Professional Documents

Culture Documents

Orca Share Media1673962301247 7021106775971098853

Uploaded by

Von AninonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Orca Share Media1673962301247 7021106775971098853

Uploaded by

Von AninonCopyright:

Available Formats

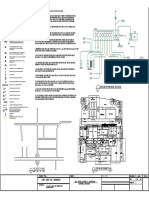

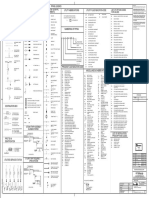

GENERAL ELECTRICAL NOTES AND STANDARDS DETAILS OF

1. ALL ELECTRICAL WORKS HEREIN INCLUDED SHALL BE EXECUTED IN ACCORDANCE WITH THE PROVISION OF THE LATEST EDITION OF THE PHILIPPINE ELECTRICAL CODE, RULES AND NOTES:

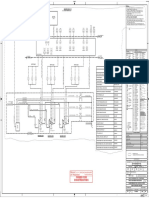

PANEL BOARD - SPB

REGULATION OF THE LOCALITY AND REQUIREMENTS OF THE POWER COMPANY.

2. ALL ELECTRICAL WORKS HEREIN INCLUDED SHALL BE EXECUTED BY EXPERIENCES MEN AND UNDER DIRECT SUPERVISION OF A FULL TIME ELECTRICAL ENGINEER, ALL WORKS SHALL BE

1. USE FLUORESCENT BULBS FOR LIGHTING FIXTURE.

DETAILS OF PANEL BOARD - MPB

NEATLY PLACED, SECURELY FASTENED AND PROPERLY FINISHED.

2. ALL CIVIL WORKS AND ELECTRICAL WORKS, FOUNDATION WORKS SHALL CONFORM TO MERALCO STANDARS. 2 SETS, 2 - 50 sq. mm THNN

TO MPB2 + 1 - 14 sq. mm TW in 30 mm Ø

3. THE ELECTRICAL SERVICE POWER IS 1-PHASE, 2-WIRE AND 1-GROUND, 230 V AC, 60 HZ.

and 15 mm Ø for EMT PIPE

3. ALL OTHER EQUIPMENT AND MATERIALS SHALL BE SUPPLIED, INSTALLED AND MAINTAINED BY THE CUSTOMER.

SPB

4. ALL MATERIALS SHALL BE NEW AND SHALL CONFORM WITH THE PHILIPPINE STANDARD, AIR CIRCUIT BREAKER TO BE USE HEREIN SHALL BE SQUARE-D, KOTEN OR EQUIVALENT.

4. THE CUSTOMER SHALL PROVIDE A PERMANENT ACCESS IN BRINGING IN AND OUT OF MERALCO EQUIPMENT DURING SCHEDULE MAINTENANCE

5. ALL CONDUITS INCLUDING FEEDER LINES SHALL BE PVC SCHEDULE 40. ATLANTA, POLY, MOLDEX, IMPERIAL OR EQUIVALENT, ALL WIRINGS ARE THEN TO BE CONCEALED IN THIS LAYOUT. AND EMERGENCY WORKS AND SHALL BE MADE ACCESSIBLE TO MERALCO PERSONNEL AT ANYTIME AS LONG AS THERE ARE MERALCO-OWNED INCOMING POWER SUPPLY 150 AT

EQUIPMENT INSIDE. 230V, 1PH, 60Hz, 2W-G 20 AT 20 AT

6. THE MINIMUM ELECTRICAL CONDUIT SHALL BE 15mm(1/2")Ø FOR IMC PIPES AND 15mm(1/2")Ø FOR PVC PIPES. MPB

5. ALL MATERIALS TO BE USED SHALL BE BRAND NEW AND APPROVED TYPE FOR THE PARTICULAR LOCATION AND PURPOSE OF USAGE. 1 2

7. ALL CONDUITS SHALL BE PROTECTED AGAINST DAMAGES BY THE ENTRANCE OF WATER AND ANY FOREIGN MATTER DURING CONSTRUCTION. ALL ENDS OF CONDUITS SHALL BE PLUGGED TO 125 AT

20 AT 20 AT

EXCLUDE MOISTURE AND DUST IMMEDIATELY AFTER THE CONDUITS ARE PLACED.

3 4

175 AT 150 AT 20 AT 20 AT

8. ALL IMC CONDUITS BENDS MADE IN FIELD SHALL BE DONE BY USING HYDRAULIC BENDERS. MOUNTING HEIGHTS: 1 2 5 6

2 SETS, 2 - 150 sq. mm THNN 20 AT 20 AT

9. ALL PIPES AND FITTINGS ON EXPOSED WORKS SHALL BE SUPPORTED AND SECURED BY MEANS OF C-CHANNELS AND CLAMPS. KILOWATTHOUR METER 1.800m FROM CENTER OF DEVICE TO FINISHED GRADE + 1 - 22 sq. mm TW in 65 mm Ø

and 15 mm Ø for EMT PIPE 7 8

10. THERE SHALL BE ADEQUATE AND EFFECTIVE EQUIPMENT GROUNDING AND THE GROUNDING RESISTANCE SHOULD BE NOT MORE THAN 5 OHMS. ALL CONDUCTOR SHALL BE THHN/THWN 20 AT 20 AT

PANELBOARD 1.900m FROM TOP OF PANEL TO FLOOR FINISH

INSULATED. THE MINIMUM SIZE OF WIRES SHALL BE 2.00mm2 (#10 AWG) STRANDED THHN/THWN OR THW FOR POWER SYSTEM. SYWIN, PHILFLEX BRAND OR APPROVED EQUIVALENT.

M

9 10

kWHR METER 20 AT 20 AT

11. THE WIRE COLOR CODING AS FOLLOW.

LINE 1 - YELLOW WALL SWITCHES, ENCLOSED 1.500m FROM CENTER OF DEVICE TO FLOOR FINISH 11 12

20 AT 20 AT

NEUTRAL - GRAY GROUND - GREEN

CIRCUIT BREAKERS 0.300m FROM CENTER OF DEVICE TO FLOOR FINISH,

13 14

12. SPLICING CONNECTION SHALL BE USED IN ALL SPLICING AND CONNECT FROM 2.0mm2 UP TO 8.mm2 WIRES. USE SOLDERLESS CONNECTORS IN ALL OTHER SIZES. CONVENIENCE OUTLET AS REQUIRED BY THE EQUIPMENT SERVED 25 AT 25 AT

13. THE FOLLOWING ELECTRICAL TEST SHALL BE CONDUCTED ANNUALLY. SPECIAL PURPOSE OUTLET 0.300m FROM CENTER OF DEVICE TO TOP OF COUNTER 15

20 AT

16

20 AT

A. INSULATION WIRE RESISTANCE TEST

B. GROUND RESISTANCE TEST AIR CONDITIONING UNIT OUTLET 1.900m FROM CENTER OF DEVICE TO FLOOR FINISH

18

C. OPERATIONAL TEST 17 20 AT 20 AT

D. PHASE BALANCING TEST

E. PHASE SEQUENCE TEST 19 20 AT 20 AT

20

F. SYSTEM TEST

21 22

LEGENDS, SPECIFICATIONS, AND SYMBOLS LOAD SCHEDULE - MAIN PANEL BOARD

10-24 W, 2256 LUMENS LED LIGHT HAND DRYER, 2.5 KW ELECTRIC RANGE, 4 KW RICE COOKER, 500 W CKT VOLT AMPERE CIRCUIT

REFRIGERATOR, 4 KW DESCRIPTION OF LOAD VOLT SIZES OF WIRES AND RACEWAY

RC

NO AMPERE LOAD AT AF P

9.5 W, 2500 LUMENS OUTDOOR LED LIGHT

OVEN TOASTER, 2.0 KW 1 GPB (GROUND FLOOR PANEL BOARD) 35253 230 170.30 175 200 2 2 SETS, 2-80 sq. mm THNN + 1-14 sq. mm TW in 35 mm Ø and 15 mm Ø for PVC Pipe

MICROWAVE OVEN, 2.0 KW ELECTRIC SINK, 10 KW WATER HEATER, 5 KW

2 SPB (SECOND FLOOR PANEL BOARD) 28100 230 135.75 150 175 2 2 SETS, 2-50 sq. mm THNN + 1-14 sq. mm TW in 30 mm Ø and 15 mm Ø for PVC Pipe

Sa SWITCH, SINGLE-GANG, 250 V, COMPLETE WITH WH

COVER LETTER DENOTES SWITCH CONTROL ELECTRIC FAN, 200 W TOTAL 63353 230 306.05

WASHING MACHINE, 450 W CON SPLIT TYPE CONDENSER LIGHTING AND POWER

Sab SAME AS ABOVE, EXCEPT TWO-GANG EF

PANEL BOARD COMPUTATION FOR WIRE:

COMPUTATION FOR CB:

I= (TOTAL CURRENT X 0.80) + (1.25 X HIGHEST CURRENT IN ALL BRANCH CKT)

Sabc SAME AS ABOVE, EXCEPT THREE-GANG WP 2 HP WATER PUMP GPB SPB HOME RUN CIRCUIT I=306.05 X 0.80 DF + 1.25 X 36.01 = 289.85 A

I= (TOTAL CURRENT X 0.80) + (1.50 X HIGHEST BRANCH CIRCUIT CURRENT)

SPLIT TYPE AIR-CONDITIONER, 4 HP 1 1 NUMERATOR DENOTES PANEL BOARD MAIN FEEDER WIRE: 2 SETS, 2-150 sq. mm THHN + 1-22sq. mm TW in 65 sq. mm Ø and 15 sq. mm Ø for EMT Pipe respectively.

I= 306.05 X 0.80 DF + 1.50 X 36.01 = 298.86 A

DENOMINATOR DENOTES CIRCUIT NUMBER

MAIN FEEDER PROTECTION: 300 AT, 350 AF, 2 POLES, 230 V

DUPLEX CONVENIENCE OUTLET

FLAT SCREEN TELEVISION, 400 W

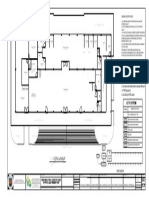

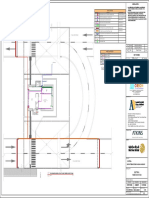

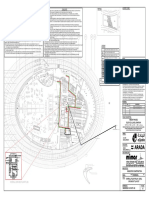

LOAD SCHEDULE - GROUND FLOOR PANEL BOARD LOAD SCHEDULE - SECOND FLOOR PANEL BOARD DETAILS OF SINGLE LINE DIAGRAM

CKT VOLT AMPERE CIRCUIT

PANEL BOARD - GPB

DESCRIPTION OF LOAD VOLT SIZES OF WIRES AND RACEWAY

NO AMPERE LOAD AT AF P CKT VOLT AMPERE CIRCUIT

DESCRIPTION OF LOAD VOLT SIZES OF WIRES AND RACEWAY INCOMING POWER SUPPLY

1 12- 24 W LED LIGHT 288 230 1.39 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe NO AMPERE LOAD AT AF P 230V, 1PH, 60Hz, 2W-G

2 - 3.5 sq. mm. THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 1 4- 24 W LED LIGHT 96 230 0.46 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe MPB

2 10- 24 W LED LIGHT 240 230 1.16 20 25 2

2 SETS, 2 - 80 sq. mm THNN 125 AT

3 10- 24 W LED LIGHT 240 230 1.16 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

2 5- 24 W LED LIGHT 120 230 0.58 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe TO MPB1 + 1 - 14 sq. mm TW in 35 mm Ø

175 AT 150 AT

and 15 mm Ø for EMT PIPE

4 288 230 1.39 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

12- 24 W LED LIGHT

3 7- 24 W LED LIGHT 168 230 0.81 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe GPB 2 SETS, 2 - 150 sq. mm THNN

