Professional Documents

Culture Documents

Assemble and Operate Halogen Exam Lights

Uploaded by

Dr. Jeisson HincapieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assemble and Operate Halogen Exam Lights

Uploaded by

Dr. Jeisson HincapieCopyright:

Available Formats

7.

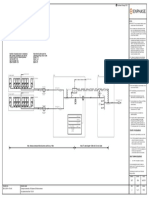

With the base/pole still lying on its side, gently pull the electrical connector from inside of the pole using the twist tie. ASSEMBLY INSTRUCTIONS FOR LS-135 & LS-150 OPERATION OF FLEXIBLE ARM

Remove and discard twist tie. Refer to photo 7. Orient the Luminaire-flexible arm assembly’s electrical connector to the

Your new LS-135 & LS-150 light has been carefully designed to give you optimum performance to enable you to easily articulate

remaining pole electrical connector and connect each by firmly pressing together. Refer to photo 8. WALL MOUNT MODELS and place the light exactly where you need it. These design attributes include:

8. Connect the flexible arm to the pole by lining up the slots on the black plastic connector (nearest the electrical connector) Required tools for assembly: Electric drill, 3mm (1/8”) and 4.7mm (3/16”) diameter drill bits, #2 phillips screwdriver, bubble level,

above the pole cut outs. Push flexible arm into pole until it clicks into place. Refer to photo 9. • The lamp has been offset at a 12° angle relative to the Luminaire housing, allowing the physician an unobstructed view

linear scale. of the field of interest.

LS-135 & LS-150 9. Prior to plugging the unit into the appropriate outlet, inspect the lamp to insure that it has not become unseated during

shipment (Refer to photo 10). If the lamp is not properly seated in the lamp housing, use your fingertips to gently press Wall Unit

• A pole to flexible arm joint that allows the flexible arm to be freely rotated about the pole 270°.

• A flexible arm to Luminaire joint that allows rotation of the Luminaire about the flexible arm 300°.

Halogen Exam Lights against the protective cover glass of the lamp to spring the lamp back into the proper position. If the lamp can not be easily

reseated by this method, refer to the Lamp Replacement instructions to open the Lamp Housing and reseat the lamp. 1. Remove all items from shipping carton and check for damage. Refer to photo and table. Notify Welch Allyn or your nearest • A 24” flexible arm that allows you to easily articulate and hold the Luminaire in an infinite number of positions.

Service Center of any damage or missing parts using the appropriate phone number listed on the back. Please use the following guidelines for proper articulation of the flexible arm:

10. Stand light assembly up onto its base and plug into an appropriate outlet. Please refer to warnings and caution section as

well as the operations section prior to use. 2. Identify the type of wall construction you intend to mount the wall unit onto (and if applicable, transformer). Generally wall • The flexible arm should be articulated (bent), NOT TWISTED. Twisting of the flexible arm

types can be described as follows: beyond its rotation stops will decrease the life of the arm and can cause it to lose its ability

• Dry wall (gypsum or plaster) with wood studs OR metal studs to hold position.

INTRODUCTION • Failure of the flexible arm due to twisting may void the warranty.

• Masonry

Thank you for purchasing your new Halogen Exam Light by Welch Allyn, the worldwide leader in illuminated medical diagnostic 3 No. Description • Wood (solid or heavy 19mm (3/4”) thick veneer) Special Note: We recommend that you DO NOT acutely bend the flexible arm as shown to the right.

instrumentation. By following the use and care guidelines given in this booklet, you will enjoy years of dependable, trouble-free

service from your new exam light. 1 Base Assembly LAMP REPLACEMENT

1

This exam light can be used for topical examinations of the skin such as abrasions, foreign body removal, and other similar

applications. 2

2 Luminaire-Flexible Arm NO. Description Disconnect power cord from electrical outlet prior to replacement.

Assembly

1 Light/Transformer Assembly

SYMBOLS 3 Pole Assembly

2 Allow lamp to cool 10 minutes prior to replacement.

1 4 Parts Kit 2 Power Cord

4

Protective shield. Replace any cracked Off position when rocker switch is ori- • Base Cover Plate 3 Mounting Hardware (443184-501)

protective shield. ented towards this marking. • Screw 1/4-20 x 1” Phillips 1. Exposing the Lamp (Refer to photo 1)

•1/4” External Lockwasher

(443062-501) • Turn power switch to the off (“ ”) position and unplug power cord from outlet.

Tungsten Halogen Lamp On or full light intensity position. 3

Table #1 • Rotate Light Assembly (A) so that the lamp points up (towards ceiling).

3. Identify the desired location for light (and if applicable, transformer). In general, the wall unit must be installed so that at • Completely loosen screw in Lamp Housing (B) and lift to expose the Lamp (C).

Indoor use only. On or low light intensity position (LS-135 #1 least two of its four fasteners extend into the walls structural members (studding or structural masonry). The cable length 2. Freeing the Lamp and Lamp Socket (Refer to photo 2)

only). between the light and transformer is 1.1m (3.5’) and power cord length is 2.4m (8’).

“INDOOR” • Release the Lamp Retaining Wire (E) from the Lamp Housing (B) by pushing on wire “ears” towards Lamp Socket and

4. Position the unit’s mounting bracket onto the wall and level. Using the bracket as a template, mark the four mount hole swing out as shown to free the Lamp (C) and Lamp Socket (D).

locations. Locate parts kit containing screws and plastic anchors. Mount as follows: 3. Removing the Lamp Socket (Refer to photos 3 and 4)

• For studded dry wall: • Hold the Lamp (C) by its outer rim. Grasp the white sides of the Lamp Socket (D) as shown, pull on the Lamp Socket (D)

WARNINGS & CAUTIONS while rocking it slightly to remove it from the Lamp (C). Do not pull on Lamp Socket Wires (G).

1. Pre-drill two 3mm (1/8”) holes 19mm (3/4”) deep that are located over the structural studding (one side of

CAUTION: All users of this exam light should be thoroughly trained in the medical examinations appropriate to the the bracket). 4. Install the new Lamp

equipment. Furthermore, they should read and understand the instructions contained within this manual before use. 2. Pre-drill two 4.7mm (3/16”) holes just through the drywall surface located opposite the previous holes.

• Verify that the lamp number located on the metal plate inside the Light Assembly (H) (photo #2) matches the

Failure to do so may result in injury to the patient or damage to the equipment. Install two plastic anchors into these holes. replacement lamp number.

3. Place mounting bracket over the holes and:

• Replace Lamp (C) and reattach Lamp Retaining Wire (E) to Lamp Housing (B).

CAUTION: Do not use the LS-135 or LS-150 for transillumination, as erythema may result. Contact Welch Allyn • Install two #8-1.5” tapping screws through bracket and into the holes drilled in step 1. • Align Lamp pins to Lamp Socket holes and reconnect Lamp Socket.

regarding appropriate lights for transillumination applications. • Reinstall Lamp Housing (B) onto Light Assembly (A) by first engaging Lamp Housing tab (opposite screw) into Light

• Install two #8- 1.5” tapping screws through bracket and into the plastic anchors installed in

#2A #2B Assembly. Fully tighten screw.

step 2.

INTENSE LIGHT: Lamp is extremely bright. Do not stare at the lamp when in use. May be harmful to eyes. • Reconnect Power cord and verify Lamp operation.

• Tighten all four screws.

• For masonry type walls: #1 #3

1. Pre-drill four 4.7mm (3/16”) holes 38 mm (1.5”) deep. Install four plastic anchors into these holes. (C)

CAUTION: Remove power cord from electrical outlet and allow lamp to cool 10 minutes before replacing with Welch 2. Place mounting bracket over the holes and:

Allyn lamp. For the LS-135 use lamp No.: 04430 and for the LS-150 use lamp No.: 04450.

• Install four #8-1.5” tapping screws through the bracket and into the plastic anchors installed in

step 1. (B)

DANGER: Electric Shock Hazard - do not disassemble the instrument. Refer servicing to qualified service personnel.

There are no user serviceable parts other than the lamp. • Tighten all four screws.

• For wood walls:

CAUTION: Use the examination light in its intended working range of 12 to 36 inches. Exposures at closer distances 1. Pre-drill four 3mm (1/8”) holes 25 mm (1”) deep. (C)

may be harmful to skin. 2. Place mounting bracket over the holes and:

(A)

• Install four #8-1.5” tapping screws through bracket and into the wall.

DANGER: Risk of explosion if used in the presence of flammable anesthetics. #3 #4 • Tighten all four screws.

(E)

#2 #4

IPXØ: Not protected against the ingress of water.

(C)

Structural Stud

HOT SURFACE: Lamp surface is hot. May be harmful to skin if touched.

(H)

Mounting Bracket

(G)

Guidelines for the safe use of the LS-135 & LS-150 include: (D) (D)

General good practices to minimize risk of harm to the skin from optical radiation hazards include: minimizing illumination intensity

at the tissue examination site, minimizing exposure times, and taking additional precautions when skin sensitivity has been altered #6 CLEANING

through tissue trauma or the use of anesthesia. #5

1. Unplug the unit prior to cleaning.

General good practices to minimize risk of harm to the eyes from optical radiation hazards include: avoiding looking at 2. The entire unit can be wiped down with a cloth slightly dampened with a mild solution of detergent and water. Wipe the

bright light sources and their reflections, and protecting eyes where normal pupil sizes and aversion responses are not TRANSFORMER unit dry with a clean, dry cloth. Be careful not to allow moisture to enter into the unit or allow the plug prongs to get wet.

present.

Mount the transformer to the wall using the hardware provided and integral brackets on the back of the transformer. Locate the 3. Do not plug the light back into the electrical outlet until the light is thoroughly dry.

NOTE: This product complies with current required standards for electromagnetic interference and should not transformer an appropriate distance from the light assembly, but within 2.4m (8’) from a suitable outlet.

NOTE: Do not sterilize the unit.

interfere with other equipment or be affected by other compliant devices. As a precaution, avoid using this NOTE: For studded dry wall, identify a stud location (preferably on the

device in close proximity to other equipment. same stud used to mount the light assembly). If a stud location is not CAUTION: Do not immerse in cleaning solutions.

available, you can use drywall only mounting as described below.

ASSEMBLY INSTRUCTIONS FOR LS-135 & LS-150 WARRANTY

1. Place the transformer at the desired height and mark a short

horizontal line corresponding to the top of the transformer. From Welch Allyn warrants that the LS135 and LS-150 Exam Light products meet the labeled specifications of the products and will be

FLOOR STAND MODELS free from defects in materials and workmanship that occur within one year after the date of purchase.

this line, mark a vertical and plumb line down approximately 12cm

NOTE: Follow the assembly instructions listed below and their corresponding photographs. #7 #8

(5”). The date of purchase is: 1) the date specified in our records if you purchased the Product directly from us, 2) the date specified in

Required tools for assembly: Phillips #2 or #3 screwdriver. 2. Mark hole location one 1.9 cm (3/4”) down from the horizontal line. 1.9 cm (3/4”) the warranty registration card that we ask you to send to us, or 3) the date of purchase of product from the authorized Welch Allyn

Mark hole location two 8 cm (3 1/8”) down from hole location one. distributor as documented from a receipt from said distributor.

1. Remove all items from the shipping carton. Check for damage or missing components. Refer to photo 1 and table 1. Notify

Welch Allyn, or your nearest Service Center of any damage or missing parts using the appropriate phone number listed on Refer to figure. This warranty does not cover damage caused by: 1)handling during shipping, 2) use or maintenance contrary to labeled instructions,

8 cm (3 1/8”)

the back. • For dry wall over a stud or wood: 3) alteration or repair by anyone not authorized by Welch Allyn, and 4) accidents.

2. Using the shipping box as an assembly aid; place the base (item 1) on its side oriented in the box as shown in photo 2a. 1. Pre-drill two 3mm (1/8”) holes 19mm (3/4”) deep If a Product or accessory covered by this warranty is determined to be defective because of defective materials, components, or

that are located over the structural studding. workmanship, and the warranty claim is made within the warranty period described above, Welch Allyn will, at its discretion, repair

3. Obtain the pole (item 3). Identify and orient the pole’s flange end with wire harness to the base and feed wire harness 2. Screw two #8 1.5” tapping screws into wall

through base center hole as shown in photo 2b. Align wire harness into notch in base as shown in photo 3, then seat pole or replace the defective Product or accessory free of charge. If your Product requires repairs covered by this warranty, upon your

allowing the screw heads to protrude 2.3mm (11/ request Welch Allyn will loan to you, at no cost, a substitute Product for use until your repaired Product is returned.

into base. EXERCISE CARE WHEN INSERTING POLE AND HARNESS INTO BASE. DO NOT PINCH WIRES. 32”).

4. Connect pole’s wire harness connector to the corresponding connector in the base as shown in photo 4. Align and press • For dry wall only or masonry: You must obtain a service notification number from Welch Allyn to return your Product before you send it to Welch Allyn’s

firmly into place. 1. Pre-drill two 4.7mm (3/16”)holes just through the drywall surface or 38mm (1.5”) into masonry. Install two designated service center for repair. Contact Welch Allyn Technical Support.

5. From the parts kit, obtain the base cover plate and attach the remaining wire connector to the corresponding tab located on Pole Cut Out plastic anchors into these holes. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

the cover plate. Refer to photo 5. 2. Install two #8-1.5” tapping screws into the plastic anchors allowing the screw heads to protrude 2.3mm WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. WELCH ALLYN’S OBLIGATION UNDER THIS

#10 (11/32”). WARRANTY IS LIMITED TO REPAIR OR REPLACEMENT OF PRODUCTS CONTAINING A DEFECT. WELCH ALLYN IS NOT

6. From the parts kit, obtain the screw and external lockwasher and install through the plate, place the plate into the base, #9

threading screw clockwise into pole. Tighten firmly, using screwdriver. Refer to photo 6. RESPONSIBLE FOR ANY INDIRECT OR CONSEQUENTIAL DAMAGES RESULTING FROM A PRODUCT DEFECT COVERED BY THE

WARRANTY.

Downloaded from www.Manualslib.com manuals search engine

CASTER BASE ACCESSORY ASSEMBLY INSTRUCTIONS SPECIFICATIONS Approximate Physical Dimensions NOTE: This product contains no materials classified as hazardous. Therefore, its disposal is not deemed as

NOTE: The Exam Light must be assembled before the Caster Base Accessory is attached.

Leakage Current: The products listed within this manual comply with 9.5 cm harmful to the environment or health risk to individuals disposing of the product. As a precaution, it is

the agency requirements listed below. (3.75”) recommended you contact your local disposal and/or recycling authority for information regarding the disposal of

Attachment Instructions: the equipment.

Place styrofoam block from accessory packaging box on floor. Then place Caster Base Accessory on Environment: 12°

center of block so that casters are not touching the floor.

Figure 1. 23 cm

Position the Exam Light flexible arm in neutral position as shown in Figure 1. Transport/Storage: Operating: (9”)

Flexible arm in

-20°C - 49°C, 10°C - 35°C Spot Size

Place the Exam Light base into Caster Base Accessory centering power cord between two wire neutral position Fuse Working Color Lamp Total Cord

frame legs, as shown in Figure 2. The Exam Light base should rest on top of bent legs on the 10% - 95% R.H. Max, 30% - 75% R.H. Max,

86 cm Model Input Output Wattage Intensity @ 65 cm

opposite side. 500hPa - 1060hPa Altitude 500hPa - 1060hPa Altitude (3) Distance Temperature Life Weight Length

(34”) (24”)

Place hand and foot as shown in Figure 3. Use your foot to push the Exam Light base down firmly Safety Class I Equipment

until the base engages into the wire frame. Continuous Operation 44300 120v~60Hz, 12v~2.9A 250v, 500mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 7.8 kg 2.9 M

63 cm 400mA (11.4”) (12” min) (2) (17.3 lbs) (9.5’)

NOTE: Do not force base into place by pushing down on the Light pole or pulling on flexible arm. (25”)

Check to insure that the Exam Light is assembled correctly with the Caster Base Accessory. To do this, lay the Exam light over on its 44302 230v~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 7.8 kg 2.9 M

side and verify that the Caster Base Assembly’s wire frame is interlocked into the notches of the Exam Light Base (see Figure 4). If 250mA (11.4”) (12” min) (2) (17.3 lbs) (9.5’)

they are not interlocked, grasp the Exam Light Base with one hand and one leg of the Caster Base Accessory with the other hand, ETL listed: 44303 100v~50/60Hz, 12v~2.9A 250v, 630mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 7.8 kg 2.9 M

and turn in opposite directions until the Caster Base Accessory locks into the Exam Light Base notches. UL2601-1, 500mA (11.4”) (12” min) (2) (17.3 lbs) (9.5’)

C US

CSA C22.2 No. 601.1,

IEC 60601-1, AS 3200.1. 44304 230/240v~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 7.8 kg 2.9 M

IEC 60601-1-2 250mA (11.4”) (12” min) (2) (17.3 lbs) (9.5’)

89 cm

(35”) 44306 240v~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 7.8 kg 2.9 M

Australia EMC Framework Compliance 250mA (11.4”) (12” min) (2) (17.3 lbs) (9.5’)

N344 44310 120v~60Hz, 12v~2.9A 250v, 500mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

400mA (11.4”) (12” min) (2)

Figure 2. Base fitted into two bent legs 44312 230v~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

Ø 36 cm

250mA (11.4”) (12” min) (2)

Figure 3. Push base into place with foot. (Ø14”)

Do not force using pole. 44313 100v~50/60Hz, 12v~2.9A 250v, 630mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

The CE mark on this product indicates that it has been tested to and conforms with the provisions noted within 250mA (11.4”) (12” min) (2)

the 89/336/EEC Electromagnetic Compatibility Directive.

44314 230/240v ~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

Figure 4. Caster Base Accessory assembled Authorized European Representative Address: 500mA (11.4”) (12” min) (2)

correctly with Exam Light Base. European Regulatory Manager

Welch Allyn, LTD. 44316 240v~50Hz, 12v~2.9A 250v, 315mA 35w 525fc (1) 29 cm 30.5 cm min 3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

Navan Business Park, 250mA (11.4”) (12” min) (2)

Dublin Road

Navan, County Meath, Republic of Ireland 44500 120v~60Hz, 12v~4.2A 350v, 800mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 7.9 kg 2.9 M

Tel: +353 46 90 67700 600mA (13”) (12” min) (2) (17.4 lbs) (9.5’)

Detachment Instructions: Fax: +353 46 90 67755 44502 230v~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 7.9 kg 2.9 M

Place locking casters in locked position. 350mA (13”) (12” min) (2) (17.4 lbs) (9.5’)

SERVICE INFORMATION

Place foot on one of the five legs of the metal frame. Then hold pole at the top near flexible arm and pole connection. 44503 100v~50/60Hz, 12v~4.2A 250v, 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 7.9 kg 2.9 M

For Technical Support or to obtain return instructions, please contact your nearest Welch Allyn service center listed below:

750mA 1000mA (13”) (12” min) (2) (17.4 lbs) (9.5’)

Simultaneously, lift and push the LS-135 & LS-150 Exam Light away from you, releasing the base from the Caster Base Accessory.

USA + 1 315 685 4560 Australia + 61 29 638 3000 44504 230/240v~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 7.9 kg 2.9 M

NOTE: Do not place foot on base while pushing and pulling. Do not pull on flexible arm. 800 535 6663 800 074 793 350mA (13”) (12” min) (2) (17.4 lbs) (9.5’)

When ordering replacement parts for your Caster Base Accessory, please use the following numbers:

Canada 800 561 8797 China + 86 216 327 9631 44506 240v~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 7.9 kg 2.9 M

350mA (13”) (12” min) (2) (17.4 lbs) (9.5’)

European Call Center + 353 46 906 7790 France + 331 6009 3366

44510 120v~60Hz, 12v~4.2A 250v, 800mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 3.4kg 2.4M (8’)

Germany + 49 747 792 7186 Japan + 81 33 219 0071

600mA (13”) (12” min) (2) (7.4 lbs)

Latin America + 1 305 669 9003 Netherlands + 31 15 750 5000

44512 230v~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 3.4kg 2.4M (8’)

Caster Base Frame Singapore + 65 6419 8100 South Africa + 27 11 777 7555 350mA (13”) (12” min) (2) (7.4 lbs)

United Kingdom + 44 207 365 6780 Sweden + 46 85 853 6551 44513 1000v~50/ 12v~4.2A 250v, 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 3.4kg 2.4M (8’)

440094 Caster with brake

Washers 60Hz,750mA 1000mA (13”) (12” min) (2) (7.4 lbs)

OR

44514 230/240v ~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 3.4kg 2.4M (8’)

440095 Caster without brake 350mA (13”) (12” min) (2) (7.4 lbs)

ORDERING INFORMATION 44516 240v~50Hz, 12v~4.2A 250v, 500mA 50w 576fc 33 cm 30.5 cm min 4700K 3,000 hrs (4) 3.4kg 2.4M (8’)

No. 440094 Caster with brake, Acorn Nut and two Washers

350mA (13”) (12” min) (2) (7.4 lbs)

No. 440095 Caster without brake, Acorn Nut and two Washers Catalog # Description

(1) Full intensity

04450 Halogen replacement lamp for LS-150 Halogen Exam Light (2) Recommended minimum working distance, see cautions regarding skin exposure.

TABLE CLAMP ACCESSORY ASSEMBLY (3) Non-user serviceable in-line single acting type.

1. Securely tighten the clamp (A) to the chosen mounting surface. 04430 Halogen replacement lamp for LS-135 Halogen Exam Light (4) Lamp life may vary slightly due to usage patterns.

2. Align the holes in the mounting bracket (B) on the light with the holes 44350 Caster base accessory, LS-135 & LS-150 Halogen Exam Light

in the table clamp. (Floor Stand Models Only)

Using the wrench provided, install the four screws provided and tighten. 44101 Table Clamp Accessories (Wall mount Models Only)

44301 Rail Mount Accessory (Wall mount Models Only)

DISASSEMBLY INSTRUCTIONS

When not in use, wrap the power cord and use a twist tie to hold it together. Place the power cord on top of the base.

To return a floor stand unit for service:

1. Turn the power switch to the OFF position ( ) and unplug the cord from the outlet.

2. Using a small flat head screwdriver, CAREFULLY pull back the tabs at the top of the pole slightly - just enough to

disengage them from the black plastic insert in the pole.

