Professional Documents

Culture Documents

TDS - CHALCOFOIL Soft

Uploaded by

Vova Tripolsky0 ratings0% found this document useful (0 votes)

21 views1 pageChalco Foil Limited produces aluminum foil for flexible packaging, aseptic packaging, and tobacco packaging. The technical data sheet provides specifications for various foil thicknesses between 0.006mm to 0.020mm, porosity levels, elongation percentages, number of splices per coil, splice types, tensile strength, thickness and width tolerances, core details, layers and telescoping limits, surface quality requirements, quality documents, and packing and storage instructions. Foil is packed in wooden boxes with protective layers for ocean transportation and storage of 1-3 years.

Original Description:

Original Title

TDS - CHALCOFOIL soft

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChalco Foil Limited produces aluminum foil for flexible packaging, aseptic packaging, and tobacco packaging. The technical data sheet provides specifications for various foil thicknesses between 0.006mm to 0.020mm, porosity levels, elongation percentages, number of splices per coil, splice types, tensile strength, thickness and width tolerances, core details, layers and telescoping limits, surface quality requirements, quality documents, and packing and storage instructions. Foil is packed in wooden boxes with protective layers for ocean transportation and storage of 1-3 years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pageTDS - CHALCOFOIL Soft

Uploaded by

Vova TripolskyChalco Foil Limited produces aluminum foil for flexible packaging, aseptic packaging, and tobacco packaging. The technical data sheet provides specifications for various foil thicknesses between 0.006mm to 0.020mm, porosity levels, elongation percentages, number of splices per coil, splice types, tensile strength, thickness and width tolerances, core details, layers and telescoping limits, surface quality requirements, quality documents, and packing and storage instructions. Foil is packed in wooden boxes with protective layers for ocean transportation and storage of 1-3 years.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CHALCO FOIL LIMITED

ROOM 302, BUILDING 38, LAVIE BUSINESS PARK, 702 SHANHE ROAD, CHENGYANG,QINGDAO, CHINA

TECHNICAL DATA SHEET

Parameter Indicative value

Product denomination Aluminium foil

Application Flexible Packaging & Aseptic Packaging & Tobacco Packaging

Final use of converted foil food & milk/beverage & tobacco

Appearance (surface) matt/bright

Foil thickness, mm From 0.006 to 0.0065 0.007 0.009 0.012 0.020

Foil porosity, number /1 m2,

600 300 50 20 /

max.

Rel.elongation, %, min. 1.0 1.2 1.5

≤φ 360 >φ 360 ≤φ 500 >φ 500

Number of splices per coil, max.

≤1 ≤2 ≤1 ≤2

Ultra-sonic welding. Strength value in the splice area to be not less than 70 % from

Splice type tensile strength of foil.

Splices marked with foil flags.

Tensile strength, MPa, min. 70

Thickness tolerance, % ±5

Condition (Temper) Soft (O)

Alloy 1235/8079/8111

Foil width, mm from 200 to 1660

Width tolerance, mm ±1

Core internal diameter, mm 76//152

Core material Steel

Wall thickness, mm 4/6

Micro holes,mm ≤0,02

Layers oscillation in coil, mm 1 within limits preventing foil edge scuffing

Coil telescoping, mm, max. ±2

Wettability A

Unwinding, m, max. 1.5

Uniform surface should be free from folds, scratches, mechanical damages,

Surface quality

corrosion, broken matte.

Quality documents Chemical composition, mechanical properties (Rm, A100/50), confirmation of

conformity with EN 602

In wooden boxes and suitable for ocean transportation. Each roll packed extra into

Packing&Storage period PE film with protective layer of foamed PE on butt-end side and with usage of

Desiccant to guarantee storage of 1-3 years depending on environment humidity

Date: 1st January 2014

You might also like

- Specification of Aluminium Foil: 1. Appearance and General ConditionsDocument3 pagesSpecification of Aluminium Foil: 1. Appearance and General Conditionsraviteja tankalaNo ratings yet

- Practical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandPractical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Neo Fiberglass Mesh 160 GSM TDSDocument1 pageNeo Fiberglass Mesh 160 GSM TDSAkosh AchuNo ratings yet

- Wear of Metals: International Series in Materials Science and TechnologyFrom EverandWear of Metals: International Series in Materials Science and TechnologyRating: 4 out of 5 stars4/5 (2)

