Professional Documents

Culture Documents

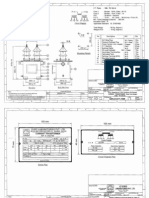

380910-Eia-0010-01 (2), Temp PDB-02 & 03

Uploaded by

Nikhil SutharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

380910-Eia-0010-01 (2), Temp PDB-02 & 03

Uploaded by

Nikhil SutharCopyright:

Available Formats

Notes

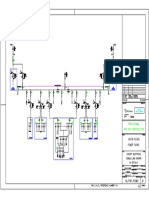

415V, 3PH, 4Wire, 50Hz, AC Supply from

Legend 1. Loading are specified in kW, unless otherwise noted.

PCC-04

Symbol Description 2. Indicating lamps shall be of LED cluster type.

3. Switchgear components for motor feeders shall be provided with Type-2 co-ordination of Simocode

Current Transformer as per IS:60947 and type-2 selection chart given in this drawing.

4. All the power cables up to & including10Sq.mm shall be of Copper conductor

A Ammeter and Aluminum conductor for 16 Sq.mm. & above.

SPD

R, G, A, (Class C) V Voltmeter 5. MCCB / MPCB shall be provided with door operating handle with pad locking &

R M Motor defeat mechanism.

6. All MCCB's 250A & above rating shall be provided with microprocessor based O/C, S/C & E/F

AS Ammeter Selector Switch releases & MCCB's up to 200A rating shall be with thermal magnetic type adjustable O/C, S/C &

*A , MCCB

SH VS Voltmeter Selector Switch E/F with CBCT unless otherwise specified, All the MCCB's shall have Ics=100% Icu.

(Refer Table 1) 7. 1 NO + 1 NC Auxiliary contacts shall be provided with MPCB / MCCB for deriving

See Note-15 CP Control Panel control supply, such that feeder can be operated / tested with MPCB in ON / OFF position.

HS Load Manager PF Power Factor Meter 8. All the starter feeders shall have 1 no. Auxiliary contactor with 2 NO + 2 NC Contacts.

0-500V KWH Kilowatt Hour Meter 9. Printed ferruling with cross reference wiring ferruling to be used.

VS V 10.Extended rotary operating handle with IP:54 degree of protection shall be

HZ Frequency Meter provided with each MCCB.

Hz 11.MCCB / MPCB handle shall be provided with handle position indication in ON/

Non Flameproof Push Button Station With Recess Type Start

OFF & tripped condition.

0-**A LCS1 P.B. & Mushroom Head Stay put Stop P.B.

1# */5A, P1 12.Each motor feeder of iMCC shall be provided with the following features

PF kW kWh THD AS A Direct-on-line (DOL) Starter With ON, OFF& Trip I/L, Recess a) Status (running, stopped, tripped).

CL*, * VA CT

type Start Push Button, Mushroom Head Stay put type Stop P.B. b) Number of contactor operations.

(Refer Table-1)

P2 , Contactor, Intelligent Relay. c) Motor current.

R - Red For Running Indication (on) d) Motor running up time (time from start to reaching operational speed).

*A, **V, 3Ph., 4 Wire, 50Hz, ** e) Motor operating time (operating hours).

G - Green For Stationary Indication (off)

Busbar,*KA for 1 sec. (See Note-33) A - Amber For Trip Indication f) Motor overload protection, setting, status, pre-alarm and time to trip.

Indication

Lamps R - Red For 'R' Phase On g) Load unbalance protection, setting and status, including pre-alarm.

Y - Yellow For 'Y' Phase On h) Thermal status of the motor, including restart inhibit time.

i) Earth fault protection of motors, setting and status

1 B - Blue For 'B' Phase On

j) Stalling protection setting and status.

TPN Moulded Case Circuit Breaker (MCCB) k) Local stop.

Load Manager MPCB Motor Protection Circuit Breaker (MPCB) l) Reset of alarms and trips via a password or key for locked rotor & earthfault.

0-500V (TYP) Air Circuit Breaker (ACB) (MDO) m) Manual reset of all other alarms and trips.

VS V SPD n) Configurable inputs for DCS communication, external trips (2 as a minimum)

Surge Protection Device MCU shall be suitable to communicate to Profibus DP using suitable connector if

Hz DOL required.

Fuse (HRC)

0-**A MCU

P1 Space Heater (SH)

PF kW kWh THD AS A

SH

Key to symbols

CT

P2 HS Heater Switch

E E Cable Gland

L R

Local Remote Selector Switch

Control Cable

Power Cable

VFD Variable Frequency Drive

MCU Motor Control Unit (MCU)

FCU Feeder Control Unit (FCU)

Star Delta Starter (SDS) with ON, OFF & Trip Indication Lamp,

Recess Type Start Push button, Mashroom head Stay-put-type

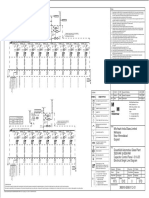

Table - 51 stop push buttons, Contractor and Electronic Timer in intelligent

relay.

For MV Panels THD Total Harmonic Distortion

Current Type of Draw out type No. of Operating principle of LM Load Manager with Ethernet port

Feeder

rating Breaker facility Poles releases & Protection

Microprocessor

Incomer ³ 800A MCCB Fixed type TP+N/4P BasedO/C, S/C, E/F,

U/V & STC

Microprocessor

TABLE - 1 ³ 800A MCCB Fixed type TP+N/4P BasedO/C, S/C, E/F

& STC

Outgoings

Bus Bar Details CT Details Power Cable Breaker Details Refer Table Microprocessor

Reference drawings

Panel No. for < 800A MCCB Fixed type TP+N/4P BasedO/C, S/C, E/F

Total Total S/C Ammeter S/C Type outgoing & STC (See Note-15)

SW. BD. Accuracy VA Size in Incoming Outgoing Incomer Rating

NO.

Connected Running Amps Level Type Ratio

Class Burden

Range

Sq. mm

Circuit Nos.

Entry Entry Type (A)

Level feeder Drawing No. Rev. Reference Drawings/Documents Remarks

Load (kW) Load (kW) (kA) (Amps) (kA) Table - 55

Utility_Eqpt_List_Format Process equipment list Dated 19/04/2018

PDB-02 220 174 400 50 Aluminium 400/5A 1 7.5 0-400 2#3.5Cx300 A2XFY PCC-04/-*-/PDB-02/P1, P2 Top Top 4P MCCB 400A 50kA Single Front Table-2 LV Subpanels / MCC/ PDB/ UPSPDB 2 Asahi

M/s Asahi email dated 02/05/18

PDB-03 391 326 800 50 Aluminium 800/5A 1 7.5 0-800 3#3.5Cx240 A2XFY PCC-03/-*-/PDB-03/P1 to P3 Top Top TP+N ACB 800A 50kA Single Front Table-3 Type of Breaker Schneider Siemens ABB 380910-PQC-101 0 Utility equipment list MM Process

Incomer

1 MCCB’s & Tmax with

NSX with Micrologic 3VA ETU 42

Outgoings PR222DS/ P

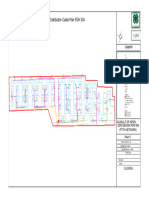

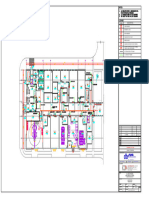

Table-2, 415V POWER DISTRIBUTION BOARD -02 : FLOOR MOUNTED TYPE, LOCATION : TEMP PLANT GROUND FLOOR BETWEEN GRID 19-20 & A-B 6A with LSIG with LCD

with LCD

Outgoing Rating (Amps.) Cable (Size in Sq.mm)

(³ 800A)

CT Detials

Local 4Field Connection

Total Peak MCCB Capacitor Incomer

Fdr. Feeder Equipment No. of Connected ACB MPCB Load Control Power Control for Power Cable

Equiptment Description Load Duty Remarks

No. Type Tag No. Phase TP+N

Four

TP+N MCB MCB

Ratio

Accuracy VA Manager Station (CP-Control Panel, MCCB’s & Tmax with

Load (kW) (kw) Pole Contactor

(Link) (Link) TPN DP Class Burden (LCS) Run Core Size Conductor Circuit No. Run Core Size Conductor Circuit No. MO-Motor) Outgoings NSX with Micrologic 3VL ETU 42

(4P) PR222DS/ P

6A with LSIG with LCD

with LCD

1 P1 GWQ-01 VQ Washing Machine-1 3 75 52 - 160 - - - 150/5 1 5 Yes - - 1 3.5 50 Cu. PDB-02/-*-/GWQ-01/P1 - - - - - CP - (250/400/630A)

2 P1 GWQ-02 VQ Washing Machine-2 3 75 52 - 160 - - - 150/5 1 5 Yes - - 1 3.5 50 Cu. PDB-02/-*-/GWQ-02/P1 - - - - - CP -

Incomer

3 P1 GPQ-01B

Printing Machine-1 for RQ Glass :

3 35 35 - 125 - - - 125/5 1 5 Yes - - 1 3.5 25 Cu. PDB-02/-*-/GPQ-01B/P1 - - - - - CP -

