Professional Documents

Culture Documents

Untitled 3

Uploaded by

JetjonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled 3

Uploaded by

JetjonCopyright:

Available Formats

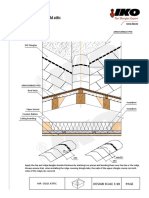

VAPOUR BARRIER

VAPOUR BARRIER WITH INCORPORATED HOT-MELT VAPOUR BARRIER WITH INCORPORATED HOT-MELT

ADHESIVE FOR THE ADHESION OF THE LAYER OF ADHESIVE FOR THE ADHESION OF THE LAYER OF

THERMAL INSULATION AND HEAT BONDING OF EXPANDED THERMAL INSULATION AND HEAT-BONDING OF

POLYSTYRENE OR POLYURETHANE, THERMOBASE PSE, HEAT-RESISTANT INSULATING PANELS OR

THERMOBASE PSE/EX AND THERMOBASE PUR PANELS THERMOBASE PUR PANELS

4b. Expanded polystyrene

4b. Heat-resistant thermal

or polyurethane thermal

insulation panels

insulation panels

4a. THERMOBASE PSE or

THERMOBASE PSE/EX or

THERMOBASE PUR 4a. Isolante termico

thermal insulation THERMOBASE PUR

STRATIFIED

ELEMENTS

1. Support

2. INDEVER or STRATIFIED

ECOVER primer ELEMENTS

3. TECTENE BV STRIP 1. Support

vapour barrier 2. INDEVER or

4a. THERMOBASE PSE ECOVER primer

or THERMOBASE PSE/ 3. PROMINENT vapour

EX or THERMOBASE barrier

PUR Thermal insulation 4a. THERMOBASE PUR

4b. Expanded thermal insulation

polystyrene or 4b. Heat-resistant

polyurethane thermal thermal insulation

1. Support insulation panels 1. Support panels

2. INDEVER 3. TECTENE BV STRIP ALU POLYESTER 2. INDEVER 3. PROMINENT ALU POLYESTER or

or ECOVER or TECTENE BV STRIP EP/V or ECOVER PROMINENT POLYESTER or PROMINENT/V

primer vapour barrier primer vapour barrier

MEMBRANES: case E MEMBRANES: case E

• TECTENE BV STRIP ALU POLYESTER case F • PROMINENT ALU POLYESTER case F

• TECTENE BV STRIP EP/V • PROMINENT POLYESTER

Reinforced elastoplastomeric polymer-bitumen vapour barrier mem- • PROMINENT/V

branes, with the upper face covered in hot-melt strips for heat-bonding Reinforced elastoplastomeric polymer-bitumen vapour barrier mem-

to the insulating panels, resistant and impermeable to gases and water branes, with the upper face covered in heat-adhesive embossings for

vapour, to be chosen according to the vapour permeability (lower for the heat-bonding to the insulating panels, resistant and impermeable to gases

ALU POLYESTER version). and water vapour, to be chosen according to the vapour permeability

These are products to be heat-bonded, which meet the specifications of (lower for the ALU POLYESTER version) or the mechanical resistance

sustainable building as by eliminating the melting pot for the oxidised bitu- (higher for POLYESTER).

men, the risks of burns are notably reduced, the laying operations on the These are products to be heat-bonded, which meet the specifications of

roof are reduced and therefore also the emission of fumes, smells and sustainable building as by eliminating the melting pot for the oxidised bitu-

noise. men, the risks of burns are notably reduced, the laying operations on the

roof are reduced and therefore also the emission of fumes, smells and

• Application method on concrete laying surface noise.

Primer. The entire surface to be coated and the vertical parts onto which

the waterproof covering must be bonded, are painted with a coat of about • Application method on concrete laying surface

300 g/m2 of INDEVER adhesion bituminous primer, or alternatively ECOV- Primer. The entire surface to be coated and the vertical parts onto which

ER water-based primer. the waterproof covering must be bonded, are painted with a coat of about

Vapour barrier. The vapour barrier sheets are overlapped longitudinally 300 g/m2 of INDEVER adhesion bituminous primer, or alternatively ECOV-

by about 6 cm along the selvages with reduced thickness, especially pro- ER water-based primer.

vided on the edge of the sheet in order to allow overlapping without any Vapour barrier. The vapour barrier sheets are overlapped longitudinally

protruding parts and to obtain a sufficiently flat laying surface for the insu- by about 6 cm along the two selvages with reduced thickness, especially

lating panels. The end overlap should be about 10 cm. provided on the edges of the sheet in order to allow overlapping without

