-skid footwear are 17. Maintain product labels and nameplates.

recommended when working. Wear restrictive These carry important safety information.

hair covering to contain long hair, preventing If unreadable or missing, contact

it from getting caught in machinery. Harbor Freight Tools for a replacement.

SAVE THESE INSTRUCTIONS.

Item 63262 For technical questions, please call 1-888-866-5797. Page 3

Operation

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Setup

For the purposes of this manual, it is assumed you will be removing a strut spring from a

MacPherson-style strut assembly which has been removed from the vehicle.

1. Place the strut assembly down on a 5. Adjust the Non-Threaded Puller Hook (2) to

workbench or other solid work surface. fit around the strut spring at the end opposite

from Step 4. Make sure the Strut Spring

2. Examine the strut spring inside the strut assembly. Compressor is parallel (straight up and down)

Identify areas at each end of the strut spring to attach with the strut assembly, as shown in Figure C.

the Puller Hooks of the Strut Spring Compressor.

There needs to be enough space between the coils Non-Threaded

for the Puller Hooks to fit between and still allow you Puller Hook

enough compression to collapse the spring enough

for safe removal. Ideally the Puller Hooks should Threaded

be placed towards the outer ends of the coil spring. Puller Hook

3. Adjust the head of the Screw (3) to move

the Threaded Puller Hook (1) to the end

of the Screw, as shown in Figure A.

Screw Head

Non-Threaded

Puller Hook

Strut Spring

Figure C

Threaded

Puller Hook 6. Tighten the head of the Screw until it

contacts the Non-Threaded Puller Hook.

Figure A

4. With the Locking Pins (4) in the unlocked

position, place the Threaded Puller Hook

around the strut spring at the spot you

identified in Step 2, as shown in Figure B.

Locking Pins

Threaded in unlocked

Puller Hook position

Figure B

Page 4 For technical questions, please call 1-888-866-5797. Item 63262

Locking Pin in Screw Non-Threaded

locked position Puller Hook

7. Push in the Locking Pins on both the Threaded and

Non-Threaded Puller Hooks until they snap into

locked position. Refer to Figure D and Figure E.

8. Repeat Steps 2 through 7 with the second

Strut Spring Compressor Assembly.

WARNING! Always use both Strut Spring

Compressors on the same spring,

at the same time.

Threaded

Puller Hook

Figure D

Removing The Strut Springs

1. Check the Locking Pins to ensure they are WARNING! To prevent serious injury or DEATH from

in the locked position. Refer to Figure E. the spring suddenly launching free:

Tighten the Screws EVENLY. Do not tighten

2. Rotate the strut assembly so the head one Strut Spring Compressor all at once.

of the Screw can be easily accessed on

each Strut Spring Compressor. 4. As the Screw on each Strut Spring Compressor is

tightened, the strut spring will begin to compress.

3. Begin to tighten the head of the Screw on one Strut When the strut spring has been compressed

Spring Compressor as shown in Figure E. Tighten enough to allow free play of the coil spring on

the Screw about one inch, then tighten the Screw of the strut assembly, you may remove the strut

the other Strut Spring Compressor an equal amount. bearing nut at the top of the strut assembly

and remove the strut bearing and top hat. The

Locking Pins compressed strut spring can now be removed.

Screw

in locked

position WARNING! To reduce the pressure on

the spring and maintain better stability,

only tighten as much as is necessary.

5. If the Strut Spring Compressors have been tightened

as far as possible and there is no free play of the

Screw coil spring on the strut assembly, DO NOT REMOVE

Head the strut bearing nut. Remove the Strut Spring

Compressors evenly and place the Puller Hooks

further apart on the coil spring in order to compress

more of the coil spring. Repeat Steps 2 through 4.

6. Do not store a compressed coil spring for ANY

length of time, even if you are immediately replacing

Screw the strut. Loosen the Screws on the Strut Spring

Figure E Compressors EVENLY to reduce pressure.

Item 63262 For technical questions, please call 1-888-866-5797. Page 5

Maintenance

Procedures not specifically explained in this manual must

be performed only by a qualified technician.

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal noise or vibration

occurs, have the problem corrected before further use.

Cleaning, Maintenance, and Lubrication

1. BEFORE EACH USE, inspect the Locking NOTE: Keep threads on Screws clean

Pins, Screws, and Puller Hooks on the and lubricated at all times with a premium

Strut Spring Compressors. Check for: quality, light weight machine oil.

• loose hardware 2. AFTER USE, wipe external surfaces

• misalignment or binding of moving parts of the tool with clean cloth.

• cracked or broken parts 3. When storing, keep the Strut Spring

• any other condition that may affect safe operation. Compressor Set in its Carrying Case.