MCCB’s &

Oven Panel-01B Outgoings Tmax with

NSX TMD 3VL TM-LI

Printing Machine-2 for RQ Glass : TMD

4 P1 GPQ-01B 3 35 35 - 125 - - - 125/5 1 5 Yes - - 1 3.5 25 Cu. PDB-02/-*-/GPQ-01B/P1 - - - - - CP - (32/63/125/160/

Oven Panel-01B

200A) 1 31.08.18 MGA Revised as per Rev-2 Utility Equipment GCB SRB

5 P1 - Spare 3 - 0 - 125 - - - 125/5 1 5 Yes - - 0 - 0 - - - - - - - CP

List & Re-Issued for Bidding

6 P1 - Spare 3 - 0 - 160 - - - 150/5 1 5 Yes - - 0 - 0 - - - - - - - CP

0 01.06.18 MGA Client Comment's Incorporated & GCB SRB

7 P1 - Spare 3 - 0 - 160 - - - 150/5 1 5 Yes - - 0 - 0 - - - - - - - CP Issued for Bidding

P1 30.05.18 MGA Issued For Approval GCB SRB

Rev Date Drawn Description Ch’k’d App’d

Table - 3, POWER DISTRIBUTION BOARD-03 : FLOOR MOUNTED TYPE, LOCATION : GROUND FLOOR TEMP PLANT BETWEEN GRID 3.5-4 & A-B

Outgoing Rating (Amps.) CT Detials Cable (Size in Sq.mm) Mott MacDonald House

Local "Field Connection for Notes Contd...

Total Capacitor 44/45, Street No - 14

Fdr. Feeder Equipment No. of ACB MCCB MPCB MFM Control Power Cable 13. All motor feeders shall have Start / Stop, O/L reset push button, On, Off & Trip

Equiptment Description Connected Duty Power Control Remarks

No. Type Tag No. Phase MCB MCB Accuracy VA Meter Station (CP-Control Panel, indication on each feeder. MIDC Area, Andheri - East

Load (kW) TP+N TP+N TP+N Ratio Contactor

TPN DP Class Burden (LCS) MO-Motor)" 14. All indicating meters shall be of digital type, 3 phase with inbuilt selector switch.

(Link) (Link) (Link) Run Core Size Cond Circuit No. Run Core Size Cond Circuit No. Mumbai, 400093

15.Power cables shall be of 1100V grade, compacted stranded Aluminum / Copper

1 P1 K-501A Air Compressor -2.5 bar (Phase 1) 3 19 - 63 - - - 60/5 1 5 Yes - - 1 4 16 Al. PDB-04/-*-/K-501A/P1 - - - - - CP - conductor, XLPE insulated, PVC extruded, inner sheathed, G.I. Flat / round India

2 P1 K-501B Air Compressor -2.5 bar (Phase 1) 3 19 - 63 - - - 60/5 1 5 Yes - - 1 4 16 Al. PDB-04/-*-/K-501B/P1 - - - - - CP - steel armoured and FRLS PVC outer sheathed. T +91 (0)22 3083 5000

16. Control cables shall be of 1100V grade, compacted stranded Copper conductor,

Air Compressor -2.5 bar (Phase 1)

F +91 (0)22 2825 3779

3 P1 K-501C 3 19 - 63 - - - 60/5 1 5 Yes - - 1 4 16 Al. PDB-04/-*-/K-501C/P1 - - - - - CP - XLPE / PVC insulated, PVC extruded inner sheathed, G.I. Flat / round steel

1 armoured and FRLS PVC outer sheathed. Minimum size of control cable shall W mottmac.com

4 P1 D-501 Air Dryer for 2.5bar (Phase-1) 3 7.4 - 32 - - - 30/5 1 5 Yes - - 1 4 4 Cu. PDB-04/-*-/D-501A/P1 - - - - - CP

be 2.5sqmm for Flameproof & Non Flameproof area.

5 P1 D-502 Air Dryer for 2.5bar (Phase-1) 3 7.4 - 32 - - - 30/5 1 5 Yes - - 1 4 4 Cu. PDB-04/-*-/D-501B/P1 - - - - - CP 17. One vertical section shall be provided in iMCC to accommodate communication

portsfor the DCS/PLC. All the starter feeder shall be Provided with Following

6 P1 D-503 Air Dryer for 2.5bar (Phase-1) 3 7.4 - 32 - - - 30/5 1 5 Yes - - 1 4 4 Cu. PDB-04/-*-/D-501C/P1 - - - - - CP signals for DCS/PLC inter face. Client

a) Trip, b) Run c) Off d) Start/ Stop Command from DCS/PLC.

7 P1 K-601A Air Compressor -7.5 bar (Phase 1) 3 90 - 250 - - - 250/5 1 5 Yes - - 1 3.5 150 Al. PDB-04/-*-/K-601A/P1 - - - - - CP

1

-

e) Local / Remote Selection in iMCC. f) Current Indication. M/s Asahi India Glass Limited

8 K-601B Air Compressor -7.5 bar (Phase 1 : Future) 3 90 250 5 Yes 3.5 150 g) Healthy

9

P1

P1 D-601A Air Dyer for 6bar CA(Phase1) 3 5.5

-

- 32

-

-

-

-

-

-

250/5

30/5

1

1 5 Yes

-

-

-

-

1

1 4 2.5

Al.

Cu.

PDB-04/-*-/K-601B/P1

PDB-04/-*-/D-601A/P1

-

-

-

-

-

-

-

-

-

-

CP

CP

-

-

18.The kW rating indicated in 1st column of Table-1 are connected load, while the Mehsana

kW rating indicated in 2nd column of Table-1 are maximum running load with load factor and

10 P1 D-601B Air Dyer for 6bar CA(Phase1 : Future) 3 5.5 - 32 - - - 30/5 1 5 Yes - - 1 4 2.5 Cu. PDB-04/-*-/D-601A/P1 - - - - - CP 1 - diversity factor without standby & spare load. Near Ahmedabad

19. Power cable sizing will be designed considering total voltage drop of 5% up to motor equipment

11 M1 CT-303A Process Cooling Tower (Phase-1) 3 1.5 - - 4 - - - - - - - Y 1 3 2.5 Cu. PDB-04/-*-/CT-303A/P1 1 4 2.5 Cu. PDB-04/-*-/CT-303A/P1 MO - during steady state and starting voltage dip of 15%. Gujarat

20. Electrical contractor shall provide the cable tag as per circuit number indicated in

12 M1 CT-303B Process Cooling Tower (Phase-1 : Standby) 3 1.5 - - 4 - - - - - - - Y 1 3 2.5 Cu. PDB-04/-*-/CT-303B/P1 1 4 2.5 Cu. PDB-04/-*-/CT-303B/C1 MO -

the drawing and also make the actual feeder number of switchboard in the cable tag in place of -*-.

13 M1 CT-303C Process Cooling Tower (Phase-1 : Future) 3 1.5 - - 4 - - - - - - - Y 1 3 2.5 Cu. PDB-04/-*-/CT-303C/P1 1 4 2.5 Cu. PDB-04/-*-/CT-303C/C1 MO - 21. The Load Manager of PDB shall be with Ethernet IP communication port .

22. Internal wiring of reactor & other modules will be in PDB vendor scope.

Process Cooling Water Circulation Pump for Title

23. Maximum 50 feeders to be considered in each nod at PDB-3 Panel, Nods switch to be provided in

14 M1 P-303A

Cold Well (Phase-1)

3 5.5 - - 12.5 - - - - - - - Y 1 3 4 Cu. PDB-04/-*-/P-303A/P1 1 4 2.5 Cu. PDB-04/-*-/P-303A/C1 MO

incomer section of Panel. Panel vendor to provide Repeater after every 25 feeders. Greenfield Automotive Glass Plant

Process Cooling Water Circulation Pump for 24. Panel shall have Ingress Protection IP-54 for Starter feeders, IP-42 for VFD feeders with proper

15 M1 P-303B

Cold Well (Phase-1 : Standby)

3 5.5 - - 12.5 - - - - - - - Y 1 3 4 Cu. PDB-04/-*-/P-303B/P1 1 4 2.5 Cu. PDB-04/-*-/P-303B/C1 MO heat dissipation arrangement. Power Distribution Baord - 02, 03 & 04

25. Required kVA rating UPS shall be provided by Panel vendor in the control compartment of panel to

16 M1 P-303C

Process Cooling Water Circulation Pump for

Cold Well (Phase-1 : Future) 3 5.5 - - 12.5 - - - - - - - Y 1 3 4 Cu. PDB-04/-*-/P-303C/P1 1 4 2.5 Cu. PDB-04/-*-/P-303C/C1 MO feed auxiliary supply to PDB-3 relay of all starter feeders and control bus for the same shall be

formed in the panel by panel vendor.

(PDB-02, 03 & 04) for TEMP Plant

17 P1 GIM-01 MAW Injection Mould Machine-PH-1 3 100 - 250 - - - 250/5 1 5 Yes - - 1 3.5 120 Cu. PDB-03/-*-/GIM-01/P1 - - - - - CP - 26. All CTs terminals shall be Short link type.

27. All switchgear ampere rating shall be in panel rating as per site operating condition.

Electrical Single Line Diagram

18 M1 - Spare 3 1.5 - - 4 - - - - - - - - - - - - - - - - - - MO - 28. Panel Incomer feeder rating is designed based on running load with 25% de-ration and outgoing

19 M1 - Spare 3 5.5 - - 12.5 - - - - - - - - - - - - - - - - - - MO - feeder rating are designed based on the connected load of the respective equipment.

29.Panel Incomer cable size is designed based on running load of the panel and outgoing feeder cable

20 P1 - Spare 3 - - 32 - - - 30/5 1 5 Yes - - - - - - - - - - - - CP are designed based on the connected load of the respective equipment. Designed N Hingorani Eng check G C Beldar

30.All the load managers/MFM's/kWH meter communication cable shall be looped at brought at at

21 P1 - Spare 3 - - 63 - - - 60/5 1 5 Yes - - - - - - - - - - - - CP

terminal block for energy monitoring. Drawn M Apastamb Coordination S Mardwar

22 P1 - Spare 3 - - 63 - - - 120/5 1 5 Yes - - - - - - - - - - - - CP 31.ACB/ MCCB s' ON/OFF feedback (potential free contacts) shall be available up to control Box,

Dwg check J Melath Approved S Bartakke

through which remote/SCADA status can be seen.

23 P1 - Spare 3 - - 250 - - - 250/5 1 5 Yes - - - - - - - - - - - - CP 32.Each microprocessor base relesse of ACB/ MCCB should be communicable to SCADA through Status Rev Security

Scale at A1

Modbus or TCP IP.

33.Arc protection relays shall be provided along with require number of arc sensing sensors duly wired NTS EXE 1 STD

up to arc protection relay in LT panels for bus bar arc protection

© Mott MacDonald Drawing Number

34.All panel shall be powder coated with RAL7032 colour shed.

This document is issued for the party which commissioned it and for specific purposes connected with the captioned project only. It should not be relied upon by any other party or used for any other purpose.

We accept no responsibility for the consequences of this document being relied upon by any other party, or being used for any other purpose, or containing any error or omission which is due to an error or omission in data supplied to us by other parties.

35.VFD shall be of Mitsubishi make shall be supplyed by panel vendor.

380910-EIA-0010-01

C:\pwlocal\pims03\apa42076\d0246935\380910-EIA-0010-01 (1).dwg Sep 3, 2018 - 11:11AM APA42076

You might also like

- Uk Vec Pdca QRQC PrésentationDocument149 pagesUk Vec Pdca QRQC Présentationmarsan1708100% (1)

- ZX 130-5g - Electrical Wiring DiagramDocument13 pagesZX 130-5g - Electrical Wiring DiagramPrudz86% (7)

- Circuit Diagram ZX200-5GDocument11 pagesCircuit Diagram ZX200-5Gdjonsen88% (8)

- Elevation Drawing of 132 - 33KV SubstationDocument10 pagesElevation Drawing of 132 - 33KV Substationpeekate100% (1)

- 13 Ship OutfittingDocument17 pages13 Ship Outfittingryan310393100% (3)

- Guowang Miao - Jens Zander - Ki Won Sung - Slimane Ben Slimane - Fundamentals of Mobile Data Networks-Cambridge University Press (2016)Document323 pagesGuowang Miao - Jens Zander - Ki Won Sung - Slimane Ben Slimane - Fundamentals of Mobile Data Networks-Cambridge University Press (2016)belial belial100% (1)

- Mike Speiser-Free Ideas - Just Add ExecutionDocument35 pagesMike Speiser-Free Ideas - Just Add Executionnrao123No ratings yet

- Sample BOS IoT Lite BMS Topology DiagramDocument2 pagesSample BOS IoT Lite BMS Topology DiagramWalter BarbaNo ratings yet

- MPPTDocument5 pagesMPPTMahir Asif ShadmanNo ratings yet

- 819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraDocument1 page819-Tw-E-102 Electrical LT Block Diagram LT Block Diagram r1 (1) - OzoraMichael NgoNo ratings yet

- Site Development Plan Auxiliary: General Notes: Legends & SymbolsDocument16 pagesSite Development Plan Auxiliary: General Notes: Legends & SymbolsIan de GaliciaNo ratings yet

- Rpipl K Oa Amp Ce DWG MCR 008Document2 pagesRpipl K Oa Amp Ce DWG MCR 008aaaaNo ratings yet

