Professional Documents

Culture Documents

Application Edge MV Motor Acceptance Testing

Uploaded by

Mohamed MiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Edge MV Motor Acceptance Testing

Uploaded by

Mohamed MiraCopyright:

Available Formats

APPLICATION EDGE VOLUME 1, ISSUE 7

MEDIUM VOLTAGE MOTOR ACCEPTANCE TESTING

It is the supplier’s responsibility to perform these

Medium voltage motors have been very well tests, record the test data, and issue a final test report

understood and studied for more than a century. to the equipment purchaser. These tests are usually

While manufacturing, assembling, and testing of a witnessed by the end user, or their representative, at

motor appear simple, the reality is quite the opposite. the equipment supplier’s facility or a third-party test

stand and are executed before the final installation at

the site. In limited cases, the equipment supplier will

Oftentimes, acceptance testing of motors is specified;

perform the tests without anyone witnessing them.

however, the terminology used in testing by vendors,

consultants, and operators can get intertwined The testing requirements MUST be defined at the purchase-

and end-user expectations can be misaligned with order stage of the equipment procurement cycle and NOT after.

equipment vendors’ procedures and deliverables.

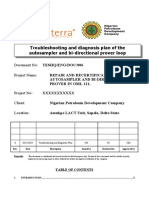

Figure 1 shows a typical MV motor- and VFD-driven

This application edge series outlines what a factory

system. In order to test this system, an end user can

acceptance test is, the different kinds of testing

make a selection from up to four types of testing

available for motors, industry standards that govern

varying in breadth and scope as shown below.

motor testing, and recommendations for the type of

This paper will focus only on motor testing (yellow

test to select.

highlight).

Factory acceptance testing (FAT) – definition

Types of electric motor testing

A factory acceptance test, commonly known as

Unlike VFDs, electric motors have several widely

acceptance testing, is a series of tests performed by

accepted types of testing. Motor testing includes “in

the equipment supplier. The purpose of these tests

process” testing, and the tests may be witnessed or

is to demonstrate to the end user that the supplier

not depending on end-user preference. Any test may

meets all the contractual agreements, which consist

be witnessed, unwitnessed, or “observed.” A witness

of the latest sets of drawings, data sheets, project

test is one where the test stand is set up and time

specifications, and any deviations that have been

allotted for the test to be witnessed.

approved by the end user or their representative.

VFD Driven

Input Air/Water Equipment

circuit Cooled

breaker

Unity Voltage, 60Hz

Motor

1800 RPM

20,000HP

Input Drive

Isolation

Transformer

(Outdoor/Indoor)

VFD Aux Services /

Motor Field Excitation

Control I/O

480 V , 3Ph 120V , 1Ph

480V MCC Lineup for

Aux Loads

Variable Frequency Drive Combined Motor and VFD Complete Unit Testing

Motor ONLY FAT FAT/Integrated Factory

ONLY FAT Acceptance Testing (IFAT) “String Test” FAT

Figure 1: MV motor and VFD driven system

The “complete” test is a very common part of a

NEMA MG-1 Sec. 20.16.2 API 541 Sec. 6.3.2 FAT to be witnessed. Described in API 541 5th ed.,

section 6.3.5.1 outlines seven additional tests to the

No Load Current No Load Current

routine test list. Note, NEMA MG1 does not have a

No Load Power

Locked Rotor Current By “complete” test definition. In some cases, if multiple

Calculation identical motors are built at the same time, a routine

Ac High Pot. Test Winding and test will be done for all motors, and one complete test

No Load Speed

Accessories will be witnessed. The complete test provides a good

High Potential Test Insulation Resistance baseline for the motor so that 5-10 years down the

line, the maintenance personnel can compare what

None Winding Resistance

changes time and operation have made to the motor.

None Vibration Table 2 compares a typical complete test to an API-

None Bearing Insulation

specified complete test.

None Bearing Temperature Test

None Inspection Of Oil and Oil Supply

Typical complete test API 541 Sec.: 6.3.5.1

Bearing Journal Clearance and

None Efficiency Efficiency

Alignment Pre-Test (Optional)

Locked Rotor Current Locked Rotor Current

Post-testing Inspection of

None

Bearing and Journal Clearance

Full-load Current and Slip Full-load Current And Slip

Measurement of Machine Air Determine the Breakdown Determine the Breakdown

None

Gap (Optional) Torque Torque

Shaft Voltage and Current None Determine Speed Torque Curve

None

Measurements

None Noise Level

Table 1: Comparison of routine test items and measurements by

NEMA and API standards Table 2: Comparison of typical complete test and API

complete test

An observed test is performed during the course of

motor production, and the purchaser’s representative Special tests can be selected by the end user on a

must be present when the factory performs the test. case-by-case basis. A common “in process” test that