1 2

+ 1 - 22 sq. mm TW in 65 mm Ø

5 18-9.5 W WALL LANTERN LIGHT 171 230 0.83 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

and 15 mm Ø for EMT PIPE

200 AT

4 2-CONVENIENCE OUTLET 360 230 1.74 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

6 ELECTRIC FAN 200 230 0.97 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 5 ELECTRIC FAN 200 230 0.97 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

20 AT 20 AT kWHR METER M

7 2- CONVENIENCE OUTLET 360 230 1.74 20 25 2

1 2

8 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 6 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT

9 TELEVISION 400 230 1.93 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 3 4

7 3-CONVENIENCE OUTLET 540 230 2.61 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT

10 WASHING MACHINE 450 230 2.17 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

8 ELECTRIC FAN 200 230 0.97 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 5 6

20 AT 20 AT

11 WATER PUMP- 2 HP 1492 230 7.21 20 25 2 2 - 3.5 sq. mm. THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC PIPE

9 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

12 AUTOMATIC HANDRYER-2.5KW 2500 230 12.08 20 25 2 2 - 3.5 sq. mm. THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC PIPE 7 8

20 AT 20 AT

2 SETS, 2 - 80 sq. mm THNN

13 3- CONVENIENCE OUTLET 540 230 2.61 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 10 4-CONVENIENCE OUTLET 720 230 3.48 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe TO MPB1 + 1 - 14 sq. mm TW in 35 mm Ø

9 10 and 15 mm Ø for EMT PIPE

20 AT 20 AT GPB

14 OVEN TOASTER 1492 230 7.21 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

11 ELECTRIC FAN 200 230 0.97 20 25 2 200 AT

2 SETS, 2 - 50 sq. mm THNN

11 12 TO MPB2 + 1 - 14 sq. mm TW in 30 mm Ø

15 MICROWAVE OVENRICE COOKER 1492 230 7.21 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT and 15 mm Ø for EMT PIPE

12 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT

SPB

16 3- CONVENIENCE OUTLET 540 230 2.61 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 1 2

13 14 20 AT 20 AT

150 AT

13 AUTOMATIC HANDRYER-2.5KW 2500 230 12.08 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT

17 REFRIGERATOR 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 3

20 AT 20 AT

4

20 AT 20 AT

15 16

18 1- CONVENIENCE OUTLET 180 230 0.87 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 14 1-CONVENIENCE OUTLET 180 230 0.87 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT 5 6 1 2

20 AT 20 AT 20 AT 20 AT

19 RICE COOKER 700 230 3.38 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 15 WATER HEATER-5 KW 3730 230 18.02 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 17

20 AT

18

7

20 AT 20 AT

8 3

20 AT 20 AT

4

20 AT

20 ELECTRIC FAN 200 230 0.97 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 9 10 5 6

16 WATER HEATER-5 KW 3730 230 18.02 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT 20 AT 20 AT

19 20 AT 20 AT

20

11 12

21 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm. THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC PIPE 20 AT 20 AT

7

20 AT 20 AT

8

17 1-CONVENIENCE OUTLET 180 230 0.87 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

13 14 9 10

22 2-CONVENIENCE OUTLET 360 230 1.74 20 25 2 2 - 3.5 sq. mm. THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC PIPE 21 20 AT 22 20 AT 20 AT 20 AT 20 AT

20 AT

18 AUTOMATIC HANDRYER-2.5KW 2500 230 12.08 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 15 16 11 12

23 ELECTRIC RANGE 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 20 AT 20 AT 20 AT

23 20 AT 40 AT 24

24 ELECTRIC SINK 7460 230 36.04 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 19 2-CONVENIENCE OUTLET 360 230 1.74 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 17

20 AT 20 AT

18 13

25 AT 25 AT

14

25 20 15 16

25 2-CONVENIENCE OUTLET 360 230 1.74 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 26 19

