Professional Documents

Culture Documents

Design of Steel Tension Members: Types, Failure Modes, Shear Lag & Connections

Uploaded by

Gopal UttupurathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Steel Tension Members: Types, Failure Modes, Shear Lag & Connections

Uploaded by

Gopal UttupurathCopyright:

Available Formats

CE401 Design of Steel Structures Module 2

MODULE 2

Tension members-Types of sections – net area- design of tension members- concept of shear

lag-use of lug angle-connections in tension members

1. TENSION MEMBERS

Tension members are linear members in which axial forces act so as to elongate (stretch) the member.

A rope, for example, is a tension member. Tension members carry loads most efficiently, since the

entire cross section is subjected to uniform stress. Unlike compression members, they do not fail by

buckling. Ties of trusses (Fig 1(a)), suspenders of cable stayed and suspension bridges (Fig.1(b)),

suspenders of buildings systems hung from a central core (Fig.4.1(c)) (such buildings are used in

earthquake prone zones as a way of minimising inertia forces on the structure), and sag rods of roof

purlins (Fig.1(d)) are other examples of tension members.

Fig.1: Tension Members in Structures

Tension members are also encountered as bracings used for the lateral load resistance. In X type

bracings (Fig.1(e)) the member which is under tension, due to lateral load acting in one direction,

undergoes compressive force, when the direction of the lateral load is changed and vice versa. Hence,

such members may have to be designed to resist tensile and compressive forces.

The tension members can have a variety of cross sections. The single angle and double angle sections

(Fig.2(a)) are used in light roof trusses as in industrial buildings. The tension members in bridge

trusses are made of channels or I sections (Fig.2(b) and (c)), acting individually or built-up. The

circular rods (Fig.2(d)) are used in bracings designed to resist loads in tension only. They buckle at

MEA ENGINEERING COLLEGE 1

CE401 Design of Steel Structures Module 2

very low compression and are not considered effective. Steel wire ropes are used as suspenders in

the cable suspended bridges and as main stays in the cable-stayed bridges.

Fig.2: Cross Sections of Tension Members

2. MODES OF FAILURE

The different modes of failure in tension members are:

i) Gross Section Yielding – Considerable deformation of member in longitudinal direction takes

place before it fractures making the structure unserviceable (as per Cl.6.2 of IS 800:2007).

ii) Net Section Rupture – Rupture occurs when the net cross-section of member reaches ultimate

stress (as per Cl.6.3 of IS 800:2007).

iii) Block Shear Failure – A segment of block material at the end of members shears out (as per

Cl.6.4 of IS 800:2007).

MEA ENGINEERING COLLEGE 2

CE401 Design of Steel Structures Module 2

3. SLENDERNESS RATIO (λ)

Unsupported Length

λ=

Least Radius of Gyration

4. DESIGN STEPS

Design strength of tension member is smaller of the above three failures. The following steps may

be followed:

1. Required gross area is also determined by

Tdg .γm0

Ag =

fy

2. Net area calculated is increased by 25-40% to compute gross cross-section area.

3. Choose a section.

4. Number of bolts per connection is calculated and are arranged in suitable pattern and net area

of section is determined.

5. Minimum tensile strength of the member is determined.

6. Check for slenderness ratio.

5. CONCEPT OF SHEAR LAG

The non-uniform stress distribution that occurs in a tension member adjacent to a connection, in

which all elements of the cross section are not directly connected, is commonly referred to as the

shear lag effect. In other words, it is a phenomenon in which the stiffer or rigid regions of the

structure or structural component attract more stresses to be unevenly distributed over the cross

section of the structure or structural component.

MEA ENGINEERING COLLEGE 3

CE401 Design of Steel Structures Module 2

6. USE OF LUG ANGLE

• Lug angle is small piece of angle used to connect outstand legs of the members to the gusset plate.

• The purpose of lug angle is to reduce the length of connection to the gusset plate and to reduce

shear lag effect.

• If lug angle is used then the unconnected length of main angle behave like a connected leg and

entire cross section area of the angle become effective in resisting tension. So if lug angle is used,

then efficiency of the tension member increases because it reduces shear lag effect.

• If lug angle is used the resultant reaction at bolt location 1 and 2 pass through CG of cross section.

Since action and reaction pass through CG of angle, stress and strain distribution are uniform

hence no shear lag.

• By using lug angles there will be saving in gusset plate, but it is upset by additional fasteners and

angle required. Hence nowadays it is not preferred.