- C32with EMCP3Document4 pagesC32with EMCP3أبو أنس المسلمNo ratings yet

- E-5-2 Marked Up Single Line Diagram HDDI-1 Revised 200722Document31 pagesE-5-2 Marked Up Single Line Diagram HDDI-1 Revised 200722Basileus CastaliensisNo ratings yet

- SLD-09 Single Line Diagram (8 of 11)Document1 pageSLD-09 Single Line Diagram (8 of 11)Mohammad GaberNo ratings yet

- MASTER SLD - NEW UPDATE-ModelDocument1 pageMASTER SLD - NEW UPDATE-Modeldhiansyah 92lifeNo ratings yet

- P4 SLD 2019 PLIRE - Recover-ModelDocument1 pageP4 SLD 2019 PLIRE - Recover-ModelMd Shamim RezaNo ratings yet

- 11 Schematic Diagrams: 11-1 Power - Sound Schematic DiagramDocument10 pages11 Schematic Diagrams: 11-1 Power - Sound Schematic DiagramGeovanny SanJuanNo ratings yet

- Note 3 Neo DiagramaDocument10 pagesNote 3 Neo DiagramaMundo PcellNo ratings yet

- Motor StartingDocument1 pageMotor StartingMoazam AliNo ratings yet

- Multilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersDocument5 pagesMultilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersPhelipe LealNo ratings yet

- Renr9477renr9477-02 - Sis 316Document2 pagesRenr9477renr9477-02 - Sis 316ait mimoune100% (1)

- Electrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System C32 Generator Set With EMCP3: Harness and Wire Electrical Schematic Symbolsyasser eljabaliNo ratings yet

- FDH504 CableDocument1 pageFDH504 CableMuhammad UmairNo ratings yet

- TTDBG EN 00 - Circuit (20151120)Document13 pagesTTDBG EN 00 - Circuit (20151120)Sherman KillerNo ratings yet

- DB Iq Avc Asb Acs 0000 00Document1 pageDB Iq Avc Asb Acs 0000 00Mohammed NadeemNo ratings yet

- Single Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Document1 pageSingle Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Silver SoulNo ratings yet

- 132 KV HANSI-ModelDocument1 page132 KV HANSI-ModelShariq KhanNo ratings yet

- Section 8 Designing The Input Supply: Figure 8-1. Rectification SchemesDocument6 pagesSection 8 Designing The Input Supply: Figure 8-1. Rectification Schemescmvb123No ratings yet

- DATUM 0.000m Levels DATUM 0.000m Levels DATUM 0.000mDocument1 pageDATUM 0.000m Levels DATUM 0.000m Levels DATUM 0.000manandpurushothamanNo ratings yet

- Schematic Electric DX520LCADocument1 pageSchematic Electric DX520LCAIrul UmamNo ratings yet

- Foundation PlanDocument1 pageFoundation PlanrajatNo ratings yet

- Union Flacq Power Plant: SEE HV Options SEE HV OptionsDocument1 pageUnion Flacq Power Plant: SEE HV Options SEE HV OptionsjavNo ratings yet

- ZX200-5G/240-5G/280-5G/330-5G Electrical Circuit DiagramDocument11 pagesZX200-5G/240-5G/280-5G/330-5G Electrical Circuit DiagramEdiiz100% (2)

- TV 2K Chassis 2122T PDFDocument14 pagesTV 2K Chassis 2122T PDFAdam LiviuNo ratings yet

- 785C - (5az1-263) PDFDocument2 pages785C - (5az1-263) PDFRuan NortjeNo ratings yet

- Piepl-Tmills-15-Module Layout-R3-02.08.2022Document1 pagePiepl-Tmills-15-Module Layout-R3-02.08.2022DIVAKARNo ratings yet

- Schema Monofilara Tablou - ModelDocument1 pageSchema Monofilara Tablou - ModelGroper AlexandruNo ratings yet

- Hps141c EeDocument1 pageHps141c Eeapi-3709639No ratings yet

- One-Line Diagram - OLV1 (Edit Mode) : Page 1 10:51:55 Jan 25, 2021 Project File: SLDDocument1 pageOne-Line Diagram - OLV1 (Edit Mode) : Page 1 10:51:55 Jan 25, 2021 Project File: SLDTommy NewtonNo ratings yet

- El 102Document1 pageEl 102SujaniNo ratings yet

- Electrical Specifications: Get AnDocument1 pageElectrical Specifications: Get Anflor johnNo ratings yet