0.97

20 AT

20 AT 20 AT

20 ELECTRIC FAN 200 230 20 25 2 20 AT 20 AT

21

26 ELECTRIC FAN 200 230 0.97 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 27 28

20 AT 20 AT 22 17 20 AT 20 AT

18

21 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe

23 24 20

27 SPLIT TYPE-ACU 2984 230 14.42 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 20 AT 40 AT 19 20 AT 20 AT

22 1-CONVENIENCE OUTLET 180 230 0.87 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 25 20 AT 20 AT 26

28 1-CONVENIENCE OUTLET 180 230 0.87 20 25 2 2 - 3.5 sq. mm THNN + 1 - 3.5 sq. mm TW in 12 mm Ø PVC Pipe 21 22

TOTAL 35253 230 170.30

TOTAL 28100 230 135.75 27 28

COMPUTATION FOR WIRE: COMPUTATION FOR CB: COMPUTATION FOR WIRE:

I= (TOTAL CURRENT X 0.80) + (1.25 X HIGHEST BRANCH CIRCUIT CURRENT) COMPUTATION FOR CB:

I= (TOTAL CURRENT X 0.80) + (1.25 X HIGHEST BRANCH CIRCUIT CURRENT) I= (TOTAL CURRENT X 0.80) + (1.50 X HIGHEST BRANCH CIRCUIT CURRENT)

I= 170.30 X 0.80 DF + 1.25 X 36.01 = 181.25 A I= 170.31 X 0.80 DF + 1.5 X 36.01 =190.26 A I=135.75 X 0.80 DF + 1.25 X 18.02 = 131.125 A I= (TOTAL CURRENT X 0.80) + (1.50 X HIGHEST BRANCH CIRCUIT CURRENT)

MAIN FEEDER WIRE: 2 SETS, 2-80 sq. mm THHN + 1-14 sq. mm TW in 35 sq. mm Ø and 1 5 sq. mm Ø for EMT Pipe respectively. MAIN FEEDER WIRE: 2 SETS, 2-50 sq. mm THHN + 1-14 sq. mm TW in 30 sq. mm Ø and 15 sq. mm Ø for EMT Pipe respectively. I= 135.75 X 0.80 DF + 1.5 X 18.02 = 135.63 A

MAIN FEEDER PROTECTION: 200 AT, 225 AF, 2 POLES, 230 V MAIN FEEDER PROTECTION: 150 AT, 175 AF, 2 POLES, 230 V

R.A. 9266,SEC.33 ENGINEER IN CHARGE PROJECT TITLE OWNER SHEET CONTENTS PROJECT NO. SHEET NO.

PROJECT LEAD:

Drawing and Specifications and other contract

documents duly signed, stamped or sealed, as ONOFRE ALGARA JR., REE PROPOSED ELECTRICAL SYSTEM LAYOUT DRAWN BY: ANIÑON, VON ADOLF

2

instruments of service, are intellectual

CHECKED BY: ENGR. ALGARA

COLEGIO DE MUNTINLUPA

property of the ARCHITECT. Whether the object

ANIÑON, VON ADOLF F. AS STATED

E

for which they are made is executed or not.

It shall be unlawful for any person to duplicate SCALE:

CE2A

2

or to make copies of said documents for use in

repetition of and for other projects or REG. NO. PTR.NO. LOCATION REVISION:

buildings, whether executed partly or in whole

without the written consent of the ARCHITECT.

ISSUED ON: ISSUED AT:

SUCAT, MUNTINLUPA CITY DATE: 07-23-22

FILENAME: COMPREHENSIVE

You might also like

- Elec 3Document1 pageElec 3Shiela Tala-oc Sapois-AndoNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- 00-Electrical-1-E001 (1)Document1 page00-Electrical-1-E001 (1)Abegail del castilloNo ratings yet

- RGDG Electrical DrawingsDocument1 pageRGDG Electrical DrawingsElezer BatchoNo ratings yet

- General Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireDocument13 pagesGeneral Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireUututNo ratings yet

