Professional Documents

Culture Documents

Spread Footing Design

Uploaded by

ANGELICA SAHAGUNOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spread Footing Design

Uploaded by

ANGELICA SAHAGUNCopyright:

Available Formats

27

3

SPREAD FOOTING DESIGN

Spread Footing Design

Topics:

▪ Introduction

▪ Determine the size of spread footing

▪ Determine the depth of spread footing

▪ Design reinforcement for spread footing

▪ Design of square footing

▪ Design of rectangular footing

▪ Design of wall footing

1. Introduction

One of the most common ways to support the column is spreading the column load over a large footing area.

There are two parts in spread footing design:

Service load design:

1. The footing area should be large enough so that soil pressure under the footing is not larger than

allowable soil bearing pressure.

2. The weight of footing should be able to out-weigh column uplift due to wind or seismic forces safely.

Reinforced concrete design:

3. The footing depth should be deep enough to resist punching shear and direct shear transferred from

column load.

4. The reinforcement in the footing should be designed to resist bending moments.

5. The dowels at the column-footing interface should be sufficient to transfer column loads.

2. Determine size of footing

Topics:

1. Column subjected to axial column load and uplift

Example 1: Determine footing sizes for axial loads and uplift.

2. Column subjected to both axial column load and moment or eccentric loading

Eccentricity is within 1/6 width of footing

Example 2: Determine maximum and minimum footing pressure for footing with eccentricity <

B/6.

Eccentricity exceeds 1/6 width of footing

Example 3: Determine maximum footing pressure for footing with eccentricity > B/6

ALLAN B. BENOGSUDAN Page 27/27 4/13/2022 / 1:09 PM

28

Column subjected to axial column load only

Since factor of safety is included in determining allowable soil bearing capacity, there is no need to add addition

factor of safety in determine the footing sizes. But, since the bottom of footing is at a depth below ground surface,

the weight of soil and footing above the bearing area should be subtracted from the allowable soil capacity. The

required footing area is column load divided by the net allowable soil bearing capacity.

P

A= [2.1]

Qanet

Where

A = required footing area.

P = Axial column load

Qa net = net allowable soil bearing capacity.

The weight of footing and the soil above should be heavy enough to offset the uplift forces from wind or seismic.

Wt U * F.S. [2.2]

Where:

Wt = Total weight of footing

U = uplift force

F.S. = factor of safety.

This situation usually occurs at column at building bracing location. The factor of safety for uplift force in most

of building codes is 1.5.

Example 1: Determine footing sizes for axial loads and uplift.

Given:

Column loads:

Live load: 110 kN

Dead load: 110 kN

Uplift = 89 kN

Factor of safety for uplift = 1.5

Footing information:

Top of footing at 0.30m below ground surface, unit weigh weight of soil: 16 kN/m3

Allowable soil bearing capacity = 144 kPa

Unit weight of concrete: 24 kN/m3

Requirement: Determine footing sizes for axial loads and uplift.

ALLAN B. BENOGSUDAN Page 28/27 4/13/2022 / 1:09 PM

29

Solution:

DL=110 kN

Wt of soil

U

0.30m

0.30m

Total column service load = 110 + 110 = 220 kN

Assume a footing depth of 0.30m

Net allowable soil bearing capacity = 144 – 24(0.30) – 16(0.30) = 132 kN/m2

220 kN

Required footing area = = 1.67 m2

kN

132 2

m

Using square footing, 1.67 = 1.30 m ➔ Try 1.30m x 1.30m, footing area = 1.69 m2

Required weight of footing to offset uplift = 89 x 1.5 = 134 kN

Weight of soil above footing = 16 (1.30 x 1.30) (0.30) = 8 kN

Required weight of footing = 134 – 110 – 8 = 16 kN

W 16

Required volume of footing = V = = = 0.67 m2

D 24

V 0.67

Required depth of footing = V = A(t ) → t = = = 0.40 m

A 1.69

Therefore, use 1.30 m x 1.30 m x 0.40 m footing

Columns subjected to both axial load and moment or eccentric loading

Columns at the base of a moment resisting frame are often subjected to moment in addition to axial load.

Columns at the edge of buildings often have to be designed with eccentricity due to limitation of property line.

The bearing pressure at the bottom of footing will distribute in trapezoidal or triangular shape. The footing has

to be sized so that maximum footing pressure does not exceed allowable soil bearing capacity.