• IS 800-2007 specifications for lug angles are given in Cl.10.12.

MEA ENGINEERING COLLEGE 4

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Chapter Two, Tension Members PDFDocument10 pagesChapter Two, Tension Members PDFZeleke TaimuNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Connection AnalysisDocument13 pagesConnection Analysispavan kumar tNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- 2 Tension MembersDocument13 pages2 Tension MembersAbel MulugetaNo ratings yet

- Mahalakshmi: Engineering CollegeDocument30 pagesMahalakshmi: Engineering CollegeSawan HussainNo ratings yet

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3Greg Rabulan100% (1)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- Steel Chap5 Ultimate Limit StateDocument35 pagesSteel Chap5 Ultimate Limit StateMesfin Derbew86% (7)

- Dr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Document41 pagesDr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Seifeldin Ali MarzoukNo ratings yet

- Lecture-6 Tension MembersDocument90 pagesLecture-6 Tension MembersMuhammad Jawad Ul HaqNo ratings yet

- Lateral TorsionalBucklingOfSteelBeamDocument5 pagesLateral TorsionalBucklingOfSteelBeammhmdwalid95No ratings yet

- Chapter 2 - Tension MembersDocument13 pagesChapter 2 - Tension MembersSami IGNo ratings yet

- Design Considerations for Prestressed ConcreteDocument23 pagesDesign Considerations for Prestressed ConcreteglaydelleNo ratings yet

- Module 9-Ductile Frame BuildingsDocument20 pagesModule 9-Ductile Frame BuildingsThomas John Doblas AgrabioNo ratings yet

- Unit 3Document29 pagesUnit 3ashok Pradhan100% (1)

- Design of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil EngineerDocument60 pagesDesign of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil Engineerpareen9No ratings yet

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNo ratings yet

- Composite Structures Full Notes Part 3 PDFDocument23 pagesComposite Structures Full Notes Part 3 PDFsvnNo ratings yet

- Earthquake Resistant Design of Steel StructuresDocument12 pagesEarthquake Resistant Design of Steel StructuresFranklin GarciaNo ratings yet

- Grillage Analysis of Structures Consist of Steel I-BeamsDocument17 pagesGrillage Analysis of Structures Consist of Steel I-Beamsjust_u_prettyNo ratings yet

- CE2352 DSS 2 Marks With AnswerDocument33 pagesCE2352 DSS 2 Marks With Answerkavithamartin28No ratings yet

- Biaxial Bending of Steel Angle Section PDFDocument3 pagesBiaxial Bending of Steel Angle Section PDFImam NakhrowiNo ratings yet

- A Study of R.C.C. Beam-Column Connection Subjected To PDFDocument7 pagesA Study of R.C.C. Beam-Column Connection Subjected To PDFInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Seminar On Shear ConnectorsDocument37 pagesSeminar On Shear Connectorssanjaymits20% (1)

- AIJ Proposal (ACI SP123)Document19 pagesAIJ Proposal (ACI SP123)hbookNo ratings yet

- Study of Reinforced Concrete Beam-Column JointDocument4 pagesStudy of Reinforced Concrete Beam-Column JointChua ZhenyuNo ratings yet

- Study On Effective Bracing Systems For High Rise Steel StructuresDocument7 pagesStudy On Effective Bracing Systems For High Rise Steel StructuresSaurabh PednekarNo ratings yet

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3B.A H100% (1)

- TGN-D-02 Fatigue Improvement of Welded StructuresDocument10 pagesTGN-D-02 Fatigue Improvement of Welded StructuresakuntayNo ratings yet

- Chapter 2 STR 4 Torsion in BeamsDocument17 pagesChapter 2 STR 4 Torsion in BeamsAbera MamoNo ratings yet

- A New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsDocument18 pagesA New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsRosNo ratings yet

- 1.1 General: Strengthening of Beam Column Joint Using External Post Tensioned Rods Seminar Report - 2016Document25 pages1.1 General: Strengthening of Beam Column Joint Using External Post Tensioned Rods Seminar Report - 2016NITHYA NANDANANNo ratings yet

- Design and Detailing of Seismic Connections For Braced Frame StructuresDocument19 pagesDesign and Detailing of Seismic Connections For Braced Frame StructuresDavid SantiagoNo ratings yet

- Hot Rolled Steel ConnectionsDocument16 pagesHot Rolled Steel ConnectionsakhileshgojeNo ratings yet