- Specs - ABSDocument3 pagesSpecs - ABSBurak KececiNo ratings yet

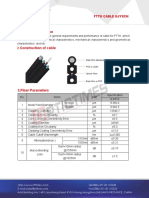

- Cable Khomax AdssDocument1 pageCable Khomax AdssHuidoQuinoQuinoNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Compocel Al FR: Aluminium and Thermoplastic Honeycombs, Laminates, Sandwich PanelsDocument3 pagesCompocel Al FR: Aluminium and Thermoplastic Honeycombs, Laminates, Sandwich Panelsbenadam10No ratings yet

- Mds Rheinzink-Artcolor Skygrey 04 2018 de enDocument3 pagesMds Rheinzink-Artcolor Skygrey 04 2018 de encarlosNo ratings yet

- Content: Stabolit Insulation Coatings For Non Grain Oriented Electrical SteelDocument8 pagesContent: Stabolit Insulation Coatings For Non Grain Oriented Electrical SteelL Mahender ReddyNo ratings yet

- Data Teknis Hive Honeycomb KoreaDocument70 pagesData Teknis Hive Honeycomb KoreailhamhanafyNo ratings yet

- 1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%Document1 page1x1.5 SIFCSI (Heat Resistance) 12-20KV-100%amir kamaliNo ratings yet

- Series Y: Strain Gages (SG)Document18 pagesSeries Y: Strain Gages (SG)Umair MansoorNo ratings yet

- N1P-1.5 Mgt-Xosswah-LDocument2 pagesN1P-1.5 Mgt-Xosswah-LRijo RajanNo ratings yet

- Physical Performance Index of EPDM Coiled Waterproof MembraneDocument4 pagesPhysical Performance Index of EPDM Coiled Waterproof MembranekrrisshnaNo ratings yet

- ST Velo Vetro EngDocument1 pageST Velo Vetro Engluca.laniNo ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- Wurth 0961003Document1 pageWurth 0961003mrcNo ratings yet

- Aluminium Foil CatalogDocument12 pagesAluminium Foil CatalogFajar Premana PutraNo ratings yet

- Data Teknis Alcoflux KoreaDocument40 pagesData Teknis Alcoflux KoreaDebby saputraNo ratings yet

- Eutalloy Thermal Spray Alloys: Alloys For Use With The Superjet-S EutalloyDocument8 pagesEutalloy Thermal Spray Alloys: Alloys For Use With The Superjet-S EutalloyLuis NarvaezNo ratings yet

- TDS Flexible 8079Document2 pagesTDS Flexible 8079Hiba NaserNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Hangzhou Xingfa Technology Co., LTD.: Tel: 0086 187 6715 3962 Skype: Ivy-Zhou0808Document1 pageHangzhou Xingfa Technology Co., LTD.: Tel: 0086 187 6715 3962 Skype: Ivy-Zhou0808Shaliya KarunathilakaNo ratings yet

- Particle Board and MDFDocument26 pagesParticle Board and MDFjosefNo ratings yet

- PCB SpecificationsDocument3 pagesPCB SpecificationsVlad VrabieNo ratings yet

- 3M92015 Double-Coated Tape PDFDocument6 pages3M92015 Double-Coated Tape PDFargh112No ratings yet

- ITO (Indium Tin Oxide) Coated PET Plastic - 100mm X 200mmDocument2 pagesITO (Indium Tin Oxide) Coated PET Plastic - 100mm X 200mmSalam Surjit SinghNo ratings yet

- ZTT MV Power Cable Rev A 20181228Document5 pagesZTT MV Power Cable Rev A 20181228Jean Pierre GoossensNo ratings yet

- Data Sheet E 8/2 U0/U4 GSTR Green: Siegling - Total Belting SolutionsDocument3 pagesData Sheet E 8/2 U0/U4 GSTR Green: Siegling - Total Belting SolutionsBaihaki StNo ratings yet

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezNo ratings yet

- Category6 Utp Copper CableDocument2 pagesCategory6 Utp Copper Cablesunil kumarNo ratings yet

- Alu Alu Cold-Forming FoilDocument1 pageAlu Alu Cold-Forming FoilManivannan KathirvelNo ratings yet

- Catalog Wurth MRODocument22 pagesCatalog Wurth MROBillNo ratings yet

- Matt80 HM100 WG62Document2 pagesMatt80 HM100 WG62Mahmud RezaNo ratings yet

- Ficha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGDocument5 pagesFicha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGluis carreñoNo ratings yet

