Professional Documents

Culture Documents

0-WD800-CA731-00329 - Rev.0 - Work Procedure For Roof and Wall Panel

0-WD800-CA731-00329 - Rev.0 - Work Procedure For Roof and Wall Panel

Uploaded by

Leo Pascual0 ratings0% found this document useful (0 votes)

30 views40 pagesOriginal Title

0-WD800-CA731-00329_Rev.0_Work Procedure for Roof and Wall Panel

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views40 pages0-WD800-CA731-00329 - Rev.0 - Work Procedure For Roof and Wall Panel

0-WD800-CA731-00329 - Rev.0 - Work Procedure For Roof and Wall Panel

Uploaded by

Leo PascualCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

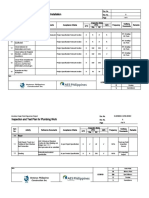

3c Global inc, WORK See UA rs ROOF AND. fash

* PROJECT CODE : BSOS32EA,

'* PROJECT NAME : MASINLOC POWER PLANT EXPANSION

Purpose

For information

PROJECT

+ DOCUMENT NO. : o:WD800-CA71-00829 For Review

+Tme WORK PROCEDURE FOR ROOF AND WALL — |. er approval

PANEL

+ owner MASINLOC POWER PARTNERS CO, LTD. beatae maa

Joaseun

0 | ForConstruction | aug 28,2017 | ‘Agnas oe 7 = =

ew rreranen | revewen | arrroven | crecreo | rewewen | aPpnoven

escriprion | oare

(owner

© aes Philippines

(Contractor

$ Ventanas Philippines

Construction Ine.

10.

20.

30.

40.

5.0.

70.

80.

"soe Power Pint Spansion Pret [BBE NO GWOIOE-CRTST 909

| WORK PROCEDURE FOR ROOF | rev. no °

‘AND WALL PANEL

TABLE OF CONTENTS

PURPOSE...

SCOPE.

ROLES & RESPONSIBILITIES.

PREPARATION...

WORK PROCEDURE.

ENVIRONMENT, HEALTH & SAFETY...

ATTACHMENT...

Job Environment & Safety Analysis

Risk Assessment

Materials Safety Data Sheet

= No OwDaDE CATS 00

WORK PROCEDURE FOR ROOF | rev. No. °

aE | Mase Power Fat Expansion Prec

‘AND WALL PANEL

4.0. PURPOSE

Ensure works and procedure associated to roof and wall panel instalation methodokogy for

‘execution in compliance with the technical specications ofthe Masinloc Power Pant

Expansion Project

20. SCOPE

‘The present work instruction is applicable to roof ané wall panel instalation works of

Masinloc Power Expansion Project,

3.0. REFERENCE

+ Approved Roof and Wall Panel Speciation

+ Approved related drawing and shop drawing

40. ROLES & RESPONSIBILITIES

44, VPC! Site Manager- shall be the overal responsible forthe implementation ofthis

procedure ensuring that works are completed on schedule and in conformity with

‘drawings and specifications.

42. VPC! Project EHS Manager shall ensure safe implementation of this procedure

‘Prometing an Incident and injury Free environment.

43. VPCI & GTC Global inc. Ste Manager shall be responsible forthe implementation

‘of work procedure, perform oF assign person to develop site work intrution and

Inspection plans and tests, Coordinate and contol resources to execute actives in

accordance with quality and schedule of project.

44, VPCI & GTC Giobal Inc. AIGC Engineer shall be responsible for he

implementation of fel qualty assurance and contol program and establish the

Inspection plan and test accordingly

48. GTC Global Inc. Site Engineer shall contro the ste application process and vert it

is accomplished accordingly and location that works comply with safety and quality

standards. The overall responsibly forthe direction, monitoring, ordination and

contol of all the constructon actives are require.

