Professional Documents

Culture Documents

PVC Suspension K-70

Uploaded by

ÜNAL AYDINCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVC Suspension K-70

Uploaded by

ÜNAL AYDINCopyright:

Available Formats

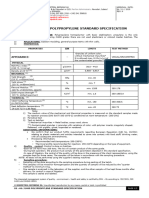

POLYVINYLCHLORIDE SUSPENSION for plastified processing

PVC K-70

GENERAL DESCRIPTION:

It is a fine, white, odourless powder, soluble in ketones and tetrahydrofuran, that is obtained

through the polymerization of vinyl chloride suspension.

TECHNICAL QUALITY CONDITIONS:

No. Technical date U/M K-70 Testing methods

1 Appearance fine white Visual

powder

2 K-value 69.0-71.0 EN ISO 1628-3:2010

3 Moisture and volatile constituents, % 0.4 ASTM D 3030-95

max.

4 Bulk density (vol.) g/cm3 0.45-0.51 ISO 60-77

5 Plasticizer absorption, min. % 95 ASTM 1755-92

6 Calcinations residues max. % 0.04 EN ISO 3451/5-02

7 Residue on 0.250 mm. sieve, max. % 1 EN ISO 4610-98

8 Residue on 0.063 mm. sieve, min. % 95 EN ISO 4610-98

6 Impurities max. No/dm2 4 EN ISO 1265-98

9 Vinyl chloride residue, max. Ppm. 1 ISO 6401-85

Note: The above characteristics are tested on an average sample collected from 5% of the

packagings in a batch.

APPLICATIONS:

PVC K-70 is recommended for plasticized profiles extrusion or calendering (footwear soles,

sheeting for outdoor upholstery use, wire and cable insulation).

PACKAGING-STORAGE:

It is packed in:

- 25kg net bags of polypropylene lined with polyethylene, (permissible limit ± 0.2kg)

- paper bags 25kg net (permissible limit ± 0.15kg), palletized and wrapped with polyethylene film

- 1000; 1100 or 1300kg big bags of polypropylene lined with polyethylene (permissible limit ± 5kg)

- silo wagons provided either by the supplier or by the customer.

The product should be stored in cool, dry and well vented areas far from inconsistent materials.

Polyvinyl chloride presents the risk of electrostatic energy storage, that is why the storage silos are

earthed.

SAFETY MEASURES:

Before handling and using this product, the personnel should be acquainted with hazards incurred.

You might also like

- Edc MembersDocument139 pagesEdc MembersArielle EstradaNo ratings yet

- Materials Engineer Test ReviewerDocument37 pagesMaterials Engineer Test ReviewerRam Gacot100% (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Method Statement For DemolitionDocument7 pagesMethod Statement For DemolitionNikita KasyanovNo ratings yet

- A380 WING RIB Feet CrackingDocument9 pagesA380 WING RIB Feet CrackinggygjhkjnlNo ratings yet

- CT5313 Quays and Jetties 2004 PDFDocument137 pagesCT5313 Quays and Jetties 2004 PDFAnand Jadoenathmisier100% (1)

- Massey Ferguson MF 373 TRACTOR Service Parts Catalogue Manual (Part Number 3311358)Document18 pagesMassey Ferguson MF 373 TRACTOR Service Parts Catalogue Manual (Part Number 3311358)qlb898316No ratings yet

- Silicone Technical TextilesDocument39 pagesSilicone Technical TextilesRahul Oza100% (4)

- In Architecture Chris Van UffelenDocument5 pagesIn Architecture Chris Van UffelenPIYUSH GAUTAM0% (1)

- Effect of Temperature Loads On Beam Design in Thermal AnalysisDocument4 pagesEffect of Temperature Loads On Beam Design in Thermal AnalysisMohammad AasimuddinNo ratings yet

- 1 3814 GY SE 901003 IS03 Technical EspecificationDocument43 pages1 3814 GY SE 901003 IS03 Technical Especificationgchaves504No ratings yet

- TDS Ausmess Lubrirec 2 PeDocument1 pageTDS Ausmess Lubrirec 2 PeJuan Sebastián Fernández RamírezNo ratings yet

- Chlorinated Polyethylene Data SheetDocument2 pagesChlorinated Polyethylene Data SheetwestmoonintNo ratings yet

- 150506T01 PVC NIC GMBHDocument15 pages150506T01 PVC NIC GMBHAthonioMourinhoNo ratings yet

- DIDP Plasticizer Properties UsesDocument2 pagesDIDP Plasticizer Properties Usessriatul2006No ratings yet

- Polipol 750 Ta H15 TDS enDocument3 pagesPolipol 750 Ta H15 TDS enjohana5c.5alvaNo ratings yet

