Professional Documents

Culture Documents

Tse 708 B420C 2

Uploaded by

ihsankeskinnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tse 708 B420C 2

Uploaded by

ihsankeskinnCopyright:

Available Formats

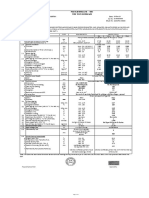

COUNTRY: STANDARD: QUALITY:

TURKEY TSE 708 B 420C

RIB GEOMETRY

DEFORMATION REQUIREMENTS

8 10 12 14 16 18 20 22 24 25 26 28 30 32 40 EXPLANATIONS

Cross sectional area

50.3 78.5 113.0 154.0 201.0 254.4 314.0 380.0 452.2 491.0 531.0 616.0 706.5 804.0 1257.0

(mm2)

min 0.371 0.589 0.848 1.156 1.509 1.910 2.359 2.851 3.390 3.677 3.980 4.613 5.300 6.026 9.416

Unit Weight ±6,0% ≤ 8mm

nom 0.395 0.617 0.888 1.210 1.580 2.000 2.470 2.985 3.550 3.850 4.168 4.830 5.550 6.310 9.860 ±4,5% > 8mm

(kg/m)

max 0.419 0.645 0.928 1.264 1.651 2.090 2.581 3.119 3.710 4.023 4.356 5.047 5.800 6.594 10.304

Transversal min 0.24 0.30 0.36 0.42 0.48 0.54 0.60 0.66 0.72 0.75 0.78 0.84 0.90 0.96 1.20

As (Table: 8)

rib height max 1.20 1.50 1.80 2.10 2.40 2.70 3.00 3.30 3.60 3.75 3.90 4.20 4.50 4.80 6.00

Transversal min

Bs

rib width max

Transversal min 3.20 4.00 4.80 5.60 6.40 7.20 8.00 8.80 9.60 10.00 10.40 11.20 12.00 12.80 16.00

Cs (Table: 8)

rib space max 9.60 12.00 14.40 16.80 19.20 21.60 24.00 26.40 28.80 30.00 31.20 33.60 36.00 38.40 48.00

Rib-Tip min

E (Sec. 7.4.2.2)

distance max 3.14 3.93 4.71 5.50 6.28 7.07 7.85 8.64 9.42 9.82 10.21 11.00 11.78 12.57 15.71

Longitudinal min

A1 (Sec. 7.4.2.3)

rib height max 1.20 1.50 1.80 2.10 2.40 2.70 3.00 3.30 3.60 3.75 3.90 4.20 4.50 4.80 6.00

Longitudinal min

B1

Rib Width max

min 35° 35° 35° 35° 35° 35° 35° 35° 35° 35° 35° 35° 35° 35° 35°

Rib slope ß (Table: 8)

max 75° 75° 75° 75° 75° 75° 75° 75° 75° 75° 75° 75° 75° 75° 75°

min 45° 45° 45° 45° 45° 45° 45° 45° 45° 45° 45° 45° 45° 45° 45°

Rib angle Ø (Sec. 7.4.2.2)

max

Rib Area min 0.040 0.040 0.040 0.056 0.056 0.056 0.056 0.056 0.056 0.056 0.056 0.056 0.056 0.056 0.056

Fr (Table: 9)

(mm2) max

Diameter of mandrel

5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 5d 180° bend.

for bend (mm)

Diameter of mandrel

for re-bend (mm)

MECHANICAL REQUIREMENTS CHEMICAL REQUIREMENTS

EXPLANATIONS EXPLANATIONS

Yield min 420 Heat Product Heat Product

Re MPa

Strength % % % %

max

Tensile min C min P min

Rm MPa

Strength max 0, max 22 24 0,0 max 50 55

min 1.15 Re act / Re nom < 1,30 Si min S min

Rm / Re

max 1.35 0, max 0,0 max 50 55

Uniform min 12.0 Mn min N min

A5 %

elongation max max ppm max 120 122

Elongation min 7.5 Cu min Ceq min Ceq=C + Mn/6 + (Cr+Mo+V)/5 +

Agt %

to fracture max 0, max 80 85 0, max 50 52 (Ni+Cu)/15

MARKING

1C KKF-006 yt:10.06.2010 r1 rt:07.01.2014

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Polycab India Ltd UH3 Type Test CertificateDocument1 pagePolycab India Ltd UH3 Type Test CertificateAlok PandeyNo ratings yet

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- 00207050Document6 pages00207050Maruda8382No ratings yet

- Gradation Sand Jan 2018Document54 pagesGradation Sand Jan 2018viswanath kasiNo ratings yet

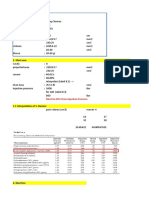

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan AranyawatNo ratings yet

- STABILITY CALCULATIONDocument3 pagesSTABILITY CALCULATIONSuga NeesNo ratings yet

- Specifications of Rebar Grade: As Per ASTM StandardDocument2 pagesSpecifications of Rebar Grade: As Per ASTM StandardMyat SuNo ratings yet

