Professional Documents

Culture Documents

Plenum Detail

Uploaded by

Syed MukasirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plenum Detail

Uploaded by

Syed MukasirCopyright:

Available Formats

SECTION I – GENERAL INFORMATION

UL EX. 3470 ULC CEx747 Page 1-2

REV. 5 4-1-06

DEFINITION OF TERMS (Continued) Pre-engineered System: NFPA 17A defines a pre-engineered

Detector: A device which includes the detector bracket, detector system as one which has “…predetermined flow rates, nozzle

linkage, and fusible link used for automatic operation of the fire pressures, and quantities of liquid agent.” The R-102 system, as

suppression system. prescribed by UL (Underwriter’s Laboratories), has specific pipe

sizes, maximum and minimum pipe lengths and numbers of fit-

Detector Linkage: A device used to support the fusible link. tings, and number and types of nozzles. The hazards protected by

Distribution Piping: Piping which delivers the extinguishing this system are also specifically limited as to type and size by UL

agent from the tank to each discharge nozzle. See also Supply or based upon actual fire tests. All limitations on hazards that can be

Branch lines. protected and piping and nozzle configurations are contained in

the R-102 installation and maintenance manual which is part of the

Ducts (or Duct System): A continuous passageway for the trans-

UL listing.

mission of air and vapors which, in addition to the containment

components themselves, may include duct fittings, plenums, Pulley Elbow: A device used to change the direction of the wire

and/or other items or air handling equipment. rope which runs between: the regulated release mechanism and

Electrostatic Precipitator: A device used to aid in the cleaning of the detectors, the regulated release mechanism and the mechan-

the exhaust air. This device is normally installed at or near the ical gas valve, and/or the regulated release mechanism and the

base of the ventilation duct. remote manual pull station.

Expellant Gas Line: Piping and/or hose which supplies the nitro- Pulley Tee: A device used to change the direction of two wire

gen or carbon dioxide gas from the regulated release assembly/ ropes which run from a regulated release or a regulated actuator

regulated actuator assembly to each agent tank. to two remote manual pull stations, or from two regulated releas-

es or regulated actuators to a single mechanical gas valve or from

Flow Number: Term used in system design to describe the flow one regulated release or regulated actuator to two gas valves.

capacity of each nozzle used to determine the quantity of tanks

needed to cover a certain group of hazards. Regulated Actuator Assembly: An assembly which contains the

regulator, pneumatic actuator, agent tank, and expellant gas hose

Fusible Links: A form of fixed temperature heat detecting device within a metal enclosure. This assembly is used to pressurize

employed to restrain the operation of a mechanical control until its additional agent tanks in a multiple tank system.

designed temperature is reached.

Regulated Release Mechanism: An enclosed device within the

Gas Valve: A device used to shut off the gas supply to the cook- ANSUL AUTOMAN regulated release assembly which releases

ing equipment when the system is actuated. the expellant gas, activates alarms, and/or shuts off other devices

Gas Valve Air Cylinder: An air cylinder, located in the release when signaled automatically by a detector or manually with a

mechanism, which operates pneumatically to mechanically remote pull station.

unlatch a mechanical gas valve actuator, causing the gas valve to Regulator: A device used to regulate the pressure from the nitro-

close upon system actuation. gen cartridge into the agent tank(s) when the system is actuated.

High Proximity: Indicates a distance (vertically) between the noz-

Remote Manual Pull Station: A device which provides manual

zle tip and the surface of the appliance being protected.

actuation of the system from a remote location.

Hood: A device provided for cooking appliances to direct and cap-

Salamander Broiler: A broiler very similar in design to the upright

ture grease-laden vapors and exhaust gases. It shall be con-

broiler. A salamander broiler is used for general broiling of meats

structed in a manner which meets the requirements of NFPA 96.

and fish, toasting, and holding/warming foods. Most contain a

Liquid Agent: A potassium-based solution used for the knock- removable grease drip tray.

down and suppression of fire.

Silicone Lubricant: A heat-resistant organic compound used to

Low Proximity: Indicates a distance (vertically) between the noz- lubricate O-rings, rubber and mechanical components.

zle tip and the surface of the appliance being protected.

Supply Line: The agent distribution piping which extends from the

Maximum Length of Cooking Appliance: The maximum dimen- agent tank outlet and serves as a manifold for the branch lines.

sion, on any side, which may be protected by one nozzle.

Series Detector: Any detector located in-line between the regu-

Maximum Piping: Specified length of piping and number of fit- lated release assembly and the terminal detector.

tings which must not be exceeded for each system.