3. Pull up on the bottom end of the flexible arm. Unplug the electrical connector and remove Luminaire-Flexible Arm

assembly from the pole.

4. Tilt the pole/base onto its side and unscrew the large phillips head screw located on the bottom center of the base.

5. Remove the metal base cover plate and disconnect the connector attached to it.

6. Disconnect the remaining electrical connector from the base and pull the pole out of the base.

7. Securely wrap the three components (base, pole, and Luminaire assembly) and loose parts in suitable protective

packaging for shipment to your authorized service center.

To return a wall mount unit for service:

1. Turn the power switch to the OFF position ( ) and unplug the cord from the outlet.

2. Pull up on transformer to remove it from its mounting screws.

3. Unscrew the four screws mounting the unit to the wall. For units fitted with the table clamp accessory, simply

4.

remove clamp from the table.

Securely wrap the components (lamp assembly and transformer) in suitable protective packaging for shipment to

80012404 Ver. A

your authorized service center.

(English)

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Teléfono Inalámbrico 26928GE1 - GE2 - IBDocument2 pagesTeléfono Inalámbrico 26928GE1 - GE2 - IBalgoncarNo ratings yet

- Manual de Usuario Obulb ProDocument1 pageManual de Usuario Obulb ProPere Civit QuiterioNo ratings yet

- Owner's Manual Manuel de l'utilisation Bedienungsanleitung Manuale di Istruzioni Manual de Instrucciones Gebruiksaanwijzing Instruktionsbok Инструкция ПользователяDocument52 pagesOwner's Manual Manuel de l'utilisation Bedienungsanleitung Manuale di Istruzioni Manual de Instrucciones Gebruiksaanwijzing Instruktionsbok Инструкция ПользователяJózsef VargaNo ratings yet

- Service Manual: Viewsonic Pj501/Pj551Document62 pagesService Manual: Viewsonic Pj501/Pj551Andrey KhodanitskiNo ratings yet

- DR1000 Installation Instruction Rev JDocument4 pagesDR1000 Installation Instruction Rev JLupita ArriagaNo ratings yet

- Redmi Buds 3 Lite-User ManualDocument1 pageRedmi Buds 3 Lite-User ManualDragutin StojkovicNo ratings yet

- 71cdnCXyIGLDocument1 page71cdnCXyIGLIstamsetty HanumantharaoNo ratings yet

- NTS-660 Series Total Station Instruction ManualDocument236 pagesNTS-660 Series Total Station Instruction ManualPrashanth Reddy TummuluriNo ratings yet

- Power Supply 1/4 Schematic Diagram: Caution ! Caution !: ATTENTION: Utiliser Un Fusible de Rechange de MDocument6 pagesPower Supply 1/4 Schematic Diagram: Caution ! Caution !: ATTENTION: Utiliser Un Fusible de Rechange de MErick MoraNo ratings yet

- InstallDocument2 pagesInstallpqcrackerNo ratings yet

- Megajet Strobe: MJ450 / MJ650 / MJ850 / MJ1050 / MJ1290Document7 pagesMegajet Strobe: MJ450 / MJ650 / MJ850 / MJ1050 / MJ1290122112100% (1)

- Nice Epmb Eplb Photocells ManualDocument2 pagesNice Epmb Eplb Photocells ManualMFANo ratings yet

- Epmab Epmab/A: PhotocellsDocument2 pagesEpmab Epmab/A: PhotocellsSupuran RichardoNo ratings yet

- Wireless Stereo Headphone System: How To UseDocument2 pagesWireless Stereo Headphone System: How To UseMon BoualNo ratings yet

- W9180B W9123B英文说明书5550644Document1 pageW9180B W9123B英文说明书5550644Supri Rhifa'i ArdiNo ratings yet

- PanasonicKX TG2122WDocument2 pagesPanasonicKX TG2122WPayphone.com100% (1)

- HS900 InstallDocument8 pagesHS900 InstallzeljkoNo ratings yet

- Dewalt dw130v Operators Manual PDFDocument6 pagesDewalt dw130v Operators Manual PDFJL AlexanderNo ratings yet

- Tips for Teachers: Circuit Construction KitDocument3 pagesTips for Teachers: Circuit Construction KitDannisa aaNo ratings yet

- Eplob Eplob/A Epmob Epmob/A: PhotocellsDocument2 pagesEplob Eplob/A Epmob Epmob/A: PhotocellsSupuran RichardoNo ratings yet

- Eartec UltraLITE Wireless Headset User Manual SEODocument2 pagesEartec UltraLITE Wireless Headset User Manual SEOAntonio Laruta choqueNo ratings yet