Do not use if you find any

cracks or other damage.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS DOCUMENT AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 6 For technical questions, please call 1-888-866-5797. Item 63262

Parts List And Assembly Diagram

Part Description Qty Part Description Qty

1 Threaded Puller Hook 2 4 Locking Pin 4

2 Non-Threaded Puller Hook 2 5 Washer 2

3 Screw 2

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

Item 63262 For technical questions, please call 1-888-866-5797. Page 7

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for the

period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper

installation, normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages arising from the use of

our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • 1-888-866-5797

You might also like

- FűkaszaDocument91 pagesFűkaszaMájinka AndrásNo ratings yet

- PHCT400 DataDocument14 pagesPHCT400 DataGabriel AguerNo ratings yet

- Makita Ls1020 Users Manual 405647Document20 pagesMakita Ls1020 Users Manual 405647Martin HaryadiNo ratings yet

- SCM - 12-58-34Document20 pagesSCM - 12-58-34Wawan GuntoroNo ratings yet

- Ensunchadora AH-114 - SignodeDocument4 pagesEnsunchadora AH-114 - SignodeTanSoloUnMinutoNo ratings yet

- Receiving / Un-Crating: Before InstallationDocument2 pagesReceiving / Un-Crating: Before Installationphannhattuan0210No ratings yet

- Walk-behind-concrete-saw-Service ManualDocument20 pagesWalk-behind-concrete-saw-Service ManualNick KrugerNo ratings yet

- Owner's Manual & Safety InstructionsDocument8 pagesOwner's Manual & Safety InstructionsOver FlownNo ratings yet

- Gerlinger LC30 Torque-Hub Final Drive ServiceDocument16 pagesGerlinger LC30 Torque-Hub Final Drive ServiceRubenNo ratings yet

- Horizontal Band SawDocument17 pagesHorizontal Band SawOscar AdrianNo ratings yet

- Wheel BalancerDocument8 pagesWheel BalancerVang ThaoNo ratings yet

- HM0810TDocument32 pagesHM0810TIVOR COSTANo ratings yet

- Jit 1850aDocument16 pagesJit 1850anengahkubalNo ratings yet

- Sears Router Table 925479Document16 pagesSears Router Table 925479Vermontique0% (1)

- Mossberg 9200Document20 pagesMossberg 9200guillermo_guerrer_40No ratings yet

- pdf4183769570452062909Document8 pagespdf4183769570452062909Jim WhitehouseNo ratings yet

- CM01 UK Manual BDocument12 pagesCM01 UK Manual Bmichael.kennedyNo ratings yet

- 2-TON HIGH POSITION HOIST STAND OwnerManualDocument11 pages2-TON HIGH POSITION HOIST STAND OwnerManualluisNo ratings yet

- Stand Fan User ManualDocument11 pagesStand Fan User ManualDNo ratings yet

- Pfaff 130-6 Sewing Machine Instruction ManualDocument43 pagesPfaff 130-6 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- MANUAL GATA HIDRAULICA DAYTONA 3TONDocument12 pagesMANUAL GATA HIDRAULICA DAYTONA 3TONBruno PowerNo ratings yet

- Oil PressDocument16 pagesOil PressGele GelevNo ratings yet

- 7600-Manual-81-0246Document12 pages7600-Manual-81-0246jmarshall2428No ratings yet

- Longworth Chuck PDFDocument6 pagesLongworth Chuck PDFBen Gerez100% (2)

- Nova TL1500 Full ManualDocument19 pagesNova TL1500 Full ManualInform7105100% (1)

- Titan 15 HP Chipper Shredder Manual14Document20 pagesTitan 15 HP Chipper Shredder Manual14Peter JenkinsNo ratings yet

- Craftsman 12-Inch Bandsaw ManualDocument32 pagesCraftsman 12-Inch Bandsaw Manualottuser100% (1)

- Craftsman Dovetail Jig L0804094Document16 pagesCraftsman Dovetail Jig L0804094Frankcw1No ratings yet

- Owner'S Manual: BC2311LE BC2611LE/WE BC3501LE/WE BC4501WEDocument4 pagesOwner'S Manual: BC2311LE BC2611LE/WE BC3501LE/WE BC4501WEAlvaro AlveoNo ratings yet

- Interruptor de PresionruelcoDocument3 pagesInterruptor de PresionruelcoantonioNo ratings yet

- Model TB-16Document20 pagesModel TB-16xuanphuong2710No ratings yet

- Router instruction manual guideDocument48 pagesRouter instruction manual guideJonathanPobletePerezNo ratings yet

- CS510e03 060701Document28 pagesCS510e03 060701Bojan PenoNo ratings yet

- Kenmore 385.15202 Sewing Machine Instruction ManualDocument65 pagesKenmore 385.15202 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Do's and DONT'sDocument2 pagesDo's and DONT'sAkkiNo ratings yet

