Professional Documents

Culture Documents

STD-InSP-0006 (Flange Inspection Procedure)

Uploaded by

airbroomOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STD-InSP-0006 (Flange Inspection Procedure)

Uploaded by

airbroomCopyright:

Available Formats

FLANGE INSPECTION PROCEDURE

Document No: STD-INSP-0006

A 07-04-2022 FIRST ISSUE

Prepare Reviewe Approve

Re AI/TPI/

Date Details d d d

v CLIENT

By By By QM

PROCEDURE NO STD-INSP-0006 REV. No. A Page 2 of 3

FLANGE INSPECTION PROCEDURE.

1. Scope:

This procedure describes the method of Physical inspection of Flanges.

2. Responsibility:

2.1 Quality Manager

2.2 Inspection Engineer

2.3 Store Supervisor.

3. Reference:

3.1 ASME Sec. VIII Div. 1 & 2, ASME Sec.1, B31.1, NBIC.

3.2 ASME Sec. IIA, IIB

(Latest Edition and Addenda on the day of use of this procedure)

3.3 Client Specification.

3.4 ASME B16.5 (1.5” TO 24”)*

3.5 ASME B16.47 Series A & B (26” TO 60”)

3.6 *MSS SP-25*

4 Equipment:

4.1 Measuring Tape.

4.2 Vernier Calliper.

4.3 Steel Rule

4.4 Thickness Meter.

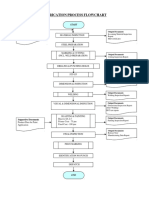

5 Procedure:

5.1 Along with the Goods Receipt Note (GRN) the following documents shall be made available:

5.1.1 Purchase order

5.1.2 Test certificates

5.1.3 ARM ( if required )

5.1.4 Dimension report (if applicable as per PO )

5.2 Review Test certificate as per Purchase order and or requirement specified in drawing /

Material Notes (ARM No.) and put review stamp on test certificate.

5.3 Visual Inspection.

The following shall be visually checked and confirmed on the

material/identification marking.

⮚ Size

PROCEDURE NO STD-INSP-0006 REV. No. A Page 3 of 3

FLANGE INSPECTION PROCEDURE.

⮚ Class (Rating)

⮚ Material Specification

⮚ Heat no./Batch no.

⮚ Manufacturer’s Name/Trademark

⮚ Third party stamp - if applicable

⮚ Project No./Position No.

⮚ Drawing No. - for non-standard flanges

⮚ Absents of surface imperfections

⮚ Gasket Face/finish

5.4 Dimensional measurement:

The dimension shall be checked and confirmed in accordance with the requirement

stated below:

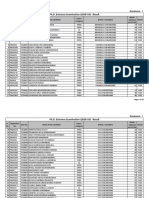

Type of Flange Dimensions to be checked Extent of Check

Inside diameter, Gasket

100%

Standard WNRF, ID/OD and thickness

LWNRF, WNRTJ All dimensions as specified in 10 % of the lot with

flanges the respective standard min. 1 No. for each

size

Standard Blind Gasket face ID/OD and 100%

flanges thickness

Other Standard All dimensions as specified in 10 % of the lot with

flanges the respective standard min. 1 No. for each

size

Non-standard flanges All dimensions as specified in 50% of the lot for

the respective each size with min. 1

drawing/specification No.

6 Inspection Ruling:

6.1 Unacceptable flanges shall be rejected and documented in the respective GRN.

6.2 Non-conformities and incomplete report, if any, shall be reported to the purchaser concerned

in a discrepancy report for further action.

5.5 Prepare “ Incoming Material Inspection Report “ & all acceptable flanges shall be cleared on

the respective GRN and recorded on MCR. The material shall be released for further work

after affixing the inspector’s stamp on it.

You might also like

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- The Data Science Design ManualDocument456 pagesThe Data Science Design Manualalbgomez100% (4)

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- QapDocument9 pagesQaprenjithv_4No ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Requirements of Brazing QualificationsDocument8 pagesRequirements of Brazing QualificationsShahul Hameed KhadarmeeranNo ratings yet

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626No ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- 4260Document10 pages4260Lipika GayenNo ratings yet

- E290 RT Rev.0Document19 pagesE290 RT Rev.0Amir Reza Rashidfarokhi100% (1)

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocument29 pagesHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyNo ratings yet

- DevOps ProjectDocument160 pagesDevOps ProjectAkhmad FarhanNo ratings yet

- 3 Phase Six Step InverterDocument25 pages3 Phase Six Step InverterRavi karanNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument5 pagesTuv India Private Limited: Inspection Visit ReportAkhtar aliNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Liquid Penetrant Test Record: Examinaion DetailsDocument1 pageLiquid Penetrant Test Record: Examinaion DetailschandraNo ratings yet

- NF - Apple EUADocument2 pagesNF - Apple EUAgustavogko01100% (1)

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- Ultrasonic Test Report: Testing TechniqueDocument2 pagesUltrasonic Test Report: Testing TechniqueMd RizwanNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- Visual Inspection ReportDocument2 pagesVisual Inspection ReportAlfian ImaduddinNo ratings yet

- STD-InSP-0005 (Plate Inspection Procedure)Document3 pagesSTD-InSP-0005 (Plate Inspection Procedure)airbroomNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubNo ratings yet

