Professional Documents

Culture Documents

CNC Machining Leads To Lower Production Costs

Uploaded by

11 - ROHITH D0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

!

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesCNC Machining Leads To Lower Production Costs

Uploaded by

11 - ROHITH DCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

1.

Greater Accuracy and Better finishing

Quality is more consistent

Faster production speeds are possible

CNC Machining Leads to Lower Production Costs.

CNC machines can handle more complex designs than conventional cutting tools

Parts can be lighter and stronger with the aid of complex geometry

CNC machining can produce near-net shapes

2. •CNC part programming is a very important software element in the NC manufacturing

system. It looks like a computer program containing a number of

lines/ statements/ instructions (called NC blocks).

• It is, therefore, the detailed plan of manufacturing instructions

proposed for machining the part.

3. •CNC part programming is a very important software element in the NC manufacturing

system. It looks like a computer program containing a number of

lines/ statements/ instructions (called NC blocks).

• It is, therefore, the detailed plan of manufacturing instructions

proposed for machining the part

4. G-code is a software programming language used to control a CNC machine.

And, even with complex CNC machining, G-code is written in a

straightforward, logical way. A “G” is followed by a number, which is a command

to change geometry. For instance, “G00” is a command for rapid movement.

G-codes activate the CNC machine and directs the machine’s motions and

functions.

5. Point to point

Point to point straight line

2-axis contouring with switchable plane

3-axis contouring with continuous path

6. • Numerical control of machine tools may be defined as a method of

automation in which various functions of machine tools are

controlled by letters, numbers and symbols.

• Basically, a NC machine runs on a program fed to it. The program

consists of precise instructions about the methodology of

manufacture as well as the movements.

7. G codes direct the machine's motion and function, while M codes direct the

operations outside movements. The G code activates the CNC machine while

the M code activates the machine's programmable logic controller.

8. • M-code controls miscellaneous functions, and typically these can be thought

of as non-geometry machine functions. Examples include spindle rotation start

and stop, coolant on and off, pallet change, etc.

For instance, M03: Rotate spindle clockwise

M-code activates the machine’s programmable logic controller and directs

the operations outside movements.

9. A canned cycle is a way of conveniently performing repetitive CNC machine

operations. Canned cycles automate certain machining functions such as

drilling, boring, threading, pocketing, etc... Canned cycles are so called because

they allow a concise way to program a machine to produce a feature of a part.

10. CNC machining produces accurate and specific parts with each production.

The programming of CNC machines and software ensures consistency in all the

pieces.

CNC machining greatly improves the safety of workers in the manufacturing

industry. With CNC machines, the operators do not have to go near the cutting

tools, which improve on safety.

You might also like

- Jit, Jimma University: Computer Aided Engineering AssignmentDocument8 pagesJit, Jimma University: Computer Aided Engineering AssignmentGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- CNC Milling ReportDocument6 pagesCNC Milling ReportMuhazman DinNo ratings yet

- CNC Milling ReportDocument15 pagesCNC Milling ReportStarscream Aisyah78% (37)

- CNC Milling MachineDocument15 pagesCNC Milling Machinenajieyuya91% (11)

- CNC Machines: Numerical Control (CNC) (Also Computer Numerical Control (CNC) ) Is TheDocument8 pagesCNC Machines: Numerical Control (CNC) (Also Computer Numerical Control (CNC) ) Is Theyash sharmaNo ratings yet

- CNC Assignment: Shagun SharmaDocument27 pagesCNC Assignment: Shagun SharmaShagun SharmaNo ratings yet

- Computer Aided Manufacturing (CAM)Document68 pagesComputer Aided Manufacturing (CAM)Ali RazaNo ratings yet

- ObjectiveDocument18 pagesObjectiveSaad AliKhanNo ratings yet

- ASSIGNMENT 1 Cad PDFDocument8 pagesASSIGNMENT 1 Cad PDFSasank SaiNo ratings yet

- CNC LAB Manual PDFDocument33 pagesCNC LAB Manual PDFrajee10133% (3)

- 1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Document38 pages1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Madhu SudhanNo ratings yet

- GTTC ReportDocument27 pagesGTTC ReportDhavan Y Kumar100% (2)

- Chapter 1 Introduction 1 1 IntroductionDocument34 pagesChapter 1 Introduction 1 1 IntroductionBeet LalNo ratings yet

- MillingDocument53 pagesMillingMuhammad Asif Shehzad KhanNo ratings yet

- EML2322L-CNC Machining PDFDocument17 pagesEML2322L-CNC Machining PDFIvan JarebNo ratings yet