- TCKT đường truyền H4 - H2Document2 pagesTCKT đường truyền H4 - H2Vô CảmNo ratings yet

- Fecha Técnica RS-GYFXS-6 - 12 - 24 Fibra Andina SM - MMDocument2 pagesFecha Técnica RS-GYFXS-6 - 12 - 24 Fibra Andina SM - MMviviana tNo ratings yet

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- Copper: Wire Electric Supplies LTD Stag Business Park Donnington Wood Telford Shropshire Tf2 7naDocument1 pageCopper: Wire Electric Supplies LTD Stag Business Park Donnington Wood Telford Shropshire Tf2 7naAnonymous WDTFw8EKNo ratings yet

- Plascoat Ppa 571: Performance Polymer Alloy CoatingDocument2 pagesPlascoat Ppa 571: Performance Polymer Alloy CoatingEidrish ShaikhNo ratings yet

- 16AWG 4 Wires Cable SpecificationDocument3 pages16AWG 4 Wires Cable SpecificationWise SoNo ratings yet

- F10BL - Pvcexcon 2LR8 DB20 U0v05 FaDocument1 pageF10BL - Pvcexcon 2LR8 DB20 U0v05 FaCustomer ServiceNo ratings yet

- Impact Modified PS CLEAR: Key Features ApplicationsDocument1 pageImpact Modified PS CLEAR: Key Features ApplicationsIceMan3No ratings yet

- Ducto 6 DieDocument1 pageDucto 6 DieEmiliano RamírezNo ratings yet

- 2 FTTH Cable GjyxchDocument2 pages2 FTTH Cable GjyxchMarco AurélioNo ratings yet

- Sealing Gasket (ENKA)Document6 pagesSealing Gasket (ENKA)Apras TyoNo ratings yet

- Data Sheet Belt PU 1.5mmDocument3 pagesData Sheet Belt PU 1.5mmBaihaki StNo ratings yet

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanNo ratings yet

- Sealstar 101 Red Asbestos Jointing Gasket SheetDocument1 pageSealstar 101 Red Asbestos Jointing Gasket SheetAkshay ValaNo ratings yet

- FO de 6 12 y 24 H Span 120 TelcomfiberDocument7 pagesFO de 6 12 y 24 H Span 120 TelcomfiberWilmer MonteroNo ratings yet

- Cable Drawing and Specification Data SheetDocument4 pagesCable Drawing and Specification Data SheetJack FrostNo ratings yet

- 3a 4360Document1 page3a 4360Gunjan GadodiaNo ratings yet

- Technical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableDocument1 pageTechnical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableRasel AhmedNo ratings yet

- Technical Specification of Utp Cat 6E 4X2X23 Awg CableDocument1 pageTechnical Specification of Utp Cat 6E 4X2X23 Awg CableRasel AhmedNo ratings yet

- Ufh951xm V.1.1 01012020Document2 pagesUfh951xm V.1.1 01012020Rang DechNo ratings yet

- Gloss80 HM300 YG62Document2 pagesGloss80 HM300 YG62Vkaka AtanasoftNo ratings yet

- Xlpe Wires Test ReportDocument3 pagesXlpe Wires Test ReportVeronica De JesusNo ratings yet

- Electric Tape P029eDocument8 pagesElectric Tape P029esakthivelNo ratings yet

- TDS Container FoilDocument2 pagesTDS Container FoilVova TripolskyNo ratings yet

- 40636738TST Maeu 598844701 Advance 20190325085303Document1 page40636738TST Maeu 598844701 Advance 20190325085303Vova TripolskyNo ratings yet

- Verification:origin Customs Gov CNDocument1 pageVerification:origin Customs Gov CNVova TripolskyNo ratings yet

- Guangzhou Baiyun Darong Fine Chemical Industry Co Сертификат на маскиDocument1 pageGuangzhou Baiyun Darong Fine Chemical Industry Co Сертификат на маскиVova TripolskyNo ratings yet

- MSDS ChalcoDocument6 pagesMSDS ChalcoVova TripolskyNo ratings yet

- MSDS of Methyl Perfluorobutylisobutyl EtherDocument5 pagesMSDS of Methyl Perfluorobutylisobutyl EtherVova TripolskyNo ratings yet

- Fda 1Document3 pagesFda 1Vova TripolskyNo ratings yet

- Project - Final Project For Postgraduate Study University of AbujaDocument39 pagesProject - Final Project For Postgraduate Study University of AbujaFolorunsho AdelekeNo ratings yet