ALLAN B. BENOGSUDAN Page 29/27 4/13/2022 / 1:09 PM

30

Eccentricity is within 1/6 width of footing

Figure 2.1 Footing pressures with eccentricity not more than 1/6 footing width

When eccentricity is less than 1/6 width of footing, footing pressure under the footing is distributed in trapezoidal

shape. When eccentricity equals to 1/6 width of footing, footing pressure distributes triangularly with zero

pressure at one end of the footing.

The soil bearing capacity can be calculated as,

P M

Q= [2.3]

A S

P = Axial column Load

A = footing area

M = P*e, column moment in the x direction, e is eccentricity in x direction.

S = LB2/6 section modulus of footing area in x direction

ALLAN B. BENOGSUDAN Page 30/27 4/13/2022 / 1:09 PM

31

For a rectangular footing, the equation can be written as

Q= P / A M / S

= P/(BL) P*e/(LB2/6)

= (P/A) [1e*B/6] [2.4]

L, B are length and width of footing.

When footing is subjected to moments or eccentricities in both directions, the equations become

Q = P / A Mx / Sx My / Sy [2.5]

Or

Q = (P/A) [1ex*B/6ey*L/6] [2.6]

Example 2: Determine maximum and minimum footing pressure for footing with eccentricity < B/6.

Given:

Column loads:

Live load: 25 kips

Dead load: 25 kips

Live load moment = 20 ft-kips

Dead load moment = 20 kips

Footing information:

Footing sizes = 6 ft x 6 ft

Requirement: Determine maximum and minimum footing pressure.

Solution:

Total axial load = 25+25=50 kips

Total column moment = 20+20=40 ft-kips

Eccentricity = 40/50=0.8 ft < B/6 = 1 ft

Maximum footing pressure = [50,000/(6x6)][1+0.8*6/6] = 2500 psf

Minimum footing pressure = [50,000/(6x6)][1-0.8*6/6] = 277 psf

Eccentricity exceeds 1/6 width of footing

When eccentricity exceeds 1/6 width of footing, soil pressure under pressure distributes in a triangular shape

with a portion of the footing having zero pressure. The resultant of footing pressure, R coincides with column

load, P as shown below. Since the center of the resultant is at 1/3 length of the triangle, the length of the bearing

area is three times of the distance from the center of the column load to the edge of footing.

ALLAN B. BENOGSUDAN Page 31/27 4/13/2022 / 1:09 PM

32

Figure 2.2 Footing pressure with eccentricity greater than 1/6 footing width

Therefore,

P = Qmax [3(B/2-2)L/2]

Then,

Qmax = 2P/[3(B/2-e)L] [2.7]

Example 3: Determine maximum footing pressure for footing with eccentricity > B/6

Given:

Column loads:

Live load: 25 kips

Dead load: 25 kips

Live load moment = 30 ft-kips

Dead load moment = 30 kips

Footing information:

Footing sizes = 6 ft x 6 ft

Requirement: Determine maximum and minimum footing pressure.

Solution:

Total axial load = 25+25=50 kips

Total column moment = 30+30=60 ft-kips

Eccentricity = 60/50=1.2 ft > B/6 = 1 ft

ALLAN B. BENOGSUDAN Page 32/27 4/13/2022 / 1:09 PM

33

Maximum footing pressure = 2*50,000/[3*(6/2-1.2)*6] = 3086 psf

3. Determine depth of spread footings for shear

This portion of reinforced concrete design of spreading footing follows the requirement of ACI code 318-99.

Factored loads should be used instead of service load. Factored footing pressure is used to determine footing

depth and reinforcement.

The topics include:

Punching shear (Two-way shear)

Director shear (One-way shear)

Example 4: Check footing depth for punching shear and direct shear for footing subjected to axial column

load only

Example 5: Check footing depth for punching shear and direct shear for footing subjected to axial column

load and moment

Determine depth of footing for punching shear and direct shear

The depth of footing is usually governed by punching shear and direct shear because shear reinforcement is

normally not used. For a square footing, punching shear usually governs the design. For a rectangular footing,

direct shear may be more critical.

Punching shear (Two-way shear)

The critical section of punching shear is located at one half effective distance from the faces of column. Shear

strength of concrete should be larger than factored shear stress at critical section as

The punching shear strength vc in ACI is

[2.8]

where = 0.85 for shear, c is the ratio of long to short sides of column, and fc' is the compressive strength of

concrete.

