Professional Documents

Culture Documents

MIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9

Uploaded by

Hüseyin VarolOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9

Uploaded by

Hüseyin VarolCopyright:

Available Formats

MIDLAND FASTENERS LTD.

,

PRE LOAD HSFG 14399-3 (HR) BOLT

STANDARDS BS EN 14399-3 8.8 &10.9 (British & EN Standard)

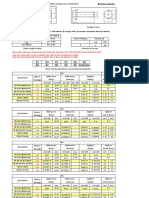

Nominal Dia M12 M16 M20 M22 M24 M27 M30 M36

Coarse Pitch 1.75 2.00 2.50 2.50 3.00 3.00 3.50 4.00

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max

Unthread Shank ds 11.30 12.70 15.30 16.70 19.16 20.84 21.16 22.84 23.16 24.84 26.16 27.84 29.16 30.84 35.0 37.00

Across Flat s 21.16 22.00 26.16 27.00 31.00 32.00 35.00 36.00 40.00 41.00 45.00 46.00 49.00 50.00 58.80 60.00

Across Corner e 23.91 min 29.56 min 35.03 min 39.55 min 45.20 min 50.85 min 55.37 min 66.40 min

Head Thickness k 7.05 7.95 9.25 10.75 11.60 13.40 13.10 14.90 14.10 15.90 16.10 17.90 17.65 19.75 21.45 23.55

Face Washer dofw 20.10 min 24.90 min 29.50 min 33.50 min 38.00 min 42.80 min 46.60 min 55.90 min

Face Washer Depth c 0.4 0.8 0.4 0.8 0.4 0.8 0.4 0.8 0.4 0.8 0.4 0.8 0.4 0.8 0.4 0.8

Radios r 1.2 min 1.2 min 1.5 min 1.5 min 1.5 min 2.0 min 2.0 min 2.0 min

Transition Diameter de 15.10 15.20 19.10 19.20 23.95 24.10 25.90 26.00 28.30 28.40 32.30 32.40 34.95 35..05 41.00 41.10

Mechanical Properties 8.8 &10.9

Characteristic Standard Size

Stress Proof Load Ultimate P. Hardness

Area min Load min HRC

2

General Requirement BS EN 14399-1 mm kN kN min max

Material Properties BS EN ISO 898-1 Property Class 8 & 10 M12 84.3 50.7 70 23 34

Mechanical Properties BS EN 14399-3, BS EN ISO 898-1 8.8 & 10.9 M16 157 94.5 130 23 34

Zinc Electroplated BS EN 14399-3 as process M20 245 147 203 23 34

Finish /

Self Color Black BS EN ISO 4042 or BS 7371-3 M22 303 182 252 23 34

Coating

Hot Dip Galvanized BS EN ISO 10684 M24 353 212 293 23 34

Dimension & Tolerance BS EN 14399-3 M27 459 275 381 23 34

Thread ISO 261, ISO 965-2 tolerance Class 6g M30 561 337 466 23 34

Product Marking BS EN 14399-3 M36 817 490 678 23 34

Under the BS EN 14399 standard it is required that the Bolt Nut & Washer shall be assembled by one Manufacture who should be responsible for the function of the assembly. A set (Bolt Nut

Washer) should identify by manufacture identification mark / Head Marking and the coating of the assembly should be controlled by the manufacture.

All dimension are based on mm

All dimenssions based on MM. All above data has been reference from DIN EN 14399-3 standard. company dose take any responsibility for any damages in any circumstance. for any further detail please refer the original reference book.