- Cadangan Membina Dan Menyiapkan Sebuah Rumah BangloDocument8 pagesCadangan Membina Dan Menyiapkan Sebuah Rumah Banglomemek gamingNo ratings yet

- GR1 - StrongholdsDocument126 pagesGR1 - StrongholdsYiğit Ünsay67% (3)

- LOD Spec 2020 Part I 2020-12-31Document272 pagesLOD Spec 2020 Part I 2020-12-31Jackie YongNo ratings yet

- Vicat Apparatus Setting Time and Consistency of Cement: StandardsDocument1 pageVicat Apparatus Setting Time and Consistency of Cement: StandardsSciencetes PlusNo ratings yet

- FINALE GFDO 6202 4b Allgemein iJOINTDocument6 pagesFINALE GFDO 6202 4b Allgemein iJOINTMohammed sabatinNo ratings yet

- Mini Project SEM 1 2021-2022Document27 pagesMini Project SEM 1 2021-2022IT'S SIMPLENo ratings yet

- Mix Design SheetDocument8 pagesMix Design SheetmudithaNo ratings yet

- Materials Log BookDocument43 pagesMaterials Log BookDaryl Badajos100% (1)

- High Speed MachiningDocument21 pagesHigh Speed MachiningRakesh NeheteNo ratings yet

- Mauritius Fire CodeDocument3 pagesMauritius Fire CodeBalgo Balgobin100% (1)

- Choose The Correct Personal Pronouns: 3. My Father Is A Farmer. Is A FarmerDocument3 pagesChoose The Correct Personal Pronouns: 3. My Father Is A Farmer. Is A FarmerAlan Gilberto AENo ratings yet

- Master Drawing ListDocument10 pagesMaster Drawing ListNethiyaaRajendranNo ratings yet

- t2 Two-Way - Slab - Design Exact With Mahbub Sir Book Details Edit by Maksud 1.4dl+1.7llDocument6 pagest2 Two-Way - Slab - Design Exact With Mahbub Sir Book Details Edit by Maksud 1.4dl+1.7llabdullah rahmanNo ratings yet

- Snag ListDocument1 pageSnag Listengr_nhelNo ratings yet

- Cebex 100Document2 pagesCebex 100Suraj shindeNo ratings yet

- Stramit Condeck HP: Product Technical ManualDocument48 pagesStramit Condeck HP: Product Technical ManualBarrasons Engineers TeamNo ratings yet

- BS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test CubesDocument10 pagesBS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test Cubesmykel_dpNo ratings yet

- Final WTP Staff Quarters-2 Bhainsa 26.08.2021Document230 pagesFinal WTP Staff Quarters-2 Bhainsa 26.08.2021BUKA RAMAKANTHNo ratings yet

- C B A A: International School of Asia and The PacificDocument9 pagesC B A A: International School of Asia and The PacificBRIAN INCOGNITONo ratings yet

- 6.temporary Work - Precast Concrete - 8 February 2019 - FINALDocument64 pages6.temporary Work - Precast Concrete - 8 February 2019 - FINALcosminNo ratings yet

- Fire Protection Systems Hensotherm - Hensomastik: e in GermDocument6 pagesFire Protection Systems Hensotherm - Hensomastik: e in GermImad QsnNo ratings yet

- Data Sheet - Joint Unions, DIN11851, ImperialDocument2 pagesData Sheet - Joint Unions, DIN11851, ImperialfedorNo ratings yet

- Bill of MaterialsDocument27 pagesBill of MaterialsAngel GrospeNo ratings yet

- Toilet BlockDocument21 pagesToilet BlocklkovijayNo ratings yet

- Kazi MD Shifun NewazDocument37 pagesKazi MD Shifun NewazMd.Bakhtiar Enam SakibNo ratings yet

- Ardency House Digital BookletDocument23 pagesArdency House Digital BookletBunnyBun2No ratings yet

- Hot Mix Asphalt Overlay Splice: (Pavement Termination Detail)Document1 pageHot Mix Asphalt Overlay Splice: (Pavement Termination Detail)JUAN RULFONo ratings yet

- Sears TowerDocument18 pagesSears Towerananya palNo ratings yet

- Clause For Seismic DesignDocument10 pagesClause For Seismic DesignFarhanah Binti FaisalNo ratings yet