The punching shear stress is factored shear force at the critical section divided by the perimeter of the critical

section and the effective depth of the footing. The factored shear force at the critical section is factored

column load minus factored footing pressure under the critical section. It can be calculated as

[2.9]

where

vu is punching shear stress,

Qu is factor footing pressure,

B, L are width and length of footing,

b, c are width and length of square column

ALLAN B. BENOGSUDAN Page 33/27 4/13/2022 / 1:09 PM

34

d is effective depth of the footing.

Figure 2.3 Critical sections of punching shear

Direct shear (One-way shear)

The critical section of direct shear is at one effective distance from the face of column. The direct shear

strength specified in ACI is

[2.10]

ALLAN B. BENOGSUDAN Page 34/27 4/13/2022 / 1:09 PM

35

The factored shear stress at the critical section is the factored shear force divided by the width and depth of the

footing at the critical section. The factored shear force at the critical section is the area from the critical section

to the edge of the footing multiplies average factored footing pressure in the area.

Figure 2.4. Critical section of direct shear

Example 4: Check footing depth for punching shear and direct shear for footing subjected to axial

column load only

Given:

Column loads:

Live load: 25 kips

ALLAN B. BENOGSUDAN Page 35/27 4/13/2022 / 1:09 PM

36

Dead load: 25 kips

Footing and column information:

Footing sizes = 4 ft x 4 ft x 1ft

Column size: 1 ft x 1 ft

Concrete strength at 28 day = 3000 psi

Requirement: Check if the footing depth is adequate for punching shear and direct shear.

Solution:

Factored column load = 1.4*25+1.7*25= 77.5 kips

Factored footing pressure = 77.5/16=4.84 ksf

Effective footing depth = 12”-3” (cover) – 0.5” (assumed diameter of #4 bar) = 8.5”

Check punching shear:

Area under critical section = [(12”+8.5”)/12]2=2.92 ft2.

Factored shear force at critical section = 77.5-4.84*2.92=63.4 kips

Perimeter of critical section = 4 (12” + 8.5”) = 82”

Factor shear stress at critical section = 63,400/(82*8.5) = 90.9 psi

Punching shear strength of concrete = 0.85*(43000) = 186 psi > 90.9 psi O.K.

Check direct shear:

Distance from critical section to edge of footing = 4/2-1/2-8.5/12=0.83’

Factored shear force = 4.84*0.83*4=16.1 kips

Factored shear stress = 16,100/(4*12*8.5) = 39.5 psi

Director shear stress of concrete = 0.85*(23000) = 93 psi >39.5 psi O.K.

Example 5: Check footing depth for punching shear and direct shear for footing subjected to axial

column load and moment

Given:

Column loads:

Live load: 25 kips

Dead load: 25 kips

Live load moment = 25 ft-kips

Dead load moment = 25 ft-kips

Footing and column information:

Footing sizes = 6 ft x 4 ft x 1ft

Column size: 1 ft x 1 ft

Concrete strength at 28 day = 3000 psi

Requirement: Check if the footing depth is adequate for punching shear and direct shear.

Solution:

Factored column load = 1.4*25+1.7*25= 77.5 kips

Factored column moment = 1.4*25+1.7*25=77.5 ft-kips

Eccentricity of factored column load = 77.5/77.5 = 1 ft

Maximum footing pressure = [77.5/(4x6)][1+1*6/6]=6.46 ksf

Minimum footing pressure = [77.5/(4x6)][1-1*6/6]=0 ksf

Effective footing depth = 12”-3” (cover) – 0.5” (assumed diameter of #4 bar) = 8.5”

Check punching shear:

ALLAN B. BENOGSUDAN Page 36/27 4/13/2022 / 1:09 PM

37

Average factored footing pressure = (6.46+0)/2=3.23 ksf

Area under critical section = [(12”+8.5”)/12]2=2.92 ft2.

Factored shear force at critical section = 77.5-3.23*2.92= 68.1 kips

Perimeter of critical section = 4 (12” + 8.5”) = 82”

Factor shear stress at critical section = 68,100/(82*8.5) = 97.8 psi

Punching shear strength of concrete = 0.85*(43000) = 186 psi > 90.9 psi O.K.