MIDLAND FASTENERS LTD.,

k Length

c Length

r

d

e

da d f 45 o

d

d dedf s

o

30

MF MF

Bolt / Nut / Washer Assembly Systems HR/HV

8.8HR 10.9HR

General Requirement BS EN 14399-1

Materials & Manufacture BS EN 14399-3 / 4

Marking HR /HV

Property Classes 8.8/8 HR 10.9/10 HV

EN 14399-3/4,5 Or

Washer (s)

EN 14399-6

Marking H

Suitable Test for

EN 14399-2

Preloading

All dimenssions based on MM. All above data has been reference from DIN EN 14399-3 standard. company dose take any responsibility for any damages in any circumstance. for any further detail please refer the original reference book.

You might also like

- Astm A325m PDFDocument1 pageAstm A325m PDFFrose KhanNo ratings yet

- Pre-Load: Bolt Assemblies HR BS EN 14399-3:2015Document5 pagesPre-Load: Bolt Assemblies HR BS EN 14399-3:2015erharsinghNo ratings yet

- Pre-Load Bolt Assemblies BS EN 14399 - 4Document4 pagesPre-Load Bolt Assemblies BS EN 14399 - 4vpjagannaathNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Structural WasherDocument1 pageStructural WasherHARDEEP SINGHNo ratings yet

- Maintenance Manual: Safety Instructions in MaintenanceDocument9 pagesMaintenance Manual: Safety Instructions in MaintenanceYankonde ChisenseNo ratings yet

- DRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CDocument2 pagesDRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CBimal DeyNo ratings yet

- Tse 708 B420C 2Document1 pageTse 708 B420C 2ihsankeskinnNo ratings yet

- Arruelas MMDocument1 pageArruelas MMsergioNo ratings yet

- Non-Pre Load Hexagon Nut Bs 3692: Standards BS3692 (British Standard)Document2 pagesNon-Pre Load Hexagon Nut Bs 3692: Standards BS3692 (British Standard)Mahfuz AlamNo ratings yet

- Particle size distribution test resultsDocument13 pagesParticle size distribution test resultskwameNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- Pacific Pipe World Class QualityDocument1 pagePacific Pipe World Class QualityDo BuiNo ratings yet

- bs1387 1 PDFDocument1 pagebs1387 1 PDFNarinder SinghNo ratings yet

- Pacific Pipe World Class QualityDocument1 pagePacific Pipe World Class QualityDo BuiNo ratings yet

- PHLAudio - Bass 20cm-8inchDocument1 pagePHLAudio - Bass 20cm-8inchRoberto richardsenNo ratings yet

- Container Crane DataDocument2 pagesContainer Crane Datathinh_vu5218No ratings yet

- Service Entrance PostDocument12 pagesService Entrance PostSarah BatallerNo ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- Floor Slab DesignDocument3 pagesFloor Slab DesignAnonymous jLLjBdrNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- 19 - Tds - Emaco r307Document5 pages19 - Tds - Emaco r307aahtagoNo ratings yet

- Polim-H02sdDocument4 pagesPolim-H02sdkatak.chanNo ratings yet

- 6030 - Kokele - 6259 - Zambouroula - FinDocument9 pages6030 - Kokele - 6259 - Zambouroula - FinDieu Donne KpeleNo ratings yet

- RKBK Dsign FinalDocument19 pagesRKBK Dsign Finalgagan kumarNo ratings yet

- Beam Design ReportDocument22 pagesBeam Design Reportkwoshaba pidsonNo ratings yet

- Oil BDV VectorDocument3 pagesOil BDV Vectorvevese8616No ratings yet

- Nickel AlloysDocument2 pagesNickel AlloysmeNo ratings yet

- Technical Data Sheet TECHSTRAP 2020Document1 pageTechnical Data Sheet TECHSTRAP 2020BalrajNo ratings yet

- LKIF in Line Strainers Product LeafletDocument3 pagesLKIF in Line Strainers Product LeafletGisela ViskaNo ratings yet

- Cable Slickline SUPA 40Document1 pageCable Slickline SUPA 40Rafael EspinosaNo ratings yet