- Lecture 2 (Material and Basic Prestressing)Document22 pagesLecture 2 (Material and Basic Prestressing)Adam SalimiNo ratings yet

- A - Review-Behavior - of - Reinforced - Concrete - Exterior - Beam-Column ConnectionsDocument12 pagesA - Review-Behavior - of - Reinforced - Concrete - Exterior - Beam-Column ConnectionsMekides KassayeNo ratings yet

- Module - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State ofDocument12 pagesModule - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State of2BA19CV059 Rakshita SarangmathNo ratings yet

- Topic 2 Section PropertiesDocument53 pagesTopic 2 Section PropertiesAmirul AshrafNo ratings yet

- A Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic LoadingDocument9 pagesA Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic Loadingمحمد تانزيم ابراهيمNo ratings yet

- Distribution of Strains and Stresses Across A Cross-Section and General Design EquationsDocument13 pagesDistribution of Strains and Stresses Across A Cross-Section and General Design EquationskingNo ratings yet

- Building Frame Bridge Bent Structural WallDocument9 pagesBuilding Frame Bridge Bent Structural WallpmergosNo ratings yet

- 07 QUTStudentConnectionDocument26 pages07 QUTStudentConnectionThaiNguyenNo ratings yet

- Chapter II - Tension Members.(0)Document35 pagesChapter II - Tension Members.(0)getachewkassa2123No ratings yet

- A New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesDocument6 pagesA New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesIoana KruckeNo ratings yet

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2Document36 pagesSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting Frames 2m7j7a7No ratings yet

- Unit 1 - NotesDocument19 pagesUnit 1 - NotesAristotle SironNo ratings yet

- Lecture Notes Structural Steel DesignDocument26 pagesLecture Notes Structural Steel DesignPeter Jean-jacques100% (1)

- Advance Design - Bracing Members Design According To Eurocode 3Document8 pagesAdvance Design - Bracing Members Design According To Eurocode 3gemo_n_fabrice69No ratings yet

- Composite Beam DesignDocument42 pagesComposite Beam Designbsitler100% (1)

- Tension MemberDocument35 pagesTension MemberLUGHANO NGAJILONo ratings yet

- Course Name: CE 3130: Steel Structures DesignDocument25 pagesCourse Name: CE 3130: Steel Structures Designcarlomonsalve1No ratings yet

- Steel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2Document22 pagesSteel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2iSoK11No ratings yet

- Modulo 4 CM 19 09 2020Document25 pagesModulo 4 CM 19 09 2020carlomonsalve1No ratings yet

- Buckling Analysis Design of Steel FramesDocument0 pagesBuckling Analysis Design of Steel FramestangkokhongNo ratings yet

- Structural Design of Cable Stayed Truss for 2002 Chonju World Cup StadiumDocument22 pagesStructural Design of Cable Stayed Truss for 2002 Chonju World Cup Stadiumnarens_skNo ratings yet

- Welds - Static and Fatigue Strength - IiDocument27 pagesWelds - Static and Fatigue Strength - IiOuseppachan Ambooken100% (1)

- Mod 1-3Document3 pagesMod 1-3Gopal UttupurathNo ratings yet

- MOD 1-6 - Question 4Document2 pagesMOD 1-6 - Question 4Gopal UttupurathNo ratings yet

- MOD 1-5 - Question 3Document3 pagesMOD 1-5 - Question 3Gopal UttupurathNo ratings yet

- MOD 1-8 - Question 6 & 7Document6 pagesMOD 1-8 - Question 6 & 7Gopal UttupurathNo ratings yet

- Bolt 1Document1 pageBolt 1Gopal UttupurathNo ratings yet

- Tension MembersDocument1 pageTension MembersGopal UttupurathNo ratings yet

- GIT Module 1Document29 pagesGIT Module 1Gopal UttupurathNo ratings yet

- MOD 2 - Question 5Document2 pagesMOD 2 - Question 5Gopal UttupurathNo ratings yet

- Mod 1-2Document4 pagesMod 1-2Gopal UttupurathNo ratings yet

- Rotating Steel ShaftsDocument3 pagesRotating Steel ShaftsSrini KumarNo ratings yet

- Hot-Rolled Steel Beam Calculation To AISC 360-16Document2 pagesHot-Rolled Steel Beam Calculation To AISC 360-16vanda_686788867No ratings yet