- 545 RXDocument66 pages545 RXJosipJosipNo ratings yet

- Owners Manual Template for Craftsman RoutersDocument16 pagesOwners Manual Template for Craftsman RoutersEvan MosemanNo ratings yet

- Miter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NDocument24 pagesMiter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NjariouNo ratings yet

- Cut-Off Machine Model CC 14SE: Handling InstructionsDocument8 pagesCut-Off Machine Model CC 14SE: Handling InstructionsseyfiNo ratings yet

- TCS6200说明书 2Document45 pagesTCS6200说明书 2aidaNo ratings yet

- Floor Press: 10 Tonne HydraulicDocument12 pagesFloor Press: 10 Tonne HydraulicjnkchaNo ratings yet

- Wildcat ManualDocument16 pagesWildcat ManualGh05t3dNo ratings yet

- Mini Cement Mixer 1.25 Cu - Ft. Model 91907 PDFDocument13 pagesMini Cement Mixer 1.25 Cu - Ft. Model 91907 PDFAKA "Tomás de Torquemada"No ratings yet

- Sears Craftsman 10-Inch Band Saw Owner's ManualDocument20 pagesSears Craftsman 10-Inch Band Saw Owner's ManualDean Antalik67% (3)

- Astra RetrivalDocument20 pagesAstra RetrivalstercostasNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- White 2335 Sewing Machine Instruction ManualDocument38 pagesWhite 2335 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- A0312624 - en - PLM Manual Roller Assembly For Compact Pellet Mill V05Document28 pagesA0312624 - en - PLM Manual Roller Assembly For Compact Pellet Mill V05jose100% (1)

- Brother Sewing Machine InstructionsDocument56 pagesBrother Sewing Machine InstructionsDwaine Webb100% (1)

- US General (Harbor Freight) 64432 Roller Cabinet User ManualDocument8 pagesUS General (Harbor Freight) 64432 Roller Cabinet User ManualRick McGuireNo ratings yet

- Dayton Arbor Presses Owners ManualDocument8 pagesDayton Arbor Presses Owners ManualBryan AceroNo ratings yet

- Instruction Manual: For Intermediate To Advance Pilots OnlyDocument20 pagesInstruction Manual: For Intermediate To Advance Pilots OnlyBert BaradasNo ratings yet

- Operation Manual: Downloaded From Manuals Search EngineDocument52 pagesOperation Manual: Downloaded From Manuals Search EngineRebecca FitzsimmonsNo ratings yet

- Craftsman Table SawDocument40 pagesCraftsman Table SawdrdaverobertsNo ratings yet

- Craftman Router ManualDocument16 pagesCraftman Router ManualBloom67No ratings yet

- Esmeril Makita PDFDocument16 pagesEsmeril Makita PDFwjzabalaNo ratings yet

- Impact-Cutting-Instructions PARTIDA 86Document3 pagesImpact-Cutting-Instructions PARTIDA 86Ale PalomoNo ratings yet

- Owner's Manual & Safety InstructionsDocument16 pagesOwner's Manual & Safety InstructionsOver FlownNo ratings yet

- Atlas 10 Thread Manual-2Document62 pagesAtlas 10 Thread Manual-2Jim WhitehouseNo ratings yet

- Battery Sizing GuideDocument1 pageBattery Sizing GuideJim WhitehouseNo ratings yet

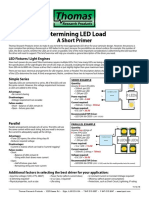

- Determining Led LoadDocument1 pageDetermining Led LoadJim WhitehouseNo ratings yet

- Chargers: Owner's Manual & Safety InstructionsDocument8 pagesChargers: Owner's Manual & Safety InstructionsJim WhitehouseNo ratings yet

- pdf4183769570452062909Document8 pagespdf4183769570452062909Jim WhitehouseNo ratings yet

- DWPA-70LED/PC/5K Specifications and DimensionsDocument1 pageDWPA-70LED/PC/5K Specifications and DimensionsJim WhitehouseNo ratings yet

- 0200 Installation ManualDocument39 pages0200 Installation ManualJim WhitehouseNo ratings yet

- 0200 Load Test The BatteryDocument3 pages0200 Load Test The BatteryJim WhitehouseNo ratings yet

- 0200 Position Sensor Error - Open CircuitDocument1 page0200 Position Sensor Error - Open CircuitJim WhitehouseNo ratings yet

- 0200 Connecting AccessoriesDocument1 page0200 Connecting AccessoriesJim WhitehouseNo ratings yet

- Craftsman 165155282Document16 pagesCraftsman 165155282Jim WhitehouseNo ratings yet

- Rimi Khanuja Vs S P Mehra Ors On 24 August 2022Document4 pagesRimi Khanuja Vs S P Mehra Ors On 24 August 2022Prakhar SinghNo ratings yet