The sheets of TECTENE BV STRIP EP/V are stuck to the laying surface any protruding parts and to obtain a sufficiently flat laying surface for the

with complete adhesion using a propane gas torch whereas TECTENE BV insulating panels, whereas the tops of the sheets are laid opposite each

STRIP EP ALU POLYESTER is spot-bonded using the same technique. other and heat-bonded onto strips of DEFEND or DEFEND ALU POLYES-

The bonding of the overlaps of both types is also performed using a torch. TER 3 mm thick and 14 cm wide, which have been previously stuck onto

The continuity of the vapour barrier on the vertical parts is carried out the laying surface.

by heat bonding, onto the edge of the bottom of the projecting parts, a The sheets of PROMINENT/V and PROMINENT POLYESTER are stuck

band of elastoplastomeric polymer-bitumen membrane reinforced with to the laying surface with complete adhesion using a propane gas torch

composite non-woven polyester fabric coupled to aluminium foil, such as whereas PROMINENT ALU POLYESTER is spot-bonded using the same

DEFEND ALU POLYESTER, in the event of laying STRIP EP ALU POLY- technique.

ESTER, or reinforced with a fibreglass felt such as DEFEND/V, in the event The bonding of the overlaps of both types is also performed using a torch.

of laying STRIP EP/V, wide enough to cover the flat part by at least 10 cm The continuity of the vapour barrier on the vertical parts is carried out by

and be turned up vertically by 5 cm more than the thickness of the envis- heat-bonding, onto the edge of the bottom of the projecting parts, a band

aged insulation. of elastoplastomeric polymer-bitumen membrane reinforced with com-

For sticking the insulating panels or THERMOBASE rolls of insulation onto posite non-woven polyester fabric coupled to aluminium foil, like DEFEND

the vapour barrier, the heat-adhesive strips, which cover their upper face, ALU POLYESTER, wide enough to cover the flat part by at least 10 cm and

must be heated with a propane gas torch activating adhesion, and the in- be turned up vertically by 5 cm more than the thickness of the envisaged

sulating layer that is pressed on top sticks to it perfectly. insulation.

For expanded polystyrene, to prevent melting, the torching must be car- For sticking the heat-resistant insulating panels or THERMOBASE PUR

ried out by appropriately trained staff. rolls of insulation above the vapour barrier, the heat-adhesive embossings,

which cover their upper face, must be heated with a propane gas torch,

activating adhesion and the insulating layer that is pressed on top sticks

to them perfectly.

Technical specification WALKABLE FLAT ROOF 7

You might also like

- Untitled 2Document1 pageUntitled 2JetjonNo ratings yet

- Guide To Wooden BuildingsDocument56 pagesGuide To Wooden BuildingsC MNo ratings yet

- Vapour Barrier: Compound StratigraphyDocument3 pagesVapour Barrier: Compound StratigraphyLavi SharmaNo ratings yet

- Untitled 1Document1 pageUntitled 1JetjonNo ratings yet

- THERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFDocument4 pagesTHERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFGeorge_Wabag_2014No ratings yet

- Industrial Hose Chemical Resistance GuideDocument32 pagesIndustrial Hose Chemical Resistance Guidemat gaiatoNo ratings yet

- Elastollan Sup ® Sup +-+Thermoplastic+Polyurethane+Elastomers+ (TPU) +-+Product+RangeDocument40 pagesElastollan Sup ® Sup +-+Thermoplastic+Polyurethane+Elastomers+ (TPU) +-+Product+RangeCeasar CapunoNo ratings yet

- Heat Shrink Sleeves Install Manual 2005 PDFDocument3 pagesHeat Shrink Sleeves Install Manual 2005 PDFkalai0% (1)

- PU Foam PresentationDocument2 pagesPU Foam PresentationDuongthithuydungNo ratings yet

- A4 Profins Corporate BrochureDocument12 pagesA4 Profins Corporate BrochureWili Nur RahmanNo ratings yet

- Flange Insulation Kits - WebDocument1 pageFlange Insulation Kits - WebabhishekNo ratings yet

- Aerospace Commercial, Defense, and Space SolutionsDocument4 pagesAerospace Commercial, Defense, and Space SolutionsgauthamNo ratings yet

- PolyflowDocument2 pagesPolyflowangel gabriel perez valdezNo ratings yet

- Series 500 PDFDocument2 pagesSeries 500 PDFChristian Veliz CamargoNo ratings yet

