0% found this document useful (0 votes)

116 views6 pagesAISC 360-16 C-Section Analysis Guide

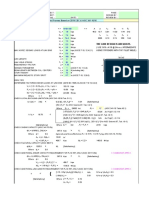

This document summarizes the structural analysis of a C-section channel. It includes:

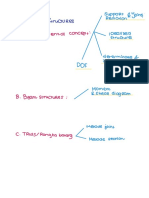

1) Geometric properties of the cross-section like dimensions, areas, moments of inertia, product of inertia, radii of gyration, and shear center.

2) Calculations of the section's tension and compression capacities according to AISC 360-16 specifications, including yield tension, rupture tension, and flexural and torsional buckling capacities.

3) The section qualifies as non-slender and its buckling capacities are controlled by either elastic or inelastic buckling depending on the axis and applied load.

Uploaded by

inaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

116 views6 pagesAISC 360-16 C-Section Analysis Guide

This document summarizes the structural analysis of a C-section channel. It includes:

1) Geometric properties of the cross-section like dimensions, areas, moments of inertia, product of inertia, radii of gyration, and shear center.

2) Calculations of the section's tension and compression capacities according to AISC 360-16 specifications, including yield tension, rupture tension, and flexural and torsional buckling capacities.

3) The section qualifies as non-slender and its buckling capacities are controlled by either elastic or inelastic buckling depending on the axis and applied load.

Uploaded by

inaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd