Professional Documents

Culture Documents

Abrasive Blasting Cabinet

Uploaded by

waleedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abrasive Blasting Cabinet

Uploaded by

waleedCopyright:

Available Formats

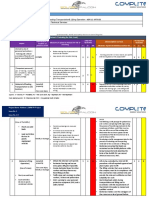

Job Hazard Analysis JHA Name: Abrasive Blasting Cabinet

Assessment Date: 12-18-13 Revision Date: 04-04-17

Building or Location: North Mankato Campus Department or Program: Ag Mechanics Program

Abrasive Blasting Tasks (e.g., Smoothing or Roughening

Description of Individual Tasks or Tools, Equipment, or Machinery

Surfaces, Removing Paint and Contaminants, Shaping Abrasive Blasting Cabinet, and Abrasive Blast Materials

Assignments: Used when Performing Task:

Material, Glass Etching, etc…).

Check if Exposure

Check for Recommends or

Hazard Type(s) Associated with Task or Assignment: Specific Hazard Exposure:

Exposure: Requires a Style of

PPE?

Example: Person(s) can strike an object, or be struck by a moving or flying/falling Potential exposure to impact hazards generated by compressed air

1 Impact X X

object (e.g., fragments, chips, particles, sand, dirt/debris). abrasive blasting stream (e.g., injuries to hands & arms)

Penetration or Example: Person(s) can strike an object, be struck by an object, or fall upon an object

2

Cut or tool that would cut or otherwise break the skin.

3 Crush or Pinch Example: An object(s) or equipment/machine may crush or pinch a body or body part

Example: Exposure to chemicals (i.e., hazardous substances and harmful physical Potential exposure to abrasive blasting dusts, however glass beads

agents), infectious agents from spills, splashing, physical contact, and/ or exposure to are used with this cabinet which would negate the dust factor (e.g.,

Chemical or

4 dusts, vapors, fumes, or gases that could cause illness, irritation, burns, asphyxiation, X respiratory irritation and illness), potential exposure to contaminates X

Harmful Dust

breathing/vision difficulty, sensitization, infection, or other toxic health effects (i.e., on work piece surfaces (e.g., dependent on surface coatings of work

acute or chronic). Note: "May also have or create ignition potential." pieces)

Example: Exposure to radiant heat sources, sparks, and splashes or spills of hot

5 Heat

material

Example: Exposure to strong light sources, glare, or intense light exposure which is a

Light (optical)

6 byproduct or a process. Note: "This category may also include hazards presented from

Radiation

lack of light (e.g., working in dark spaces/areas)."

Electrical

7 Example: Exposure, contact, or proximity to live or potentially live electrical objects.

Contact

Example: Working in cramped spaces, repetitive movements, awkward postures,

vibration, heavy lifting, etc… Note: "This category may also include unique hazards

Ergonomic/

8 presented from tasks that require demanding or challenging degrees of mental and/or

Human Factors

physical effort to be exerted by an individual. See Physical Effort Definition/Examples

category for further explanation of physical effort.”

Example: Exposure to noisy environments, hot or cold work environments, poor

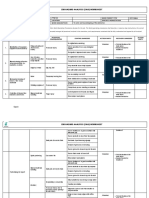

Potential exposure to loud/ prolonged noise (abrasive blasting

9 Environmental weather conditions, working at a height, and any other conditions in the workplace that X X

cabinet)

could cause danger, discomfort, and/or negative health effects.

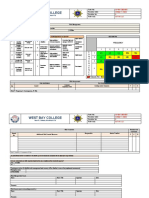

Job Hazard Analysis JHA Name: Abrasive Blasting Cabinet

Assessment Date: 12-18-13 Revision Date: 04-04-17

Building or Location: North Mankato Campus Department or Program: Ag Mechanics Program

Abrasive Blasting Tasks (e.g., Smoothing or Roughening

Description of Individual Tasks or Tools, Equipment, or Machinery

Surfaces, Removing Paint and Contaminants, Shaping Abrasive Blasting Cabinet, and Abrasive Blast Materials

Assignments: Used when Performing Task:

Material, Glass Etching, etc…).

