Professional Documents

Culture Documents

Hot-Rolled Steel Beam Calculation To AISC 360-16

Uploaded by

vanda_686788867Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot-Rolled Steel Beam Calculation To AISC 360-16

Uploaded by

vanda_686788867Copyright:

Available Formats

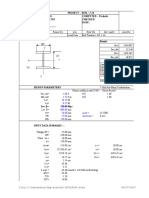

Hot-Rolled Steel Beam Calculation to AISC 360-16

1. Meterial Properties and Design Method :

Yield Stress (Fy) = 235.0 MPa Elastic Modulus (E) = 200000 MPa Design Method : AISC-360-16-LRFD

Tensile Strength (Fu) = 360.0 MPa Shear Modulus (G) = 77200 MPa AISC-360-16-LRFD

2. Design Load :

Major Moment (M ux ) = 33.09 kN-m Major Shear Force (Vux ) = 100.00 kN Torsional Moment (T u) = 0.00 kN-m

Minor Moment (M uy) = 0.00 kN-m Minor Shear Force (Vuy) = 0.00 kN

3. Section Properties :

Laterla Unbrace's Length of Compression Flange (L b ) = 3.000 m LTB Modification Factor (C b) = 1.14 (F1-1)

China Wide Flange (I)

Section Name : I 250x125x25.8

d= 248.00 mm Ix = 3563.96 cm 4 bf Ix = 85.62

4

bf = 124.00 mm Iy = 254.97 cm tf Iy = 6.13

tw = 5.00 mm rx = 10.41 cm rx = 4.10

tw

tf = 8.00 mm ry= 2.78 cm ry= 1.10

A= 32.89 cm² Cw = 36715.39 cm6 h X Sx = 17.54

d

W= 25.82 kg/m J= 5.23 cm 4 Sy = 2.51

Sx = 287.4 cm³ Sy = 41.12 cm 3 Z x = 19.64

tf

Zx = 321.8 cm³ Zy = 63.74 cm 3 Z y = 3.89

Y

c= 1.00 FL= 164.50 Mpa

0.4 cm cm

4. Flexural Strength Calculation :

l w = 41.20 l pw = 109.69 l rw = 166.29 Web - Compact (Table B4.1b Case 15)

l f = 7.75 l pf = 11.09 l rf = 29.17 Flanges - Compact (Table B4.1b Case 10)

4.1. Yielding - Major Axis :

M n = Mp = Fy Z x = 75.62 kN-m (F2-1)

4.2. Lateral-Torsional Buckling :

L p = 1.430 m (F2-5) L r = 4.256 m (F2-6) r ts = 3.26 cm (F2-7) Lp < Lb Lr

Lb - L p

M n = C b Mp -(Mp - 0.7FyS x)( ) = 68.26 kN-m (F2-2)

L r- L p

4.3. Compression Flange Local Buckling - Major Axis :

Flanges Compact - The Limit State of Compression Flange Local Buckling does not Apply

Distance from Maximum to Zero Shear Force (L v) = 1.00 m

4.4. Yielding - Minor Axis :

M n = Fy Z y ≤ 1.6FyS y = 14.98 kN-m (F6-1)

4.5. Flange Local Buckling - Minor Axis :

Flanges Compact - The Limit State of Compression Flange Local Buckling does not Apply

4.6. Allowable Flexural Strength and Ultilization:

7. Member Utilization: Allowable Bending Moment on Major Axis M ax = j M

j = 0.9 nx = 61.43 kN-m

Allowable Bending Moment on Major Axis M ay = j M ny = 13.48 kN-m

Member Ultilization Due to Bending Moment ( M ux /M ax + M uy/M ay) = 0.539 Satifactory

5. Shear Strength Calculation :

5. Shear Strength Calculation :

h/tw = 49.60 2.24 E/ F y = 65.35 j=1 , Cv 1 = 1 Kv = 5.34 (G2-2)

b/2t f = 7.75 1.10 Ekv /F y = 35.15 j = 0.9 , Cv 2 = 1 k v = 1.20 (G2-2)

Nominal Shear Strength on Major Axis Vnx = 0.6FyA w C v1 = 174.84 kN (G2-1)