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocument3 pagesIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarNo ratings yet

- UMTS Performance KPI and Resource Capacity Training: Security LevelDocument46 pagesUMTS Performance KPI and Resource Capacity Training: Security LevelIyesusgetanewNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- QAP - Gate Valve - NPCILDocument6 pagesQAP - Gate Valve - NPCILkaustavNo ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Process Flow Chart - SeeDocument2 pagesProcess Flow Chart - Seesukanth tejaswiNo ratings yet

- CERTIFICATE FormatDocument1 pageCERTIFICATE FormatRonanki Ravi100% (1)

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- 8 Material Inspection ReportDocument1 page8 Material Inspection Reportvinson bayNo ratings yet

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNo ratings yet

- Letter For Testing of PQRDocument1 pageLetter For Testing of PQRPA PROJECTS PVT LTDNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- TK®-236 Physical Properties: 1. HardnessDocument2 pagesTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- QAP IP Format Electrical Instrumentation APEDocument2 pagesQAP IP Format Electrical Instrumentation APEKoushik DeyNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Qap Gate ValveDocument1 pageQap Gate ValveAjit PatilNo ratings yet

- Certificate TC-5329 PDFDocument1 pageCertificate TC-5329 PDFAnubhav LakhmaniNo ratings yet

- Srinivasan Chandran: Objective MatrixDocument4 pagesSrinivasan Chandran: Objective MatrixPaul PhiliphsNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Subh (Pipe Inspection Procedure)Document3 pagesSubh (Pipe Inspection Procedure)subhashaheer524No ratings yet

- Technological Institute of The Philippines: Determination of COP of A Refrigeration SystemDocument15 pagesTechnological Institute of The Philippines: Determination of COP of A Refrigeration SystemDessa GuditoNo ratings yet

- NM-238 GBDocument27 pagesNM-238 GBShania GintingNo ratings yet

- Data Interpretation PO Mains PDF Set 11Document42 pagesData Interpretation PO Mains PDF Set 11Nisha PariharNo ratings yet

- Sem 5 and 6 BSC Computer ScienceDocument5 pagesSem 5 and 6 BSC Computer ScienceKalyani ChilukuriNo ratings yet

- READ ME - InfoDocument2 pagesREAD ME - InfoSalih AktaşNo ratings yet

- Minnesota Commercial Energy Code (PDF) - 201412101121047449Document23 pagesMinnesota Commercial Energy Code (PDF) - 201412101121047449Netto Rodrigues AlvesNo ratings yet

- TYBCA Cyber Security Notes 1Document99 pagesTYBCA Cyber Security Notes 1pradneshshinde29No ratings yet

- About Jordan's PolicyDocument20 pagesAbout Jordan's PolicySaeed Al-SaeedNo ratings yet

- Fujitsu Ten 86120 Pinout New in 2023 - Car Stereo Systems, Car Stereo, Car AudioDocument1 pageFujitsu Ten 86120 Pinout New in 2023 - Car Stereo Systems, Car Stereo, Car AudiosvezxboxNo ratings yet

- Code Source Du Script Shell C99Document3 pagesCode Source Du Script Shell C99Mora SOWNo ratings yet

- Principles of Technology Dissemination 2020Document75 pagesPrinciples of Technology Dissemination 2020Musa MasolwaNo ratings yet

- Data Sheet: NPN General Purpose TransistorDocument8 pagesData Sheet: NPN General Purpose TransistorNewsUPdateNo ratings yet

- Result - Final (Annexure - I) - 923680Document25 pagesResult - Final (Annexure - I) - 923680patelsandip1989No ratings yet

- Tic Tac Toe IntroductionDocument8 pagesTic Tac Toe IntroductionYagnik SakhiyaNo ratings yet

- Test Plan and DocumentsDocument4 pagesTest Plan and DocumentsvimudhiNo ratings yet

- Sealed & Shielded Type Double Row Angular Contact Ball BearingsDocument3 pagesSealed & Shielded Type Double Row Angular Contact Ball BearingsMai Thế ToanNo ratings yet

- Pubg - Freefire (Swapon Vai)Document3 pagesPubg - Freefire (Swapon Vai)Shafiqul Islam Sajib100% (1)

- Excel Black Belt (Answers)Document54 pagesExcel Black Belt (Answers)21Y6C41 SHARMAINE SEET SHIENNo ratings yet

- Smart Robotic Arm: CrustcrawlerDocument3 pagesSmart Robotic Arm: CrustcrawlerOmar FranciaNo ratings yet

- Three Phase Full and Semi Converter - R and RL LoadDocument18 pagesThree Phase Full and Semi Converter - R and RL LoadDHINESH J100% (1)

- Linking Your Thinking - Idea EmergenceDocument1 pageLinking Your Thinking - Idea EmergenceLee NamNo ratings yet

- Elimination MethodsDocument58 pagesElimination MethodsmanankNo ratings yet

- Canyon RanchDocument3 pagesCanyon RanchBob_Meyer_4026100% (1)

- CV Nicolas Duarte Cifuentes InglesDocument2 pagesCV Nicolas Duarte Cifuentes InglesNicolas Duarte CifuentesNo ratings yet

- Service Manual: Split Type Room Air ConditionerDocument14 pagesService Manual: Split Type Room Air ConditionerMuhamad PriyatnaNo ratings yet