- Lec - 1 .CAMDocument21 pagesLec - 1 .CAMOmar AlkadyNo ratings yet

- Report Untuk Budak Mekanik Sem 2Document3 pagesReport Untuk Budak Mekanik Sem 2Muhammad HafizNo ratings yet

- Assignment-1 Computer Aided Manufacturing ME-418Document21 pagesAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79No ratings yet

- Tech Ascend CNC Student ManualDocument42 pagesTech Ascend CNC Student ManualabyzenNo ratings yet

- CNC Machining & Additive ManufacturingDocument17 pagesCNC Machining & Additive ManufacturingArun kumar rouniyarNo ratings yet

- Title Objective: Figure 1: Hitachi Seiki Hitec-Turn20SiiDocument11 pagesTitle Objective: Figure 1: Hitachi Seiki Hitec-Turn20SiiSilang KataNo ratings yet

- CNC and NC MachineDocument36 pagesCNC and NC MachineShaaf AmjadNo ratings yet

- Numeric ControlDocument22 pagesNumeric ControlMUSKAN PRNNo ratings yet

- IJRPR937Document8 pagesIJRPR937Prenank ChandrolNo ratings yet

- CNC MachineDocument21 pagesCNC MachineKuhely GhoshNo ratings yet

- Computer Aided Manufacturing (Cam) 18-Feb-21Document25 pagesComputer Aided Manufacturing (Cam) 18-Feb-21Ramesh Kavitha Sanjit 18BME0677No ratings yet

- Cam Lab 1Document40 pagesCam Lab 1Madhusudhan Rao KNo ratings yet

- Fundamentals of NC Technology-Unit-1Document38 pagesFundamentals of NC Technology-Unit-1Swarna Paul100% (1)

- Department of Mechanical Engineering Iit Madras: NC MachineDocument6 pagesDepartment of Mechanical Engineering Iit Madras: NC MachineLee RockNo ratings yet

- A Mechatronics Approach To Design A General CNC Controller: September 2015Document7 pagesA Mechatronics Approach To Design A General CNC Controller: September 2015Tony K PaulNo ratings yet

- Cad/Cam: NC, CNC, DNC TechnologiesDocument37 pagesCad/Cam: NC, CNC, DNC TechnologiesVijay ShakarNo ratings yet

- CNC Basic & Prog.Document89 pagesCNC Basic & Prog.Christine BrownNo ratings yet

- Manufacturing Processes AssignmentDocument6 pagesManufacturing Processes AssignmentAamir RafiqNo ratings yet

- G J U S T S M e D M LDocument4 pagesG J U S T S M e D M LZlo6No ratings yet

- Module - Additive Manufacturing 18 SchemeDocument54 pagesModule - Additive Manufacturing 18 SchemeSANTOSHNo ratings yet

- CNC by AsfiDocument4 pagesCNC by AsfiMuhaimenul SaschoNo ratings yet

- Unit 3Document9 pagesUnit 3JaliJaNo ratings yet

- WINSEM2022-23 MEE3502 ETH VL2022230500781 2022-12-14 Reference-Material-IDocument25 pagesWINSEM2022-23 MEE3502 ETH VL2022230500781 2022-12-14 Reference-Material-Ibikki sahNo ratings yet

- Unit 6 PlcaDocument21 pagesUnit 6 PlcaAyush SinghNo ratings yet

- CNC PPT AkDocument16 pagesCNC PPT AkArun Kumar YadavNo ratings yet

- CNC - Machines PresentationDocument31 pagesCNC - Machines PresentationSascha SchranzNo ratings yet

- Introduction To CNC Programming and Industrial RoboticsDocument50 pagesIntroduction To CNC Programming and Industrial RoboticstaridanNo ratings yet

- CNC MachinesDocument15 pagesCNC Machinesshweta_770587No ratings yet

- CNC Mid 1 KeyDocument14 pagesCNC Mid 1 Keypala srinivas reddyNo ratings yet

- NCDocument7 pagesNCsugiantobarusNo ratings yet

- Unit 4 & 5 ME8691 Computer Aided Design and ManufacturingDocument26 pagesUnit 4 & 5 ME8691 Computer Aided Design and ManufacturingMECHGOKUL KRISHNA KNo ratings yet

- What Is CNCDocument9 pagesWhat Is CNCHayyanNo ratings yet

- Manufacturing Processes Lab Ninth ExperimentDocument6 pagesManufacturing Processes Lab Ninth ExperimentWesam abo HalimehNo ratings yet

- Definition of Numerical ControlDocument5 pagesDefinition of Numerical ControlRanjan Kumar SinghNo ratings yet

- Conclusion What We Can Conclude From This Report Is We Able To Study The Meaning of CNC WhichDocument1 pageConclusion What We Can Conclude From This Report Is We Able To Study The Meaning of CNC WhichMuhd Qayyum Mohd Fuad80% (5)

- Practical No1Document8 pagesPractical No1Dept. Of Mechanical Engg.No ratings yet

- Experiment No 6Document11 pagesExperiment No 6harisraja47985No ratings yet

- CNC Programming InteriorSampleDocument13 pagesCNC Programming InteriorSampleSilviu PetronelNo ratings yet

- Conclusion CNC MillingDocument1 pageConclusion CNC MillingSlim ShaddysNo ratings yet

- Lab Manual CNC LatheDocument10 pagesLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- MP 2nd Mid-Sem Question PaperDocument1 pageMP 2nd Mid-Sem Question PaperAnshul KhandelwalNo ratings yet

- Design and Analysis On Ajm NozzleDocument34 pagesDesign and Analysis On Ajm NozzleRahul KolukuluriNo ratings yet

- A. Introduction To WeldingDocument29 pagesA. Introduction To WeldingRonel LawasNo ratings yet

- Footcandle Light Guide ALCONDocument3 pagesFootcandle Light Guide ALCONAritra DasguptaNo ratings yet

- Design and Development Mini Compression Molding For Teaching and LearningDocument7 pagesDesign and Development Mini Compression Molding For Teaching and LearningNeemsNo ratings yet

- Brederoshaw Pds 3lpeDocument2 pagesBrederoshaw Pds 3lpejleonosNo ratings yet

- Chemicals: Medium StrengthDocument128 pagesChemicals: Medium Strengthk mNo ratings yet

- PRO Ex 30: Exterior Sheen EmilsionDocument2 pagesPRO Ex 30: Exterior Sheen EmilsionlongNo ratings yet

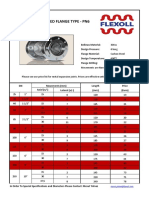

- Flexoll Price ListDocument10 pagesFlexoll Price ListRibhi HamdanNo ratings yet

- Permastic Vinyl Acrylic EmulsionDocument1 pagePermastic Vinyl Acrylic EmulsionCynthia MillerNo ratings yet

- Paraloid Au 608xDocument7 pagesParaloid Au 608xCHIRE SARAYASI MANUELNo ratings yet

- Welding & Hot Dip Galvanizing PDFDocument9 pagesWelding & Hot Dip Galvanizing PDFויליאם סן מרמיגיוסNo ratings yet

- CrossPure Cartridge FilterDocument2 pagesCrossPure Cartridge FilterLU DustinNo ratings yet

- Workshop Practice Series The Definitive Library For The Small WorkhsopDocument1 pageWorkshop Practice Series The Definitive Library For The Small WorkhsopceljkoNo ratings yet

- 6) Types of Saws Used in CarpentryDocument3 pages6) Types of Saws Used in CarpentryKrako TramNo ratings yet

- Coating & Painting Inspection ChecklistDocument3 pagesCoating & Painting Inspection Checklisthans100% (3)

- Welder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeDocument4 pagesWelder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeSpectex dubaiNo ratings yet

- 15 5PH Bars Sheets Plates SpecificationsDocument2 pages15 5PH Bars Sheets Plates SpecificationsSachin RoutNo ratings yet

- Quiz - Gas Cutting WeldingDocument5 pagesQuiz - Gas Cutting Weldingjacobpm2010No ratings yet

- CarbonFiberHowTo2 PDFDocument20 pagesCarbonFiberHowTo2 PDFSolidWorksNo ratings yet

- Dasco HvacDocument35 pagesDasco HvacrafaelNo ratings yet

- DR OplusDocument17 pagesDR OpluswapsplanNo ratings yet

- Unit 3: Cleaning and MaintenanceDocument24 pagesUnit 3: Cleaning and MaintenanceSrivalli Krishnan100% (1)

- Course Material TwoDay Workshop Sheetemetal DHIO GTTCDocument132 pagesCourse Material TwoDay Workshop Sheetemetal DHIO GTTChsvjvv100% (1)

- Welding Inspection Technology Module 4Document9 pagesWelding Inspection Technology Module 4Shaheed MohammedNo ratings yet

- MPS ITP Bare Pipe - PT Sari Dumai Oleo (Signed SAP)Document30 pagesMPS ITP Bare Pipe - PT Sari Dumai Oleo (Signed SAP)Alfian ImaduddinNo ratings yet

- YedaiDocument4 pagesYedaiAbel SánchezNo ratings yet

- SprutCAM7 Manual Manual UsuarioDocument578 pagesSprutCAM7 Manual Manual UsuariorenatoNo ratings yet

- Flypress ToolingDocument4 pagesFlypress Toolingxx xxxNo ratings yet