Personal Protective Equipment Requirements:

Eyes & Face: Safety Glasses with Side Shields or Goggles (Required when operating Abrasive Blast Cabinets)

Head & Ears: Hearing Protection Devices (Required when operating Abrasive Blast Cabinets)

Whole Body:

Feet:

Hands: Abrasive Blasting Cabinet Gloves- "attached to cabinet" (Required when operating Abrasive Blast Cabinets)

Respiratory: 1/2 Mask Respirators (Required when working in areas of where hazardous contaminate levels exceed OSHA PELs and When Cleaning or Adding Abrasive Media to Cabinet)

Other:

Other Control Measures or Requirements (Engineering & Administrative Controls):

#1) Impact Hazards: Never point an abrasive nozzle/gun or direct its stream towards yourself. #4) Chemical or Harmful Dust Hazards: Personnel should receive Right-to-Know training (e.g., regarding chemical &

physical hazards). SDS should be provided/available for all hazardous chemicals. Local Exhaust Ventilation (LEV) should be provided/maintained on abrasive blast cabinets. Respirators are available for personnel

experiencing respiratory discomfort from dust generated; however, personnel (desiring to use respirators) and personnel required to wear respiratory equipment should receive a medical evaluation, Respirator training

(e.g., regarding respiratory hazards), and fit-testing prior to wearing respirators. Respiratory equipment must be worn when cleaning the cabinet or adding abrasive materials. Never use abrasive cabinets with their access

doors open. Only open the abrasive blast cabinet's doors when the abrasive dust has been removed from the cabinet by the LEV. #9) Environmental Hazards: Personnel should receive Hearing Conservation training

(e.g., regarding noise hazards). Personnel using compressed air for cleaning/drying should be included in the Hearing Conservation Program. Miscellaneous Considerations: Dead-man switches or constant pressure

triggers must be equipped on all abrasive nozzles/guns to stop air flow if the nozzle is released or dropped. Operators of tools, equipment, and machinery should read and follow all Manufactures' recommendations/

requirements (e.g., inspections, servicing/ maintenance, safe usage, etc...). Any tools, equipment, or machinery found damaged, defective, or otherwise unsafe should immediately be removed from service and not used

until repaired or replaced. Personnel should always consult their Supervisors on the selection and use of PPE for the tasks being performed.

Physical Effort Definition/Examples

1.) Physical Mobility- Movement from place to place on the job, considering distance and speed 2.) Physical Agility- ability to maneuver body while in place or in static position 3.) Physical Strength (Light to Moderate)- Ability to handle

routine office materials and tools 4.) Physical Strength (Moderate to Heavy)- Ability to handle 50lbs+ objects, considering frequency 5.) Dexterity- skill and ability in using hands, fingers, and feet 6.) Physical Balance- ability to maintain

balance and physical control 7.) Coordination- harmonious functioning of body parts (e.g., eye/hand, hand/foot, etc…) 8.) Endurance- ability to sustain a prolonged stressful effort or activity with limited opportunity to rest

Note: "This JHA provides only the minimum PPE/safety requirements necessary to safely complete the task or assignment, and the JHA Certification: This document certifies a hazard assessment was conducted meeting

only covers the hazards or exposures that are most likely to be encountered. Nothing within this JHA bars or restricts personnel from the provisions specified under 29 CFR 1910.132 (d) and South Central College's

requesting higher degrees of PPE or control to mitigate workplace hazards. In addition, South Central College personnel (e.g., employees related safety programs and policies.

and students) are required to complete any applicable safety or on-the-job trainings required prior to performing their positions or

participating in their programs of study. Finally, South Central College personnel should consult their supervisors/instructors, the college’s Name: Al Kluever

written safety programs/policies, and/or the Security & Safety Director whenever they have questions or concerns."