Terminal Detector: The last in a series of detectors, or the only

Medium Proximity: Indicates a distance (vertically) between the detector used in a single-detector system. This detector is thus

nozzle tip and the surface of the appliance being protected. named because it is at the point at which the wire rope ends,

Minimum Piping: Minimum length of distribution piping required or ‘‘terminates.’’ There is only one terminal detector per detection

between the agent tank outlet and any nozzle protecting a griddle, system.

range, or fryer. Transition: An extension of the hood or canopy which allows for

Nozzle: A device designed to deliver the liquid agent with a spe- the smooth transmission of gases, air, and vapors between the

cific flow rate and stream pattern. hood opening and the base of the ventilation duct.

Overlapping Protection: When discharge nozzles are spaced Vent Plug: A device used to prevent pressure build-up within the

equally apart over one or more appliances requiring protection. agent tank or agent distribution lines due to temperature

Nozzles used in this manner provide area protection of eligible fluctuations.

appliances within the protected area. Two types of overlapping

protection is available: full hood continuous protection and group

protection. Overlapping protection is in addition to appliance spe-

cific coverages.

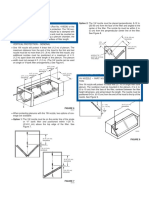

Plenum: The

Plenum: Thespace

spaceenclosed

enclosedabove

by thethe hoods

filters andfilters and protion

the portion of the

with the

hood hood

above thespace.

filters. Some of Europe designs are not

integrated with US standard due to space and UV light system.

You might also like

- R0 AM20046 DALIAN 300K TANKER T300K-101 R-102 Galley Duct INSTRUCTION MANUALDocument85 pagesR0 AM20046 DALIAN 300K TANKER T300K-101 R-102 Galley Duct INSTRUCTION MANUALPranabNo ratings yet

- R-102 DSDocument4 pagesR-102 DSSimone DoeNo ratings yet

- R-102 Restaurant Fire Suppression Systems: FeaturesDocument4 pagesR-102 Restaurant Fire Suppression Systems: FeaturesAdil SyedNo ratings yet

- Preaction System Design GuideDocument15 pagesPreaction System Design GuideMarkNo ratings yet

- Fire Alarm Training ManualDocument41 pagesFire Alarm Training ManualVenu Vanamali Rugved YadavNo ratings yet

- 2012 NC Fuel Gas Code: Level I TrainingDocument318 pages2012 NC Fuel Gas Code: Level I TrainingSean AkirangaNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Deluge System Design GuideDocument14 pagesDeluge System Design GuideMarkNo ratings yet

- Deluge System Design GuideDocument14 pagesDeluge System Design GuidePassmore DubeNo ratings yet

- Fire Alarm Training ManualDocument34 pagesFire Alarm Training Manualsossie100% (8)

- Clean Agents 1Document16 pagesClean Agents 1omarrgb97No ratings yet

- Fire Alarm Training ManualDocument34 pagesFire Alarm Training Manualmmahmad1989No ratings yet

- Ashare 15Document4 pagesAshare 15Pawel MielnikNo ratings yet

- Chapter 6 - Plant Start Up & Shut DownDocument16 pagesChapter 6 - Plant Start Up & Shut DownDharshica MohanNo ratings yet

- NaysDocument12 pagesNaysMark AriolaNo ratings yet

- Smoke Sensor in AHUDocument23 pagesSmoke Sensor in AHUmingming1No ratings yet

- GAPS Guidelines: Extinguishing System Detection and ControlDocument6 pagesGAPS Guidelines: Extinguishing System Detection and Controlasad khanNo ratings yet

- PCSU Chapter 6Document16 pagesPCSU Chapter 6rawanisephiaNo ratings yet

- Fire SPRKLR Train ManDocument81 pagesFire SPRKLR Train ManHESuarezNo ratings yet

- Fire Suppression Systems UL 300: Length of HoodDocument3 pagesFire Suppression Systems UL 300: Length of Hoodkdsessions100% (2)

- NEE 4101 - Bautista Process and Instrumentation DiagramDocument7 pagesNEE 4101 - Bautista Process and Instrumentation DiagramJETTDOMINIC BAUTISTANo ratings yet

- Automatic Sprinkler System GuideDocument4 pagesAutomatic Sprinkler System Guidebugoff700100% (2)

- Fire Sprinkler Monitoring & Releasing Systems PDFDocument189 pagesFire Sprinkler Monitoring & Releasing Systems PDFMichel CorrêaNo ratings yet

