Professional Documents

Culture Documents

BV Faultfinding Manual

BV Faultfinding Manual

Uploaded by

Roger RogelioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BV Faultfinding Manual

BV Faultfinding Manual

Uploaded by

Roger RogelioCopyright:

Available Formats

Philips Healthcare

NEWSLETTER Service

Issued by : GXR Best Reference No. : XRD-Best 305

Publication No. : 4522 981 62981 Date : November 2008

Information for :

FSE X-ray Surgery Surgery Specialist

BV family R.2.X. Faultfinding Guide

APPLIES TO:

This newsletter applies to the BV Family R.2.X. systems.

SUMMARY

The main purpose of this document is to address the newly released FCO’s published in 2008. These FCO’s

are focusing on solutions for a number of error codes (Error, 206, 327, 343, 393 and other messages which

can be found in the system logfile) and image quality problems like pixilated images and lines across the

image. These problems are mainly release 2.X system based. The workflow explained in this document could

greatly reduce the problems in the field related to error codes listed in this document and the image quality

problems.

NOTE: This document will not address problems related to the generator, battery (ESU), DFI and collimator.

This document mainly focuses on faultfinding on the imaging chain.

Further we give some references to 5 FCO’s that have been published recently

• FCO71800024 (Upgr. Stand-Mvs cable for BV-Family R2 systems)

• FCO71800026 (Modification of extended rotation brake)

• FCO71800027 (R2.x Upgr. to BV-Family SW R2.2.6.)

• FCO71800029 (R2.3 Upgr. to BV-Family SW R2.3.3.)

• FCO71800030 (C-Arc cable replacement for BV-Pulsera R2 systems (USA only, GSSI will follow)

FCO71800031 will be published shortly, this is the C-arc cable replacement for the BV-Endura (USA only)

The system faults in a BV Family release 2 system can be distinguished into 3 categories:

1. Errors indicated by error messages on the system.

2. Distorted images.

3. Other system faults (not described in the standard BV Family R2 service manuals).

Some system error messages reported on the C-Arm stand (SUCO) are explained in chapter 2.

When the system (C-arm stand) generates no error messages, and when distorted images are observed refer

to chapter 3.

XRD-Best 305 CSIP Level 1 ( 08.0) 1

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Contents:

APPLIES TO: .....................................................................................................................................................1

SUMMARY .........................................................................................................................................................1

INTRODUCTION ................................................................................................................................................3

1.1 Abbreviations & terms..............................................................................................................................3

1.2 Overview of released FCO’s....................................................................................................................3

1.3 Schematic overview of the system ..........................................................................................................4

1.4 How to find and handle error messages..................................................................................................6

1.5 Error messages on the C-arc stand display ............................................................................................6

2 ERROR RELATED FCO’S......................................................................................................................7

2.1 Error 050 ..................................................................................................................................................8

2.2 Error 393 ................................................................................................................................................10

2.3 Error 206 ................................................................................................................................................14

2.4 Error 326/327.........................................................................................................................................15

2.5 Error 343 ................................................................................................................................................16

2.6 Guarding messages...............................................................................................................................17

2.7 Corrupt system logfile ............................................................................................................................18

3 IQ COMPLAINTS ..................................................................................................................................19

3.1 Camera Test pattern..............................................................................................................................20

3.2 Stand MVS cable failure ........................................................................................................................22

3.3 C-arc cable failure..................................................................................................................................23

3.4 Auto Contrast Brightness artefacts........................................................................................................27

3.5 Movement ..............................................................................................................................................29

3.6 Movement distortion in subtracted images ............................................................................................29

3.7 “Dirty Noise” ...........................................................................................................................................29

3.8 Digital Exposure.....................................................................................................................................30

2 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

INTRODUCTION

1.1 ABBREVIATIONS & TERMS

Abbreviations/terms Description

ACB Automatic Contrast Brightness

Burndy plug SA-X1 connector

CAMLINK Camera link (between XTV-7 or IDS and Timing Control Board SHA3)

DFI Digital Fluoroscopy Imaging

FCO Field Change Order

GBE GigaBitEthernet

GBE link GigaBitEthernet link (= IDS link)

MVS Mobile Viewing Station

SUCO SUrgery CO-ordinator

SCPU Stand Controller and Power Unit

IDS Image Detection Subsystem

IDS7 Image Intensifier with digital XTV-7 camera

IDS link Image Detection Subsystem link

TCB Timing Control Board (SHA3)

UI User Interface

Unrel Unreliable IDS link

Table 1

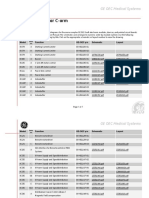

1.2 OVERVIEW OF RELEASED FCO’S

The following FCO’s haven been published, some will be superseded:

FCO Type Problems Æ solutions

FCO71800017 Service Recom. Pixel faults, error 206 Æ C-arc cable modification.

USA only

FCO71800018 Service Recom. XGC pulse board error M326/327 Æ Change SHA-4 board

FCO71800019 Action for Perf. Error M393 / IDSlink errors Æ Improve the connections.

Superseded by FCO 71800024

FCO71800020 Service Recom. USB connections not working Æ Change USBBOB

FCO71800021 Action for Perf. Error M343 Æ Reprogram the mains voltage.

USA only

FCO71800022 Mandatory C-arc stand shutdown Æ Software Upgrade to 2.2.4.

Superseded by FCO71800027

Table 2

The following FCO’s haven been published recently (august 2008):

FCO Type Problems Æ solutions

FCO71800024 Mandatory Error M393 / IDSlink errors Æ Improve connections :

This FCO supersedes FCO71800019

FCO71800026 Mandatory Adjustment of the Extended rotation brake

FCO71800027 Action for Perf. IQ Æ Software Upgrade to 2.2.6. (rel 2.1 & 2.2)

This FCO supersedes FCO71800022

FCO71800029 Action for Perf. IQ Æ SW Upgrade to 2.3.3 for SCPU (rel. 2.3) systems

FCO71800030 Action for Perf. Pixel faults, error 206 Æ new designed C-arc cable for Pulsera R2

Table 3

The following FCO will be issued within short terms (januari 2008):

FCO Type Problems Æ solutions

FCO71800031 Action for Perf. Pixel faults, error 206 Æ new designed C-arc cable for Endura R2

Table 4

XRD-Best 305 CSIP Level 1 ( 08.0) 3

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

1.3 SCHEMATIC OVERVIEW OF THE SYSTEM

1.3.1 Signal routing with TCB-2 version

4 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

1.3.2 Signal routing with TCB-3 version

1.3.3 Signal routing in SCPU systems

XRD-Best 305 CSIP Level 1 ( 08.0) 5

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

1.4 HOW TO FIND AND HANDLE ERROR MESSAGES

Error messages can appear on the display of the C-arc stand or on the left monitor of the mobile viewing

station. Messages generated by the SUCO or SCPU processor will appear on the User Interface (UI) of the C-

arc stand. Messages generated by the DFI processor will appear at the bottom of the left screen of the Mobile

Viewing Station (MVS). This guideline focuses on the error messages which appear on the UI of the C-arc

stand. These system faults are related to a problem in the C-arc stand.