- Schedule of Loads: Electrical NotesDocument1 pageSchedule of Loads: Electrical NotesKenneth RicafrancaNo ratings yet

- Anflocor Office Interiors Anflocor: General Notes: Fdas NotesDocument1 pageAnflocor Office Interiors Anflocor: General Notes: Fdas NotesIan RustNo ratings yet

- Legends & Symbols Electrical Panel DiagramDocument1 pageLegends & Symbols Electrical Panel DiagramAngelice Alliah De la CruzNo ratings yet

- 1007-ZN01-BM-103 - Small Power LayoutDocument1 page1007-ZN01-BM-103 - Small Power LayoutMHD MKNo ratings yet

- M100Document1 pageM100Ahmed YaseenNo ratings yet

- Ee001 RevisedDocument1 pageEe001 Revisedkeijohn62No ratings yet

- Electrical Engineering NotesDocument1 pageElectrical Engineering Noteskimdalipe13No ratings yet

- SPECIFICATIONS FOR SIDEWALK AND ELECTRONICS INSTALLATIONDocument1 pageSPECIFICATIONS FOR SIDEWALK AND ELECTRONICS INSTALLATIONalezandro del rossiNo ratings yet

- ELECTRICALDocument1 pageELECTRICALMaenaj SogubacNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 10010Document1 pageR12 T07B24 Ifmi XX XX SDW El 10010Abrar DigitalNo ratings yet

- 3 Mps Building Dingras ElectricalDocument7 pages3 Mps Building Dingras ElectricalJuan MarcosNo ratings yet

- Foundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Document11 pagesFoundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Parth K PatelNo ratings yet

- Royal Prince Dasma Electrical Plan 1Document2 pagesRoyal Prince Dasma Electrical Plan 1Ryan Anthony UmaliNo ratings yet

- 400kV ICT1 RegisterDocument27 pages400kV ICT1 RegisterMidhun VargheseNo ratings yet

- Philippine building electrical notesDocument2 pagesPhilippine building electrical notesIzzah LNo ratings yet

- Load Schedule PB1 Load Schedule PB2,3,4,5 Unit 01 UNIT 02-03-04-05Document1 pageLoad Schedule PB1 Load Schedule PB2,3,4,5 Unit 01 UNIT 02-03-04-05domin domNo ratings yet

- 106 - E1.0-Electrical Site PlanDocument1 page106 - E1.0-Electrical Site PlanJosé Luis Falcon100% (1)

- EX00-CCTV-FS-XX0001 - 001008-ModelDocument1 pageEX00-CCTV-FS-XX0001 - 001008-Modelengrabbas75No ratings yet

- Jubail-4&6 ElecticalDocument1 pageJubail-4&6 Electicalnazih sedrakNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- AMC Moreau Town Center Alarm DetectionDocument1 pageAMC Moreau Town Center Alarm DetectionAnonymous MDkp0hnb3lNo ratings yet

- E-5-2 Marked Up Single Line Diagram HDDI-1 Revised 200722Document31 pagesE-5-2 Marked Up Single Line Diagram HDDI-1 Revised 200722Basileus CastaliensisNo ratings yet

- FS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- Sample BOS IoT Lite BMS Topology DiagramDocument2 pagesSample BOS IoT Lite BMS Topology DiagramWalter BarbaNo ratings yet

- 564shj22-01-Gym-Tc-100 R1Document1 page564shj22-01-Gym-Tc-100 R1IbrahimUnesNo ratings yet

- 07 RmmuDocument7 pages07 RmmuveerendrareddyNo ratings yet

- 400kV ICT2 RegisterDocument27 pages400kV ICT2 RegisterMidhun VargheseNo ratings yet

- QGTL1 Pro 07 00002 001 - 10Document1 pageQGTL1 Pro 07 00002 001 - 10Muhammad Arham KhalilNo ratings yet

- Voltage Drop Calculation Illumination Design: SpecificationsDocument1 pageVoltage Drop Calculation Illumination Design: SpecificationsKAngNo ratings yet