Note, an observed test is usually not a “hold point” in is special is the sacrificial coil test. In this test, the

the motor manufacturing schedule. Typically, the end coils are placed in the vacuum pressure impregnation

user will get notice of the approximate time for the (VPI) tank at the same time as the stator and the

test. This test can be used as an inexpensive option rotor. The coils are separate from the motor coil that

rather than formal witness testing; however, it is not can be tested and cut apart to confirm the VPI was

as formal as a full witness test. successful. The end user may require the coils to be

sent to an independent laboratory for verification. The

Common terms in motor testing, such as “routine” test coil reports should be available before the FAT to

and “complete” test are defined in standards such ensure the motor has been properly insulated during

as NEMA MG-1 [1], IEEE 112 [2], and the IEC 60034- the VPI process with testing and visual inspection.

2-1 [3]. A “routine test,” as the name suggests, is

normally or routinely done by the motor manufacturer Other special tests may be done based on the specific

on every motor whether the end user requests it application. It is important to understand that some

or not. However, depending on which one of the special tests can have an adverse effect on the life of

foregoing standards is applied to the motor, routine the motor. The API standards for motors, such as 541

test items can vary in scope. For example, routine test and 546, are a good guide for terminology, acceptance

items defined in API 541 5th ed. [4] are significantly criteria, why the test is done, and the impact that a

different from routine tests described in NEMA MG-1. test will have on the life of the motor. Understanding

Table 1 compares the test items of the two standards. which test may be harmful to the motor should be

part of the preparation. A technician may want to

Hence, it is critical that the testing standard be defined rerun a test for some reason, and that should be

and agreed upon before the contract for procurement considered carefully if the test can reduce the life of

is issued. This is considered a minimum test. the motor.

The IEEE 112 standard is a test procedure that References

describes motor efficiency testing. The method F is

common for very large motors. It also describes most 1. NEMA Standards Publication MG 1-2011, Motors

other common poly-phase motor tests. For testing and Generators, Rosslyn, VA: National Electrical

large motors, NEMA MG 1 Sec. 20.16.1 specifically Manufacturers Association, 2011.

indicates that testing be done per IEEE 112.

2. IEEE Standard 112-2004: Standard test procedure

IEC 60034, with all its parts, is similar to NEMA MG for polyphase induction motors and generators.

1. IEC 60034-2 is an efficiency testing standard which

3. IEC 60034-2-1:2014: Rotating electrical machines –

IEEE has published a number of papers comparing

Part 2-1: Standard methods for determining losses

the different methods. For the purposes of this article,

and efficiency from tests (excluding machines for

the efficiency standard should be defined at the time

traction vehicles)

of the contract, and the witnessing engineer should be

familiar with the procedure and acceptance criteria. 4. API Standard 541: Form-Wound Squirrel Cage

Induction Motors – 375 kW (500 HP) and Larger,

Recommendations for motor testing

5th Edition, 2014, American Petroleum Institute.

For NEMA motors (>500 HP), every manufacturer will

have a set of predefined inspection and test plans

(ITPs). Regardless of the type of motor procured, the

API 541 standard for induction motors and API 546 for

synchronous motors is a good reference document to

use to specify testing. The API standard provides a list

of tests, testing procedures, acceptance criteria, and a

guide in the annex for the significance of each test. If

there were a “standard” test, it would be the routine

test that is defined in most motor standards as the

“factory” normal or routine test. These tests are much

the same as for a small 1HP motor, so they should

never be seen as adequate for an MV motor.

It is not common to do a full-load test of large multi-

megawatt motors. Setting up a load to run long

enough for the motor to rise up to full temperature

can take hours or even a day, leading to a lot of

wasted energy and expense. Full-load testing does

not provide any real insight into a motor’s quality or

performance that the short-duration testing doesn’t

already provide.