- Winsem2020-21 Mee4005 TH Vl2020210501802 Reference Material I 18-May-2021 l35-g1 Tg1-W-Thermal and Electron Beam PVDDocument29 pagesWinsem2020-21 Mee4005 TH Vl2020210501802 Reference Material I 18-May-2021 l35-g1 Tg1-W-Thermal and Electron Beam PVDRishav RayNo ratings yet

- 3M Fire Barrier Rated Foam FIP 1-Step: 1. Product DescriptionDocument2 pages3M Fire Barrier Rated Foam FIP 1-Step: 1. Product DescriptionAhmed Mohamed HassanNo ratings yet

- TDS Kingspan AIR-CELL Insulbreak-FRDocument2 pagesTDS Kingspan AIR-CELL Insulbreak-FRMuhkorobinNo ratings yet

- ChemTite ButterflyDocument2 pagesChemTite ButterflyDiego OrtegaNo ratings yet

- ARDEX Guide To Torch Applied MembranesDocument12 pagesARDEX Guide To Torch Applied MembranesKakat MercadoNo ratings yet

- Untitled 4Document1 pageUntitled 4JetjonNo ratings yet

- Flange Isolation Kits PDFDocument4 pagesFlange Isolation Kits PDFVILLANUEVA_DANIEL2064No ratings yet

- 00d - Metal House Teflon ValvesDocument6 pages00d - Metal House Teflon ValvesBASKARNo ratings yet

- Chemical Compatibility Guide: First Choice When Quality CountsDocument28 pagesChemical Compatibility Guide: First Choice When Quality CountsYavuz SolmazNo ratings yet

- Eng-InsulationDocument37 pagesEng-InsulationNoveljaNo ratings yet

- Eltherm Heating Mats and Jackets PDFDocument12 pagesEltherm Heating Mats and Jackets PDFKamal1616No ratings yet

- DetailsDocument2 pagesDetailsMecirdi Mohamed el AmineNo ratings yet

- ASTM C168-97 Standard Terminology Relating To Thermal InsulationDocument6 pagesASTM C168-97 Standard Terminology Relating To Thermal Insulationdodi ikhsan100% (1)

- ASTM C168 Terminology For Thermal Insulating Material PDFDocument6 pagesASTM C168 Terminology For Thermal Insulating Material PDFAbassNo ratings yet

- Proofex Torchseal 3P & 4P: Torch Applied Bitumen Waterproofing MembraneDocument3 pagesProofex Torchseal 3P & 4P: Torch Applied Bitumen Waterproofing MembraneNur AziilahNo ratings yet

- Betagum P Tech SheetDocument2 pagesBetagum P Tech SheetLayla Al MazroeiNo ratings yet

- 4.1 Hip. Cold Attic 4.1 Hip. Cold AtticDocument4 pages4.1 Hip. Cold Attic 4.1 Hip. Cold AtticAyaNo ratings yet

- Alfa Clean&coldroom BrochureDocument19 pagesAlfa Clean&coldroom BrochureSiddhant GoyalNo ratings yet

- Deflagration Flame Arrester-Endurance Burning-Proof, End-of-Line Protego Be/Hr-EDocument2 pagesDeflagration Flame Arrester-Endurance Burning-Proof, End-of-Line Protego Be/Hr-EChintan ShahNo ratings yet

- Mov Eng1Document16 pagesMov Eng1hacene omarNo ratings yet

- Title Composite Material Data Sheets TabDocument7 pagesTitle Composite Material Data Sheets TabffontanaNo ratings yet

- CUI ProductFlyer 040516Document2 pagesCUI ProductFlyer 040516Surung P. Kreison (CARBOLINE)No ratings yet

- 1 ArmaFlex - Class - 0Document4 pages1 ArmaFlex - Class - 0Bismech EngineeringNo ratings yet

- Air Fin Coolers: BGR Energy Systems LimitedDocument6 pagesAir Fin Coolers: BGR Energy Systems LimitedPrabu100% (1)

- Machining Engineering PlasticsDocument28 pagesMachining Engineering PlasticsLong NguyenNo ratings yet

- On Line Certification Directory UL 790 Curacreto TGFU.R39020 EspañolDocument5 pagesOn Line Certification Directory UL 790 Curacreto TGFU.R39020 EspañolÁngel Rodríguez IsassiNo ratings yet

- Apresentação Colombia 03.06.2005Document33 pagesApresentação Colombia 03.06.2005Davrison BorgesNo ratings yet

- CableDocument2 pagesCablesaeedNo ratings yet

- 06 CableDocument8 pages06 CableYan MALONGANo ratings yet

- Etem Catalog Tehnic Fatade Ventilate PDFDocument110 pagesEtem Catalog Tehnic Fatade Ventilate PDFNitaNo ratings yet

- Offshore Onshore Pipeline Coatingsolutions PDFDocument12 pagesOffshore Onshore Pipeline Coatingsolutions PDFfeghbalibNo ratings yet

- SKFP COEXTRUSION SOLUTIONS Jan 31 2022Document26 pagesSKFP COEXTRUSION SOLUTIONS Jan 31 2022李万福No ratings yet

- Shashi Fluoroplastiks E-BrochureDocument6 pagesShashi Fluoroplastiks E-BrochureYogesh LadolaNo ratings yet

- Danosa Descimper Desc 19Document6 pagesDanosa Descimper Desc 19Abdelilah Ouedghiri SaidiNo ratings yet

- TMP0001 ThermaSeam BrochureDocument4 pagesTMP0001 ThermaSeam BrochureniyasNo ratings yet

- Document 3Document1 pageDocument 3leoNo ratings yet

- Sanitary Diaphragm Valve: Type 672Document7 pagesSanitary Diaphragm Valve: Type 672Hilux PabloNo ratings yet

- Grease Duct ManualDocument4 pagesGrease Duct Manualsaifi2004No ratings yet

- Catalogue - Sundez Brine To Water Heat Pump 3 9kwDocument4 pagesCatalogue - Sundez Brine To Water Heat Pump 3 9kwMarko PetricNo ratings yet

- General Specifications For Common Superstructure WaterproofingDocument7 pagesGeneral Specifications For Common Superstructure WaterproofingVisam SagarNo ratings yet

- Ficha Tecnica Selladores - SealersDocument5 pagesFicha Tecnica Selladores - SealersANDRES DOMINGUEZNo ratings yet

- Tesa® ACX Seal Line: Our Solutions For Mounting of Window and Water Box SealsDocument2 pagesTesa® ACX Seal Line: Our Solutions For Mounting of Window and Water Box Sealsteam37No ratings yet

- Isoladores Polimericos para Ancoragem Ou Suspensao IngDocument2 pagesIsoladores Polimericos para Ancoragem Ou Suspensao IngRenzo Romero ArenasNo ratings yet

- Aeroflex Metric Catalogue and SubmittalDocument8 pagesAeroflex Metric Catalogue and SubmittalZeeshanNo ratings yet

- PC1 53Document148 pagesPC1 53bharatsehgal00@gmail.comNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Extracted Document 2Document1 pageExtracted Document 2JetjonNo ratings yet

- Extracted Document 1Document1 pageExtracted Document 1JetjonNo ratings yet

- TEMP2023052600504229Document6 pagesTEMP2023052600504229JetjonNo ratings yet

- Untitled 5Document1 pageUntitled 5JetjonNo ratings yet

- 215233908Document79 pages215233908JetjonNo ratings yet

- TEMP2023051518165173Document2 pagesTEMP2023051518165173JetjonNo ratings yet

- Extracted Document 5Document1 pageExtracted Document 5JetjonNo ratings yet

- TEMP2022121121273874Document2 pagesTEMP2022121121273874JetjonNo ratings yet

- Extracted Document 4Document1 pageExtracted Document 4JetjonNo ratings yet

- Untitled 3Document1 pageUntitled 3JetjonNo ratings yet

- TEMP2022121121250853Document1 pageTEMP2022121121250853JetjonNo ratings yet

- Untitled 1Document1 pageUntitled 1JetjonNo ratings yet

- Untitled 4Document1 pageUntitled 4JetjonNo ratings yet

- Untitled 2Document1 pageUntitled 2JetjonNo ratings yet

- TEMP2022101609381339Document2 pagesTEMP2022101609381339JetjonNo ratings yet

- TEMP2022111023590074Document3 pagesTEMP2022111023590074JetjonNo ratings yet

- TEMP2022101609513788Document1 pageTEMP2022101609513788JetjonNo ratings yet

- TEMP2022121121253941Document2 pagesTEMP2022121121253941JetjonNo ratings yet

- TEMP2022101223065864Document2 pagesTEMP2022101223065864JetjonNo ratings yet

- TEMP2022111023583827Document4 pagesTEMP2022111023583827JetjonNo ratings yet

- TEMP2022111100001139Document4 pagesTEMP2022111100001139JetjonNo ratings yet

- TEMP2022061513102236Document1 pageTEMP2022061513102236JetjonNo ratings yet

- Untitled 4Document1 pageUntitled 4JetjonNo ratings yet

- TEMP2022101223045736Document3 pagesTEMP2022101223045736JetjonNo ratings yet

- TEMP2022101223060766Document2 pagesTEMP2022101223060766JetjonNo ratings yet

- TEMP2022101223052392Document2 pagesTEMP2022101223052392JetjonNo ratings yet

- TEMP2022101223064026Document2 pagesTEMP2022101223064026JetjonNo ratings yet

- TEMP202206161500433Document2 pagesTEMP202206161500433JetjonNo ratings yet

- FCC Process Fundamentals & Technology EvolutionDocument42 pagesFCC Process Fundamentals & Technology Evolutionranjith_asp0% (1)