Nominal Shear Strength on Minor Axis Vny = 0.6Fy b f t f C v 2 = 279.74 kN (G6-1)

Allowable Shear Strength on Major Axis Vax= jV nx = 174.84 kN

Allowable Shear Strength on Minor Axis Vay= jV ny = 251.77 kN

Member Ultilization Due to Shear Force on Major Axis V ux / V ax = 0.572 Satifactory

Member Ultilization Due to Shear Force on Minor Axis V uy / V ay = 0.000 Satifactory

You might also like

- AISC 360-16 Hot-Rolled Steel Beam CalculationDocument2 pagesAISC 360-16 Hot-Rolled Steel Beam Calculationvanda_686788867No ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Beam Column AiscDocument6 pagesBeam Column AiscWintun73No ratings yet

- Crane Bridge Box+4l100Document5 pagesCrane Bridge Box+4l100Wintun73No ratings yet

- Girder AISCDocument6 pagesGirder AISCWintun73No ratings yet

- Cold Formed Design SummaryDocument11 pagesCold Formed Design SummaryDinesh PatilNo ratings yet

- Foundation Design Sheet OutputDocument14 pagesFoundation Design Sheet OutputAwais HameedNo ratings yet

- Perhitungan Baja Girder - SeptiyanDocument37 pagesPerhitungan Baja Girder - SeptiyanTiyanNo ratings yet

- Purlin design for metal roofDocument2 pagesPurlin design for metal roofJONAS NGNo ratings yet

- Steel Beam Design by KDocument68 pagesSteel Beam Design by KKhandaker Khairul AlamNo ratings yet

- Base Plate, Anchor & Foundation (Pipe)Document39 pagesBase Plate, Anchor & Foundation (Pipe)nizardsouissiNo ratings yet

- MONORAIL BEAM ANALYSIS AND DESIGNDocument3 pagesMONORAIL BEAM ANALYSIS AND DESIGNeljammal100% (1)

- Verify ASTM A992 W12 × 30Document29 pagesVerify ASTM A992 W12 × 30qgfytzvqabzqrxyilmNo ratings yet

- Verify ASTM A992 W12 × 30Document28 pagesVerify ASTM A992 W12 × 30ankhbayar batkhuuNo ratings yet

- Beams and Other Flexural MemberDocument6 pagesBeams and Other Flexural MemberAgbanglo JuneNo ratings yet

- Refer Design Calculation No. 2323/R/SC/002/R1 Sheet 17 of 18 T 1.33 TM 1.33 TM 1.33 MDocument9 pagesRefer Design Calculation No. 2323/R/SC/002/R1 Sheet 17 of 18 T 1.33 TM 1.33 TM 1.33 MHerman GallegosNo ratings yet

- Balok Kolom Braced UnDocument3 pagesBalok Kolom Braced UnIkbal ImanudinNo ratings yet

- ASD-Design of Steel BeamDocument5 pagesASD-Design of Steel BeamsivakumarNo ratings yet

- Design of Intermediate BeamDocument3 pagesDesign of Intermediate BeamMike GocotanoNo ratings yet

- AISC123Document2 pagesAISC123Nhân Lê TrọngNo ratings yet

- BEAMS4and5 With FiguresDocument5 pagesBEAMS4and5 With FiguresKim PinedaNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- Beam SpliceDocument42 pagesBeam SpliceifsrebraNo ratings yet

- SAMBUNGAN KONSOL BK DENGAN K1: Calculating Beam to Column Connection StrengthDocument3 pagesSAMBUNGAN KONSOL BK DENGAN K1: Calculating Beam to Column Connection StrengthAnanta Eka YudistiraNo ratings yet

- WF Simply Supported Beam Design With Torsional Loading Based On AISC 360-10/16Document2 pagesWF Simply Supported Beam Design With Torsional Loading Based On AISC 360-10/16Karen Esther Acuña VelasquezNo ratings yet

- The Hashemite University Faculty of Engineering Civil Engineering DepartmentDocument31 pagesThe Hashemite University Faculty of Engineering Civil Engineering DepartmentengsalamNo ratings yet