Please refer to the Service Manual Corrective Maintenance (SMCM) when a DFI error occurs.

1.5 ERROR MESSAGES ON THE C-ARC STAND DISPLAY

Error messages on the C-arc stand display are generated by the SUCO or SCPU processor.

To identify an error:

1. Press <INFO> on the C-arc stand. A list of errors appears that occurred around the same point in

time. The first error in the list is probably the cause of the other errors.

2. Connect Service PC to the Service Ethernet port of the MVS.

3. Restart the system on the MVS.

4. In the setup panel of the MVS: select Enable service.

5. Startup BV-Scope on the Service PC.

6. Enter the Service IP-address from the system in BV-Scope.

7. In BV-Scope select: Faultfind > Logging > Logfile Complete System.

8. Save the logfile with the Serial number of the system and with the extension txt. (e.g. FK259.txt). To

do so, press the SAVE button in BV-Scope and change “logging.txt” to systemserialnumber.txt as

described above.

9. Open the logfile with Notepad.

10. Start the search function. Press <CTRL>+<F>

11. Fill in the parameters from table 5 (below) into the search window, press Find Next, exit the search

window by pressing <esc> and press F3 (next).

12. When one or more error(s) is/are found refer to the relevant FCO’s to solve the problem.

NOTE: when following this sequence it’s easier to search for errors in the logfile.

6 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2 ERROR RELATED FCO’S

The following table (table 5) shows the relation between an error code, applicable FCO that is associated with

this error code and the possible cause of this error.

Error code & (Possible) cause Refer to FCO Problem explanation

messages

No communication between DFI and

Error 050 n.a. Chapter 2.1

SUCO

Doselink problem. IDS link connection

Error 393 FCO71800024 Chapter 2.2

problem between SUCO and DFI

FCO71800028,

Camera link problem (C-arc cable),

Error 206 FCO71800030, Chapter 2.3

IDS-7 or bad IDS Interface Board

FCO71800031

Incorrect functioning ADC circuit on

Error 327 FCO71800018 Chapter 2.4

the XGC-board

Error 343 Mains voltage too low FCO71800021 Chapter 2.5

Unreliable IDS IDS link connection problem between

FCO71800024 Chapter 2.2

link SUCO and DFI

• Interrupted Stand-MVS

communication

guarding • Problem with SHA 1 board FCO71800022 Chapter 2.6

• Software handling when using the

remote control.

Wrong writing of pointer corrupts

logfile, solved in 2.2.6. software.

Corrupt logfile FCO71800027 -

This problem is not present in 2.3

releases.

Table 5

NOTE:

Error 0 in the logfile does not mean a real error occurred in the system, but a message from the system. The

error can be caused by the key switch (X-ray disabled) or after fluoroscopy longer then 5 minutes.

For faultfinding Error 0 can be ignored.

Error 371 refers to a malfunction of the oil pump of the monoblock(xray tank). When this error pops up

occasionally, it is caused by mis-communcation between the units. In these cases also this error can be

ignored.

XRD-Best 305 CSIP Level 1 ( 08.0) 7

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.1 ERROR 050

Error 50 is displayed when there is no communication between the DFI and the SUCO. In most cases this is

in combination with another, fatal error. So, always check with the information button or the logging for other

error messages.

2.1.1 Normal start up

In a normal start up you can find a sequence of the following lines:

0xf8c5108 (tPPPFramework_C_1): PPP connection between subsystems established

This line indicates the DFI/MVS has noticed there is a stand connected to the MVS and starts to communicate

with the MIDAS.

…..

08-05-14 21:04:36 S INI Connect_subsystems(): DFI <-> STAND connection established.

Connection between DFI and MIDAS is starting

…..

08-05-14 21:04:38 M INI Synchronising Databases...

The DFI sends out to MIDAS information

…..

08-05-14 21:04:39 M INI Done synchronising Databases...

The MIDAS replies, start up has passed the connection state

2.1.2 error 50 in combination with another error

2.1.2.1 Logging example

07-10-31 10:32:15 W<XGI Error 326

The self test of the RA generator board SHA4 has

failed. The X-ray function is disabled. See

error message 325

07-10-31 10:32:15 N<XGI XGIMAC: Unexpected event "WRITE_KV" in state STATE_INIT

07-10-31 10:32:15 S<INI All suco tasks started

07-10-31 10:32:15 S SYS System startup ERROR: not all SHAL packages ready

07-10-31 10:32:15 S SYS GUI software compatibility level=4

07-10-31 10:32:15 S SYS DFI software compatibility level=4

07-10-31 10:32:15 S SYS System startup ERROR: a fatal error occurred

07-10-31 10:32:15 W SYS Error 50

A system startup problem occurred. Switch the system

off and on. If the problem persists, check if

the Mobile Viewing Station and the Stand are

correctly connected. Check the Stand-Mobile

Viewing Station cable.

2.1.2.2 Solution

Check the system for other errors and first solve these. Most likely afterwards the system will operate without

these errors.

8 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.1.3 No Boot up.

When first line is missing none of the other will follow. i.e. The DFI has not detected any present stand.

When the system does not start normally and remains in the black screen with the hourglass, the application

has not started.

2.1.3.1 Logging example

08-04-25 08:55:29 S INIT Initialising software modules

08-04-25 08:55:31 M SYS Fluoro timer task started

08-04-25 08:55:31 S SYS BIST of SRV_pack passed

08-04-25 08:55:31 S SRV Successfully registered WWS symbols as windmarks

0xf8c5108 (tPPPFramework_C_1): PPP connection between subsystems established

08-04-25 08:55:36 S INI Connect_subsystems(): DFI <-> STAND connection established.

08-04-25 08:55:36 S INI Using shal: /scsi0/bins/shal

08-04-25 08:59:10 S INIT Network hook initialized for interface emac, firewall is enabled

08-04-25 08:59:10 S INIT > > > > INIT_Main: Starting application < < < <

08-04-25 08:59:10 S INIT R2.2.4

08-04-25 08:59:10 S INIT 23-July-2007

08-04-25 08:59:10 S INIT

Note the time gap between 08-04-25 08:55:36 and 08-04-25 08:59:10. Over here the customer has waited for

3.5 minutes before giving a restart to the system. During this time the system logfile did not record any action.

2.1.3.2 Solution

For this issue perform FCO71800027. Install software rel 2.2.6 (SUCO systems), this bug is already solved in

all 2.3 SCPU releases.

XRD-Best 305 CSIP Level 1 ( 08.0) 9

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.2 ERROR 393

When error 393 occurs the doselink signal form DFI to Midas is interrupted. This can occur in different ways.

All have different causes.

2.2.1 Error 393 in combination with message “unreliable IDS Link detected”.

This is caused by an incorrect stand-MVS cable and / or the interconnection between SA-X1 pin S and T and

the SHA 3 board.

2.2.1.1 Logging example

Example of error 393 in combination with the message “unreliable IDS Link detected”. Note the error message

is directly followed by the message.

