Professional Documents

Culture Documents

Infratec Weld Check H en Mail

Uploaded by

Shami MudunkotuwaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Infratec Weld Check H en Mail

Uploaded by

Shami MudunkotuwaCopyright:

Available Formats

Automated Testing System WELD-CHECK

Thermography-Based Testing of Welded Joints

WELD-CHECK for testing welded connections serves as an ideal Flash Head Test Object Infrared Control and

Camera Evaluation Unit

system for automotive car body manufacturing. It is based on

the principle of active heat flow thermography with impulse

excitation and can be operated as an offline measuring cell as

well as an inline testing station. The corresponding component

is excitated with an optical high performance flash for the test.

Thermographic cameras record the resulting chronological

sequence of the heat propagation on the surface of the

component with the welded connection. The two flash heads

of the system allow the selective recording of thermal image Transmissive order

sequences in transmissive or reflexive order.

Test Object Flash Head Control and

Evaluation Unit

After starting the component testing and entering the com-

ponent detection, the thermographic measurements start

automatically. WELD-CHECK evaluates the thermal images of

the welded connections automatically in parallel with the further

recording. On request, a visual evaluation is also possible,

Infrared

which can be carried out decoupled from the recording process Camera

immediately or later by the tester.

Reflexive order

WELD-CHECK Testing System at a Glance

Used in a variety of applications

Testing laser-welded seams or resistance welding points by

means of heat flow thermography

Efficiency enhancement

Completely automatic inspection system with measurement

times of a few seconds per welding point

Defect detection

High level of test reliability by means of analysis with

extensively configurable software algorithms

Quality documentation

Integration into the local quality management through

direct preparation of measurement protocols and links to

databases

Process monitoring

Detection and classification of various defect types for

early detection of deviations in the joining process

Automated testing system

Headquarters USA office

InfraTec GmbH Phone +49 351 82876-610 InfraTec infrared LLC Phone +1 844-226-3722 (toll free)

Infrarotsensorik und Messtechnik Fax +49 351 82876-543 5048 Tennyson Pkwy. E-mail thermo@InfraTec-infrared.com

Gostritzer Straße 61 – 63 E-mail thermo@InfraTec.de Plano TX 75024 / USA www.InfraTec-infrared.com

01217 Dresden / GERMANY www.InfraTec.eu

Automated Testing System WELD-CHECK

Thermography-Based Testing of Welded Joints

Testing Software

The WELD-CHECK testing software has a modular structure and operates with database support during component testing.

Important functions

Recording the components to be tested

Automatic evaluation of the thermal images immediately

after completion of recording and simultaneously during

the implementation of further recordings

Automatic or visual evaluation of all test positions

Generating a test report and entering the results in a

quality database

Your benefits when using the WELD-CHECK testing software

Various operating modes for teach-in, testing and offline

analysis Inspection of laser welding seams with automatic evaluation

Displaying of all information in test mode with live image,

difference image, evaluation image and reference image

Extensive presentation of results

Offline mode for the parameterisation and evaluation of

large data sets

Flexible integration into the local system architecture via

universal interfaces and bus systems

Evaluation algorithms

Precise and high-resolution recording of the temperature

profile

Automatic detection of the welding points by means of the

temporal and local heat dispersion User interface for set-up mode and manual evaluation

Independence from the absolute material temperature by

evaluation of temperature differences and temperature relations

Efficient filter-algorithms for the suppression of production-related interferences and deviations

Integrated positioning and sizing as well as comparison of predefined threshold values

Hardware

High-end thermographic camera ImageIR® from InfraTec

Temperature resolution: Up to < 15 mK @ 30 °C

Frame rate: Up to 450 Hz (full-frame) / 25 kHz (sub-frame)

High-performance flash with efficient cooling

Maximum flash power of up to 6,000 J

Control and evaluation unit in 19" control cabinet

Industrial PC for testing software and system control

Integrated control and cooling unit for flash

Camera / flash head combination from InfraTec

© InfraTec 02/2018 (All stated product names and trademarks remain in property of their respective owners.)

Design, specification and technical progress subject to change without prior notice.