- Project:-Ato Eyasu Merachew G+2 Residential Date: - 25/12/2007 E.C Description: - Analysis and Design of Solid Slab By: - Abdela MohammedDocument7 pagesProject:-Ato Eyasu Merachew G+2 Residential Date: - 25/12/2007 E.C Description: - Analysis and Design of Solid Slab By: - Abdela MohammedGemechuNo ratings yet

- Area of SteelDocument26 pagesArea of Steelaqib.syed1011No ratings yet

- RW14.4 MeterDocument4 pagesRW14.4 Metermoorastar1No ratings yet

- Go PiDocument5 pagesGo PiStacey ShortNo ratings yet

- Metric DIN 6926 SpecDocument4 pagesMetric DIN 6926 Spec叶开No ratings yet

- PS + MG Specifications: Model PS1 PS2 PS3 PS4 PS5 PS6Document1 pagePS + MG Specifications: Model PS1 PS2 PS3 PS4 PS5 PS6peter vuNo ratings yet

- Wall Thickness Dnno: Profile Size Outside Diameter MM No. of Pipes Per Bundle No. of Pipes Per Ton (Average)Document1 pageWall Thickness Dnno: Profile Size Outside Diameter MM No. of Pipes Per Bundle No. of Pipes Per Ton (Average)Dilhara WickramaarachchiNo ratings yet

- #REF! Name of The Work: Replacement of Filter Media in Slow Sand Filter of Size 10.00M DiaDocument12 pages#REF! Name of The Work: Replacement of Filter Media in Slow Sand Filter of Size 10.00M Diaae rwsNo ratings yet

- PT Paver Strength CalculationsDocument3 pagesPT Paver Strength CalculationsEr Narayan ApawatNo ratings yet

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- TDS PH MacTexMXL May2014Document1 pageTDS PH MacTexMXL May2014Catherine MagnayeNo ratings yet

- Comparative (3) RaaDocument13 pagesComparative (3) RaaRajeev MishraNo ratings yet

- S-CONCRETE Results Report PDFDocument2 pagesS-CONCRETE Results Report PDFDani MelkiNo ratings yet

- Concrete Section S-CONCRETE Version 2017.2.2 Job #A123.45Document2 pagesConcrete Section S-CONCRETE Version 2017.2.2 Job #A123.45Dani MelkiNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Kadamane Mini Hydel Scheme Stiffener Plate CalculationDocument5 pagesKadamane Mini Hydel Scheme Stiffener Plate CalculationKumaranNo ratings yet

- Stressing Record Form - RC BlisterDocument20 pagesStressing Record Form - RC Blistermayoo1986No ratings yet

- Diseño Puente Compuesto de Vigas-I Puente 8.00 Datos Superestructura MaterialesDocument12 pagesDiseño Puente Compuesto de Vigas-I Puente 8.00 Datos Superestructura MaterialesJesús Rodríguez RodríguezNo ratings yet

- Western Irrigation System Pvt. LTD.: Quality in Every WayDocument8 pagesWestern Irrigation System Pvt. LTD.: Quality in Every WayRameshPrithivirajNo ratings yet

- NEISCO Technical Catalog 2020 Features UPVC Pressure FittingsDocument66 pagesNEISCO Technical Catalog 2020 Features UPVC Pressure FittingsKadiri El MoustaphaNo ratings yet

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- BS_EN_14399-3_8_8Document10 pagesBS_EN_14399-3_8_8minhhieu.qcNo ratings yet

- Juja RCBeamDes22Document36 pagesJuja RCBeamDes22derichanzuNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Kyodo Pipe Producs SpecificationDocument3 pagesKyodo Pipe Producs SpecificationTengku MunzirNo ratings yet

- Steel Construction: Today & TomorrowDocument20 pagesSteel Construction: Today & Tomorrowthanhbt81No ratings yet

- Arch Bridge DesignDocument38 pagesArch Bridge DesignHüseyin Varol100% (1)