07-01-31 08:53:47 M SYS Xray mode continuous fluoro

07-01-31 08:53:47 M USR START FLUORO RUN

07-01-31 08:53:47 M USR MEASURE AREA

07-01-31 08:53:47 M USR CHANGE IRIS SETTINGS

07-01-31 08:53:47 M USR MEASURE AREA

07-01-31 08:53:47 M USR CHANGE SHUTTER SETTINGS

07-01-31 08:53:47 M USR MEASURE AREA

07-01-31 08:53:47 W IP intErrParamValidate

07-01-31 08:53:47 M LIVE Image received at 123823

07-01-31 08:53:48 M SYS rec ABORT XRAY from XGI_pack

07-01-31 08:53:48 W<XGI Error 393

Check cabling between SUCO Midas board (SHA1) and DFI.

07-01-31 08:53:48 M USR STOP FLUORO RUN

07-01-31 08:53:48 W IP Unreliable IDS link detected, 22 frames, 6662 bit err/frame, 146568 total bit errors

07-01-31 08:53:49 W LIVE DICOM suspend: DCM server has completed without cancel!

07-01-31 08:54:05 M SYS USR kv reg manual

2.2.1.2 Solution

Replace the Stand-MVS cable and the interconnection between SA X1 (pin S and T) and the SHA3 board as

mentioned in FCO 718 00 024.

10 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.2.2 Error 393 during examination

It is possible the error 393 occurs during examinations, and directly after this it is possible to perform

fluoroscopy again without error. This also indicates the stand-MVS cable or the interconnection between SA

X1 pin S and T towards the SHA3 board is unreliable.

Error 393 can be caused by 2 situations:

• Bad IDS-link (stand-trolley cable and problems in the wired-bracket.

• Timing issues causes M393 at first fluoro after startup.

2.2.2.1 Logging example

06-12-06 10:36:49 M SYS Xray mode continuous fluoro

06-12-06 10:36:49 M USR START FLUORO RUN

06-12-06 10:36:49 M DCM Wait for association is aborted

06-12-06 10:36:49 M LIVE Image received at 75694

06-12-06 10:36:51 M SYS USR switch off at 75845

06-12-06 10:36:51 M SYS actual kV setting = 45 kV

06-12-06 10:36:51 M USR STOP FLUORO RUN

06-12-06 10:36:53 M SYS USR switch on LEFT at 76068

06-12-06 10:36:53 M SYS Xray mode continuous fluoro

06-12-06 10:36:53 M USR START FLUORO RUN

06-12-06 10:36:53 M DCM Wait for association is aborted

06-12-06 10:36:53 M LIVE Image received at 76118

06-12-06 10:37:05 M SYS rec ABORT XRAY from XGI_pack

06-12-06 10:37:05 W<XGI Error 393

Check cabling between SUCO Midas board (SHA1) and DFI.

06-12-06 10:37:05 M USR STOP FLUORO RUN

06-12-06 10:37:05 W<TVI CxaPsWait4Ack : Timeout

06-12-06 10:37:06 W IP intErrAtrFrameLost

06-12-06 10:37:06 W IP Exclusion levels timing error

06-12-06 10:37:06 W<TVI CxaPsWait4Ack : Timeout

06-12-06 10:37:06 W IP intErrAtrFrameLost

06-12-06 10:37:06 W IP Exclusion levels timing error

06-12-06 10:37:06 W IP intErrAtrFrameLost

06-12-06 10:37:06 W<TVI CxaPsWait4Ack : Timeout

06-12-06 10:37:10 M SYS USR switch on LEFT at 77811

06-12-06 10:37:10 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 31

06-12-06 10:37:10 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 32

06-12-06 10:37:10 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 33

06-12-06 10:37:10 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 34

06-12-06 10:37:10 M SYS Xray mode continuous fluoro

06-12-06 10:37:10 M USR START FLUORO RUN

06-12-06 10:37:10 M DCM Wait for association is aborted

06-12-06 10:37:11 M LIVE Image received at 77858

06-12-06 10:37:16 M SYS USR switch off at 78354

06-12-06 10:37:16 M SYS actual kV setting = 45 kV

06-12-06 10:37:16 M USR STOP FLUORO RUN

2.2.2.2 Solution

Replace the Stand-MVS cable and the interconnection between SA X1 (pin S and T) and the SHA3 board as

mentioned in FCO 718 00 024.

XRD-Best 305 CSIP Level 1 ( 08.0) 11

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.2.3 Error 393 at first time fluoro after system start up.

When the error 393 occurs when the first time fluoroscopy is used after start up of the system most likely the

communication between the camera and the DFI has not proper set up (note the last lines, indicating no

image has been received at the DFI).

2.2.3.1 Logging example

Example of an error 393 at the first time fluoroscopy directly after start up.

08-09-22 11:10:58 M SYS Xray mode continuous fluoro

08-09-22 11:10:58 M USR START FLUORO RUN

08-09-22 11:10:58 M DCM Wait for association is aborted

08-09-22 11:10:58 M USR MEASURE AREA

08-09-22 11:10:58 M USR CHANGE IRIS SETTINGS

08-09-22 11:10:58 M USR MEASURE AREA

08-09-22 11:10:58 M USR CHANGE SHUTTER SETTINGS

08-09-22 11:10:58 M USR MEASURE AREA

08-09-22 11:10:58 M SYS rec ABORT XRAY from XGI_pack

08-09-22 11:10:58 W<XGI Error 393

Check cabling between SUCO Midas board (SHA1)and DFI.

08-09-22 11:10:58 M USR STOP FLUORO RUN

08-09-22 11:11:06 M SYS USR switch on LEFT at 142750

08-09-22 11:11:06 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 1

08-09-22 11:11:06 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 2

08-09-22 11:11:06 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 3

08-09-22 11:11:06 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 4

2.2.3.2 Solution

Check the Knova tip regarding this issue. It will be updated on a regular basis. Look in Knova for the

searchstring “error 393 at first fluoro”. A definitive solution is still under investigation by PMG Best.

12 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.2.4 Error 393 at start up on a rel 2.3.1. system

In the systems with a SCPU the logging text has been changed. The new, more detailed error information

shows 4 steps to determine the cause of error.

2.2.4.1 Logging example

08-08-28 08:33:15 M SYS Xray mode continuous fluoro

08-08-28 08:33:15 M USR START FLUORO RUN

08-08-28 08:33:15 M USR CHANGE IRIS SETTINGS

08-08-28 08:33:15 M USR MEASURE AREA

08-08-28 08:33:15 M USR CHANGE SHUTTER SETTINGS

08-08-28 08:33:15 M USR MEASURE AREA

08-08-28 08:33:15 M SYS rec ABORT XRAY from XGI_pack

08-08-28 08:33:15 W<XGI Error 393

Automatic dose adjustment failed. Perform the

following steps to solve this problem.

Step (1): Check if this error is combined with the

log message [Warning IDS Link......]. If Yes, check

the connections and cable between C-arm stand and MVS.

If No go to step 2.

Step (2): Switch the system to manual kV and start

radiation. When an image is displayed at the MVS check the

dose link between the SCPU (SCC) and DFI (connections and

cable between C-arm stand and MVS, DFI connection WD:X8).

When NO image is displayed go to step 3.