You might also like

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Torpedo Car MonitoringDocument6 pagesTorpedo Car MonitoringPedro GarciaNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Ladle Refractory Monitoring WebDocument6 pagesLadle Refractory Monitoring WebsusantaNo ratings yet

- Reliability Prediction from Burn-In Data Fit to Reliability ModelsFrom EverandReliability Prediction from Burn-In Data Fit to Reliability ModelsRating: 3 out of 5 stars3/5 (2)

- 2022 Price List: Power ToolsDocument7 pages2022 Price List: Power ToolsrkinspiresNo ratings yet

- Thermalspection 724Document12 pagesThermalspection 724Phong DuongNo ratings yet

- FLIR - Substation MonitoringDocument2 pagesFLIR - Substation Monitoringrony silvaNo ratings yet

- 3117 301 LCF Furnace ControllerDocument4 pages3117 301 LCF Furnace ControllerEzgi PelitNo ratings yet

- Mentor UT: A New Generation of Ultrasonic InspectionDocument8 pagesMentor UT: A New Generation of Ultrasonic InspectionMarioNo ratings yet

- ESA Easy PowerDocument4 pagesESA Easy PowerChristopher PerkinsNo ratings yet

- A Project On Automated Harness TesterDocument42 pagesA Project On Automated Harness TesterSantosh KumarNo ratings yet

- Thermal Scanning System: Proof of ConceptDocument23 pagesThermal Scanning System: Proof of ConceptSam HanieNo ratings yet

- Ronds Wireless CMS CatalogueDocument6 pagesRonds Wireless CMS Cataloguemortazavi.technicalNo ratings yet

- IP HDV6 Spec Sheet Ray Ran USDocument3 pagesIP HDV6 Spec Sheet Ray Ran USمحمد مقلدNo ratings yet

- 832 Series: Carbon/Sulfur Analysis by CombustionDocument6 pages832 Series: Carbon/Sulfur Analysis by Combustionlaoying qdNo ratings yet

- LayTec X Link In-Line FlyerDocument2 pagesLayTec X Link In-Line FlyerGorosabel GroupNo ratings yet

- Wti Datasheet en 201125Document8 pagesWti Datasheet en 201125熙槃No ratings yet

- CEIA THS PH21 Series Pharmaceuticals (90698)Document16 pagesCEIA THS PH21 Series Pharmaceuticals (90698)san dipNo ratings yet

- Mentro UT Waygate-TechnoloigesDocument8 pagesMentro UT Waygate-TechnoloigesMauricio Reyes MoralesNo ratings yet

- Plant Condition Monitoring by Using Infrared ThermographyDocument17 pagesPlant Condition Monitoring by Using Infrared ThermographyGoutham Reddy50% (2)

- Eng e WDocument4 pagesEng e WRAM KUMARNo ratings yet

- Thermasense ConferenceDocument5 pagesThermasense ConferenceAhmad UsmanNo ratings yet

- Inspectioncam - Spec Sheet v3Document2 pagesInspectioncam - Spec Sheet v3Communications ShipyardNo ratings yet

- Brochure SL 18843Document8 pagesBrochure SL 18843juan guerreroNo ratings yet

- Presentation On Numerical RelaysDocument36 pagesPresentation On Numerical RelaysSukant Kumar Mohanty0% (1)

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Manual ModusDocument410 pagesManual ModusJuanillo100% (1)

- P P H H D D: Rocessor en Anced EtectionDocument4 pagesP P H H D D: Rocessor en Anced EtectionRomly FerlandoNo ratings yet

- Home Monitoring/Automation System Using WSN by IotDocument21 pagesHome Monitoring/Automation System Using WSN by IotHarish KhanNo ratings yet

- Automatic Diagnostic System of Electrical EquipmenDocument7 pagesAutomatic Diagnostic System of Electrical EquipmenIuli BaicoianuNo ratings yet

- Vision & TighteningDocument9 pagesVision & TighteningJesús MartínezNo ratings yet

- Automotive GoniometerDocument6 pagesAutomotive GoniometerifofanahNo ratings yet

- Optris IR Camera BrochureDocument17 pagesOptris IR Camera BrochureqwertyNo ratings yet

- Thermography Application NotesDocument95 pagesThermography Application NotesGabor100% (1)

- Building Automation System: Prepared By: Team PanaginipDocument44 pagesBuilding Automation System: Prepared By: Team PanaginipLavida LocaNo ratings yet

- 2021 Price List: Power ToolsDocument7 pages2021 Price List: Power ToolsRolando Albuquerque MartinsNo ratings yet

