Professional Documents

Culture Documents

TLE EIM Basic Maintenance of Electrical Tools and Equipment

TLE EIM Basic Maintenance of Electrical Tools and Equipment

Uploaded by

Junelyn FragataCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TLE EIM Basic Maintenance of Electrical Tools and Equipment

TLE EIM Basic Maintenance of Electrical Tools and Equipment

Uploaded by

Junelyn FragataCopyright:

Available Formats

Basic Maintenance of Electrical Tools and Equipment

1. Clean out the Dust.

2. Check the Cords

3. Use the right tool correctly.

4. Protect your Tools.

5. Use double-insulated tools

6. Storing Your Tools

Note: Proper care of your electric tools is the key to making sure that they last for many years

Classification of non-functional and functional tools

Tools are very useful to us in our homes especially to our job. But tools that are no longer functional may cause

harm.

A. Make an inventory of functional and non-functional tools in your shop.

B. Classify your tools according to its function.

Functional tools and equipment- are those that are in good condition and can perform its regular functions.

Non-functional tools and equipment are those that are not able to perform its regular function because of

impaired and damage part. Examples of these are the following:

Hammer with a broken handle Screw driver with a broken handle

A broken/ cut foot rule Electrical Electrical equipment with damage cord

Method of identifying non-functional tools and equipment

1. Visual inspection. It refers to the visual observation of an expert on the appearance of the tools and

equipment.

2. Functionality. Vibration or extra noise from the operation means problems on parts and accessories started to

develop.

3. Performance. When there is something wrong with the performance of either hand tools or equipment, they

need an immediate repair or maintenance.

4. Power supply (for electrically operated only). Failure to meet the required power supply, malfunction will

occur in the part of hand tools or equipment.

5. Person’s involved. It refers to the technical person who has the knowledge and skills about the technology.

PERFORM BASIC PREVENTIVE MAINTENANCE

Lubricant is a substance introduced to lessen friction between moving surfaces. It may also transport external

particles. The property of reducing friction is known as lubricity.

1. Anti-rust lubricant spray: 4. Lubricant Oil and Engine Oil:

2. Wire Pulling Lubricant: 5. Silicon Lubricant:

3. All Purpose Anti Rust Lubricant:

Types and Kinds of Cleaning Solvents

Solvent is a component of a solution that dissolves solute and is usually present in large proportion or amount. It

can be classified as polar and nonpolar. Polar solvents are solvents which dissolve/are soluble in water; while

nonpolar solvents are solvents which do not dissolve/are insoluble in water.

Solvents are usually used for cleaning in workshops. They are water, gasoline, kerosene, thinner and detergent

soap.

Uses of Cleaning Solvents

Gasoline Washes greasy tools/ equipment

Kerosene Removes dust, grease oil, paint, etc.

Thinner Removes spilled paint on the floor, walls and tools.

Water Washes dust in the floor, walls, etc.

Detergent Soap and water Washes/cleans benches, tables, cabinets, etc.

5’s Approach in workshop keeping

5’S is a reference to a list of five Japanese words translated into English. This is an approached of organizing and

managing the workplace and work flow with the intent to improve efficiency by eliminating wastes, improving flow

of production, reducing process delays. These words are:

Japanese words English translation

Seiri Sort

Seiton Set in order (systematize)

Seiso Sweep

Seiketsu Standardize (sanitize)

Shitsuke Sustain (Self-discipline)

Sorting is an action to identify and eliminate all unnecessary items from your work place and dispose them.

Systematizing is an action to arrange or put every necessary item in good order so that they can be easily

picked for use. o A place for everything o Everything is in place

Sweeping is an action to clean your work place thoroughly so that there is no dust on floor, machines and

equipment.

Sanitizing is a condition of maintaining high standard of cleaning and workshop organization at all times.

Self-discipline is a condition of training people to follow cleaning disciplines independently.