- Mezzanine Level Fire AlarmDocument1 pageMezzanine Level Fire Alarmdanish0229No ratings yet

- DMM 1 e 007Document1 pageDMM 1 e 007mahesh reddy mNo ratings yet

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- Mulimbayan Residence - EE (For Construction)Document4 pagesMulimbayan Residence - EE (For Construction)Jhanchris CortezNo ratings yet

- 380910-Eia-0010-01 (2), Temp PDB-02 & 03Document1 page380910-Eia-0010-01 (2), Temp PDB-02 & 03Nikhil SutharNo ratings yet

- M3 Ton 23 4: Pod1 - Mezz. SlabsDocument1 pageM3 Ton 23 4: Pod1 - Mezz. SlabsHamza QudahNo ratings yet

- EXISTING Electric Floor PLAN 1 E-1 SCALE: 3/16" 1'-0": Electrical Riser DiagramDocument1 pageEXISTING Electric Floor PLAN 1 E-1 SCALE: 3/16" 1'-0": Electrical Riser DiagramRaúl Carbonell HerreraNo ratings yet

- ISO A1 594x841mm distribution board layoutDocument1 pageISO A1 594x841mm distribution board layoutGopa KumarNo ratings yet

- Bah053 Red 00 XX DR e 720Document1 pageBah053 Red 00 XX DR e 720Gopa KumarNo ratings yet

- Cable Trench and Road Banka Combine PDFDocument3 pagesCable Trench and Road Banka Combine PDFManas MondalNo ratings yet

- Electrical notes for building revisionDocument1 pageElectrical notes for building revisionRaúl Carbonell HerreraNo ratings yet

- General notes for construction drawingsDocument1 pageGeneral notes for construction drawingsmhazarath murariNo ratings yet

- QP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Document1 pageQP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Nassif Abi AbdallahNo ratings yet

- B130279002P03Document1 pageB130279002P03Mohammad ShayanNo ratings yet

- Staircase design dimensions and notesDocument1 pageStaircase design dimensions and notesKARTHIK SGNo ratings yet

- Fa 3RDDocument1 pageFa 3RDAhmed KhalilNo ratings yet

- Electrical Notes for Building ComplianceDocument1 pageElectrical Notes for Building ComplianceKenneth RicafrancaNo ratings yet

- DIN-rail Mounted Fieldbus TerminatorsDocument4 pagesDIN-rail Mounted Fieldbus Terminatorsravi_fdNo ratings yet

- 60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendDocument1 page60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendSohail SurveNo ratings yet

- 101.a 1 001 01 102Document1 page101.a 1 001 01 102Lady Johanna Quintero OsorioNo ratings yet

- UntitledjsjjsDocument1 pageUntitledjsjjsPaulo GallardoNo ratings yet

- Plot Stamp - A1 - Adv 20-01-20-Electrical.Document1 pagePlot Stamp - A1 - Adv 20-01-20-Electrical.nadeem UddinNo ratings yet

- Samsung-led-monitor-SA300 Service ManualDocument41 pagesSamsung-led-monitor-SA300 Service ManualLuciano GerloNo ratings yet

- P011-0002, Symbols & Legends (2,3)Document1 pageP011-0002, Symbols & Legends (2,3)Mubashir fareedNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- Can't Help Falling in LoveDocument2 pagesCan't Help Falling in LoveVon AninonNo ratings yet

- Christ Be Our LightDocument1 pageChrist Be Our LightVon AninonNo ratings yet

- Orca Share Media1673962301261 7021106776030602051Document1 pageOrca Share Media1673962301261 7021106776030602051Von AninonNo ratings yet

- As The DearDocument2 pagesAs The DearVon AninonNo ratings yet

- Your Are The LightDocument4 pagesYour Are The LightVon AninonNo ratings yet

- Des Piece F Se 2003 MotorDocument26 pagesDes Piece F Se 2003 MotorPACHYYNNo ratings yet

- The Volcanic Explosivity Index (VEI)Document8 pagesThe Volcanic Explosivity Index (VEI)Rakhmatul ArafatNo ratings yet