48. GTC Global inc. EHSS Engineer along with the Safety Officer shallensure

Implementation of all safety procedures, safely measures related te the nature of

works being cared out

S$

60.

asnies Powor Pt Expansion Projet [Oas-No OWDROR-CATST.O0308

puame tps | WORK PROCEDURE FOR ROOF | ov. no. °

oe "AND WALL PANEL

47. GTC Global nc, Rigging Supervisor shall check and contol ll the ling, ensuring

the implementation al iting are in safe and proper process, Calton of loads for

Permits

GTC Giobal nc. Rigger shall be in charge in rigging works and iting, Ensure all

‘material ited are in safe and proper process folowing safely coneions

49. Crane operator shal in charge on crane operation and shal be contral the position

ofthe unit,

PREPARATION

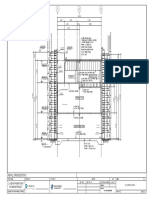

5.1. Roof Framing Preparation

All puri ofthe areas to be covered with roofing shal be propery installed.

‘shouldbe straight, leveled and paalel to each other to ensure corect alignment of

the root panels Ensure also that al purins are propery attached othe rafter by

‘means of bolt anchorage, Proper etouching on the corroded areas shal also be

‘mate pir to laying of rot panels

52. Wall Framing Preparation

All side gits ofthe areas to be covered with wall panels shall be propery installed

It should be straight, leveled and parallel to each athe to enue comect ignment

ofthe wall panels. Ensure also that all the side girth are propety attached to the

columns by means of bolt anchorage. Proper retouching on the ceeded areas shal

‘also be made prior o instalation of wall panels,

WORKING PROCEDURE

Roofing Installation

6.1.1. All workers shall wear appropriate PPE forthe work.

6.1.2. All roofing panels and bended accessories shall be lied using Crane and

shall be aligned and fixed manually with iting gear.

6.13, For the case of insulated roof panels, concealed ridge rol shall also be

installed on the ridge prio to roo! panel instalation,

16.14, It should have a minimum side lapping of 100mm and jveted at 150mm

spacing on centre. For the roof panel instalation, & i recommended that

laying of panes start at the opposite direction of the prevaiing monsoon wind,

6.1.5. Panels with the anticaplary rib should be covered by male ib.

6.1.8. All roof panels shall have a minimum overhang of SOmm at the eaves, it

‘should not also extend past the center ofthe ridge tne.

‘uasae Powar Par Expansion Project | Dos. No OWOEOGCATST.00R29-

Seema ans mtpines | WORK PROCEDURE FOR ROOF | Rev. No °

62.

"AND WALL PANEL |

6.17. After the frst panel has been propery signed, fasten kt with approved

tekscrew. All ibs at the gutter line and ridge ine should be fastened with @

sealing screw with neoprene washer. For inlermediat> puri, fastener

‘shouldbe applied at every other nib forming a“damond” pattern.

8.1.8. Atleast one bid of sealant must be applied on the se Bpping of the roof

‘panel before the adjoining root panel wil be insalie.

8.1.8. For cases where end lap must be used, install the lower panel row first

followed with upper row panels. Place the panel ontop the adjoining panels

shouldbe fastened on al pane ibs. Sealant must also be applied onthe area

Cf the bottom panel where lapping wil be placed prio to placing ofthe upper

roof pane!

6.1.10.After the roof panels have been installed, ridge rol and flashing instalation

shall folow. Ridge rol, and ridge lashings should be fattened using stich

screw (Type S screw) at each rb. While side flashings al every 300mm on

center.

1.1.14. Trim the ridge rol them to conform the oof profile contourt should tthe rib

not allowing any gap.

6.1.12, Remove and clean any accumulated dus, debris and any unwanted materials

ter the installation has been done,

Wall Pano! Installation

6.2.1. Allworkers shall wear appropiate PPE forthe work.

6.2.2. Gutter suppor wll be installed before the instalation of wal panel

6.2.3, Install the base mouldingsicappings prorto the instalation ef wall panels, Use