Step (3) Check the IDS-Link LED at the DFI. When this

LED is not active check the connections between the SCPU

(X10) and DFI (WD:X10). When the LED is active and still

no image go to step 4.

Step (4): Check IDS LED at SCPU and if this

LED blinks during X-ray (kV=manual), check, measure

(connection and short cuts) of the Stand connector plate

and cable between C-arm stand and MVS.

Change the connector plate and/or cable when defect.

08-08-28 08:33:16 M USR STOP FLUORO RUN

08-08-28 08:33:16 W LIVE DICOM suspend: DCM server has completed without cancel!

08-08-28 08:33:25 M SYS USR switch on LEFT at 9108

08-08-28 08:33:25 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 1

08-08-28 08:33:25 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 2

08-08-28 08:33:25 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 3

08-08-28 08:33:25 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 4

08-08-28 08:33:25 W SYS SYSDRC_prepare_system: flushed xray actual message xact_seqno 5

2.2.4.2 Solution

See step 1 till 4 as described in the log file above for faultfinding on this issue in the R2.3 systems.

XRD-Best 305 CSIP Level 1 ( 08.0) 13

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.3 ERROR 206

This error is caused by a malfunction of the connection between the camera (IDS or XTV-7) and the SUCO

(rel 2.2 system) or he SCPU (for the rel 2.3. systems).

2.3.1 Error 206 at start up

When the fault occurs at start up, one of the electronic components (XTV-7, Camera Interface board or the

SHA-3) is suspected.

2.3.1.1 Logging example

06-08-09 11:42:52 M<GUI GUI initialisation timer task started

06-08-09 11:42:52 M<GUI Smooth progress bar task started

06-08-09 11:42:52 S<RSI RSI bist succesfully completed

06-08-09 11:42:52 S<KEY KEY bist succesfully completed

06-08-09 11:42:52 N<PMI CAMLINK test failure, Camera link not OK!

06-08-09 11:42:52 W<PMI Error 206

No camlink OK signal detected between IDS and

Timing Control Board. Check IDS subsystem and cabling.

06-08-09 11:42:52 S<MISC MISC bist succesfully completed

06-08-09 11:42:52 S<GUI GUI bist succesfully completed

06-08-09 11:42:52 S<PMI PMI bist failed

06-08-09 11:42:52 S<XGI XGC Selftest passed

2.3.1.2 Solution

Check camera, Camera Interface board and interconnections. In case all this is correct replace the c-arc

cable. Additional information can be found in FCO71800017. Before replacing the C-arc cable use the pre-

check FCO C-arc cable replacement document, listed on Incenter at FCO71800030 (452298162991) to check

the C-arc cable for its status.

2.3.2 Error 206 during examination

When the error occurs during examinations the c-arc cable is suspected.

2.3.2.1 Logging example

Note in the last line with the message “error 206 resolved”

06-08-09 14:31:25 W IP intErrAtrFrameLost

06-08-09 14:31:27 M SYS rec ABORT XRAY from PMI_pack

06-08-09 14:31:27 N<PMI CAMLINK not OK triggers an emergency stop of the Timing Control Board !

06-08-09 14:31:27 F<PMI Performing emergency stop Timing Control Board !

06-08-09 14:31:27 W<PMI Error 206

06-08-09 14:31:27 M SYS rec ABORT XRAY from SYS_pack

06-08-09 14:31:27 M SYS rec BLOCK XRAY, PMI block cnt: 1, block cnt sum: 1

No camlink OK signal detected between IDS and

Timing Control Board. Check IDS subsystem and cabling.

06-08-09 14:31:46 W IP Exclusion levels timing error

06-08-09 14:31:46 W IP intErrAtrFrameLost

06-08-09 14:31:47 W<PMI Error 206 resolved

2.3.2.2 Solution

Use the pre-check FCO C-arc cable replacement document, listed on Incenter at FCO71800030

(452298162991) to check the C-arc cable for its status. If necessary replace the c-arc cable.

14 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.4 ERROR 326/327

Error M327 shows up after startup. Error M326 becomes visible by activating the info button. Both errors can

also be found in the error log file. A restart usually fixes the problem. The problem only occurs during the

startup phase of the system. It will not occur during normal operation.

The root cause of the problem is an incorrect initialization of an ADC circuit on XGC Pulse board.

2.4.1.1 Logging example error 326 at start up

08-05-07 10:02:12 N<XGI BIST failure, ALARM active, check ALARM status of:

Filament | Generator | Tank Thermal Switch | Backup Timer |

Battery Charger

ALARM.GEN_RDY = 1

ALARM.FILAL = 0

ALARM.GENAL_N = 1

ALARM.THERMSW_N = 1

ALARM.ROT_OK_N = 1

ALARM.TIMAL = 0

ALARM.BC_FLT_N = 0

ALARM.PUMP_OK_N = 1

08-05-07 10:02:13 F<XGI XGC Selftest failed

08-05-07 10:02:13 W<XGI Error 326

The self test of the RA Generator Control Board SHA4

has failed. The X-ray function is disabled.

Check the cabling between the Generator Control Board

and the SE unit. Replace the Generator Control Board.

08-05-07 10:02:13 N<XGI XGIMAC: Unexpected event "WRITE_KV" in state STATE_INIT

08-05-07 10:02:13 S<PMI Timing Control Board : HW version 0001, CPLD version 0004

08-05-07 10:02:13 M<GUI GUI initialisation timer task started

2.4.1.2 Logging example error 327

07-04-05 08:20:31 S<INI BV300 User Interface detected

07-04-05 08:20:31 S<DISP DISP bist succesfully completed

07-04-05 08:20:31 S<XGI X-Ray RA Generator Board : HW version 7

07-04-05 08:20:31 S<CLI Collimator Control Board: HW version 1

07-04-05 08:20:31 W<XGI Error 327

There was a ADC conversion failure on the

Generator Control Board.

Replace the Generator Control Board SHA4.

07-04-05 08:20:31 F<XGI block_xray: XGIRADRV, ADC error !

2.4.1.3 Solution

Replace the SHA4 generator control board according FCO 718 00 018

XRD-Best 305 CSIP Level 1 ( 08.0) 15

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.5 ERROR 343

For systems which are programmed on 120 Volt the system can generate error 343 when the mains voltage

of the hospital is too low or drops too much for a short period.

2.5.1.1 Logging example

07-12-18 14:07:59 M SYS Xray mode continuous fluoro

07-12-18 14:07:59 M USR START FLUORO RUN

07-12-18 14:07:59 M USR MEASURE AREA

07-12-18 14:07:59 N<XGI XGIMAC: ERROR event "ALARM_INT" in state STATE_PREPARING

07-12-18 14:07:59 M SYS rec ABORT XRAY from SYS_pack

07-12-18 14:07:59 M SYS rec BLOCK XRAY, XGI block cnt: 1, block cnt sum: 1

07-12-18 14:07:59 M USR STOP FLUORO RUN

07-12-18 14:07:59 M SYS rec ABORT XRAY from XGI_pack

07-12-18 14:07:59 F<XGI Alarm interrupt: xgen status = 43

07-12-18 14:07:59 W<XGI Error 343

Generator alarm active status is active.