Check direct shear:

Distance from critical section to edge of footing with maximum footing pressure

= 6/2-1/2-8.5/12=1.83’

Distance from critical section to edge of footing with maximum footing pressure

= 6-1.83=4.17’

Factor footing pressure at the location of critical section=6.46*4.17/6=4.49 ksf

Factored shear force = [(6.46+4.49)/2]*1.83*4=40.1 kips

Factored shear stress = 40,100/(4*12*8.5) = 98.3 psi

Director shear stress of concrete = 0.85*(23000) = 93 psi <98.3 psi N.G. Need to

increase footing depth.

4. Design reinforcement for spread footings

This portion of reinforced concrete design of spreading footing follows the requirement of ACI code 318-99.

Factored loads should be used instead of service load. Factored footing pressure is used to determine footing

reinforcement.

The topics include:

Moment calculation

Calculating Reinforcement

Minimum and maximum reinforcements

Example 6: Determine footing reinforcement for footing subjected to axial column load

Placing reinforcements.

Design column dowels

Bearing strength of concrete at base of column

Reinforcement required at the base of column

Length of dowel for compression

Example 7: Design of column dowel

Design footing reinforcements

Moment calculation

ALLAN B. BENOGSUDAN Page 37/27 4/13/2022 / 1:09 PM

38

The footing needs to be reinforced for the bending moment producing from upward footing pressure. According

to ACI code, the critical section is at the face of column. The factored moment at the critical section can be

calculated as

Mu = Qu * l2/2 [2.11]

Where

Qu is factored footing pressure

l is the distance from the face of column to the edge of footing.

Figure 2.5 Critical moment section of a footing

Calculating Reinforcement

The footing reinforcements are designed based on ACI strength design method. At ultimate stress situation, the

concrete at top portion is subjected to compression. The compressive stresses distribute uniformly over a depth

ALLAN B. BENOGSUDAN Page 38/27 4/13/2022 / 1:09 PM

39

a. The resultant of compressive stress, C is located at a distance, a/2, from the top surface. Tensile force is

taken by rebars at an effective distance, d, from the top surface.

Figure 2.6 Tensile and compressive forces and stresses on a footing secti0n

According to ACI code, the ultimate compressive is 0.85f’c, where f’c is compressive strength of concrete.

Therefore, the compressive stress, C = 0.85 f’c a b, where b is the width of the footing in calculation. By

equilibrium, the tensile force is equal to the compression resultant,

T = C = 0.85f’c a b [2.12]

Therefore,

[2.13]

The nominal moment strength of the section,

Mn = T (d-a/2) [2.14]

ACI code requires that the factored moment,

Mu Mn

Where, = 0.9, is the strength reduction factor for beam design. Then, the tensile force,

[2.15]

and, the area of reinforcement is

[2.16]

where Fy is the yield strength of reinforcing steel.

ALLAN B. BENOGSUDAN Page 39/27 4/13/2022 / 1:09 PM

40

There are many ways to determine reinforcements. One simple method is using a trial and error method by

assuming the depth of compression block, a. The steps are as follows:

1. Assume a depth of the stress block, a.

2. Calculate tensile force, T using equation [2.16].

3. Calculate new depth of the stress block, a, using equation [2.13].

4. If the new depth, a, is not close to the assumed, a, in step 1, repeat step 2 and 3 with new depth, a.

5. If the new depth, a, is close to the assume, a, calculate area of reinforcement using equation [2.16]

Minimum and maximum reinforcements

ACI code requires the minimum reinforcement ratio,

[2.17]

Where, As is the area of reinforcements. In addition, it also said that the minimum reinforcement does not need

to be more than 4/3 of the calculated value,

[2.18]

Example 6: Determine footing reinforcement for footing subjected to axial column load

Given:

Column loads:

Live load: 25 kips

Dead load: 25 kips

Footing and column information:

Footing sizes = 4 ft 6 in. x 4 ft 6 in. x 1ft

Column size: 1 ft x 1 ft

Concrete strength at 28 day = 3000 psi

Yield strength of rebars = 60 ksi

Requirement: Calculate footing reinforcements

Solution:

Calculate factored column load,

Pu = 1.4*25+1.7*25=77.5 kips

Factored footing pressure = 77.5/(4.5*4.5) =3.827 ksf

Distance from critical section to edge of footing = (4.5-1)/2=1.75’

Factored moment at critical section = (3.827)*1.752/2=5.86 ft-kips/ft

Effective depth = 12”-3” (cover)-0.5” (rebar size) = 8.5”

Assume a = 1”

T = (5.86*12)/[0.85*(8.5-1/2)]=10.3 kips/ft

Check a = 10.3/[0.85*3*12] =0.34”

Assume a = 0.34”

ALLAN B. BENOGSUDAN Page 40/27 4/13/2022 / 1:09 PM

41

T = (5.86*12)/[0.85*(8.5-0.34/20]=9.9 kips

Check a = 9.9/[0.85*3*12]=0.32” (close enough)

As =9.9/60=0.165 in2/ft

The reinforcement ratio, = 0.165/[8.5*12]=0.0016

Less than min = 200/ 60=0.0033 or min = (4/3) 0.00162=0.00216

For a footing width of 4’6”, As = 0.216*8.5*4.5*12= 0.99in2.

Use 5#4 in both direction, As = 5*0.2=1.0 in2.

Placing reinforcements

Reinforcements should be placed at the tension side at the bottom of the footing.

For a square footing, rebars are placed uniformly in both directions. ACI code requires that the rebars be placed

not more than 18 inch apart.

For a rectangular footing, rebars in the long direction are placed uniformly but not the short direction. ACI code

requires a certain portion of reinforcements in short direction to be placed within a band equal to the width of

footing in the short direction. The distribution ratio is calculated based on the aspect ratio of footing as

[2.19]

where is the ratio of length to short side.

Design column dowels

Dowel rebars that go from the bottom of footing into the footing need the meet the following requirements:

1. Transfer vertical column forces when column load exceeds the compressive strength of concrete.

2. Transfer moment at column base.

3. Meet minimum reinforcement in ACI code.

4. Meet splice requirement for column reinforcement.

Bearing strength of concrete at base of column

The bearing strength of column at the column base

Pc = 0.7*0.85fc’Ag

Where Ag is the gross section area of column

The bearing strength of footing at the column base is

Pc = 0.7*0.85fc’Ag = A2/A1 2.

Edge length of A1, A2 are shown in the figure below.

ALLAN B. BENOGSUDAN Page 41/27 4/13/2022 / 1:09 PM

42

Reinforcement required at the base of column

Where there is no moment at the column base, the area reinforcement through column base can be calculated

as

As = (Pu - Pc) / fy [2.20]

Pu is factored column load. When Pu < Pc, ACI code requires that the minimum reinforcement for dowel

through column base is 0.005Ag. Ag is the cross section area of column. The diameter of the dowel should not

exceeds the longitudinal reinforcement of column by 0.15 in.

When the column base is subjected to both axial loads and moments, the column dowel needs to be designed

to resist column moment. The design procedure is the same as design of beam-columns.

Length of dowel for compression

The length of dowel below the column base needs to meet minimum development length of ACI code.

Basic development length for compression member is the larger of

Ldb = 0.02 (fydb/fc’) [2.21]

Ldb =0.0003 fydb [2.22]

Where db is the diameter of rebar

The length of dowel is modified by the area of reinforcement as

Ld = (As required / As provided)( Ldb) [2.23]

The length of dowel that projects above the footing needs to meet the compression splice requirement of column

reinforcement.

When, fy 60,000 psi, Lap = 0.0005 fydb, > Ld or 12” [2.24]

When, fy > 60,000 psi, Lap = (0.0009 fy – 24)db > Ld or 12” [2.25]

ALLAN B. BENOGSUDAN Page 42/27 4/13/2022 / 1:09 PM

43

When column base is subject to moment and the rebars are in tension, length of splice and anchor should be

designed based on tension requirement.

Example 7: Design of column dowel

Given:

Column loads:

Live load: 20 kips

Dead load: 40 kips

Footing and column information:

Footing sizes = 4 ft x 4 ft x 1ft

Column size: 1 ft x 1 ft

Concrete strength at 28 day for footing = 3000 psi

Concrete strength at 28 day for column = 4000 psi

Yield strength of rebars = 60 ksi

Column reinforcement: 4#6

Footing reinforcement: 4#4 each way.

Requirement: Design column dowels including sizes and length

Solution:

1. Determine number and size of rebar

Factored column load = 1.4*40+1.7*20=90 kips

Bearing strength of column = 0.7*0.85*4*12*12=342 kips >90 kips

A1 = 12*12=144 in2.

Effective depth = 12-3-1=8 in.

Edge length of A2 = 12+8*2*2 = 44” < 48”

Area of A2 = 44*44=1936 in^2.

The ratio, = A2/A1=1936/144=3.7 >2 Use 2.

The bearing strength of footing at column base = 0.7*0.85*2*3*144=514 kips >90 kips

Use minimum reinforcement, As = 0.005*144=0.72 in^2

Use 4#4, As = 0.8 in^2

2. Length of dowel in footing:

Basic development for #4 bars:

Ldb = 0.02 (fydb/fc’) = 0.02(60,000*0.5/3000) = 11”

Ldb =0.0003 fydb=0.0003*60000*0.5= 9 in.

Required development length, Ld = 11”*(0.72/0.8) = 9.9”

Since the distance from the top of footing to the #4 bottom reinforcement is 7.5”, use dowel with 90 degree hook,

7.5 in vertical and 2.5 “ turn.

3. Splice length in column:

For #6 bars in column,

Lap = 0.0005 fydb = 0.0005*60000*0.75=22.5 in

Ld = 0.02*60000*0.75/40000=14 in.

ALLAN B. BENOGSUDAN Page 43/27 4/13/2022 / 1:09 PM

44

Ld = 0.0003*60000*0.75=13.5 in.

Use Lap = 22.5 in.

5. Design of square footings

The procedure for designing a square footing is as follows:

Service load design:

Determine size of footing.

Reinforced concreter design:

Determine depth of footing for punching shear and direct shear

Determine footing reinforcement for bending moment.

Determine column dowel to transfer column load.

Example 8: Design of a square footing

Given:

Column loads:

Live load: 100 kips

Dead load: 100 kips

Footing uplift: 0 kips

Column size: 1 ft. x 1 ft.

Soil information:

Allowable soil bearing capacity: 4000 psf

Soil cover above footing: 1 ft

Unit weight of soil: 120 pcf

Materials used:

Concrete strength at 28 day = 3000 psi

Yield strength of rebars = 60 ksi

Requirement: Determine size, depth, and reinforcement for a square footing.

Solution:

Service load design:

1. Determine footing sizes:

1. Assume a footing depth of 18”,net soil bearing capacity ,

2. Qnet = 4000 – 150*18/12-120*1 = 3655 psf

3. Required footing are, A = (100+100) (1000) / 3655 = 54.7 ft2

4. Use 7'-6" by 7'-6" square footing. The footing area is 56.3 ft2.

Reinforced concrete design:

2. Determine footing depth

The factored footing pressure can be calculated as

ALLAN B. BENOGSUDAN Page 44/27 4/13/2022 / 1:09 PM

45

Qu = (1.4 x 120 + 1.7 x 80) / 56.3 = 5.5 psf

a. Check punching shear

1. Assume the reinforcements are #6 bars, the effective depth

2. d = 18" - 3" (cover) - 0.75" (one bar size) = 14.3 " = 1.2'

3. The punch shear stress can be calculated as

4.

5. The shear strength of concrete is

6. vc = 0.85 x 4 x 3000 = 186 psi O.K.

b. Check direct shear:

1. The distance from the critical section of direct shear to the edge of the footing,

2. l = (7.5)(12)/2 - 1/2 – 1.2 = 24.75" = 2.05'

3. The direct shear stress is

4. vu = (5.5)(1000)(2.05) / (12)(14.3) = 65.7 psi per foot width of footing.

5. The shear strength of concrete for direct shear is

6. vc = 0.85 x 2 x 3000 = 93 psi > 65.7 psi O.K.

3. Determine footing reinforcement

1. The distance from face of column to the edge of the footing is

2. l = 7.5/2 – 1/2 = 3.25'

3. The factored moment at the face of the column is

4. Mu = (5.5)(3.25)2/2 = 29 k-ft. per foot width of footing

5. Use trial method for reinforcement design

6. Assume a = 0.9".

7.

8. Calculate new a,

9. 0.9”

10. at one foot section.

11. The reinforcement ratio is

12.

13. Minimum reinforcement ratio,

14. < min =( (4/3)*0.0028=0.00373

15. Use min = 0.0033,

16. As = (0.0033 )(7.5)(12)(14.3) = 4.2 in2.

ALLAN B. BENOGSUDAN Page 45/27 4/13/2022 / 1:09 PM

46

17. Use 10 - #6 bars in both directions, As = 4.4 in2.

4. Designing column dowels:

1. The bearing capacity of concrete at column base is

2. Pc = (0.7)(0.85)(3)(12)(12) = 257 kips

3. The factor column load is

4. Pu = (1.4)(100)+ (1.7)(00) = 310 kips

5. The required area of column dowels is

6. As = (304 - 257) / 60 = 0.783 in2

7. The minimum dowel area is

8. As,min = (0.0005)(12)(12) = 0.72 in2

9. Use 4 - #4 dowels As = 0.8 in2

10. The footing is shown in below

6. Design of rectangular footings

Design procedure:

ALLAN B. BENOGSUDAN Page 46/27 4/13/2022 / 1:09 PM

47

Service load design:

Determine required footing size from required footing area and limitation of footing width.