- STEP 1 - Load Analysis: Select Size To UseDocument16 pagesSTEP 1 - Load Analysis: Select Size To UseKishan MadhooNo ratings yet

- Design of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BDocument13 pagesDesign of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BAwais HameedNo ratings yet

- Desain Struktur Gedung Serbaguna PacitanDocument4 pagesDesain Struktur Gedung Serbaguna PacitanUsaNo ratings yet

- Structural analysis & design of roof beam, column and footingDocument7 pagesStructural analysis & design of roof beam, column and footingAntonio EstradaNo ratings yet

- PADEYE Design AnalysisDocument9 pagesPADEYE Design AnalysisRamesh SelvarajNo ratings yet

- Design-Investigation of Steel BeamDocument38 pagesDesign-Investigation of Steel BeamPrince Jerald BasijanNo ratings yet

- PLATE 9 Girder FlexureDocument23 pagesPLATE 9 Girder FlexureFrances Gayle de GuzmanNo ratings yet

- Diseño DiafragmaDocument3 pagesDiseño DiafragmaJulia Quispe BejarNo ratings yet

- Design of Base Plate Baseplate 'C1' Load:: MXT MX-FT Ey MXC MX+FC Ey Myt My-Ft Ex Myc My+Fc ExDocument7 pagesDesign of Base Plate Baseplate 'C1' Load:: MXT MX-FT Ey MXC MX+FC Ey Myt My-Ft Ex Myc My+Fc ExAlma M. LaraNo ratings yet

- Design of Beams for Roof and Floor StructuresDocument6 pagesDesign of Beams for Roof and Floor StructuresShōya IshidaNo ratings yet

- Perhitungan Gording CNPDocument5 pagesPerhitungan Gording CNPWidhijonoS100% (1)

- PT. TECHNICs SPREADER BEAM CALCULATIONDocument4 pagesPT. TECHNICs SPREADER BEAM CALCULATIONHari Kiran100% (1)

- Column Is800Document4 pagesColumn Is800rammohanNo ratings yet

- Compact Section Calculation SheetDocument12 pagesCompact Section Calculation Sheetinnovativekarthi0% (1)

- Calc Leg Check of Cross BracingDocument4 pagesCalc Leg Check of Cross Bracingdinesh_akabariNo ratings yet

- Steel Beam NSCP2015Document307 pagesSteel Beam NSCP2015Sherwin CairoNo ratings yet

- Aluminium GlazingDocument4 pagesAluminium Glazingशशि शंकरNo ratings yet

- Steel Design LatestDocument52 pagesSteel Design LatestAhsan HabibNo ratings yet

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Isolated footing design for load case 1Document3 pagesIsolated footing design for load case 1Yisrael AshkenazimNo ratings yet

- Bab 4 Perencanaan Sambungan Baut Kuda-Kuda KK1Document3 pagesBab 4 Perencanaan Sambungan Baut Kuda-Kuda KK1Ananta Eka YudistiraNo ratings yet

- Beam Rolled Section (Rev.2.00)Document2 pagesBeam Rolled Section (Rev.2.00)HamOdy SadeqNo ratings yet

- 1.1 Assumption: Column Dimension:: Column Bi-Axial 4 FlashDocument10 pages1.1 Assumption: Column Dimension:: Column Bi-Axial 4 Flashramel sigueNo ratings yet

- Flexural Buckling About Y-Y AxisDocument2 pagesFlexural Buckling About Y-Y AxisjanethfinlangNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- PERHITUNGAN SAMBUNGAN END PLATE KOLOM DAN BALOKDocument51 pagesPERHITUNGAN SAMBUNGAN END PLATE KOLOM DAN BALOKAchmad Zaki ZulkarnainNo ratings yet

- Ce Elect 3s-Quiz SolutionDocument5 pagesCe Elect 3s-Quiz SolutionCharey CamaraoNo ratings yet

- Design of RafterDocument4 pagesDesign of RafterFarly VergelNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Box Culvert CalculationDocument15 pagesBox Culvert CalculationPetec Claudiu MariusNo ratings yet

- Width-to-thickness ratios for steel membersDocument2 pagesWidth-to-thickness ratios for steel membersbryamdv23100% (1)