- Slides 10Document33 pagesSlides 10aaroncete14No ratings yet

- LV Room Cable Tray ScheduleDocument1 pageLV Room Cable Tray ScheduleOmer SharifNo ratings yet

- 23102019-Rural Core Agriculture (20X20)Document1 page23102019-Rural Core Agriculture (20X20)Nawaz ShaikhNo ratings yet

- Level 7 Floor Plan - Electrical Powerpoint Layout Plan: Service Apartment BlockDocument1 pageLevel 7 Floor Plan - Electrical Powerpoint Layout Plan: Service Apartment BlockcRi SocietyNo ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- SPUPL - Kadapa - APDocument1 pageSPUPL - Kadapa - APNeeraj SinghNo ratings yet

- 4011-DRA-ABE-079-103-0002 Rev01 BSDG Interconnection Cooling SystemDocument5 pages4011-DRA-ABE-079-103-0002 Rev01 BSDG Interconnection Cooling SystemtskumarNo ratings yet

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocument1 pagePB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangNo ratings yet

- FT HSR 2d Hanyoung NuxDocument1 pageFT HSR 2d Hanyoung NuxJP Vásquez HidalgoNo ratings yet

- Parcial 2 PDFDocument1 pageParcial 2 PDFjorge etayoNo ratings yet

- 315B Forest Swing MachineDocument2 pages315B Forest Swing MachineLeonardo NunesNo ratings yet

- Block A TB Layout Rev 2Document1 pageBlock A TB Layout Rev 2gagan.saluja85No ratings yet

- Canon Eos-1v SCHDocument38 pagesCanon Eos-1v SCHClément SaillantNo ratings yet

- Diagrama Electrico 777f JRPDocument4 pagesDiagrama Electrico 777f JRPManuel BarronNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- If I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)From EverandIf I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)No ratings yet

- CZ30NA06 Torrent Power bill detailsDocument2 pagesCZ30NA06 Torrent Power bill detailsNikhil SutharNo ratings yet

- Apr-2022Document1 pageApr-2022Nikhil SutharNo ratings yet

- GST Masta Casting CertificateDocument3 pagesGST Masta Casting CertificateNikhil SutharNo ratings yet

- May 2022Document2 pagesMay 2022Nikhil SutharNo ratings yet

- Apr-2022Document1 pageApr-2022Nikhil SutharNo ratings yet

- 380910-EIA-0005-01 (0) SLD For PCC-04 - Temp PlantDocument1 page380910-EIA-0005-01 (0) SLD For PCC-04 - Temp PlantNikhil Suthar100% (1)

- What To Do When You Realize You Made A Bad Hire: LeadershipDocument7 pagesWhat To Do When You Realize You Made A Bad Hire: LeadershipNikhil SutharNo ratings yet

- Series Reactors Specifications and RatingsDocument1 pageSeries Reactors Specifications and RatingsNikhil SutharNo ratings yet

- 380910-EIB-0112-01 (0) - CCP-01 To 03 (Lam, Temp)Document1 page380910-EIB-0112-01 (0) - CCP-01 To 03 (Lam, Temp)Nikhil SutharNo ratings yet

- 380910-EIE-0009-01 (0) SLD For UPSDB-03 To 05 For TempDocument1 page380910-EIE-0009-01 (0) SLD For UPSDB-03 To 05 For TempNikhil SutharNo ratings yet

- GoibiboDocument4 pagesGoibiboNikhil SutharNo ratings yet

- How A Coolie's Son Set Up A Rs 100 Crore Company - RediffDocument9 pagesHow A Coolie's Son Set Up A Rs 100 Crore Company - RediffNikhil SutharNo ratings yet

- GEDA Authorized Energy Audit Consultants List For Year 2019-20Document15 pagesGEDA Authorized Energy Audit Consultants List For Year 2019-20DishankNo ratings yet

- GEDA Authorized Energy Audit Consultants List For Year 2019-20Document15 pagesGEDA Authorized Energy Audit Consultants List For Year 2019-20DishankNo ratings yet

- G.P. Bvc-(Y)-201-5000-4-08.10Document3 pagesG.P. Bvc-(Y)-201-5000-4-08.10Nikhil SutharNo ratings yet

- ρ (Ω - m) at 20 °C σ (S/m) at 20 °C Temperature coefficient ReferenceDocument4 pagesρ (Ω - m) at 20 °C σ (S/m) at 20 °C Temperature coefficient ReferenceNikhil SutharNo ratings yet

- Understanding Power FactorDocument5 pagesUnderstanding Power FactorromeshmoreyNo ratings yet