- GN 4-03Document4 pagesGN 4-03Hüseyin VarolNo ratings yet

- RSA 2015 - Wind - SimulatorDocument16 pagesRSA 2015 - Wind - Simulatorsautier_thomasNo ratings yet

- 6 Restrained Beams HandoutDocument2 pages6 Restrained Beams HandoutHakan EzcanNo ratings yet

- Feasibility ReportDocument10 pagesFeasibility ReportAdityaNo ratings yet

- SMAI Assignment 7 Report - 20161204 PDFDocument6 pagesSMAI Assignment 7 Report - 20161204 PDFAliNo ratings yet

- MR Khurram Chakwal 6kw Hybrid - 024627Document6 pagesMR Khurram Chakwal 6kw Hybrid - 024627Shahid HussainNo ratings yet

- Java Programming: Lab Assignment 2Document17 pagesJava Programming: Lab Assignment 2Sanjana chowdary50% (4)

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Document6 pagesPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNo ratings yet

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- Truck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionDocument4 pagesTruck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionRodrigo LealNo ratings yet

- Bus Crash LawsuitDocument7 pagesBus Crash LawsuitNewsTeam20No ratings yet

- Azbil - SS2 DEO412 0010 02Document12 pagesAzbil - SS2 DEO412 0010 02Magoroku D. YudhoNo ratings yet

- HMSWeb - Handover Management SystemDocument21 pagesHMSWeb - Handover Management SystemGG GRNo ratings yet

- Plan & Elevation of Dog-Legged StaircaseDocument1 pagePlan & Elevation of Dog-Legged Staircasesagnik bhattacharjeeNo ratings yet

- Altracs: A Superior Thread-Former For Light AlloysDocument8 pagesAltracs: A Superior Thread-Former For Light AlloysSquidwardNo ratings yet

- SDSU PhD Research on Soil HealthDocument2 pagesSDSU PhD Research on Soil HealthTiruneh GA25% (4)

- Document 10Document5 pagesDocument 10Filza FatimaNo ratings yet

- Pulse of Fintech h2 2020Document72 pagesPulse of Fintech h2 2020OleksandraNo ratings yet

- Connect Debug LogDocument20 pagesConnect Debug LogrohanZorba100% (1)

- Davall Stock Gears Worm Wheel Gear Sets 17pages PDFDocument17 pagesDavall Stock Gears Worm Wheel Gear Sets 17pages PDFharish ahireNo ratings yet

- Osg VS Ayala LandDocument17 pagesOsg VS Ayala LandJan BeulahNo ratings yet

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet

- 12.CEH Module 3 Assignment 3.1Document7 pages12.CEH Module 3 Assignment 3.1piyuhNo ratings yet

- Cebu Oxygen Acetylene Co., vs. Drilon, G.R. No. 82849, August 2, 1989Document6 pagesCebu Oxygen Acetylene Co., vs. Drilon, G.R. No. 82849, August 2, 1989JemNo ratings yet

- Operating Instructions MA 42 - Maico Diagnostics PDFDocument28 pagesOperating Instructions MA 42 - Maico Diagnostics PDFJuan PáezNo ratings yet

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- Robotic Surgery History and SystemsDocument28 pagesRobotic Surgery History and SystemsLidhi DileepNo ratings yet

- Matrix 210N Reference Manual 2017 PDFDocument167 pagesMatrix 210N Reference Manual 2017 PDFiozsa cristianNo ratings yet

- UntitledDocument29 pagesUntitledsav 1011100% (1)

- Lucsuhin National High School Daily Lesson Plan on Accounting ConceptsDocument6 pagesLucsuhin National High School Daily Lesson Plan on Accounting ConceptsALMA ACUNANo ratings yet

- DataSheet ULCAB300Document2 pagesDataSheet ULCAB300Yuri OliveiraNo ratings yet

- More User Manuals OnDocument78 pagesMore User Manuals OnNicolae HincuNo ratings yet