- Animals Adaptation LessonDocument6 pagesAnimals Adaptation LessonPascal Bou NajemNo ratings yet

- 17 The Tarrying TimeDocument22 pages17 The Tarrying Timeapi-303147801100% (1)

- 特变电工画册(英文定稿)Document52 pages特变电工画册(英文定稿)Diego MantillaNo ratings yet

- Assignment 1 (Total Marks: 70) EEE 323: Power System IIDocument2 pagesAssignment 1 (Total Marks: 70) EEE 323: Power System IIShahriar SauravNo ratings yet

- Brazed Tool ArDocument5 pagesBrazed Tool ArRoni MustafiqNo ratings yet

- CRRT (RVS) One Day TrainingDocument46 pagesCRRT (RVS) One Day TrainingwantoNo ratings yet

- 3204-9-Resource Use and SustainabilityDocument25 pages3204-9-Resource Use and SustainabilityKezia NatashaNo ratings yet

- DIESEL PARTS OF AMERICA DPA-240 USER'S MANUALDocument54 pagesDIESEL PARTS OF AMERICA DPA-240 USER'S MANUALEdinson Ariel Chavarro QuinteroNo ratings yet

- Comparison and Contrast EssayDocument2 pagesComparison and Contrast Essayputri fadillahNo ratings yet

- MarlinDocument28 pagesMarlincumpio425428No ratings yet

- Strength of CSG and TBGDocument10 pagesStrength of CSG and TBGTiffany DacinoNo ratings yet

- Formulation Development and Evaluation of Sustained Release Tablets of AceclofenacDocument128 pagesFormulation Development and Evaluation of Sustained Release Tablets of Aceclofenacraju narayana padala0% (1)

- Rift Vally BC N RegularDocument308 pagesRift Vally BC N RegularCabdisacid yasinNo ratings yet

- Hurqalya - HavarqalyaDocument64 pagesHurqalya - HavarqalyaBVILLARNo ratings yet

- ERT Techniques for Volunteer Fire BrigadesDocument45 pagesERT Techniques for Volunteer Fire BrigadesZionNo ratings yet

- #Healthy Food Recipes EasyDocument4 pages#Healthy Food Recipes EasyTHE NEXT GENNo ratings yet

- Revisiting The Irish Royal Sites: Susan A. JohnstonDocument7 pagesRevisiting The Irish Royal Sites: Susan A. JohnstonJacek RomanowNo ratings yet

- Chapter 11: The EyesDocument26 pagesChapter 11: The Eyesriley2021No ratings yet

- 2.seismic Coefficient CalculationDocument14 pages2.seismic Coefficient CalculationVenkat PalliNo ratings yet

- 60 Minutes-60 Questions: Mathematics TestDocument15 pages60 Minutes-60 Questions: Mathematics TestJihyun YeonNo ratings yet

- Analyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphDocument13 pagesAnalyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphRamil NacarioNo ratings yet

- ABR College Mechanical Mid Exam Questions on MetrologyDocument1 pageABR College Mechanical Mid Exam Questions on MetrologySrinu ArnuriNo ratings yet

- Dialysis PrescriptionDocument23 pagesDialysis PrescriptionMercy Juliana Jacqualine100% (1)

- PSPD Activity 3Document4 pagesPSPD Activity 3laurynnaNo ratings yet

- Power Systems Analysis Short Ciruit Load Flow and HarmonicsDocument1 pagePower Systems Analysis Short Ciruit Load Flow and HarmonicsJurij BlaslovNo ratings yet

- SP18368 Automotive Radar Comparison 2018 Sample 2Document33 pagesSP18368 Automotive Radar Comparison 2018 Sample 2Chipisgood YuNo ratings yet

- Acute Pain - Mastectomy - Breast CADocument2 pagesAcute Pain - Mastectomy - Breast CAAngie MandeoyaNo ratings yet

- White Chicken KormaDocument5 pagesWhite Chicken Kormamkm2rajaNo ratings yet