+1-540-283-2300 www.tmeic.com

2060 Cook Drive • Salem, VA 24153 USA

AE-120216-2 Rev 0

© TMEIC Corporation. All Rights Reserved

You might also like

- Application Edge-MV VFDs Acceptance TestingDocument3 pagesApplication Edge-MV VFDs Acceptance TestingThọ NguyễnNo ratings yet

- DRI800 Inspection and TestingDocument21 pagesDRI800 Inspection and Testingmika cabelloNo ratings yet

- L&T Switchboards Tested For ASTA Certification (Jan - Mar 03)Document4 pagesL&T Switchboards Tested For ASTA Certification (Jan - Mar 03)santhoshNo ratings yet

- 13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The Manufacturer - EEPDocument1 page13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The Manufacturer - EEPkakagoNo ratings yet

- Monitoring and Diagnostics For GeneratorsDocument4 pagesMonitoring and Diagnostics For GeneratorsEdson França RodriguesNo ratings yet

- MeasurementBestPractices WillwerthHammond 0612Document18 pagesMeasurementBestPractices WillwerthHammond 0612andres monederoNo ratings yet

- Dow Capacitor Maintenance ProceduresDocument5 pagesDow Capacitor Maintenance ProceduresMohammad QureshiNo ratings yet

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Dri en 800Document20 pagesDri en 800pkolNo ratings yet

- Factory Test Off Meduim VoltageDocument6 pagesFactory Test Off Meduim Voltagem khNo ratings yet

- EPS Startup Test Procedure - SECDocument45 pagesEPS Startup Test Procedure - SECEng Zaid NawaysehNo ratings yet

- G7M-0670-00 - Off-Line Maintenance & Acceptance Testing Procedures For Synchronous MotorsDocument18 pagesG7M-0670-00 - Off-Line Maintenance & Acceptance Testing Procedures For Synchronous MotorsMohammad Qureshi100% (1)

- Ausgrid Utiltiy Cable Test Plan 2017Document31 pagesAusgrid Utiltiy Cable Test Plan 2017Ali NaderianNo ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- POWER TRANSFORMER TESTINGDocument14 pagesPOWER TRANSFORMER TESTINGRahim KhanNo ratings yet

- Specifying Generator TestingDocument4 pagesSpecifying Generator TestingAmit BiswasNo ratings yet

- Powerflex 70 Adjustable Frequency Ac Drive: Installation InstructionsDocument52 pagesPowerflex 70 Adjustable Frequency Ac Drive: Installation InstructionsTâm ĐoànNo ratings yet

- Valves CutsheetDocument1 pageValves CutsheetAntony PrabhakaranNo ratings yet

- Capacitor Bank TestingDocument8 pagesCapacitor Bank TestingIranthaMuthuNo ratings yet

- Motor Surge Test ProcedureDocument2 pagesMotor Surge Test ProcedureMohammad QureshiNo ratings yet

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesDocument9 pagesStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhNo ratings yet

- Ee 04 946Document21 pagesEe 04 946Carlos FigueiredoNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- Con Edison EO-10904Document20 pagesCon Edison EO-10904fakename mcgeeNo ratings yet

- STP-ELECT-DB Distribution Board TestDocument18 pagesSTP-ELECT-DB Distribution Board TestYouwan LeeNo ratings yet

- MVAR Test ProcedureDocument11 pagesMVAR Test ProcedureSuresh BabuNo ratings yet

- On-Line Capacitance and Dissipation Factor MonitorDocument13 pagesOn-Line Capacitance and Dissipation Factor MonitorAnurag PugaliaNo ratings yet

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- 307 Lapp - NFPA79-Whitepaper-2018Document8 pages307 Lapp - NFPA79-Whitepaper-2018Милан100% (1)

- Chafai 2013Document6 pagesChafai 2013Mohamed Daw HamoudaNo ratings yet

- Manual CMC 356 OMICRONDocument12 pagesManual CMC 356 OMICRONRusber Michel Llama FloresNo ratings yet

- Low Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesDocument2 pagesLow Voltage Ride-Through (LVRT) Testing of Distributed Generation SourcesgoyalmanojNo ratings yet

- Maxon DC Motormaxon DC MotorDocument88 pagesMaxon DC Motormaxon DC MotorDamien RIGUTTONo ratings yet

- Condition tests motorsDocument13 pagesCondition tests motorsYogananda Madhava SettyNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNo ratings yet

- Checklist Testing and Inspection With Interconnection-Version 1 0 August 2015Document32 pagesChecklist Testing and Inspection With Interconnection-Version 1 0 August 2015Sunil SinghNo ratings yet

- Type Tested Solutions in Sub DistributionDocument2 pagesType Tested Solutions in Sub DistributionHassanNo ratings yet

- PTM WhatsNew V4 - 10 ENUDocument30 pagesPTM WhatsNew V4 - 10 ENUYusuf BhikhapurwalaNo ratings yet

- G7M-1131-00 - OFF-LINE MAINTENANCE PROCEDURE FOR MORE THAN 1kV CIRCUIT BREAKERSDocument9 pagesG7M-1131-00 - OFF-LINE MAINTENANCE PROCEDURE FOR MORE THAN 1kV CIRCUIT BREAKERSMohammad QureshiNo ratings yet