- Functional Testing of IEC 61850Document6 pagesFunctional Testing of IEC 61850Andrei BobocNo ratings yet

- Optris IR Camera BrochureDocument17 pagesOptris IR Camera BrochuresreeNo ratings yet

- Ir Inspections Brochure TSGDocument4 pagesIr Inspections Brochure TSGapi-441649245No ratings yet

- Automate PRC-005 - PF00547Document4 pagesAutomate PRC-005 - PF00547Obey O MadzivireNo ratings yet

- Cooper Ls Datasheet Easicheck 2 0Document4 pagesCooper Ls Datasheet Easicheck 2 0Martin HermsenNo ratings yet

- Signal Conditioner: Clip. Measure. ControlDocument12 pagesSignal Conditioner: Clip. Measure. ControlMichael GuckesNo ratings yet

- MONGEMO Brochure ENUDocument12 pagesMONGEMO Brochure ENUHANIF AKBARNo ratings yet

- Mongemo Brochure EnuDocument16 pagesMongemo Brochure EnuAhmad JunaidiNo ratings yet

- Technical Product Guide V10 - Sep 2009Document84 pagesTechnical Product Guide V10 - Sep 2009Karthik SubramaniyamNo ratings yet

- iCE-3300 AAS Thermo PDFDocument2 pagesiCE-3300 AAS Thermo PDFtamiaNo ratings yet

- Temperature and Humidity SystemDocument2 pagesTemperature and Humidity SystemwaheedNo ratings yet

- gb4000c Opman 6164.1007.02 03Document48 pagesgb4000c Opman 6164.1007.02 03P Plaza MolinaNo ratings yet

- SKM 2019 Price ListDocument7 pagesSKM 2019 Price ListDaniel CamargoNo ratings yet

- Trusted Safety System PDFDocument2 pagesTrusted Safety System PDFalimohebbi1361No ratings yet

- LT-300A ACCELERATED AGING & LIFE TEST SYSTEM For LED Luminaires.Document7 pagesLT-300A ACCELERATED AGING & LIFE TEST SYSTEM For LED Luminaires.Juan Carlos Caceres FernandezNo ratings yet

- USBKIT Software Interface BrochureDocument2 pagesUSBKIT Software Interface BrochureWavelength Electronics, Inc.No ratings yet

- HOPFDocument85 pagesHOPFAl Fitra RaihanNo ratings yet

- Solutions: UV-visible SpectrosDocument16 pagesSolutions: UV-visible SpectrosMuhamad SubriNo ratings yet

- 34-SAMSS-623 Programmable Controller Based ESD SystemsDocument31 pages34-SAMSS-623 Programmable Controller Based ESD Systemscherif yahyaouiNo ratings yet

- Thermalapplication Edu-Series PDFDocument95 pagesThermalapplication Edu-Series PDFTomi GánnNo ratings yet

- ElectroPuls Controller Console and Software PDFDocument2 pagesElectroPuls Controller Console and Software PDFLeonid PastukhovNo ratings yet

- Training Ppt16Document28 pagesTraining Ppt16Kirti BhumbeeNo ratings yet

- NI CaseStudy Cs 15338Document6 pagesNI CaseStudy Cs 15338Rohit MoreNo ratings yet

- Action Plan 2023-Q1 Progress ReportDocument104 pagesAction Plan 2023-Q1 Progress ReportShami MudunkotuwaNo ratings yet

- Code of Ethics 2020 DDocument5 pagesCode of Ethics 2020 DLuis EduardoNo ratings yet

- Sex Yourself - The Woman's Guide To Mastering Masturbation and Achieving Powerful Orgasms (PDFDrive)Document227 pagesSex Yourself - The Woman's Guide To Mastering Masturbation and Achieving Powerful Orgasms (PDFDrive)Mariel FigueroaNo ratings yet

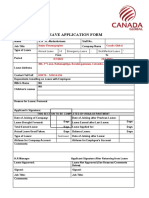

- Leave ApplicationDocument2 pagesLeave ApplicationShami MudunkotuwaNo ratings yet

- General School Rules For StudentsDocument2 pagesGeneral School Rules For StudentsShami MudunkotuwaNo ratings yet

- Diesel Generator Systems - U - S - Regulatory History and Operational and Maintenance PracticesDocument94 pagesDiesel Generator Systems - U - S - Regulatory History and Operational and Maintenance PracticesShami Mudunkotuwa100% (1)

- Cipctoro$L Urpe1Rdl: El@Uunr - $FDocument3 pagesCipctoro$L Urpe1Rdl: El@Uunr - $FShami MudunkotuwaNo ratings yet

- Transfer / Cancellation / Refund PolicyDocument1 pageTransfer / Cancellation / Refund PolicyGonzalo TelleríaNo ratings yet

- 17th July - Gazette 2184.21 - EDocument122 pages17th July - Gazette 2184.21 - EShami MudunkotuwaNo ratings yet

- Applicant Details: Department of Imports and Exports ControlDocument3 pagesApplicant Details: Department of Imports and Exports ControlShami MudunkotuwaNo ratings yet

- Application For Membership of Labse: Section 1Document4 pagesApplication For Membership of Labse: Section 1Shami MudunkotuwaNo ratings yet

- Y%S, XLD Èk Oy - KH Èk Oy - KH 2021 2021Document1 pageY%S, XLD Èk Oy - KH Èk Oy - KH 2021 2021Shami MudunkotuwaNo ratings yet

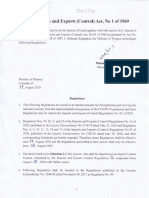

- Imports and Exports (Control) Act, No. 1 of 1969: Mahinda RajapaksaDocument45 pagesImports and Exports (Control) Act, No. 1 of 1969: Mahinda RajapaksaShami MudunkotuwaNo ratings yet

- Imports and Exports (Control) Act, No. 1 of 1969: RegulationsDocument15 pagesImports and Exports (Control) Act, No. 1 of 1969: RegulationsShami MudunkotuwaNo ratings yet

- Infrared Thermography Testing Level 1Document1 pageInfrared Thermography Testing Level 1Shami MudunkotuwaNo ratings yet

- PI Confirmation ChecklistDocument1 pagePI Confirmation ChecklistShami MudunkotuwaNo ratings yet

- The Stirling Cycle: The Ultimate Way To Generate Cooling PowerDocument2 pagesThe Stirling Cycle: The Ultimate Way To Generate Cooling PowerVIPIN THAPLIYALNo ratings yet

- Cipctoro$L Urpe1Rdl: El@Uunr - $FDocument3 pagesCipctoro$L Urpe1Rdl: El@Uunr - $FShami MudunkotuwaNo ratings yet

- Y%S, XLD Èk Oy - KH Èk Oy - KH 2021 2021Document1 pageY%S, XLD Èk Oy - KH Èk Oy - KH 2021 2021Shami MudunkotuwaNo ratings yet

- Imports and Exports (Control) Act, No. 1 of 1969: RegulationsDocument15 pagesImports and Exports (Control) Act, No. 1 of 1969: RegulationsShami MudunkotuwaNo ratings yet

- Operating InstructionsDocument3 pagesOperating InstructionsShami MudunkotuwaNo ratings yet

- Operating InstructionsDocument3 pagesOperating InstructionsShami MudunkotuwaNo ratings yet

- 17th AugDocument46 pages17th AugShami MudunkotuwaNo ratings yet

- ASNT L3 ApplicationDocument13 pagesASNT L3 ApplicationAbdur RahimNo ratings yet

- ASNT-L3 Fees PDFDocument4 pagesASNT-L3 Fees PDFElankumaran PeriakaruppanNo ratings yet

- ASNT-L3 Qualifications PDFDocument3 pagesASNT-L3 Qualifications PDFElankumaran PeriakaruppanNo ratings yet

- ASNT L3 Required FormsDocument6 pagesASNT L3 Required FormsErick PachasNo ratings yet

- NDT CP Asnt PDFDocument5 pagesNDT CP Asnt PDFG Prabhakar RajuNo ratings yet

- Online Application For Certification Guide: Do Not Begin Until You Have All Required DocumentationDocument6 pagesOnline Application For Certification Guide: Do Not Begin Until You Have All Required DocumentationizmitlimonNo ratings yet

- Testing and Commissioning Procedure For Earthing System Method StatementDocument2 pagesTesting and Commissioning Procedure For Earthing System Method StatementHumaid ShaikhNo ratings yet

- 20687B ENU TrainerHandbook PDFDocument540 pages20687B ENU TrainerHandbook PDFRodolfo Jose Moncada AriasNo ratings yet