- AlchemyDocument5 pagesAlchemySylab InstrumentsNo ratings yet

- j1400 Eng 1874Document2 pagesj1400 Eng 1874ervin87No ratings yet

- Ivan Wan ResinDocument3 pagesIvan Wan ResinmuhannadNo ratings yet

- PVC Resin TDSDocument3 pagesPVC Resin TDSLav JhaNo ratings yet

- Vitralit 1650 English Tds Panacol AdhesiveDocument4 pagesVitralit 1650 English Tds Panacol Adhesivetito3007No ratings yet

- Epofine 404 - Finehard 2404Document3 pagesEpofine 404 - Finehard 2404Karishma PrabhuNo ratings yet

- Sicomet 9020Document2 pagesSicomet 9020Gilad KorenNo ratings yet

- Licowax S FlakesDocument1 pageLicowax S Flakes王偉仲No ratings yet

- Polyfoam B-235 PIR pipe insulationDocument2 pagesPolyfoam B-235 PIR pipe insulationA MahmoodNo ratings yet

- Vayusorb™ CCDocument1 pageVayusorb™ CCManikandan SWMSNo ratings yet

- Solid Acrylic Resin Pchem Bm11: Technical Data SheetDocument1 pageSolid Acrylic Resin Pchem Bm11: Technical Data SheetDuc NguyenNo ratings yet

- Atbc Ficha TécnicaDocument2 pagesAtbc Ficha TécnicadanielaNo ratings yet

- Epvc 167GZDocument1 pageEpvc 167GZDevashish AgnihotriNo ratings yet

- Renolin CLP - PIDocument6 pagesRenolin CLP - PIDương LêNo ratings yet

- Injection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Document3 pagesInjection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Abdou BidaouiNo ratings yet

- PURINJECT 1C 55 LV Polyurethane Injection SystemDocument3 pagesPURINJECT 1C 55 LV Polyurethane Injection SystemAbdou BidaouiNo ratings yet

- VINNOL H 1545 M en 2020.07.01Document4 pagesVINNOL H 1545 M en 2020.07.01Asit RayNo ratings yet

- Vinnol H 15/45 M: Vinyl Chloride Co-And TerpolymersDocument4 pagesVinnol H 15/45 M: Vinyl Chloride Co-And TerpolymersAlvaro Nerviani AltieriNo ratings yet

- Datasheet Royal Press Gloss - 0Document1 pageDatasheet Royal Press Gloss - 0mohamed fayedNo ratings yet

- Technical Data Sheet H200Document3 pagesTechnical Data Sheet H200luis jonathan duran velazquezNo ratings yet

- Licowax® 371 FPDocument2 pagesLicowax® 371 FP王偉仲No ratings yet

- Tandy 4301Document2 pagesTandy 4301Kamal PriyanNo ratings yet

- Polyfoam B250Document2 pagesPolyfoam B250A MahmoodNo ratings yet

- TDS Polyvest MA 75Document3 pagesTDS Polyvest MA 75Fairmont Ind Quality DivisionNo ratings yet

- Winpower International Limited: ApplicationDocument2 pagesWinpower International Limited: ApplicationAHMED YOUSEFNo ratings yet

- Q8 Bitumen: High Quality Products from Kuwait Export CrudeDocument2 pagesQ8 Bitumen: High Quality Products from Kuwait Export CrudeMile BelojicaNo ratings yet

- D 329 - 99 - Rdmyos1sruq - PDFDocument3 pagesD 329 - 99 - Rdmyos1sruq - PDFgravity castNo ratings yet

- Polyfoam SS45Document71 pagesPolyfoam SS45BavishNo ratings yet

- Technical Data Sheet Chemitac 28: DescriptionDocument3 pagesTechnical Data Sheet Chemitac 28: DescriptionPhuong The NguyenNo ratings yet

- Bitoner Resin C5 BT-2104 TDSDocument2 pagesBitoner Resin C5 BT-2104 TDSdamiendamNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Tds Renolin CLP enDocument7 pagesTds Renolin CLP enrytNo ratings yet

- Licowax CDocument1 pageLicowax C王偉仲No ratings yet

- TDS of LP-40Document3 pagesTDS of LP-406f67crt5cpNo ratings yet

- TBT-100 Magnesium BoardDocument5 pagesTBT-100 Magnesium BoardAndrei PantuNo ratings yet

- EMI Shielding Silicone Rubber with Excellent ConductivityDocument1 pageEMI Shielding Silicone Rubber with Excellent Conductivityme likeNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- PDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680Document2 pagesPDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680LeoNo ratings yet

- Acrylic Polyol Resin Technical Data SheetDocument1 pageAcrylic Polyol Resin Technical Data SheetNura Alam SiddiqueNo ratings yet

- Vinnol H 15/45 M: Vinyl Chloride Co-And TerpolymersDocument4 pagesVinnol H 15/45 M: Vinyl Chloride Co-And TerpolymersAlvaro Nerviani AltieriNo ratings yet