You might also like

- EIM Exploratorys DLL Week 4Document4 pagesEIM Exploratorys DLL Week 4henryNo ratings yet

- CG - Electrical Installation and MaintenanceDocument10 pagesCG - Electrical Installation and MaintenanceEl G. Se ChengNo ratings yet

- Lesson 3: Interpret Technical Drawings and Plans (Id) : Yes MaamDocument6 pagesLesson 3: Interpret Technical Drawings and Plans (Id) : Yes MaamArniel Morato AmpaloNo ratings yet

- LubricatingDocument4 pagesLubricatingRJLifeOfPedzNo ratings yet

- Summative TestDocument1 pageSummative Testnerissa dollenteNo ratings yet

- Pretest G7Document3 pagesPretest G7Paul Senen DiduloNo ratings yet

- Summative Test in Automotive Servicing 8: Name: Score: Grade & Section: DateDocument2 pagesSummative Test in Automotive Servicing 8: Name: Score: Grade & Section: DateAriel100% (1)

- Automotive-Small Engine 7-8 Module 2Document24 pagesAutomotive-Small Engine 7-8 Module 2FLORDELIZA ALBANO PAGLINAWANNo ratings yet

- Eim 8 Lesson 4Document6 pagesEim 8 Lesson 4accel sillaNo ratings yet

- EIM Lesson PlanDocument2 pagesEIM Lesson PlanLAURENCE DIAZNo ratings yet

- Maintain Tools and EquipmentDocument30 pagesMaintain Tools and Equipmentmico alilayaNo ratings yet

- Technology and Livelihood Education: Quarter 3 - Module 1 - Week 1Document14 pagesTechnology and Livelihood Education: Quarter 3 - Module 1 - Week 1SITTIE ASIA MINALANG100% (1)

- Cot 3 Electrical InstallationDocument3 pagesCot 3 Electrical InstallationJoanne CabangilNo ratings yet

- Quiz No 1 tl3 ElectricityDocument2 pagesQuiz No 1 tl3 ElectricityIsrael Marquez100% (2)

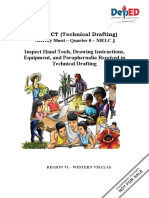

- Grade 7/8 Technology and Livelihood Education Technical Drafting (40 Hours)Document34 pagesGrade 7/8 Technology and Livelihood Education Technical Drafting (40 Hours)Jhobhel Christopher GalivoNo ratings yet

- DLL Entries Eim - Marjorie MagaboDocument24 pagesDLL Entries Eim - Marjorie MagaboMATHEW ANGELO GAMBOANo ratings yet

- Name of Learner: - Grade & SectionDocument10 pagesName of Learner: - Grade & SectionAxel Nicerio RoveloNo ratings yet

- Lesson Plan in EIM8Document10 pagesLesson Plan in EIM8Aldren MahilumNo ratings yet

- Lesson Plan For COT Electrical ToolsDocument6 pagesLesson Plan For COT Electrical ToolsMarites TagaytayanNo ratings yet

- Lesson Plan in Electrical Installation and Maintenance: President Diosdado Macapagal High SchoolDocument2 pagesLesson Plan in Electrical Installation and Maintenance: President Diosdado Macapagal High SchoolDominic HawangNo ratings yet

- Ia - Electricity TG Grade 7 & 8 P&DDocument8 pagesIa - Electricity TG Grade 7 & 8 P&DNix Roberts100% (1)

- W4 Volume, Area and CircumferenceDocument2 pagesW4 Volume, Area and CircumferenceShirlyn Navarro RamirezNo ratings yet

- Updated-PPE 7Document5 pagesUpdated-PPE 7Mc LloydNo ratings yet

- Modified Learning Activity Sheet in CarpentryDocument14 pagesModified Learning Activity Sheet in CarpentryDonna Marie Arcangel100% (1)

- WLP G8 EIM 3rd QUARTER - W1 W4Document9 pagesWLP G8 EIM 3rd QUARTER - W1 W4sheryl victorioNo ratings yet

- Technology and Livelihood Education: Home EconomicsDocument9 pagesTechnology and Livelihood Education: Home EconomicsJacquilyn Dela Cruz100% (1)

- TLE 8-EIM - Lesson PlanDocument6 pagesTLE 8-EIM - Lesson PlanBernadette RosalitaNo ratings yet

- EIM Exploratorys DLL Week 3Document4 pagesEIM Exploratorys DLL Week 3henry100% (1)

- COT 2 Exemplary Dll-Template COT2Document3 pagesCOT 2 Exemplary Dll-Template COT2Joanne Cabangil100% (2)

- Epas 9 Summative Test Week 7 and 8Document3 pagesEpas 9 Summative Test Week 7 and 8marjie adameNo ratings yet

- LP16 Drawing Symbols and SignsDocument4 pagesLP16 Drawing Symbols and SignsGlenn Fortades SalandananNo ratings yet