- Anita Ekawati, S.Pd.,M.Si. SMA Negeri 4 Lahat Sumatera SelatanDocument10 pagesAnita Ekawati, S.Pd.,M.Si. SMA Negeri 4 Lahat Sumatera SelatanRolly AfriantiNo ratings yet

- Practice Problem4Document6 pagesPractice Problem4Nathaniel MendozaNo ratings yet

- Cummins Apc110tDocument4 pagesCummins Apc110tAndi AnchaNo ratings yet

- 5 Three Phase System1Document28 pages5 Three Phase System1Sayuti SidikNo ratings yet

- Quiz - 2 Solution-DP 2019Document2 pagesQuiz - 2 Solution-DP 2019dash spiderNo ratings yet

- ISO 9001 General AwarenessDocument24 pagesISO 9001 General AwarenesspvendaraNo ratings yet

- UCCX - 11 - Unified CCX Design Guide 11Document126 pagesUCCX - 11 - Unified CCX Design Guide 11yuriNo ratings yet

- Java Terminology-3157Document5 pagesJava Terminology-3157CEO OF BOLLYWOODNo ratings yet

- C3 Hydraulic DiagramDocument1 pageC3 Hydraulic DiagramMiguel GutierrezNo ratings yet

- Yhje 12 To 24 Zj6axborxDocument4 pagesYhje 12 To 24 Zj6axborxNOITIER ALBERTO GARANADOS ANo ratings yet

- Cam Gears Install PDFDocument2 pagesCam Gears Install PDFArshed RosalesNo ratings yet

- Lenovo G460 Hardware Maintenance Manual V4.0 PDFDocument91 pagesLenovo G460 Hardware Maintenance Manual V4.0 PDFhefersonNo ratings yet

- Arsl Resume Compressed 2023Document1 pageArsl Resume Compressed 2023Arslan Thaheem (Arsl)No ratings yet

- EE4188 Wireless Communications - OBTLDocument7 pagesEE4188 Wireless Communications - OBTLAaron TanNo ratings yet

- 2023-01-06 15-29-26Document9 pages2023-01-06 15-29-26Lukass PedersenNo ratings yet

- Iplug Xdma7715Document24 pagesIplug Xdma7715IPhone AppleNo ratings yet

- WSN SyllabusDocument2 pagesWSN SyllabusAnil V. WalkeNo ratings yet

- ST06Document23 pagesST06Hung HoangTheNo ratings yet

- Introduction To DC Motors: Experiment 13Document4 pagesIntroduction To DC Motors: Experiment 13Apna VeerNo ratings yet

- Microprocessor and Microcontroller Kec 502Document2 pagesMicroprocessor and Microcontroller Kec 50220ME082 Yash litoriyaNo ratings yet

- MTPDF1 - Common Specification InformationDocument34 pagesMTPDF1 - Common Specification InformationMaboo LozanoNo ratings yet

- 7473.00.ruDocument3 pages7473.00.ruMaria Carmen ValenciaNo ratings yet

- PS SB QS Deploy Tenable - SCDocument7 pagesPS SB QS Deploy Tenable - SCTiago PeNo ratings yet

- 20480A ENU TrainerHandbookDocument627 pages20480A ENU TrainerHandbookMiticuta SurubNo ratings yet

- Training Manual For National E-Government Procurement System of NepalDocument38 pagesTraining Manual For National E-Government Procurement System of NepalRanjan Raj KoiralaNo ratings yet

- Informer 37 PDFDocument32 pagesInformer 37 PDFthesmartsakthiNo ratings yet

- Introduction To Programmable Logic Controllers (PLCS)Document20 pagesIntroduction To Programmable Logic Controllers (PLCS)eyob feshaNo ratings yet

- EC Council University CatalogDocument100 pagesEC Council University CatalogTheban PerumalNo ratings yet

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityFrom EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityRating: 5 out of 5 stars5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersFrom EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersRating: 4 out of 5 stars4/5 (32)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Culture, Health and Illness: An Introduction for Health ProfessionalsFrom EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNo ratings yet

- Handbook of Hazardous Chemical PropertiesFrom EverandHandbook of Hazardous Chemical PropertiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Epidemiology and Demography in Public HealthFrom EverandEpidemiology and Demography in Public HealthJaphet KillewoRating: 5 out of 5 stars5/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)