- Constitutional Crisis in the PhilippinesDocument37 pagesConstitutional Crisis in the Philippineslee viceNo ratings yet

- Resume - Telecom Trainer, 3g Live Jobs, Tunis, Tunisia, AfricaDocument2 pagesResume - Telecom Trainer, 3g Live Jobs, Tunis, Tunisia, AfricaDiwakar MishraNo ratings yet

- Hotel Invoice Details for $804.04 StayDocument2 pagesHotel Invoice Details for $804.04 StayTiana IrvineNo ratings yet

- 8 Critical Change Management Models To Evolve and Survive - Process StreetDocument52 pages8 Critical Change Management Models To Evolve and Survive - Process StreetUJJWALNo ratings yet

- Nike, Inc. and The Athletic Footwear Industry Strategy and Competition AnalysisDocument25 pagesNike, Inc. and The Athletic Footwear Industry Strategy and Competition AnalysisFernando Jorge Gomez Sulca100% (1)

- Epc Contracts Process Plant SectorDocument30 pagesEpc Contracts Process Plant Sectorlimpama100% (2)

- ENGLISH - Radio Rebel Script - DubbingDocument14 pagesENGLISH - Radio Rebel Script - DubbingRegz Acupanda100% (1)

- McDonald's Corporation Future in a Changing Fast Food IndustryDocument29 pagesMcDonald's Corporation Future in a Changing Fast Food IndustryKhor Lee KeanNo ratings yet

- Article 7 "From There He Will Come Again To Judge The Living and The DeadDocument14 pagesArticle 7 "From There He Will Come Again To Judge The Living and The DeadQueen Jessel R. LomboyNo ratings yet

- The Girl in Room 105 Is The Eighth Novel and The Tenth Book Overall Written by The Indian Author Chetan BhagatDocument3 pagesThe Girl in Room 105 Is The Eighth Novel and The Tenth Book Overall Written by The Indian Author Chetan BhagatSiddharrth Prem100% (1)

- ScanCentral Guide 20.2.0Document80 pagesScanCentral Guide 20.2.0Nabil El FilaliNo ratings yet

- (UPCAT) Result 2006 Fiona DLRDocument4 pages(UPCAT) Result 2006 Fiona DLRapi-37595710% (2)

- Tri-Cities Community Bank Case Study SolutionDocument2 pagesTri-Cities Community Bank Case Study SolutionJohn Marthin ReformaNo ratings yet

- 5081 PDFDocument159 pages5081 PDFTemp PersonNo ratings yet

- HR GDDocument8 pagesHR GDNisheeth BeheraNo ratings yet

- Surah Zalzala Dream Tafseer NotesDocument19 pagesSurah Zalzala Dream Tafseer NotesAbu Ammar AsrafNo ratings yet

- Product Life Cycle Strategies of Nestle PakistanDocument16 pagesProduct Life Cycle Strategies of Nestle PakistanFahad MushtaqNo ratings yet

- Name: Roll Number: Room No: Class: MKT1602: Student InformationDocument6 pagesName: Roll Number: Room No: Class: MKT1602: Student InformationNguyen Thi Thuy Linh (K16HL)No ratings yet

- Things Fall Apart Reading GuideDocument8 pagesThings Fall Apart Reading GuideJordan GriffinNo ratings yet

- Instant Download Communicate 14th Edition Verderber Test Bank PDF Full ChapterDocument32 pagesInstant Download Communicate 14th Edition Verderber Test Bank PDF Full ChapterCarolineAvilaijke100% (10)

- All 18 QSS in One-1 PDFDocument314 pagesAll 18 QSS in One-1 PDFkishan23100% (1)

- Capstone Project 1: Product BacklogDocument11 pagesCapstone Project 1: Product BacklogHoàng Văn HiếuNo ratings yet

- Exercise 1: Read and Circle The Correct AnswerDocument5 pagesExercise 1: Read and Circle The Correct AnswerDiệu HườngNo ratings yet

- Immanuel Kant's Categorical Imperative and Kantian EthicsDocument4 pagesImmanuel Kant's Categorical Imperative and Kantian EthicsSylpauline EboraNo ratings yet

- Hacking - Reconnaissance Reference SheetDocument1 pageHacking - Reconnaissance Reference SheetMigue FriasNo ratings yet

- September 2017 Real Estate Appraiser Licensure ExamDocument12 pagesSeptember 2017 Real Estate Appraiser Licensure ExamRapplerNo ratings yet

- Lease and HPDocument27 pagesLease and HPpreetimaurya100% (1)

- Los Del Camino #5 (Inglés)Document8 pagesLos Del Camino #5 (Inglés)benjaminNo ratings yet

- Resume-Roberta Strange 2014Document3 pagesResume-Roberta Strange 2014Jamie RobertsNo ratings yet