- MASsoft V7 Training ManualDocument84 pagesMASsoft V7 Training ManualNgọc Đỉnh ThiênNo ratings yet

- Enyecontrols System Info UpdatedDocument116 pagesEnyecontrols System Info UpdatedJon Elmer DelgadoNo ratings yet

- Aspiration Smoke Detection Positioning Paper: BackgroundDocument7 pagesAspiration Smoke Detection Positioning Paper: BackgroundJohn simpsonNo ratings yet

- SprinklerTrainingManualDocument108 pagesSprinklerTrainingManualAsmir Ahmetović0% (1)

- Control Engineering Design Criteria: Appendix 10EDocument7 pagesControl Engineering Design Criteria: Appendix 10EkyahuaNo ratings yet

- Training ManualDocument15 pagesTraining Manualrajeshrahul321No ratings yet

- R-102 Restaurant Fire Suppression SystemsDocument4 pagesR-102 Restaurant Fire Suppression SystemsasmaNo ratings yet

- Advanced Fire Training - 8700055 - REV D - 10/07Document32 pagesAdvanced Fire Training - 8700055 - REV D - 10/07mastersaizNo ratings yet

- HYGOOD iFLOW DatasheetDocument2 pagesHYGOOD iFLOW DatasheetAry TubagusNo ratings yet

- FA QCDD Exam Questions KIC by TrekaDocument7 pagesFA QCDD Exam Questions KIC by TrekaSHERIF KHATTABNo ratings yet

- Definitions - NFPADocument365 pagesDefinitions - NFPAAnand KrishnaNo ratings yet

- Stairwell PresentationDocument32 pagesStairwell PresentationEdz EduardoNo ratings yet

- Detectia Scanteilor PDFDocument27 pagesDetectia Scanteilor PDFValentin RadulescuNo ratings yet

- Control EngineeringDocument144 pagesControl EngineeringRommel Roldan100% (1)

- Clean Agent SystemDocument8 pagesClean Agent Systemstanjack99No ratings yet

- U1l2s Shop EquipmentDocument30 pagesU1l2s Shop EquipmentpmcisissengueNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- User ManualDocument26 pagesUser ManualRodney CutinhoNo ratings yet

- Sultan Manual InglesDocument103 pagesSultan Manual InglesHéctor Andrés Echazú EspinozaNo ratings yet

- Airframe Quizlet PDFDocument11 pagesAirframe Quizlet PDFSaroj ShahNo ratings yet

- Ee 1C Lesson 6 MeasurementsDocument2 pagesEe 1C Lesson 6 MeasurementsJohnNo ratings yet

- Fire Detection and ExtinctionDocument34 pagesFire Detection and Extinctionbsaikia0062No ratings yet

- Services: Hospital GasesDocument41 pagesServices: Hospital GasesRevati shinde100% (1)

- InstrumentationDocument4 pagesInstrumentationfemidagsNo ratings yet

- VavcontentDocument6 pagesVavcontentapi-288448664No ratings yet

- Assignment 2Document36 pagesAssignment 2Monika SadhaNo ratings yet

- AFSS & FDAS - Techincal ReportDocument36 pagesAFSS & FDAS - Techincal ReportChris de Leon100% (3)

- Centralize Manifold Room and Medical Gases PipelineDocument12 pagesCentralize Manifold Room and Medical Gases PipelineRanjan ShahNo ratings yet

- Fire Sprinkler DesignDocument68 pagesFire Sprinkler DesignJuan Paulo Mayor89% (9)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Data Sheet Motor 15HP WegDocument1 pageData Sheet Motor 15HP WegRUBEN ACOSTANo ratings yet

- Data Sheet Motor 15HP WegDocument1 pageData Sheet Motor 15HP WegRUBEN ACOSTANo ratings yet

- HEAF-LR-01 - BPT BOX 15-15 HT COMPACT 3 KWDocument8 pagesHEAF-LR-01 - BPT BOX 15-15 HT COMPACT 3 KWSyed MukasirNo ratings yet

- Data Sheet Motor 15HP WegDocument1 pageData Sheet Motor 15HP WegRUBEN ACOSTANo ratings yet

- KH Rfi FP 0036 02 PDFDocument33 pagesKH Rfi FP 0036 02 PDFSyed MukasirNo ratings yet

- Nozzles TypesDocument1 pageNozzles TypesSyed MukasirNo ratings yet

- KH Rfi FP 0036 02 PDFDocument40 pagesKH Rfi FP 0036 02 PDFSyed MukasirNo ratings yet