The generator will be reset within a few seconds.

If problem persists, check that the HF

generator's fan is rotating. Check error LEDs

on generator unit. Follow the fault finding

procedure given in the HF Generator service

manual.

07-12-18 14:08:00 W LIVE DICOM suspend: DCM server has completed without cancel!

07-12-18 14:08:10 M SYS rec UNBLOCK XRAY, XGI block cnt: 0, block cnt sum: 0

07-12-18 14:08:10 W<XGI Error 343 resolved

2.5.1.2 Solution

Perform the procedure mentioned in FCO 71800021.

16 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.6 GUARDING MESSAGES

Most of the time the logging “no msg received within …..” is caused, by a normal shut-down action, by

switching off the system at either the User Interface of the Stand or the MVS.

2.6.1 Normal shutdown logging

There are differences in logging for those two types of switching off the system.

2.6.1.1 Logging example shutdown from the stand:

07-03-12 15:50:32 W IP IdsLnkStatus changed from LINK_PRESENT to NO_LINK

07-03-12 15:50:34 W INI Warning: no msg received within GUARDING_WARNING time

07-03-12 15:50:36 W INI Warning: no msg received within GUARDING time

07-03-12 15:50:36 F CCO System error, Connection with remote subsystem lost

2.6.1.2 Logging example shutdown from the MVS(delayed):

07-03-15 15:32:09 M USR USR_AC_SYSTEM_SHUTDOWN

07-03-15 15:32:09 W IP IdsLnkStatus changed from LINK_PRESENT to NO_LINK

07-03-15 15:32:11 W INI Warning: no msg received within GUARDING_WARNING time

07-03-15 15:32:13 W INI Warning: no msg received within GUARDING time

07-03-15 15:32:13 F CCO System error, Connection with remote subsystem lost

2.6.2 Connection lost by a fault

In case the shutdown was not performed in a controlled way (as described above) the line

”W IP IdsLnkStatus changed from LINK_PRESENT to NO_LINK” is missing before the line “W INI Warning:

no msg received within GUARDING_WARNING time”

in the logging.

2.6.2.1 Logging example

07-04-11 16:54:30 M USR PARK & PROTECT

07-04-11 16:54:30 M DB Stored [1] new image(s) on disk

07-04-11 16:54:32 W INI Warning: no msg received within GUARDING_WARNING time

07-04-11 16:54:34 W INI Warning: no msg received within GUARDING time

07-04-11 16:54:34 F CCO System error, Connection with remote subsystem lost

XRD-Best 305 CSIP Level 1 ( 08.0) 17

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

2.6.3 Update information for C-arc stand reboot (FCO71800022)

When using the remote control it’s possible that the C-arc stand is going to reboot.

In this case the logfile of the system will show the following information:

2.6.3.1 Logging example in case of C-arc stand reboot when using the remote control:

07-06-15 11:23:01 M USR STOP FLUORO RUN

07-06-15 11:23:01 M DB Stored [17] new image(s) on disk

07-06-15 11:23:01 M DB Deleted [4] image(s) from disk

07-06-15 11:23:03 M UPIDR rc5RegVal->rc5KeyToggle is 1

07-06-15 11:23:03 M UPIDR keep image command code sent to USR

07-06-15 11:23:03 M USR PROTECT / RELEASE

07-06-15 11:23:05 W INI Warning: no msg received within GUARDING_WARNING time

07-06-15 11:23:07 M UPIDR rc5RegVal->rc5KeyToggle is 0

07-06-15 11:23:07 M UPIDR park image command code sent to USR

07-06-15 11:23:07 M USR PARK & PROTECT

07-06-15 11:23:07 W INI Warning: no msg received within GUARDING time

07-06-15 11:23:07 F CCO System error, Connection with remote subsystem lost

07-06-15 11:23:07 S CCO System executes COLD restart

Performing system controller restart type 2...

07-06-15 11:23:07 M USR STOP FLUORO RUN

07-06-15 11:23:07 M INI Disconnect_subsystems(): close the PPP connection.

07-06-15 11:23:07 W SYS SUCO not available for use

2.6.3.2 Solution

This problem will be solved by installing software release 2.2.4. (Refer to mandatory FCO 71800022),

superseded by software release 2.2.6 (refer to action for performance proactive FCO 71800027). Software

2.2.6. is not compatible with the 3DRX system, use 2.2.4. on these systems.

2.7 CORRUPT SYSTEM LOGFILE

In rel 2.2.4 systems it is possible the logging does not function correctly.

2.7.1.1 Logging example

BV-Scope

Click here to proceed to end of logging

[System ID Header]

System type : BV Pulsera-12"

System serial number : FK00996

SW Release : R2.2.4

Hospital name : PHILIPS HEALTHCARE

There was an error during ....

Click here to proceed to start of logging

2.7.1.2 Solution

This problem will be solved by installing software release 2.2.6 (refer to FCO’s 718 00 027 (SuCo) and

718 00 029 (SCPU)). With the installation of the SW rel 2.2.6 (SCUO) or SW rel 2.3.3 (SCPU) the system log

file will be reset automatically.

18 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3 IQ COMPLAINTS

This chapter describes which steps to take when a customer complains about Image Quality (IQ) being

unsatisfactorily without a clear technical cause. Additionally no error message is displayed on the system. In

such a case you can check if the IQ issue can be recognized as a failure caused by one of the following

known cases:

• Stand MVS cable failure

• C-arc cable failure

• Auto Contrast Brightness artefacts

• Movement

• Incorrect use of Digital Exposure

If the cause of the IQ problem can be explained by one of the above specified situations, the cause and

solution can be will be clarified within this document.

If the cause of the IQ problems does not meet the one of the above specified examples, this document

describes some further checks and test which may lead to a solution. In case no clear failure cause can be

isolated or doubts remain, you’re advised to contact your Tier 2 helpdesk

The images in this document are best viewed as a digital document, IQ problems are difficult to see on black

and white prints.

XRD-Best 305 CSIP Level 1 ( 08.0) 19

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.1 CAMERA TEST PATTERN

Using the test pattern of the camera, one can check if the entire digital imaging path from the camera to the

DFI is working OK.

• When the test pattern is activated and the image shown on the monitor looks fine, the Image Quality

problem is caused by something else then the digital data communication path.

• When the test pattern is activated and the image on the monitor is distorted (see images below), the

digital data communication path is causing problems.

Activating of the test pattern is done in the following way:

1. Select in BV-Scope: Install > Performance Test > Fault finding/Investigation

2. Select the following settings in the Fault finding/Investigation panel as shown below:

- Noise/Movement level: off

- Edge enhancement: off

- Contrast : 0

- Brightness: 0

- White compression: off

- Vignette correction: off

- Camera test pattern: on

- Click on the apply button.

3. Press the X-ray button. Watch the camera test image on the live monitor.

NOTE

No X-ray will be generated during this test.

________

4. Check for image disturbance caused by play on the stand-trolley plug and cable but leave it connected to

the system.