- Tle - Ia (Electrical Installation Maintenance) : Activity Sheet-Quarter 1-4-MELC 2Document13 pagesTle - Ia (Electrical Installation Maintenance) : Activity Sheet-Quarter 1-4-MELC 2Reinier Paclibar Federizo100% (1)

- DLL COOKERY 8 - Week 2Document2 pagesDLL COOKERY 8 - Week 2SHAZEL LUSTRIA100% (1)

- Eim 8 Summative TestDocument2 pagesEim 8 Summative TestMaribel G. Montiar100% (2)

- Tle Grade 8 Epas Melcs - It Is Aligned On The Most Essential Competencies Need in The New Normal in TheDocument15 pagesTle Grade 8 Epas Melcs - It Is Aligned On The Most Essential Competencies Need in The New Normal in TheLoli Gonzales ArtiagaNo ratings yet

- Maintain, Organize and Be Safe!: Epas 9 (Electronics Products Assembly and Servicing)Document18 pagesMaintain, Organize and Be Safe!: Epas 9 (Electronics Products Assembly and Servicing)Lambert De VeraNo ratings yet

- 4.3.1 Preparing and Interpreting Technical DrawingDocument11 pages4.3.1 Preparing and Interpreting Technical DrawingFlorie Capales-Pelin67% (3)

- 1st Quarter Summative TestDocument4 pages1st Quarter Summative TestLani DolleroNo ratings yet

- Budget of Work Electronics Group Sy2019 2020Document4 pagesBudget of Work Electronics Group Sy2019 2020MN Feruelo100% (1)

- EIM Exploratorys DLL Week 5Document6 pagesEIM Exploratorys DLL Week 5henryNo ratings yet

- Detailed Lesson Plan in TLE 10 Electronics I. ObjectivesDocument5 pagesDetailed Lesson Plan in TLE 10 Electronics I. Objectivesalden indemneNo ratings yet

- Daily Lesson Log School Grade Level Teacher Learning Areas Teaching Week Quarter Time DatesDocument6 pagesDaily Lesson Log School Grade Level Teacher Learning Areas Teaching Week Quarter Time DatesELMER DEMITNo ratings yet

- Tle Quarter 4 Electrical Installation and Maintenance (Eim)Document23 pagesTle Quarter 4 Electrical Installation and Maintenance (Eim)Kong ArciagaNo ratings yet

- Dll-Epas Sep 18-22Document3 pagesDll-Epas Sep 18-22JOSEPH ONGNo ratings yet

- Technical Drafting-7&8-LAS-3-Week2Document6 pagesTechnical Drafting-7&8-LAS-3-Week2Franklin Lirazan100% (1)

- Tle 7 Mechanical DraftingDocument1 pageTle 7 Mechanical DraftingJanix Magbanua100% (2)

- EIMDocument3 pagesEIMRene Janog DenoreNo ratings yet

- Hazards - IndustrialDocument5 pagesHazards - IndustrialGuyan GordonNo ratings yet

- DLP 3 Plumbing ExporatoryDocument2 pagesDLP 3 Plumbing ExporatoryIan Varela100% (1)

- Performance Tasks: Skinning of Wire Using Different Tools/EquipmentsDocument2 pagesPerformance Tasks: Skinning of Wire Using Different Tools/EquipmentsRoniel BalverdeNo ratings yet

- Cronasia Foundation College IncDocument4 pagesCronasia Foundation College Incnoy100% (2)

- Eim Quiz MeasurementDocument2 pagesEim Quiz Measurementbernie evaristo bacsaNo ratings yet

- Semi-Detailed Lesson Plan in Tle8 (Productivity, Humility) January 26, 2017Document3 pagesSemi-Detailed Lesson Plan in Tle8 (Productivity, Humility) January 26, 2017gaea louNo ratings yet

- FINAL CASTILLO-Module-1-TLE-IA-ELECTRICAL-7-8Document26 pagesFINAL CASTILLO-Module-1-TLE-IA-ELECTRICAL-7-8Bravey Purpose100% (2)

- DLL Technical Drafting ExploratoryDocument18 pagesDLL Technical Drafting ExploratoryDANGAY NATIONAL HIGH SCHOOL0% (1)

- DLLDocument8 pagesDLLTupa Integrated School100% (1)

- DLP COTDocument5 pagesDLP COTHerbert LaluzNo ratings yet

- Occupational Health and Safety: Computer System ServicingDocument17 pagesOccupational Health and Safety: Computer System ServicingSer Crz JyNo ratings yet