- Inspection and Testing Transformer InstallationsDocument37 pagesInspection and Testing Transformer InstallationsJellyn Base100% (1)

- EXP3000-EXP3000R ExplorerDocument4 pagesEXP3000-EXP3000R ExplorerkarthimeenaNo ratings yet

- A Novel Approach To Detection of Some Parameters For IMDocument6 pagesA Novel Approach To Detection of Some Parameters For IMsajs201No ratings yet

- Sabp G 006Document8 pagesSabp G 006Li PengNo ratings yet

- Ceiling Fan Laboratory Guidance ManualDocument35 pagesCeiling Fan Laboratory Guidance ManualSsdssddNo ratings yet

- Sec16 - Electrical Construction Checkout and TestingDocument13 pagesSec16 - Electrical Construction Checkout and TestingYusufNo ratings yet

- Motor Data: IMAGE 2: PDIV ChartDocument2 pagesMotor Data: IMAGE 2: PDIV ChartAMITAVA RAYNo ratings yet

- Ur E10 Rev6 pdf2451 PDFDocument10 pagesUr E10 Rev6 pdf2451 PDFJoannes Lenny EstibeiroNo ratings yet

- Testing and Commissioning ProcedureDocument7 pagesTesting and Commissioning ProcedurepdrichNo ratings yet

- Delta Manual Control UG - V02Document24 pagesDelta Manual Control UG - V02Adrián Darío Nieves LeyvaNo ratings yet

- IP-16-14-01 Standard LV Variable Frequency DrivesDocument6 pagesIP-16-14-01 Standard LV Variable Frequency DrivesHarold Gutierrez MartinezNo ratings yet

- Testing and Commissioning of Electrical Equipment ProceduresDocument45 pagesTesting and Commissioning of Electrical Equipment ProceduresJonathan Feruelo100% (1)

- Troubleshooting Plan - Autosampler and BD Prover Repair 07 12 2021Document7 pagesTroubleshooting Plan - Autosampler and BD Prover Repair 07 12 2021Gilbert NdibeNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- 3M Cable Joint Data SheetDocument4 pages3M Cable Joint Data SheetMohamed MiraNo ratings yet

- Preview2 9 - 5-2018 CTC 2015Document76 pagesPreview2 9 - 5-2018 CTC 2015Mohamed MiraNo ratings yet

- Earthing in Electrical Network - Purpose, Methods and Measurement EEPDocument13 pagesEarthing in Electrical Network - Purpose, Methods and Measurement EEPMohamed MiraNo ratings yet

- Fundamental Characteristics of A Circuit-Breaker - Electrical Installation GuideDocument5 pagesFundamental Characteristics of A Circuit-Breaker - Electrical Installation GuideMohamed MiraNo ratings yet

- Installation manual for KC-series solar modulesDocument4 pagesInstallation manual for KC-series solar modulesMohamed MiraNo ratings yet

- Nema Insulation ClassesDocument6 pagesNema Insulation ClassesMohamed MiraNo ratings yet

- NEMA Insulation Classes For Motors - Drives and AutomationDocument7 pagesNEMA Insulation Classes For Motors - Drives and AutomationMohamed MiraNo ratings yet

- The Importance of Measuring InductanceDocument8 pagesThe Importance of Measuring InductanceMohamed MiraNo ratings yet

- Star-Delta Starter Design Tool - Wye-Delta Starter Design ToolDocument8 pagesStar-Delta Starter Design Tool - Wye-Delta Starter Design ToolMohamed MiraNo ratings yet

- Emergency Power System UPSDocument16 pagesEmergency Power System UPSMohamed MiraNo ratings yet

- Star-Delta Starter Design Tool - Wye-Delta Starter Design ToolDocument8 pagesStar-Delta Starter Design Tool - Wye-Delta Starter Design ToolMohamed MiraNo ratings yet

- Electric Motors: Shell Global SolutionsDocument37 pagesElectric Motors: Shell Global SolutionsMohamed MiraNo ratings yet

- UPSguideDocument69 pagesUPSguideMohamed MiraNo ratings yet

- Module 6.4 Switchgear SpecificationDocument7 pagesModule 6.4 Switchgear SpecificationMohamed MiraNo ratings yet

- Module 6.3 Switchgear Performance RequirementsDocument28 pagesModule 6.3 Switchgear Performance RequirementsMohamed MiraNo ratings yet

- Introduction To Robotics: Why Build Robots?Document10 pagesIntroduction To Robotics: Why Build Robots?api-115728880No ratings yet