- ANTI-OXIDANT TECH DATA BIONOX 565Document1 pageANTI-OXIDANT TECH DATA BIONOX 565Xuân Giang NguyễnNo ratings yet

- 2102TX00Document2 pages2102TX00mohamad mostafaviNo ratings yet

- CirRenew C14 LD2420DDocument3 pagesCirRenew C14 LD2420DJaime222No ratings yet

- Domalkyd 9314 60 X 478409 TDSDocument1 pageDomalkyd 9314 60 X 478409 TDSI Love MusicNo ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- TDS ACRILIC ResinDocument1 pageTDS ACRILIC ResinAji PradahNo ratings yet

- PREMIUM Hydraulic Oil 32 46 68 - TDSDocument1 pagePREMIUM Hydraulic Oil 32 46 68 - TDSazimchemNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- SYNTHETIC GEAR OIL SPECDocument4 pagesSYNTHETIC GEAR OIL SPECdfbdfbfdbfbNo ratings yet

- CR C14 LD2420KDocument3 pagesCR C14 LD2420KJaime222No ratings yet

- Technical Data Sheet: Anti-OxidantDocument1 pageTechnical Data Sheet: Anti-OxidantXuân Giang NguyễnNo ratings yet

- EPA Compliant Biodegradable Lubricant for Stern Tubes & ThrustersDocument2 pagesEPA Compliant Biodegradable Lubricant for Stern Tubes & ThrustersJosh Ndoky SantosNo ratings yet

- TDS LacovylDocument2 pagesTDS LacovylEURL CITETUBESNo ratings yet

- Technical Data for CARBOFOL HDPE 406 1,5 s/s GeomembraneDocument1 pageTechnical Data for CARBOFOL HDPE 406 1,5 s/s GeomembraneRicardo SanchezNo ratings yet

- Structural Steel For BuildingsDocument6 pagesStructural Steel For Buildingsramu karriNo ratings yet

- Whitehall Surgical Scrub Sink Three StationDocument2 pagesWhitehall Surgical Scrub Sink Three Stationcvl1983No ratings yet

- Guidance Notes ON Panelling Design & Joint Construction of Concrete SlabsDocument12 pagesGuidance Notes ON Panelling Design & Joint Construction of Concrete SlabsMohammed AlkhateebNo ratings yet

- Cost Estimate for Interlocking Tiles at Dusshera Maidan Area 1Document4 pagesCost Estimate for Interlocking Tiles at Dusshera Maidan Area 1Sandeep ChoudharyNo ratings yet

- Interpretations ASME B16.34-1998Document21 pagesInterpretations ASME B16.34-1998Claudenir AlvesNo ratings yet

- Ghalemdi Khola Hydropower Project: Site Visit Report FOR LOT-2Hydraulic Steel StructureDocument6 pagesGhalemdi Khola Hydropower Project: Site Visit Report FOR LOT-2Hydraulic Steel StructureKish Shan S SubediNo ratings yet

- Indigenous MaterialsDocument8 pagesIndigenous MaterialsStephanie ChenNo ratings yet

- Peek Compression MoldingDocument3 pagesPeek Compression MoldingSh.nasirpurNo ratings yet

- Build cost centre codes and descriptionsDocument1 pageBuild cost centre codes and descriptionsKwen Codizal MendozaNo ratings yet

- The Industrialised Building System IBSDocument12 pagesThe Industrialised Building System IBSMuhammad Asyari Mohammad Shah100% (2)

- Basement Column Design Analysis and Capacity CheckDocument3 pagesBasement Column Design Analysis and Capacity CheckPhanithNo ratings yet

- 8x10 NH 5 UnitsDocument3 pages8x10 NH 5 UnitsMantenimiento ElectroPlastNo ratings yet

- Is 1786 2008Document22 pagesIs 1786 2008Jeevan Kumar ShettyNo ratings yet

- MNT-384-15-2022-OOR-AKT-MAR-X-0001 Rev00 - 4Document24 pagesMNT-384-15-2022-OOR-AKT-MAR-X-0001 Rev00 - 4a.aaqib0704No ratings yet

- 497TC TBL315VDocument48 pages497TC TBL315VKamaldeep SinghNo ratings yet

- N.Sharma Construction provides greenhouse quotationDocument2 pagesN.Sharma Construction provides greenhouse quotationSandhya NundahNo ratings yet

- Email - Tridhaatu - Sita Sadan PDFDocument47 pagesEmail - Tridhaatu - Sita Sadan PDFvinujohnpanickerNo ratings yet

- Bye Laws For MirzapurDocument6 pagesBye Laws For MirzapurUtkarsh SharmaNo ratings yet

- Fahizpm 123Document2 pagesFahizpm 123Ali HaiderNo ratings yet

- DR - Fixit Flexi PU 270IDocument4 pagesDR - Fixit Flexi PU 270IKiran KumarNo ratings yet