- Career Options in Civil EngineeringDocument27 pagesCareer Options in Civil Engineeringparth bhavsarNo ratings yet

- Peb Design PPT ModelDocument37 pagesPeb Design PPT ModelYELLAMANDA SANKATINo ratings yet

- 5.0 TAD 1.1 - May 2022Document114 pages5.0 TAD 1.1 - May 2022kenesuuu 06No ratings yet

- GITC 4th Floor C N D Repairs BOQDocument4 pagesGITC 4th Floor C N D Repairs BOQAbhisheK MishrANo ratings yet

- Brick Layout Parapet: 15 CM Setback From First Floor Brick WallDocument3 pagesBrick Layout Parapet: 15 CM Setback From First Floor Brick WallGeorgy OommenNo ratings yet

- Data Excel SheetDocument7 pagesData Excel SheethiteshcparmarNo ratings yet

- Nzcs tr32Document145 pagesNzcs tr32Jianhua WuNo ratings yet

- FINAL Design - of - RCC Two Way Slab S2Document5 pagesFINAL Design - of - RCC Two Way Slab S2sujit naikwadiNo ratings yet

- Alain Pecker - Rion Antirion (Presentation)Document78 pagesAlain Pecker - Rion Antirion (Presentation)Miky CastenNo ratings yet

- Beam Force Detail Summary: Axial Shear Torsion Bending Beam L/C D FX Fy FZ MX My MZDocument23 pagesBeam Force Detail Summary: Axial Shear Torsion Bending Beam L/C D FX Fy FZ MX My MZsnoariNo ratings yet

- Retaining Wall DesignDocument126 pagesRetaining Wall DesignSeph RjyNo ratings yet

- R-Valuedensitieschart 1Document5 pagesR-Valuedensitieschart 1api-235337654No ratings yet

- CFD Is 456 2000Document85 pagesCFD Is 456 2000Angel VargasNo ratings yet

- Design of RCC SlabsDocument7 pagesDesign of RCC SlabsprashmceNo ratings yet

- Shopping Mall Design (Structures)Document114 pagesShopping Mall Design (Structures)Shams Abbas Naqvi67% (3)

- ACI 445R-99: Reported by Joint ACI-ASCE Committee 445Document55 pagesACI 445R-99: Reported by Joint ACI-ASCE Committee 445Jimmy Tien TrinhNo ratings yet

- Truss - 1 Detail 1: See Spot Purlin DetailDocument1 pageTruss - 1 Detail 1: See Spot Purlin DetailEarl Vergille Petiluna ReveloNo ratings yet

- Foundation of Burj KhalifaDocument18 pagesFoundation of Burj KhalifaR Saha100% (1)

- Expansion Joint Pelat Injak T 300 Granular Backfill (Well Compacted)Document1 pageExpansion Joint Pelat Injak T 300 Granular Backfill (Well Compacted)Anonymous 5OUozYNo ratings yet

- EverComp 47.5 Property SheetDocument1 pageEverComp 47.5 Property SheetSapphire RahimNo ratings yet

- Presentation (Part Superstructure)Document21 pagesPresentation (Part Superstructure)940623015859No ratings yet

- PCA Chapter 15 - Specify, Design, ProportionDocument91 pagesPCA Chapter 15 - Specify, Design, Proportiongreat_triskelionNo ratings yet

- Concept Report For BuildingDocument13 pagesConcept Report For Buildingnimish.aquamarineNo ratings yet

- Introduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoDocument35 pagesIntroduction To Reinforced Conrete: Prepared By: Engr. Christopher E. RodolfoKristoff LorenzoNo ratings yet

- Chap 1 Beam Curved in PlanDocument24 pagesChap 1 Beam Curved in Planhussain adelNo ratings yet

- The Advanced Strip Method A Simple Design Tool 1982Document7 pagesThe Advanced Strip Method A Simple Design Tool 1982Melkamu DemewezNo ratings yet

- Microsoft Word - Floor FinishesDocument9 pagesMicrosoft Word - Floor FinisheskokueiNo ratings yet

- Steel Joists and Joist Girders 1 PDFDocument216 pagesSteel Joists and Joist Girders 1 PDFhilander2k2No ratings yet