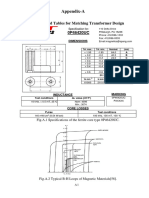

- Matching Transformer Design Specification and Core Loss DataDocument3 pagesMatching Transformer Design Specification and Core Loss DataNaeemo IraqiNo ratings yet

- NH35-45MIC Alloy Material Data SheetDocument3 pagesNH35-45MIC Alloy Material Data SheetJean-Noël LerouxNo ratings yet

- 41Cr4 Chemical PDFDocument2 pages41Cr4 Chemical PDFGayathriRajasekaranNo ratings yet

- Column DesignDocument20 pagesColumn DesignSaman AdelNo ratings yet

- Jumper CablesDocument2 pagesJumper CablescecilkazimirNo ratings yet

- Aluminium ExtruderDocument108 pagesAluminium ExtruderGoutam BiswasNo ratings yet

- One - Way Slab: Design SpecificationsDocument4 pagesOne - Way Slab: Design Specificationssetiawan hendroNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- Triaxial Test Data Sheet MEGA IDocument121 pagesTriaxial Test Data Sheet MEGA ILao Nong NgoNo ratings yet

- Lo-Driv: A Superior Thread-Former For SteelDocument2 pagesLo-Driv: A Superior Thread-Former For SteelSquidwardNo ratings yet

- Line - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPEDocument3 pagesLine - Pipe - IS - TOLERANCE ON OUTSIDE DIAMETER, WALL THICKNESS, WEIGHT AND LENGTH OF PIPECristi DemNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Three Phase Induction Motor Data SheetDocument7 pagesThree Phase Induction Motor Data SheetA aaa AaaNo ratings yet

- DIA - Calcul Grinzi Din Beton ArmatDocument12 pagesDIA - Calcul Grinzi Din Beton ArmatCristina DumitriuNo ratings yet

- Insulating Epoxy Dotted Paper Technical SpecificationDocument1 pageInsulating Epoxy Dotted Paper Technical SpecificationMly Saad BoudiafNo ratings yet

- 3.5 Core Al Xlpe ArmdDocument1 page3.5 Core Al Xlpe ArmdRavindra JadhavNo ratings yet

- DZ1040 - 12 Ring - 20231010141123Document4 pagesDZ1040 - 12 Ring - 20231010141123subhashkumarmandalamcivilNo ratings yet

- WBM Report RECAP wbmDocument22 pagesWBM Report RECAP wbmAbdul Hameed OmarNo ratings yet

- SL Series 85° SMD Ecap: FeaturesDocument6 pagesSL Series 85° SMD Ecap: FeaturesAlberto IsmaelNo ratings yet

- SL Series 85° SMD Ecap: FeaturesDocument6 pagesSL Series 85° SMD Ecap: FeaturesAlberto IsmaelNo ratings yet

- En ChemiklerepdmDocument2 pagesEn Chemiklerepdmeloy marroquinNo ratings yet

- DZ1040 - 6 Ring - 20231010123044Document4 pagesDZ1040 - 6 Ring - 20231010123044subhashkumarmandalamcivilNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- Astm A325m PDFDocument1 pageAstm A325m PDFFrose KhanNo ratings yet

- SERIES - Lead Terminal: FeaturesDocument4 pagesSERIES - Lead Terminal: FeaturesVenu Gopal Rao AggressNo ratings yet

- Quantity of Concrete: 1: 4 Volume of Wall Is To Be ConstructedDocument6 pagesQuantity of Concrete: 1: 4 Volume of Wall Is To Be ConstructedJohn MichaelsNo ratings yet

- NIC Components NEXM SeriesDocument1 pageNIC Components NEXM SeriesNICCompNo ratings yet

- Based On Lifting Point CheckingDocument22 pagesBased On Lifting Point CheckingandreashendiNo ratings yet

- Kel.4 - TekbanDocument51 pagesKel.4 - TekbanTri FerinaNo ratings yet

- AKASH InputDocument3 pagesAKASH InputJitendra PatelNo ratings yet

- Part Number: Acw-107: Electrical SpecificationsDocument2 pagesPart Number: Acw-107: Electrical SpecificationsgfshhdNo ratings yet

- BETAflam Solar 125 RV Flex 1500V DC - E - Voltagedrop Current LoadDocument4 pagesBETAflam Solar 125 RV Flex 1500V DC - E - Voltagedrop Current LoadMay OngNo ratings yet

- Film Resistors GuideDocument1 pageFilm Resistors GuideGeorge RibeiroNo ratings yet

- MO & MO Aggregates With BlendingDocument8 pagesMO & MO Aggregates With BlendingAbu FalasiNo ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- Raw Materials Granulometry and Ball Charge DesignDocument11 pagesRaw Materials Granulometry and Ball Charge DesignKaran_Agarwal_4807100% (2)

- Parameter Tolerance Worksheet: Starting Values Unit ValueDocument1 pageParameter Tolerance Worksheet: Starting Values Unit ValuehernanNo ratings yet