- 1N&1W 2Document1 page1N&1W 2Syed MukasirNo ratings yet

- Plot 002317-01-01Document1 pagePlot 002317-01-01Syed MukasirNo ratings yet

- 3RD Summative Exam in Science 6Document6 pages3RD Summative Exam in Science 6Maricris Palermo SancioNo ratings yet

- SyllabusDocument2 pagesSyllabusPrakash KumarNo ratings yet

- 1often Wonder About My Future As I Am About To Finish Secondary SchoolDocument2 pages1often Wonder About My Future As I Am About To Finish Secondary SchoolMidz Santayana100% (1)

- Chapter 10 Fitness Training PrinciplesDocument80 pagesChapter 10 Fitness Training Principlesapi-115744109No ratings yet

- Immulite Homocysteine 2000Document30 pagesImmulite Homocysteine 2000Symbolin MusenkoNo ratings yet

- Electrochemistry NotesDocument4 pagesElectrochemistry NotesAyush RorNo ratings yet

- Dont Sweat The Small Stuff For Men - Richard CarlsonDocument226 pagesDont Sweat The Small Stuff For Men - Richard CarlsonAaliyah Csmrt100% (1)

- Key MechanicalDocument72 pagesKey MechanicalDasuki FahmiNo ratings yet

- JECFA Carrageenan MonographDocument5 pagesJECFA Carrageenan MonographSurya SaputraNo ratings yet

- Banana Disease 2 PDFDocument4 pagesBanana Disease 2 PDFAlimohammad YavariNo ratings yet

- Lesson Plan Personality DisorderDocument7 pagesLesson Plan Personality DisorderRaj MeghwalNo ratings yet

- Cognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)Document105 pagesCognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)SOUFIANE RACHID100% (8)

- Awsum BrandingDocument18 pagesAwsum Brandingdharam123_904062105No ratings yet

- B2 Practice ListeningDocument2 pagesB2 Practice ListeningDavy EverhartNo ratings yet

- Buoyancy Calculation Report For 10INCH PipelineDocument7 pagesBuoyancy Calculation Report For 10INCH PipelineEmmanuel LawrenceNo ratings yet

- Bronce C90700Document2 pagesBronce C90700Luis Enrique CarranzaNo ratings yet

- FM 200Document3 pagesFM 200raviNo ratings yet

- Problem 21-02 Wright Company Spreadsheet For The Statement of Cash Flows Dec. 31 Changes Dec. 31 2020 Debits Credits 2021 Balance SheetDocument17 pagesProblem 21-02 Wright Company Spreadsheet For The Statement of Cash Flows Dec. 31 Changes Dec. 31 2020 Debits Credits 2021 Balance SheetVishal P RaoNo ratings yet

- A Systematic Review of Electromyography Studies in Normal Shoulders To Inform Postoperative Rehabilitation Following Rotator Cuff RepairDocument14 pagesA Systematic Review of Electromyography Studies in Normal Shoulders To Inform Postoperative Rehabilitation Following Rotator Cuff Repairshsh ShshsshNo ratings yet

- DAFTARRUJUKANDocument4 pagesDAFTARRUJUKANIndahNo ratings yet

- Department of Civil Engineering Uttara University: LaboratoryDocument102 pagesDepartment of Civil Engineering Uttara University: LaboratorytaniaNo ratings yet

- My Project PresentationDocument12 pagesMy Project Presentationkarunasand15No ratings yet

- SM - Business PoliciesDocument46 pagesSM - Business PoliciesPrithvi AcharyaNo ratings yet

- Is 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Document5 pagesIs 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Indira BanerjeeNo ratings yet

- Brochures EW HTDocument20 pagesBrochures EW HTavinash rathodNo ratings yet

- QTR-2 2023 Meeting Format Nov.23Document45 pagesQTR-2 2023 Meeting Format Nov.23skumar31397No ratings yet

- Type Test Verification SafePlus 12 24 KVDocument8 pagesType Test Verification SafePlus 12 24 KVGary FortuinNo ratings yet

- Soiltac Safety Data Sheet: Section 1 - IdentificationDocument9 pagesSoiltac Safety Data Sheet: Section 1 - IdentificationSameh AhmedNo ratings yet

- Microcosmic Orbit Breath Awareness and Meditation Process: For Enhanced Reproductive Health, An Ancient Taoist MeditationDocument1 pageMicrocosmic Orbit Breath Awareness and Meditation Process: For Enhanced Reproductive Health, An Ancient Taoist MeditationSaimon S.M.No ratings yet