- Quotation 1Document37 pagesQuotation 1Nikhil SutharNo ratings yet

- BEST TariffDocument15 pagesBEST TariffNikhil SutharNo ratings yet

- LT APP - Energe CapDocument1 pageLT APP - Energe CapNikhil SutharNo ratings yet

- Reliance DrawingDocument1 pageReliance DrawingNikhil SutharNo ratings yet

- Avvnl DRGSDocument7 pagesAvvnl DRGSNikhil SutharNo ratings yet

- Eim 1Document11 pagesEim 1Kat ManuelNo ratings yet

- Oracle Process Manufacturing (OPM) Operating Guide LinesDocument13 pagesOracle Process Manufacturing (OPM) Operating Guide LinesAtif Masood100% (1)

- Industrial Training Report GuideDocument4 pagesIndustrial Training Report GuideDhanush SNo ratings yet

- User Manual THC3T 02 - V103Document20 pagesUser Manual THC3T 02 - V103tarom nasteknikaNo ratings yet

- International Journal of Multimedia and Ubiquitous EngineeringDocument10 pagesInternational Journal of Multimedia and Ubiquitous EngineeringPeter Osundwa KitekiNo ratings yet

- TesiDocument109 pagesTesirodrigo.sanchez98No ratings yet

- OperManual SB ST310U Rev112 09 12 2017 PDFDocument67 pagesOperManual SB ST310U Rev112 09 12 2017 PDFrichardNo ratings yet

- Controlled Document Lazy River Manual Provides Technical Specifications, Installation, and Maintenance InstructionsDocument43 pagesControlled Document Lazy River Manual Provides Technical Specifications, Installation, and Maintenance InstructionsLove FebNo ratings yet

- User Manual ADM PDFDocument464 pagesUser Manual ADM PDFLuis100% (1)

- Catalogue of International Standards Used in The Petroleum and Natural Gas IndustriesDocument129 pagesCatalogue of International Standards Used in The Petroleum and Natural Gas IndustriesmehranlnjdNo ratings yet

- ANSI-IEEE Device Numbers PDFDocument12 pagesANSI-IEEE Device Numbers PDFMario SamudioNo ratings yet

- Tape HDDocument77 pagesTape HDLuis Anibal Navas BojorquezNo ratings yet

- Athena Constantine ResumeDocument2 pagesAthena Constantine Resumeapi-549396216No ratings yet

- Safety Issues On The Use of ICT Including E-Safety RulesDocument12 pagesSafety Issues On The Use of ICT Including E-Safety RulesYael NinaNo ratings yet

- Direct Gain Method ExplainedDocument29 pagesDirect Gain Method ExplainedAbishaTeslinNo ratings yet

- Muhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailDocument2 pagesMuhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailUmairIsmailNo ratings yet

- Netcourse 101: Answers To Exercises in Lesson 3Document7 pagesNetcourse 101: Answers To Exercises in Lesson 3Adetola AdeosunNo ratings yet

- Axis Statement Kirandeep KaurDocument2 pagesAxis Statement Kirandeep KaurTanvi DhingraNo ratings yet

- Automatic Transfer Switch ATS021: Installation and Operating Instructions 34ATS021 / 1SDH000759R0002Document36 pagesAutomatic Transfer Switch ATS021: Installation and Operating Instructions 34ATS021 / 1SDH000759R0002ase.olgaNo ratings yet

- JWS-400 Triplex Well Service Pump: SpecificationsDocument2 pagesJWS-400 Triplex Well Service Pump: SpecificationsgfwtNo ratings yet

- Meco Ah AP FTL Seal TechnologyDocument2 pagesMeco Ah AP FTL Seal Technologycristobal_tl2277No ratings yet

- Grabner MINIFLASH TOUCH Flash Point TesterDocument2 pagesGrabner MINIFLASH TOUCH Flash Point Testerbu7amudNo ratings yet

- Install Radmin 3 - General Installation Guide for Remote AccessDocument10 pagesInstall Radmin 3 - General Installation Guide for Remote AccessPerryRimandaNo ratings yet

- Level 3 Troubleshooting GuideDocument44 pagesLevel 3 Troubleshooting GuideFabiomarferreira100% (1)

- Technical Specifications for IE3 General Performance Cast Iron MotorsDocument1 pageTechnical Specifications for IE3 General Performance Cast Iron Motorsramadani bimaNo ratings yet

- USER Manual For Online Booking: Rev. No. 1.7 Date: 14 September 2016 Page 1 of 7Document7 pagesUSER Manual For Online Booking: Rev. No. 1.7 Date: 14 September 2016 Page 1 of 7SaiAchutuniNo ratings yet