Date: 04-04-17

You might also like

- Standard Operation Procedure: Hazard Identification, Risk Assessment & Determining Control (Hiradc)Document3 pagesStandard Operation Procedure: Hazard Identification, Risk Assessment & Determining Control (Hiradc)Sham Ji100% (1)

- FM JsaDocument4 pagesFM JsaASLAM MULANINo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- Risk Assessment - Rev01 8 4 2020-2Document14 pagesRisk Assessment - Rev01 8 4 2020-2shaibaz chafekar100% (1)

- Chandelier Hoist SystemDocument10 pagesChandelier Hoist SystemNishadh 83No ratings yet

- To Remove & Reinstall Heat Insulation Cover 350Document7 pagesTo Remove & Reinstall Heat Insulation Cover 350Saleem AkhtarNo ratings yet

- Production Risk AssessmentDocument4 pagesProduction Risk AssessmentEmilyNo ratings yet

- HIRAC - Transportation and Unloading of MVPSDocument9 pagesHIRAC - Transportation and Unloading of MVPSMarc IvoNo ratings yet

- JHA On Bar Bending Machine - Cutting MachineDocument8 pagesJHA On Bar Bending Machine - Cutting Machineshannu mishraNo ratings yet

- Basic Occupation Safety and HealthDocument8 pagesBasic Occupation Safety and HealthCarl Vincent TaboadaNo ratings yet

- Personal Protective Equipment - GustinaDocument24 pagesPersonal Protective Equipment - GustinaHidayatullah HidayatullahNo ratings yet

- ESE Method Statement Underground Utility Survey Rev3Document22 pagesESE Method Statement Underground Utility Survey Rev3بسام عوضNo ratings yet

- Risk Assessments - Offloading-Transportation& Lifting Operation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Offloading-Transportation& Lifting Operation - ADFI-GFTS-CESIbrahim EsmatNo ratings yet

- RA - Painting Works - Car ParkDocument14 pagesRA - Painting Works - Car ParkDurai KailasamNo ratings yet

- Method of Statement-1Document35 pagesMethod of Statement-1Fo Mu100% (1)

- JHA For Welding ShopDocument36 pagesJHA For Welding ShopSaboor KhanNo ratings yet

- Health, Safety & WellbeingDocument13 pagesHealth, Safety & WellbeingImran ChowdhuryNo ratings yet

- Electrical and Machine SafetyDocument49 pagesElectrical and Machine SafetyJely Taburnal Bermundo100% (1)

- HIRA OfficeDocument1 pageHIRA OfficeRakesh ChauhanNo ratings yet

- JHA HousekeepingDocument3 pagesJHA HousekeepingFatin ZawawiNo ratings yet

- Risk Assesment - MobilisationDocument7 pagesRisk Assesment - Mobilisationشاز إياسNo ratings yet

- 2.25 - Fall Protection PlanDocument5 pages2.25 - Fall Protection PlanWAQAS AHMEDNo ratings yet

- Safety: By: Anahi MaganaDocument12 pagesSafety: By: Anahi MaganaKei CamalNo ratings yet

- Risk Assessment Hot WorkDocument3 pagesRisk Assessment Hot WorkIbrahim EsmatNo ratings yet

- 6 RA Installation Testing Commissioning of Fire Fighting PumpsDocument7 pages6 RA Installation Testing Commissioning of Fire Fighting PumpsAdel MorsyNo ratings yet

- AMB-172-004 Cement Gypsum BoardDocument2 pagesAMB-172-004 Cement Gypsum BoardRues AgNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (2)

- Iosh RaDocument5 pagesIosh Rajamal motaNo ratings yet

- Housekeeping JsaDocument9 pagesHousekeeping JsaShahid BhattiNo ratings yet

- Health and Safety Risk Assessment: Activity Hazard Risk Rating (0 Low, 5 High) SolutionDocument2 pagesHealth and Safety Risk Assessment: Activity Hazard Risk Rating (0 Low, 5 High) SolutionBarry TuriNo ratings yet

- Basf Mastertile 333 TdsDocument3 pagesBasf Mastertile 333 TdsdipinnediyaparambathNo ratings yet

- MKN-SOP ReopeningSafely vF-ENG Clean-1Document17 pagesMKN-SOP ReopeningSafely vF-ENG Clean-1Ohlala KitchenNo ratings yet

- Method Statement: Site Set Up: Compound, Parking & Material StorageDocument19 pagesMethod Statement: Site Set Up: Compound, Parking & Material StorageVICTORNo ratings yet

- 1ig2 Forms Electronic SubmissionDocument20 pages1ig2 Forms Electronic SubmissionAejaz MujawarNo ratings yet