- Vinci X 2 User ManualDocument1 pageVinci X 2 User ManualRizkyNo ratings yet

- A320 Non Rated 2Document47 pagesA320 Non Rated 2Flyer BernNo ratings yet

- Manual Servicio Mini Component Sound System Noblex MNX 3000sDocument35 pagesManual Servicio Mini Component Sound System Noblex MNX 3000sNey TrajanoNo ratings yet

- Korg MicroarrangerDocument244 pagesKorg MicroarrangerAntal KöbliNo ratings yet

- Models Available Psp1 Plug-In Special Purpose Supervisory SwitchDocument2 pagesModels Available Psp1 Plug-In Special Purpose Supervisory SwitchArgile-assholeNo ratings yet

- Before Reading This User ManualDocument2 pagesBefore Reading This User ManualJeancarlos DominguezNo ratings yet

- Creating A Reactive Energy Pulse Output Based On The ADE7753Document12 pagesCreating A Reactive Energy Pulse Output Based On The ADE7753api-3744762No ratings yet

- SMC PFMB QuickguideDocument1 pageSMC PFMB QuickguideFRANNo ratings yet

- Surveying ToolsDocument6 pagesSurveying ToolsAbigail Marie Therese FuentesNo ratings yet

- E4 Charger Instruction Manual Features Fast Charge 2S-4S BatteriesDocument1 pageE4 Charger Instruction Manual Features Fast Charge 2S-4S BatteriesJess PoseyNo ratings yet

- Shimano 1Document1 pageShimano 1nelson mantzNo ratings yet

- 小米生态链产品包装图纸Document1 page小米生态链产品包装图纸Stani Jude JohnNo ratings yet

- User Manual 3971431Document1 pageUser Manual 3971431Avinash MalviyaNo ratings yet

- Esquema - Zivan NGXDocument2 pagesEsquema - Zivan NGXSalomao DelfinoNo ratings yet

- H3AC3 English Installation GuideDocument1 pageH3AC3 English Installation Guidejmom18_647241209No ratings yet

- MFL38868794Document2 pagesMFL38868794kk1116No ratings yet

- IV4.2 - Installation - BaxiRoca Novanox 2 - 2 - F - RU - ENGDocument15 pagesIV4.2 - Installation - BaxiRoca Novanox 2 - 2 - F - RU - ENGJuan Antonio GarcíaNo ratings yet

- MIG Welding Tips and TechniquesDocument3 pagesMIG Welding Tips and TechniquesQA QCNo ratings yet

- RC 1082 OmDocument56 pagesRC 1082 OmCapitanSalamiNo ratings yet

- MI-X175 Retro Heritage LiteDocument1 pageMI-X175 Retro Heritage Litexintong liuNo ratings yet

- AQ Mistral Guide RoundDocument1 pageAQ Mistral Guide RoundgeorgelorinczNo ratings yet

- Installed Gain As A Control Valve Sizing Criterion - Valin3Document7 pagesInstalled Gain As A Control Valve Sizing Criterion - Valin3Kyriakos MichalakiNo ratings yet

- McGraw-Edison Power Drawer Wall Light Series Brochure 1980Document6 pagesMcGraw-Edison Power Drawer Wall Light Series Brochure 1980Alan MastersNo ratings yet

- Orca Share Media1673962301247 7021106775971098853Document1 pageOrca Share Media1673962301247 7021106775971098853Von AninonNo ratings yet

- UserGuideDocument2 pagesUserGuidedksxmasterNo ratings yet

- American Cinema To 12 AmerDocument642 pagesAmerican Cinema To 12 AmerMatthew BanksNo ratings yet

- Drag Nano2 User ManualDocument1 pageDrag Nano2 User ManualUstass TatsumiNo ratings yet

- GrowerSELECT - HS783 Fan Pulley Laser Alignment Kit Instruction ManualDocument4 pagesGrowerSELECT - HS783 Fan Pulley Laser Alignment Kit Instruction ManualOvidiu RaicovNo ratings yet

- Typical Enphase SLD 3ph ResiDocument1 pageTypical Enphase SLD 3ph Resielectromec technologyNo ratings yet

- Pokewalker Tri PDFDocument3 pagesPokewalker Tri PDFHaseeb KhawajaNo ratings yet

- Argus GT User ManualDocument1 pageArgus GT User ManualDian RusdianaNo ratings yet

- ABB - AF - Contactor - 4poleDocument6 pagesABB - AF - Contactor - 4poleAhmad HamdanNo ratings yet

- Mi Smart Band 6 User ManualDocument1 pageMi Smart Band 6 User ManualDivakar KethisvarasuthanNo ratings yet