tox wth metal screw to attach the base moulding/capping lo the zocalo wal,

spaced at 400mm on center. Ensure thattis well aligned leveled, and parallel

to the side gith,

1624. Installthe base mouldinglcappings adjacent o each other without lapping,

625. Wal panel shal be ited using crane. Short wall panel or structure with low

)paw/anosos

‘ove 1U9p}su 24) uo puodsas oy suo aut 99 PInous 9

spaxinave Aan 40 9se9u

papasu uaudnby

z Iaquoseal

epainooxe

qm anssos © mor,

tuyod senso asa1eau 949 03 05 5

wea ssvodso Aouodiouls ay i0}u) |

sioyiom sayio aun wem an wiele ath punos “e

‘wlauidinbofeaus29p fe Brydun /anouay

“om aun dogs Astepaunt

sfoustsauig yo ase

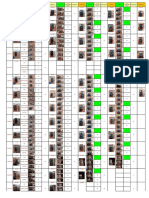

NOLdIIOSIq NvTd ADNADWAINHK

inact 1 ‘onc eee

mis oo mie si saen |

anes un. anes en

anime sun. sninis oo

“smautig oo [enews en

orneute ‘smd ue

‘iseutis erie = ue

‘remus 7 ‘outs race

Srneut = Sts = ue

nig [emus | oc

“FUnLWNOIS ONY aWYN

S3NSSI YBHLO GNY SLNSWOD

uM, z wewsi03p08ivednS ‘Auouny ean

| veupuen seweany ‘183100 JOON OL one007

‘oneoueseID Gor : (@ncurpp ieee ‘Buen AudweS

NoUolsDads sor

sishjeuy Ayes qor aid

8 “ou joqo19 2

saved

XS INITIATIVE

1

(Semmes | WORK PROCEDURE TOR ROOF | Reno °

SS Somer ‘AND WALL PANEL

Attachment # 02

Risk Assessment

| 2 | moesy | sneedipeniaaucnprapeoy |

nia

(noe

o| «| « |e] eft en dina

“TENYE TIYM GNY 4008 40 NOLLVTIVISNI

ug soog paniog aoe aoe

LNAWSS3SSV SIN

a oe :

aren, & ae ou paoi9

seas ot

2 rau rie

. >} «| | et swapee ten

“Ba haa app sean ad

om Sl tot hae pt See Casta to me Td st wonesedeig

>] e] | romme weneatenro Bowers Buy0OH “a

| “| secmen

sa

e]o Jewitt smut imroe 5204

Jone Be soul Anes at en wad ead a nf

ef 4 waned 2 | © snes

wan pr seu pd og i vn Bale on}

ata iad

. 2] e| 2] womee ewan

Jamoes

‘ana

. 2 |e] e) tects | riers pew xi otamneny | vontaedeig

sem ‘Bowes ea >

‘ w]e] «fetta etme imenepnipg

ee —— Ea aS

z io

ole a ns mess any

a “Ou joqo}p 2

: serena

> a

oe] fetal oem

o| e| =| at, oe

meena

fn i ere a es

sia o] =) fetta) mmr etme

motors

[al emma

cmniamenmnncmmreecnnd | *| * Magy Snntanmemma

Eaaaanarocisheeemrnewnaeeere

a oe

anatase aera a

1 x0 OP 39 BOWE nan / HR pence ee

els ele 7 sense

al els vosciniamanantmamamnnersucpud o/ e| @ Ed

“ae

commu og enh 3

(oman sbeeriee nan

“Duy |OGO}s) 2

ncruouaep set

fete] senenmtutnmenictn — |puneptossaa

aon usomnoypse una]

beroesonsitn “9

Yornainsa niiponiad naka mera]

tetas

SS at apo Ra

et ea op Bene Se]

. vo Fecha) mar eaieca sp poe

nud on pr te yea an oe

ot bun no neon yon 2 en)

Aa canouday

Ag aauvanta

2 [ren —

soci sees oem n y

1 asnoals] samen na pai

sos

ca] ce. ae)

_

ie ene

oo

‘ou goa 3

inet, S

: Mssic Power Pat Expansion Projet | Ooe No GWDAO0-CATS 100800

ran Minin | WORK PROCEDURE FOR ROOF | Rv. No. °

SS Seoreter ae ‘AND WALL PANEL

Attachment #03

Materials Safety Data Sheet

Material Safety Data Sheet

‘March 25, 2005

N 2000 PRO ago 1/9

1 Product and Company information

1.1 Product Name [NURISEAL OXIME SIUICONE SEALANT N 2000 PRO

4.2 Company Detail

anufacture/Supplie : NURICHEM CO, LTD

Adress 391-2, Chupa Paengsung-up,Pyungtaekst,

yung do, Korea

TWdephone Number: 62-31-683-3685

Fc Number 2-21-652-268,

2. Hazardous Ingredients

Hydeoteated mide petroleum

Distitter

Sea, amorphous

Met tietyretyetoxime)