- Hot Work Safety ProgramDocument14 pagesHot Work Safety Programsefina mec100% (1)

- Pre-Assembly of Hopper: Larsen & Toubro LimitedDocument26 pagesPre-Assembly of Hopper: Larsen & Toubro LimitedAmrit SinghNo ratings yet

- Safety Questions and AnswersDocument30 pagesSafety Questions and AnswersSubash RockNo ratings yet

- 106 Toolbox Talks e BookDocument181 pages106 Toolbox Talks e BookZakirhas100% (1)

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper InstallationDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper Installationmohammed tofiqNo ratings yet

- My Company Short Service Employee (SEE) ProgramDocument6 pagesMy Company Short Service Employee (SEE) ProgramMashur Al JunaibiNo ratings yet

- Risk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESIbrahim Esmat0% (1)

- 12 Ways To Boost Workplace SafetyDocument6 pages12 Ways To Boost Workplace Safetymuhammadarifh4486No ratings yet

- Scha 3010Document106 pagesScha 3010AFEC AGIRONo ratings yet

- HIRARC IBS Components Installation Rev 0Document21 pagesHIRARC IBS Components Installation Rev 0Suraindran ManoharanNo ratings yet

- RISK ASSESSMENT-RevantaDocument4 pagesRISK ASSESSMENT-RevantaMehboob ChoudharyNo ratings yet

- Generic Risk Assessment Form: (To Be Used For Routine Tasks and For Reference When Developing Project Specific RDocument6 pagesGeneric Risk Assessment Form: (To Be Used For Routine Tasks and For Reference When Developing Project Specific Rghada gattouchNo ratings yet

- Hirarc Table VikiDocument7 pagesHirarc Table VikiTAMILARASI A/P THOUMALAI MoeNo ratings yet

- RA 001 Risk Analysis - Risk AssessementDocument2 pagesRA 001 Risk Analysis - Risk AssessementJoshua Guerrero CaloyongNo ratings yet

- Workplace Noise and Vibration Management Global Standard 1.0Document8 pagesWorkplace Noise and Vibration Management Global Standard 1.0Gebeyehu Sebsibie WoldetsadikNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- 3-WD 40 Spray (Anti Rust)Document2 pages3-WD 40 Spray (Anti Rust)MainrajNo ratings yet

- Hazardous Materials PPEDocument89 pagesHazardous Materials PPESUNNYWAY CONSTRUCTIONNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Job: Hvac Prepared By: Checked By: Reviewed By: Approved byDocument2 pagesJob: Hvac Prepared By: Checked By: Reviewed By: Approved byMonu KhanNo ratings yet

- Igc 3 Practical NeboshDocument18 pagesIgc 3 Practical NeboshNaveen C PaulNo ratings yet

- Fire Risk Assessment FormDocument20 pagesFire Risk Assessment FormAhmed Ibrahim100% (1)

- IRON ORE Risk AssessmentDocument5 pagesIRON ORE Risk AssessmentMamunNo ratings yet

- Name Position Signature Date: Hse/KbrDocument9 pagesName Position Signature Date: Hse/Kbrالبصرة العراقيNo ratings yet

- 8 Hours Prescribe Training Presentation For Workers - 2022Document140 pages8 Hours Prescribe Training Presentation For Workers - 2022chum onaNo ratings yet

- Grinder - Angle-Electric and PneumaticDocument2 pagesGrinder - Angle-Electric and PneumaticjoessterNo ratings yet

- Rams PresentationDocument31 pagesRams PresentationwaleedNo ratings yet

- Contractor Management Handbook-2020Document52 pagesContractor Management Handbook-2020waleedNo ratings yet

- Getting To The Root of Root Cause AnalysesDocument45 pagesGetting To The Root of Root Cause AnalyseswaleedNo ratings yet

- Safety Manual-Appendix J-Root Cause Analysis ChecklistDocument6 pagesSafety Manual-Appendix J-Root Cause Analysis ChecklistwaleedNo ratings yet

- Carrying Worksheet: Analysis Incident No.Document1 pageCarrying Worksheet: Analysis Incident No.waleedNo ratings yet