5. Bend and move the cabling of the IDS-link connection inside the C-arc stand.

(For systems with a TCB-2 this is the connection between SHA3-X4 and the wired bracket SAX-1. In

case of a TCB-3D this is a round connector on SHA3-X5)

6. Check if the gray values are distorted on the camera test image during this action. (see examples of the

camera test image below)

7. If necessary replace the wired bracket SAX-1 or TCB2/TCB3 adapter cable and stand-trolley cable

(FCO71800024) if one or more of these items are suspected to be defect or worn.

20 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Camera test pattern OK Camera test pattern NOT OK

A correct test pattern shown on the monitor should have the following characteristics:

• 16 grey levels visible in the upper and lower bar.

• In the middle a transition (in 32 steps) from black to white is visible.

XRD-Best 305 CSIP Level 1 ( 08.0) 21

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.2 STAND MVS CABLE FAILURE

An IQ problem caused by a bad stand MVS cable link can be characterized by:

• Stripes in the image (horizontal, vertical or diagonal)

• Bars of different brightness in the image, also known as “the louvre effect”.

Additionally one can check the system log-file on the appearance of “unreliable IDS link” and/or “error M393”.

3.2.1 Solution:

Perform Mandatory FCO 718 00 024.

3.2.2 Example images

Image with stripes in image due to Stand-MVS Image with bars of different brightnesses in image

cable failure (the so called “louvre effect”)

22 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.3 C-ARC CABLE FAILURE

A fault caused by a bad C-arc cable (camera link) can be characterized by:

• Black pixel disturbance in a limited range of the grey level spectrum.

• Some areas of the image are not distorted at all, others are affected.

Image with pixel disturbance (this case in the grey level on the edge of the object)

XRD-Best 305 CSIP Level 1 ( 08.0) 23

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.3.1 Typical pixel failure examples.

Clear example of the pixilation issue.

Note that besides pixelated areas, areas with Example of an extremity with pixilation edging on the

correct grey-levels and sharp details are visible. edges of the clinical part.

Large pixelated area, with clear grey level problems. Another example of an extremity with pixilation.

Note the pixilation on the left edge of the II as well.

24 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.3.2 Solution:

First step is to check the connection of the small blue ribbon cable (flex cable) from camera to the interface

board. This cable can be found in the II. Make sure that the cable is well connected on both ends.

Second step to be taken is to check which c-arc cable type is installed:

o From 2006 we introduced the Surgery BV Family 2 systems (Pulsera and Endura) with the original C-arc

cable. This cable turned out to be not very reliable.

o Since mid October 2007 we introduced an improved C-arc cable. The basic C-arc cable did not change

but by performing a modification the C-arc cable becomes reliable again. In such an improved C-arc

cable, on both sides of the CameraLink subcable:

9 The outer transparent- and black foil is stripped / removed.

9 The analog screen / braid of the outer cable must be able to make a good connection to the metal

connector housing.

9 All remaining black foil on the 9 outer twisted-pair wires is removed,

9 All 9 screens / braids of the twisted-pair wires (the additional two twisted-pair wires in the center are

not critical) and the 9 drain wires are connected to each other and connected to the 4 digital ground

pins (pin 1, 13, 14 and 26) of the connector (by means of a metal ty-wrap or different)

9 There is no electric connection between analog and digital ground.

For more detailed information on the recognition of the C-arc cables and the various versions see the

following document that is published with FCO71800030 available on Incenter.

Pre-check FCO’s C-arc cable replacement 452298162991.

XRD-Best 305 CSIP Level 1 ( 08.0) 25

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.3.3 Correct modified cables:

Shielding of twisted pairs connected to each Shielding of twisted pairs connected to each other by

other by means of a soldered wire means of a metal tie-wrap

NOTE: when mounting the connector housing make sure that the analog ground contacts the connector

(white arrow) while the digital ground is isolated with isolation tape or equivalent (grey tape in the picture) to

ensure that there is no connection between the digital and the analog ground.

If the original c-arc cable is installed, repair the cable as described above and in FCO 71800017 or replace the

cable by the latest spare part version.

From November 2008 onwards an new designed c-arc cable will be offered in an FCO:

FCO 718 00 030 for BV Pulsera rel 2.2 (SUCO systems)

FCO 718 00 031 for BV Endura rel 2.2 (SUCO systems, currently to be released in Jan 2009)

26 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.4 AUTO CONTRAST BRIGHTNESS ARTEFACTS

This effect is caused by the fact the original image contains low contrast and the ACB function is activated.

The resulting image is characterized by:

• “Flat” image / limited grey levels in full image.

• Noise will be more visible.

• Effects visible over full image.

The ACB function will “over-stretch” the limited grey-level range, resulting in an image which appears to be

distorted.

3.4.1 Solution:

Application instruction to customer with respect to correct use of kV /mA stabilization.

3.4.2 Simulation

The pixilation effect can be simulated by lowering the kV in manual mode. Below an example of such

simulation is shown:

Automatic stabilization at 60 kV. This image is Same situation but now in hand mode at 55 kV.

made at 56 kV. Note there are ACB artifact visible in the image

(Note there are no ACB artifacts visible) everywhere.

XRD-Best 305 CSIP Level 1 ( 08.0) 27

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.4.3 Examples

Image with ACB issue, note that the effect is Example of an image with ACB distortion while still

visible over the whole image. having a quite large contrast in the image.

Example of a spine with ACB artefacts. Example of an almost empty II showing ACB

artefacts.

28 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.5 MOVEMENT

This distortion can be divided in two categories:

3.6 MOVEMENT DISTORTION IN SUBTRACTED IMAGES

characterized by:

• “Pepper and salt” noise

• Bright and dark object

edges (enhanced)

3.6.1 Solution:

Application instruction to customer with respect to subtraction procedures.

3.7 “DIRTY NOISE”

characterized by:

• Noisy edges caused by

movement of the organs

(limited area of the full

image) of extremities.

• In the picture the dirty

noise is visible in the

organ (bowel), highlighted

with a circle.

3.7.1 Solution:

improved exam setting as supported in rel 2.2.6. or rel 2.3.3.

XRD-Best 305 CSIP Level 1 ( 08.0) 29

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.8 DIGITAL EXPOSURE

Poor image quality caused by incorrect usage of Digital exposure is characterized by:

• Poor or almost no contrast

• Relative dark image

Image where the scout fluoroscopy time was too short Image with correct scout fluoroscopy

Image with digital exposure without using scout fluoro,

made at 40 KV. Check with logging and date/time stamp.

30 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3.8.1 Check logfile for digital exposure issues:

Check the system logfile for the date/time stamp of the bad image to verify if scout fluoro is performed adequately

prior before using Digital Exposure mode. The kV value should correspond to the region of interest.