- Abs Terlurangp35 (Rohs)Document2 pagesAbs Terlurangp35 (Rohs)AdirSchoierNo ratings yet

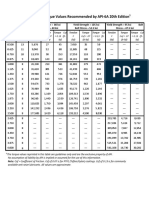

- Flange Bolting Torque Values API 6ADocument1 pageFlange Bolting Torque Values API 6Aparthameister100% (1)

- Automotive Interior eDocument32 pagesAutomotive Interior ecvazquez999No ratings yet

- P-Y CurvesDocument242 pagesP-Y CurvesAnonymous Vi1lrHNo ratings yet

- Utilization of Plastic Bags in Pavement Blocks: Mohan D.M.S, Vignesh.J, Iyyappan.P, C.SureshDocument10 pagesUtilization of Plastic Bags in Pavement Blocks: Mohan D.M.S, Vignesh.J, Iyyappan.P, C.SureshAbhishek ChaurasiaNo ratings yet

- Concrete Centre Spreadsheet User GuidesDocument32 pagesConcrete Centre Spreadsheet User GuidesChris Evans86% (14)

- Review of Common Non-Destructive Testing Methods for ConcreteDocument9 pagesReview of Common Non-Destructive Testing Methods for Concretepatricklim1982No ratings yet

- MMAN3400 Lecture 2Document21 pagesMMAN3400 Lecture 2Zenik AGNo ratings yet

- DSA InconelDocument12 pagesDSA InconeltazzorroNo ratings yet

- RAM Connection Standalone CE ReportDocument8 pagesRAM Connection Standalone CE ReportMos LugtuNo ratings yet

- Arstruct Reviewer Compilation (GRP 7)Document9 pagesArstruct Reviewer Compilation (GRP 7)Nicole FrancisNo ratings yet

- Anticorrosive Rubber Lining 2017Document6 pagesAnticorrosive Rubber Lining 2017Ebrahim MohamadikhahNo ratings yet

- Ribbed Slab PDFDocument16 pagesRibbed Slab PDFmahletNo ratings yet

- The Brazing BookDocument129 pagesThe Brazing BookGuille Rmo100% (1)

- DTE Unit 1 MCQs (Keys Shafts and Couplings)Document6 pagesDTE Unit 1 MCQs (Keys Shafts and Couplings)Mannam Sarath Sarath100% (2)

- 1 s2.0 S014102962300367X MainDocument15 pages1 s2.0 S014102962300367X MainmohamedNo ratings yet

- Solution 1.: Problem & Solve Mine Design and PlanningDocument14 pagesSolution 1.: Problem & Solve Mine Design and PlanningOla Bibi100% (1)

- High-Temperature High-Strength Nickel-Base Alloys: A Practical Guide To The Use of Nickel-Containing Alloys N 393Document86 pagesHigh-Temperature High-Strength Nickel-Base Alloys: A Practical Guide To The Use of Nickel-Containing Alloys N 393DNH RND - VijaykumarNo ratings yet

- Polyester-Resin CreepDocument18 pagesPolyester-Resin CreepJulio LópezNo ratings yet

- ASTM B280 - pdqv6897Document8 pagesASTM B280 - pdqv6897Nayth Andres GalazNo ratings yet

- Structural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesDocument11 pagesStructural Assessment of Corroded Reinforced Concrete Beams Modeling GuidelinesnagarajuNo ratings yet

- 1-Stress &Strain-Mechanics of MaterialsDocument55 pages1-Stress &Strain-Mechanics of MaterialsFelix Wahyu UtomoNo ratings yet

- Crack Propagation in Aluminum Sheets PDFDocument248 pagesCrack Propagation in Aluminum Sheets PDFvidal3213No ratings yet

- Analysis and Design of Flare Tower Subjected To Wind LoadingDocument99 pagesAnalysis and Design of Flare Tower Subjected To Wind Loadingajivakkom50% (2)

- AMIE Civil Engineering SyllabusDocument7 pagesAMIE Civil Engineering Syllabussuji_sujithrajNo ratings yet

- Consideration of Questions About Beam-Column Joints: Aci Structural Journal Technical PaperDocument10 pagesConsideration of Questions About Beam-Column Joints: Aci Structural Journal Technical PaperMarimuthu KaliyamoorthyNo ratings yet

- Goncz 2015Document11 pagesGoncz 2015Anonymous LaMda8EXNo ratings yet