- Foreign Interests Shaped the War of the PacificDocument24 pagesForeign Interests Shaped the War of the PacificcustionesNo ratings yet

- IMU 25,26 Oct 2014 (Other) ResultDocument2,582 pagesIMU 25,26 Oct 2014 (Other) ResultMuhammadFarhanShakee100% (1)

- Multimedia ExerciseDocument1 pageMultimedia ExercisemskgghNo ratings yet

- Natural Resources Management IntroDocument14 pagesNatural Resources Management IntroJoaquin David Magana100% (2)

- PDF Penstock Manual DLDocument160 pagesPDF Penstock Manual DLWilmer Fernando DuarteNo ratings yet

- Group No 5 - Ultratech - Jaypee 20th Sep-1Document23 pagesGroup No 5 - Ultratech - Jaypee 20th Sep-1Snehal100% (1)

- 5-Page Proposal Writing GuideDocument2 pages5-Page Proposal Writing GuideJason McCoyNo ratings yet

- The Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Document656 pagesThe Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Rita PereiraNo ratings yet

- Kisan Seva Android Application: ISSN 2395-1621Document4 pagesKisan Seva Android Application: ISSN 2395-1621Survive YouNo ratings yet

- Test Bank For Oral Pathology 7th Edition by RegeziDocument11 pagesTest Bank For Oral Pathology 7th Edition by RegeziSteve Isola100% (23)

- ITC Gardenia LavendreriaDocument6 pagesITC Gardenia LavendreriaMuskan AgarwalNo ratings yet

- September/News/Septiembre 2013: P.O. Box 44 WWW - Hecatomberecords.esDocument7 pagesSeptember/News/Septiembre 2013: P.O. Box 44 WWW - Hecatomberecords.eshecatomberecordsNo ratings yet

- Lab Skill Workbook - Applied Physics - Seph0009 07-12-2023Document87 pagesLab Skill Workbook - Applied Physics - Seph0009 07-12-2023rahulsaitalasilaNo ratings yet

- Power2 Leading The Way in Two-Stage TurbochargingDocument4 pagesPower2 Leading The Way in Two-Stage TurbochargingМаксим АгеевNo ratings yet

- Soal Mid Ganjil 14Document4 pagesSoal Mid Ganjil 14Anonymous a2C6YgevfNo ratings yet

- Lighting Design: Azhar Ayyub - Akshay Chaudhary - Shahbaz AfzalDocument27 pagesLighting Design: Azhar Ayyub - Akshay Chaudhary - Shahbaz Afzalshahbaz AfzalNo ratings yet

- Seniors Playing Record Nov 20 To Dec 2021 New SystemDocument6 pagesSeniors Playing Record Nov 20 To Dec 2021 New Systemapi-313355217No ratings yet

- Guide to Preparing STEM Fellowship ApplicationsDocument14 pagesGuide to Preparing STEM Fellowship ApplicationsNurrahmiNo ratings yet

- Free PPT Templates: Insert The Title of Your Presentation HereDocument10 pagesFree PPT Templates: Insert The Title of Your Presentation HereMaybelyn Medrano100% (1)

- Sat Psat Word GamesDocument166 pagesSat Psat Word Gamesapi-360773187No ratings yet

- Faculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Document3 pagesFaculty of Health and Medical Sciences: Academic Terms and Fee Schedule For 2022Sadwi MulatsihNo ratings yet

- Course Registration Slip MBA 2023Document3 pagesCourse Registration Slip MBA 2023Piyush RaghuwanshiNo ratings yet

- Quotes by Swami VivekanandaDocument6 pagesQuotes by Swami Vivekanandasundaram108No ratings yet

- IN THE COURT OF - SUIT/APPEAL No. - JURISDICTION OF 2017Document1 pageIN THE COURT OF - SUIT/APPEAL No. - JURISDICTION OF 2017Adv Pooja AroraNo ratings yet

- Curative Petition Draft TutorialDocument4 pagesCurative Petition Draft TutorialBhavya SinghNo ratings yet

- Pornhub 2021 Year in Review defines searchesDocument57 pagesPornhub 2021 Year in Review defines searchesRickPornAdams RickNo ratings yet

- Housing Inequality Causes and SolutionsDocument5 pagesHousing Inequality Causes and SolutionsFredrickNo ratings yet

- Cing - Common Interface For NMR Structure Generation: Results 1 - 10 of 978Document3 pagesCing - Common Interface For NMR Structure Generation: Results 1 - 10 of 978Judap FlocNo ratings yet