- PT Paver Strength CalculationsDocument3 pagesPT Paver Strength CalculationsEr Narayan ApawatNo ratings yet

- En Chem10upesdDocument2 pagesEn Chem10upesdeloy marroquinNo ratings yet

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- DIA Calcul Grinzi Din Beton ArmatDocument8 pagesDIA Calcul Grinzi Din Beton ArmatMadalin Popa0% (1)

- WP Dynamic Data-Sheet200925Document4 pagesWP Dynamic Data-Sheet200925Tan VuNo ratings yet

- Epoxy Conformal Coated, Axial Leaded: Vishay DaleDocument2 pagesEpoxy Conformal Coated, Axial Leaded: Vishay DaleWilson Yecit OrtizNo ratings yet

- Capa Panasonic Low EsrDocument5 pagesCapa Panasonic Low EsrClovis APOVONo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- MIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9Document2 pagesMIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9Hüseyin VarolNo ratings yet

- Data Sheet HPL 50 7/8 LA AST M5422: Fire Resistant Low Smoke Zero Halogen JacketDocument1 pageData Sheet HPL 50 7/8 LA AST M5422: Fire Resistant Low Smoke Zero Halogen JacketEugeneZarubinNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Instruction Manual Enardo Series 950 Pressure Vacuum Relief Valve Series 7 Flame Arrestor en Us 166422Document16 pagesInstruction Manual Enardo Series 950 Pressure Vacuum Relief Valve Series 7 Flame Arrestor en Us 166422comercial mox asesoria100% (2)

- AN00122-003 - Rotary Axis Flying ShearDocument6 pagesAN00122-003 - Rotary Axis Flying ShearamirixmNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Generator Design StepsDocument40 pagesGenerator Design StepsrajfabNo ratings yet

- ManifoldDocument10 pagesManifoldjosé_filipe_35No ratings yet

- Performance BMW - November 2015Document108 pagesPerformance BMW - November 2015adonxNo ratings yet

- Cooling Tower Specs & FeaturesDocument3 pagesCooling Tower Specs & FeaturesAndi SogaraNo ratings yet

- Sandvik DT820Document4 pagesSandvik DT820Boni Christian100% (3)

- Dewan: Cement LimitedDocument6 pagesDewan: Cement LimitedIrfan AhmedNo ratings yet

- Acura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairDocument11 pagesAcura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairCarlos Gunter Tamayo MoralesNo ratings yet

- 2019 - 1.19. Zavarivačke LaboratorijeDocument33 pages2019 - 1.19. Zavarivačke LaboratorijeticmaNo ratings yet

- Unit 7 - Week 6: Assignment 06Document3 pagesUnit 7 - Week 6: Assignment 06SaurabhNo ratings yet

- Vaccum Pump DatasheetDocument6 pagesVaccum Pump DatasheetQuietRideNo ratings yet

- Advanced Gas Turbine CyclesDocument230 pagesAdvanced Gas Turbine CyclesHùng Nguyen100% (1)

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 21R807-0012-B5Document27 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 21R807-0012-B5pepiperepalo3No ratings yet

- Methanolinjection - XLS: This Spreadsheet Calculates The Minimum Amount of Required Inhibotor Usage. InstructionsDocument3 pagesMethanolinjection - XLS: This Spreadsheet Calculates The Minimum Amount of Required Inhibotor Usage. Instructionsmath62210100% (1)

- CFD Modelling and Analysis of Clark Y Airfoil For Turbulent FlowDocument4 pagesCFD Modelling and Analysis of Clark Y Airfoil For Turbulent FlowInnovative Research PublicationsNo ratings yet

- Report of Railway Workshop Parel 44Document35 pagesReport of Railway Workshop Parel 44informaadil05No ratings yet

- 7 - Control and MonitoringDocument963 pages7 - Control and MonitoringGláucio QuintanilhaNo ratings yet

- Chill Down Process of Hydrogen Transport PipelinesDocument19 pagesChill Down Process of Hydrogen Transport PipelinesmsreerajvarmaNo ratings yet

- W13 GR EX 4 OpCraningDocument31 pagesW13 GR EX 4 OpCraningbayu septianNo ratings yet

- Injection Pump Test Specifications 093000-677#Document3 pagesInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- P310Document2 pagesP310CoreconNo ratings yet

- FCU ChecklistDocument11 pagesFCU ChecklistdesignselvaNo ratings yet

- Thin-Walled Structures: Full Length ArticleDocument17 pagesThin-Walled Structures: Full Length ArticleSeban ACNo ratings yet

- Multi Baypas MB-504Document16 pagesMulti Baypas MB-504Veseljko RikićNo ratings yet

- Asonic Ghy 72 IngDocument2 pagesAsonic Ghy 72 IngseegnaNo ratings yet

- 1.design For Shear For Prestressed ConcreteDocument34 pages1.design For Shear For Prestressed ConcretealexNo ratings yet

- Motion and Gravity LessonsDocument14 pagesMotion and Gravity LessonsMEERA JOY BLANCONo ratings yet

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarNo ratings yet