- Office Safety ChecklistDocument3 pagesOffice Safety ChecklistJaijeev Pali100% (1)

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- Primary Energy - Part B - STUDENTDocument6 pagesPrimary Energy - Part B - STUDENTHao Phan AnhNo ratings yet

- Pharmaceutical AerosolDocument42 pagesPharmaceutical AerosolAnaliza Kitongan LantayanNo ratings yet

- 1-Bolt Geometry, Symbol of Bolts in Proj (19 Files Merged) PDFDocument28 pages1-Bolt Geometry, Symbol of Bolts in Proj (19 Files Merged) PDFSimi NagyNo ratings yet

- Bathtub: What Are They?Document5 pagesBathtub: What Are They?John Paul DenajibaNo ratings yet

- DEAERATORDocument26 pagesDEAERATORSai Swaroop100% (2)

- Craftsman Tractor ManualDocument72 pagesCraftsman Tractor Manualbjhoxie106No ratings yet

- RR-1304 Vancouver Phase III Construction and Instrumentation Rev01Document17 pagesRR-1304 Vancouver Phase III Construction and Instrumentation Rev01bibore7908No ratings yet

- BETE TF MetricDocument2 pagesBETE TF Metricajo2402No ratings yet

- Summer Internship Project Budget and Budgetory Control in Sail, Bokaro Steel PlantDocument54 pagesSummer Internship Project Budget and Budgetory Control in Sail, Bokaro Steel PlantZaki ArfinNo ratings yet

- Aryan 170206134129Document21 pagesAryan 170206134129api-402308093No ratings yet

- All Ablut Glowplugs BERUDocument16 pagesAll Ablut Glowplugs BERURoman AdamNo ratings yet

- En71 SGSDocument46 pagesEn71 SGSMax Arias100% (1)

- Rotary Pallet Rack CenterDocument1 pageRotary Pallet Rack CenterKittisak SungsanaNo ratings yet

- Traymaster Boiler BookDocument7 pagesTraymaster Boiler Bookfauzi endraNo ratings yet

- The Dental LaboratoryDocument71 pagesThe Dental Laboratoryputrird67% (3)

- DFBN FilterDocument10 pagesDFBN FilterPutut SuprihartonoNo ratings yet

- Subject: Proposal For Supply and Fixing of Ultralite (Formerly Bayer Material Science) 10mm Multiwall Polycarbonate Sheet Both Sides U.V. ProtectedDocument3 pagesSubject: Proposal For Supply and Fixing of Ultralite (Formerly Bayer Material Science) 10mm Multiwall Polycarbonate Sheet Both Sides U.V. ProtectedRaghvendra AgarwalNo ratings yet

- HP Security-Matrix 2021Document44 pagesHP Security-Matrix 2021kswongNo ratings yet

- 3 Glass Bead Making ProjectsDocument11 pages3 Glass Bead Making ProjectsAngela R. Lacey100% (1)

- Chapter 01 Welcome To PLCsDocument35 pagesChapter 01 Welcome To PLCsmmonyca1981No ratings yet

- Laboratory Equipment and Skills: Recognizing Lab EquipmentDocument2 pagesLaboratory Equipment and Skills: Recognizing Lab EquipmentDinesh ManikandanNo ratings yet

- Retainning WallDocument14 pagesRetainning Wallahamedtouhid899No ratings yet

- Lambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónDocument8 pagesLambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónAlfredo MéndezNo ratings yet

- Polycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiDocument1 pagePolycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiAshwin SupeNo ratings yet

- Azkoyen Palma M Tech ManualDocument42 pagesAzkoyen Palma M Tech ManualrxNo ratings yet

- TF4L3 We 889ar PDFDocument229 pagesTF4L3 We 889ar PDFFelipe ChimborazoNo ratings yet

- TM1566 - Tecnico 8875Document419 pagesTM1566 - Tecnico 8875Luis Alberto Rivas Garcia100% (2)