3.8.1.1 Logging example when used Digital Exposure correct

08-09-14 11:47:14 M SYS Xray mode continuous fluoro

08-09-14 11:47:14 M USR START FLUORO RUN

08-09-14 11:47:14 M DCM Wait for association is aborted

08-09-14 11:47:15 M LIVE Image received at 1162075

08-09-14 11:47:15 M SYS USR switch off at 1162077

08-09-14 11:47:15 M SYS actual kV setting = 63 kV

08-09-14 11:47:15 M USR STOP FLUORO RUN

08-09-14 11:48:00 M SYS USR switch on RIGHT at 1166547

08-09-14 11:48:00 M USR APF CT [9] sub [0], High dose [1] Run3D [0]

08-09-14 11:48:00 M USR CHANGE STORE RATE Rate [0] RateUi [0] TimeLeft [0] Ratio [0]

08-09-14 11:48:00 M USR STORE LIH ON

08-09-14 11:48:00 M SYS Xray mode digital exposure

08-09-14 11:48:00 M USR START FLUORO RUN

08-09-14 11:48:00 M DCM Wait for association is aborted

08-09-14 11:48:00 M USR MEASURE AREA

08-09-14 11:48:01 M SYS rec ABORT XRAY from SYS_pack

08-09-14 11:48:01 M USR STOP FLUORO RUN

As you can see first there’s a run on continuous fluoroscopy which sets the actual kV value. After this the

digital exposure is activated.

3.8.1.2 Logging example when used Digital Exposure incorrect

……….from system startup no x-ray or fluoro was yet performed……, no kV_set

08-09-04 10:57:23 M USR APF CT [9] sub [0], High dose [1] Run3D [0]

08-09-04 10:57:23 M USR CHANGE STORE RATE Rate [0] RateUi [0] TimeLeft [0] Ratio [0]

08-09-04 10:57:23 M USR STORE LIH ON

08-09-04 10:57:23 M SYS Xray mode digital exposure

08-09-04 10:57:23 M USR MEASURE AREA

08-09-04 10:57:23 M USR START FLUORO RUN

08-09-04 10:57:24 M USR MEASURE AREA

08-09-04 10:57:24 M USR MEASURE AREA

08-09-04 10:57:25 M LIVE Image received at 6454

08-09-04 10:57:25 M USR STOP FLUORO RUN

08-09-04 10:57:25 M SYS rec ABORT XRAY from SYS_pack

08-09-04 10:57:25 M SYS rec BLOCK XRAY, XGI block cnt: 1, block cnt sum: 1

08-09-04 10:57:25 M DB Stored [1] new image(s) on disk

This results in almost blank grey images as shown in the 3rd digital exposure example.

3.8.1.3 Solution:

Application instructions to customer to perform LDF scout prior to using digital exposure to set the correct KV

level.

XRD-Best 305 CSIP Level 1 ( 08.0) 31

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Proprietary Notice CSIP Level 1:

This document and the information contained in it is strictly reserved for current Philips Healthcare (“Philips”) personnel, Philips licensed representatives and Philips customers who have

purchased a valid service agreement for use by the customer’s designated in-house service employee on equipment located at the customer’s designated site. Use of this document by

unauthorized persons is strictly prohibited. This document must be returned to Philips when the user is no longer licensed and in any event upon Philips’ first written request.

Liability / Warranty Disclaimer:

Philips provides this DOCUMENT without warranty of any kind, implied or expressed, including, but not limited to, the implied warranties of merchantability and fitness for a particular

purpose. Philips has taken care to ensure the accuracy of this document. However, Philips assumes no liability for errors or omissions and reserves the right to make changes without

further notice to any products herein to improve reliability, function, or design. Philips may make improvements or changes in the product(s) or program(s) described in this document at

any time.

32 CSIP Level 1 ( 08.0) XRD-Best 305

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

(c) 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

You might also like

- Siemens Mobilett XP Replacement of PartsDocument186 pagesSiemens Mobilett XP Replacement of PartsDhoy Gaviola83% (6)

- Philips MicroDose-L30-full CalibrationDocument12 pagesPhilips MicroDose-L30-full CalibrationTony Kututo100% (1)

- Mobilett PlusDocument157 pagesMobilett Plusgildardo ruizNo ratings yet

- 10 10.service ManualDocument485 pages10 10.service ManualbertoNo ratings yet

- DC30-049 TechVision Service Manual - Rev GDocument96 pagesDC30-049 TechVision Service Manual - Rev GJ Hernán Vázquez Benítez100% (1)

- Exposcop 7000 Service Manual PDFDocument355 pagesExposcop 7000 Service Manual PDFTodd50% (2)

- CR QS 3.5 - Service Manual For Download 2009-11-16Document605 pagesCR QS 3.5 - Service Manual For Download 2009-11-16Fernando Chavarría MarínNo ratings yet

- Siemens Polydoros LX 30-50 X-Ray - AdjustmentDocument82 pagesSiemens Polydoros LX 30-50 X-Ray - Adjustmenthaseeb100% (1)

- GE OEC Medical Systems: Service Manual 7700Document158 pagesGE OEC Medical Systems: Service Manual 7700solcarwxNo ratings yet

- BCA 9, DIP240S Operator's Manual Code 49 80 004 BMIDocument110 pagesBCA 9, DIP240S Operator's Manual Code 49 80 004 BMIHasan Sevinç0% (1)

- POLYDOROS LX 30, 50 Installation Inst.Document46 pagesPOLYDOROS LX 30, 50 Installation Inst.engr zohaib0% (1)

- 4008B Operacion Ingles 16 10 03 v52Document357 pages4008B Operacion Ingles 16 10 03 v52Roger RogelioNo ratings yet

- Schematic C-Arm NavigationDocument7 pagesSchematic C-Arm Navigationbruce hu100% (1)

- Shimadzu WHA 200 Opescope C Arm SMDocument135 pagesShimadzu WHA 200 Opescope C Arm SMArmando Agarijo Concha100% (1)

- Panoura Ultra Service Manual - Image WorksDocument85 pagesPanoura Ultra Service Manual - Image Worksitalo brasil vasquez leon75% (4)

- OEC-7700 - Service SetupDocument18 pagesOEC-7700 - Service Setuplorisaszigi100% (3)

- Siremobil Compact L Troubleshooting Guide PDFDocument216 pagesSiremobil Compact L Troubleshooting Guide PDFKhon ReaksaNo ratings yet

- MX-600 S2 OperationDocument39 pagesMX-600 S2 OperationRashid KhNo ratings yet

- Oec 7600 Service Manual Руководство По ОбслуживаниюDocument110 pagesOec 7600 Service Manual Руководство По ОбслуживаниюJuriyNo ratings yet

- Kodak Service-Manual POC 120 - 140Document167 pagesKodak Service-Manual POC 120 - 140Bubba UglyNo ratings yet

- Serial Changer For Duo Diagnost 4512-984-23293abDocument32 pagesSerial Changer For Duo Diagnost 4512-984-23293abDiep Nguyentuan100% (2)

- Troubleshooting Eva 325 525 195Document39 pagesTroubleshooting Eva 325 525 195Dante Nuevo100% (6)

- OEC 7700 CalibrationDocument7 pagesOEC 7700 CalibrationWade Dyer100% (5)

- Technical Arco en CDocument427 pagesTechnical Arco en CChris Valdez DrumsNo ratings yet

- ArcoCeil Service ManualDocument310 pagesArcoCeil Service ManualNauman100% (2)

- Siemens Iso CDocument6 pagesSiemens Iso CFrancisco Diaz100% (2)