- Quick-Start Guide: Installation For Lights With One Wall Switch (Single-Pole)Document6 pagesQuick-Start Guide: Installation For Lights With One Wall Switch (Single-Pole)EdNo ratings yet

- Panasonic FP X ManualDocument544 pagesPanasonic FP X ManualAngel Santos Santos100% (1)

- 3 Hours / 70 Marks: Seat NoDocument4 pages3 Hours / 70 Marks: Seat Nofreefire23075No ratings yet

- Micro Drives pdc1000 Manual en-US en-USDocument36 pagesMicro Drives pdc1000 Manual en-US en-USPezhmandmNo ratings yet

- Series NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualDocument70 pagesSeries NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualHamilton GutierrezNo ratings yet

- Frequency Response With MATLAB ExamplesDocument107 pagesFrequency Response With MATLAB ExamplesDisco JockeyNo ratings yet

- Catálogo IC-M73 ICOMDocument2 pagesCatálogo IC-M73 ICOMassociacaodistritalNo ratings yet

- Troubleshooting Guidelines: AlternatorsDocument5 pagesTroubleshooting Guidelines: AlternatorsanilNo ratings yet

- Service Manual for Daewoo Color TV ModelsDocument43 pagesService Manual for Daewoo Color TV Modelshilario moyaNo ratings yet

- All Product Catalogue Small SizeDocument9 pagesAll Product Catalogue Small SizeGD SinghNo ratings yet

- 80010892V01 Penta Band PDFDocument4 pages80010892V01 Penta Band PDFJurandir Auad Beltrão Jr.No ratings yet

- Flow Brochure2014Document6 pagesFlow Brochure2014PRECITECNo ratings yet

- DEWAStandardsforDistributedRenewableResourcesGenerators V 20 March 2016Document164 pagesDEWAStandardsforDistributedRenewableResourcesGenerators V 20 March 2016harikollam1981No ratings yet

- Current ConverterDocument27 pagesCurrent ConvertersamsangNo ratings yet

- Ericsson Gsm/W-Cdma 900Mhz RF Module, 80W KRC 118 62/1 R1C Model Rus01 B8 November 2011Document5 pagesEricsson Gsm/W-Cdma 900Mhz RF Module, 80W KRC 118 62/1 R1C Model Rus01 B8 November 2011Mauricio ConusNo ratings yet

- Lepton Series 7-28-23Document2 pagesLepton Series 7-28-23Scarllet Osuna TostadoNo ratings yet

- EENG115 Introduction to Logic Design LabDocument10 pagesEENG115 Introduction to Logic Design Labasdf lkjNo ratings yet

- Iso 18563 1 2015 en PDFDocument11 pagesIso 18563 1 2015 en PDFlingtiNo ratings yet

- Data Book - RCN-T-36W-E_remote for KX6Document9 pagesData Book - RCN-T-36W-E_remote for KX6fakir mohammadNo ratings yet

- Vfi VFD ViDocument2 pagesVfi VFD ViPablo CabreraNo ratings yet

- Detailed Lesson Plan in Consumer Electronic ServicingDocument6 pagesDetailed Lesson Plan in Consumer Electronic ServicingSanja Shishin100% (5)

- C2G DS C2G10379 84 Performance Series Ultra Flexible Active High Speed HDMI CableDocument3 pagesC2G DS C2G10379 84 Performance Series Ultra Flexible Active High Speed HDMI CableStephen RivettNo ratings yet

- Metrology Measurement Unit-5Document27 pagesMetrology Measurement Unit-5R NAVEEN KUMAR MECHNo ratings yet

- Brochure Imaxeon Salient SINGLEDocument4 pagesBrochure Imaxeon Salient SINGLEQuyet LeNo ratings yet

- D093, D094 Service ManualDocument779 pagesD093, D094 Service ManualMr DungNo ratings yet

- Dav Public School Airoli: Physics Investigatory ProjectDocument14 pagesDav Public School Airoli: Physics Investigatory ProjectAditya Banare100% (1)

- 4.9-6.5GHz 19dBi Horn AntennaDocument2 pages4.9-6.5GHz 19dBi Horn AntennaPSW TelecomNo ratings yet

- GMT Global Mixed Mode Tech G718TM1U - C356796Document7 pagesGMT Global Mixed Mode Tech G718TM1U - C356796BonetzNo ratings yet

- UT595Document1 pageUT595leagallo00No ratings yet

- Power System Protection (Directional)Document9 pagesPower System Protection (Directional)Aisamuddin SubaniNo ratings yet

- Ig5 ManualDocument118 pagesIg5 Manualdanankstya40% (5)