Sane

Methyletiyetoxime

Poyimethystoxane

CAS Nos

3317653

69742.46-7

22984.56-9

@uioes

wo

30-60

30.60

wo

<0

9

(lassicaton fish and Safety Phrases

Not haraous

Not hazardous,

Not hazardous

Not hazardous

Ita.

senstzing

Initating to eyes nd skin

May couse serstization by skin

Harm

tan

Sensing

Not hazardous

Material Safety Data Sheet

‘March 25, 2008

N 2000 PRO

i etyimethyetoxine ems at

Methorynethy stone

Ambeettylaninopropyimethory 1760-243.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationLeo PascualNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- INSTALLATION OF Toilet Cubicle PartitionDocument4 pagesINSTALLATION OF Toilet Cubicle PartitionLeo Pascual50% (2)

- Work Procedure For CCB North Wall & Column RectificationDocument5 pagesWork Procedure For CCB North Wall & Column RectificationLeo PascualNo ratings yet

- Design Responsibility MatrixDocument1 pageDesign Responsibility MatrixLeo PascualNo ratings yet

- Thermal MonitoringDocument8 pagesThermal MonitoringLeo PascualNo ratings yet

- JESA-plumbing Works Rev. BDocument15 pagesJESA-plumbing Works Rev. BLeo PascualNo ratings yet

- Work Procedure For CCB Pouring Scheme For North Wall & Column - Line C3Document12 pagesWork Procedure For CCB Pouring Scheme For North Wall & Column - Line C3Leo PascualNo ratings yet

- Corrective and Preventive Action Plan: Masinloc Power Plant Expansion Project 2X300 MW (Net) Coal Fired Power ProjectDocument3 pagesCorrective and Preventive Action Plan: Masinloc Power Plant Expansion Project 2X300 MW (Net) Coal Fired Power ProjectLeo PascualNo ratings yet

- JESA - Welding Grinding & Cutting WorksDocument7 pagesJESA - Welding Grinding & Cutting WorksLeo PascualNo ratings yet

- CCB 2nd Floor Slab Pouring PlanDocument8 pagesCCB 2nd Floor Slab Pouring PlanLeo PascualNo ratings yet

- Job Environmental Safety AnalysisDocument24 pagesJob Environmental Safety AnalysisLeo PascualNo ratings yet

- FAT Procedure RequirementDocument1 pageFAT Procedure RequirementLeo PascualNo ratings yet

- WORK PROCEDURE FOR CCB Installation of Temporary Working Platform at CCB StaircaseDocument8 pagesWORK PROCEDURE FOR CCB Installation of Temporary Working Platform at CCB StaircaseLeo PascualNo ratings yet

- Work Procedure For The Scaffolding Modification - East of CCB For Bridge Installation of I-SteelDocument7 pagesWork Procedure For The Scaffolding Modification - East of CCB For Bridge Installation of I-SteelLeo PascualNo ratings yet

- Structural Calculation Sheet: Structural Design and AnalysisDocument10 pagesStructural Calculation Sheet: Structural Design and AnalysisLeo PascualNo ratings yet

- Work Procedure For CCB Scaffolding - FinalDocument80 pagesWork Procedure For CCB Scaffolding - FinalLeo PascualNo ratings yet

- 16.welder Qualification - WPQDocument1 page16.welder Qualification - WPQLeo PascualNo ratings yet

- Install Cross Section 2: 2 X 300 MW Power Plant Expansion ProjectDocument1 pageInstall Cross Section 2: 2 X 300 MW Power Plant Expansion ProjectLeo PascualNo ratings yet

- Philippines Masinloc Power Plant: Project TileDocument1 pagePhilippines Masinloc Power Plant: Project TileLeo PascualNo ratings yet

- 5578-E7-EPC-QA-007 - Quality Record Control ProcedureDocument16 pages5578-E7-EPC-QA-007 - Quality Record Control ProcedureLeo PascualNo ratings yet

- Inspection ChecklistDocument56 pagesInspection ChecklistLeo PascualNo ratings yet

- Work Procedure For STB Steel ErectionDocument108 pagesWork Procedure For STB Steel ErectionLeo PascualNo ratings yet