- Siemens Mobilett XP Hybrid Eco Installation and Start Up System PDFDocument62 pagesSiemens Mobilett XP Hybrid Eco Installation and Start Up System PDFFélix EnríquezNo ratings yet

- Mobilett-Plus-E-M FrancaisDocument110 pagesMobilett-Plus-E-M FrancaisRomuald Eric TefongNo ratings yet

- Error Code ShimadzuDocument14 pagesError Code ShimadzuPhong DoNo ratings yet

- Mtmammograph ItalrayDocument194 pagesMtmammograph ItalrayKhalil Issaad100% (3)

- Varian2020x 0Document74 pagesVarian2020x 0mauricio100% (1)

- 5950 Service Manual AA2206 - En-BDocument320 pages5950 Service Manual AA2206 - En-BAsad Kazmi100% (1)

- Troubleshooting - spr8-230.840.01.14.02Document104 pagesTroubleshooting - spr8-230.840.01.14.02Rubén Díaz100% (1)

- Generator - Indico 100 Service ManualDocument359 pagesGenerator - Indico 100 Service ManualJuriyNo ratings yet

- Quantum Odyssey HF SeriesDocument102 pagesQuantum Odyssey HF SeriesMohammed AliNo ratings yet

- 11 Dynarad Hf-110a Service ManualDocument41 pages11 Dynarad Hf-110a Service Manualkizen_50% (1)

- Siemens Siremobil 2000 PDFDocument247 pagesSiemens Siremobil 2000 PDFTeresa Rosas Guzmán100% (5)

- Mam1000-3000Nova ServiceProgram 4.0 PDFDocument110 pagesMam1000-3000Nova ServiceProgram 4.0 PDFRodrigo Dos Santos SilvaNo ratings yet

- Маммограф «Giotto IMAGE»Document180 pagesМаммограф «Giotto IMAGE»Tony Kututo100% (1)

- Installation Kodak CR 825 850Document72 pagesInstallation Kodak CR 825 850pablo100% (1)

- Drypix Prima PrinterDocument12 pagesDrypix Prima Printerayham hamamaNo ratings yet

- Arcadis - Configuration W Orbic 3D CalDocument96 pagesArcadis - Configuration W Orbic 3D Calllpbio2No ratings yet

- Kalibracja Lampy Service Manual Engl. HfeDocument162 pagesKalibracja Lampy Service Manual Engl. HfeSebastian SamolewskiNo ratings yet

- Polydoros SX 65 - 80 - Function DescriptionDocument18 pagesPolydoros SX 65 - 80 - Function DescriptionMaximus Decimus MeridiusNo ratings yet

- Opera Swing Service Manual MotorDocument20 pagesOpera Swing Service Manual MotorAndrey100% (1)

- OEC 9600 SpecificationsDocument2 pagesOEC 9600 Specificationsantoniod179237No ratings yet

- POX-100BT High Powered Mobile X-Ray System Product Manual (Operation & 0DQXDO)Document47 pagesPOX-100BT High Powered Mobile X-Ray System Product Manual (Operation & 0DQXDO)Mirwansyah Tanjung100% (1)

- Siemens MobilettDocument10 pagesSiemens MobilettDanielec1No ratings yet

- Digital Radiography System Image Quality Adjustment ManualDocument64 pagesDigital Radiography System Image Quality Adjustment ManualLuis Fernando Garcia SNo ratings yet

- IMD Rasius DIM (DataSheetDocument1 pageIMD Rasius DIM (DataSheetahmed_galal_waly1056No ratings yet

- IDC Service ManualDocument358 pagesIDC Service Manualfourioer100% (1)

- REGIUS 210 Service Manual - 1202IA01EN01 PDF - PDF - Power Supply - LaserDocument180 pagesREGIUS 210 Service Manual - 1202IA01EN01 PDF - PDF - Power Supply - Lasershams UddinNo ratings yet

- Shenzhen LWX-50 X-Ray - Service ManualDocument54 pagesShenzhen LWX-50 X-Ray - Service ManualAhmed Torky100% (1)

- Stephanix BRS - Service Manual PDFDocument52 pagesStephanix BRS - Service Manual PDFathinabeba100% (1)

- User ManualDocument251 pagesUser ManualMuhammad Ahmad100% (1)

- Mammomat Unit Firmware Installation Software Xpw7-330.816.04.02.02Document18 pagesMammomat Unit Firmware Installation Software Xpw7-330.816.04.02.02Gon LizaNo ratings yet

- Simatic Hmi SeriesDocument288 pagesSimatic Hmi SeriesRoger RogelioNo ratings yet

- TL3000 5000 - InstallationManual - 55000 00017 002 04 1528406Document274 pagesTL3000 5000 - InstallationManual - 55000 00017 002 04 1528406Roger RogelioNo ratings yet

- User Manual 74 80 002 R 1Document190 pagesUser Manual 74 80 002 R 1Roger Rogelio100% (1)

- ECG-12 B&ECG-12 C Electrocardiograph User Manual 82-01.54.456476-1.0 (189886)Document149 pagesECG-12 B&ECG-12 C Electrocardiograph User Manual 82-01.54.456476-1.0 (189886)Roger RogelioNo ratings yet

- P 750294 091 Amsco Medallion Manual Serioes RectangularDocument128 pagesP 750294 091 Amsco Medallion Manual Serioes RectangularRoger RogelioNo ratings yet

- Electrical Drawings 32kw - EVODocument40 pagesElectrical Drawings 32kw - EVORoger RogelioNo ratings yet

- Plasma Freezers TSX Series - Installation and Operation ManualDocument45 pagesPlasma Freezers TSX Series - Installation and Operation ManualRoger RogelioNo ratings yet

- Technical Man Code 74 80 012 r1Document264 pagesTechnical Man Code 74 80 012 r1Roger RogelioNo ratings yet

- 0-Level Documentation Part - 2 (System Reference Manual BV Family R2.3)Document24 pages0-Level Documentation Part - 2 (System Reference Manual BV Family R2.3)Roger RogelioNo ratings yet

- AIAT BV FamilyDocument121 pagesAIAT BV FamilyRoger RogelioNo ratings yet

- 2019 05 Preventive Maintenance Register BAX00 Rev.2Document4 pages2019 05 Preventive Maintenance Register BAX00 Rev.2Roger RogelioNo ratings yet

- BA200 ISE Module MaintenanceDocument4 pagesBA200 ISE Module MaintenanceRoger RogelioNo ratings yet

- Affinity4 DrapingDocument3 pagesAffinity4 DrapingRoger RogelioNo ratings yet

- Affinity 4configDocument2 pagesAffinity 4configRoger RogelioNo ratings yet

- Affinity4 Skills ChecklistDocument2 pagesAffinity4 Skills ChecklistRoger RogelioNo ratings yet

- Affinity 4 - Brochure v3 - LR5EN137303 02Document8 pagesAffinity 4 - Brochure v3 - LR5EN137303 02Roger RogelioNo ratings yet

- Modo Servicio Oxy3000Document16 pagesModo Servicio Oxy3000Roger RogelioNo ratings yet

- BiBag Man Tec en 02-11-98Document80 pagesBiBag Man Tec en 02-11-98Roger RogelioNo ratings yet