Reinforced concreter design:

1. Determine footing depth for punching shear and direct shear in the longitudinal direction.

2. Determine footing reinforcement for longitudinal direction.

3. Determine footing reinforcement for transverse direction. Distribute reinforcement based on length to

width aspect ratio.

4. Determine column dowel to transfer column load.

Example 9: Design of a rectangular footing

Given:

Column loads:

Live load: 60 kips

Dead load: 100 kips

Footing uplift: 0 kips

Column size: 1 ft 6 in. x 1 ft.

Footing information:

One side of footing is limited to 5’ due to property line

Soil information:

Allowable soil bearing capacity: 3500 psf

Soil cover above footing: 1 ft

Unit weight of soil: 100 pcf

Materials used:

Concrete strength at 28 day = 3000 psi

Yield strength of rebars = 60 ksi

Requirement: Determine size, depth, and reinforcement for a square footing.

Solution:

Service load design

1. Determine footing sizes

1. Assume a footing depth of 18”,net soil bearing capacity ,

2. Qnet = 3500 – 150*18/12-100*1 = 3175 psf

3. Required footing are, A = (60+100) (1000) / 3175 = 50.4 ft2

4. Since one side of the footing is limited to 5', the length of footing is

5. L = 50.4/5 = 10.1' Use 10’, the footing area is 50 ft2.

Reinforced concrete design:

2. Determine footing depth

ALLAN B. BENOGSUDAN Page 47/27 4/13/2022 / 1:09 PM

48

The factored footing pressure can be calculated as

Qu = (1.4 x 100 + 1.7 x 60) / 50 = 4.84 psf

a. Check punching shear

Assume the reinforcements are #8 bars, the effective depth

d = 18" - 3" (cover) - 1" (one bar size) = 14" = 1.16'

The punch shear stress can be calculated as

The shear strength of concrete is vc = 0.85 x 4 x 3000 = 186 psi

O.K.

b. Check direct shear:

The distance from the critical section of direct shear to the edge of the footing,

l = (10– 1.5)/2 – 1.16 = 3.09'

The direct shear stress is vu = (4.84)(1000)(3.09) / (12)(14) = 89 psi per foot width of footing.

The shear strength of concrete for direct shear is vc = 0.85 x 2 x 3000 = 93 psi > 89 psi O.K.

3. Determine footing reinforcement.

Longitudinal direction

The distance from face of column to the edge of the footing is

l = (10– 1.5)/2 =4.25 '

The factored moment at the face of the column is

Mu = (4.84)(4.25)2/2 = 43.7 k-ft. per foot width of footing

Use trial method for reinforcement design

Assume a = 1.4".

Calculate new a,

1.4”

at one foot section.

The reinforcement ratio is

Minimum reinforcement ratio,

< = 0.00434

Use calculated reinforcement

As = (0.00434)(5)(12)(14) = 3.64 in2.

Use 5#8, As = 0.79*5=3.95 in2.

ALLAN B. BENOGSUDAN Page 48/27 4/13/2022 / 1:09 PM

49

Transverse direction

The distance from face of column to the edge of the footing is

l = (5– 1)/2 =2'

The factored moment at the face of the column is

Mu = (4.84)(2)2/2 = 9.68 k-ft. per foot width of footing

Use trial method for reinforcement design

Assume a = 0.3".

Calculate new a,

= 0.3” assumed

at one foot section.

The reinforcement ratio is

Minimum reinforcement ratio,

> min =(4/3)*0.00095=0.0013

Use min =0.0013

As = (0.0013 )(10)(12)(14) = 2.2 in2.

Use 11 #4 bars, As = 0.2*11=2.2 in2.

Distribute reinforcements

1. The aspect ratio, = 10/5=2

2. The distribution ratio, = 2/(2+1) = 0.67

3. The reinforcement in the 5’ width center band is

4. N=11*0.67=7.4

5. Use 7 #4 in the center 5’ band, spacing = 5*12/7 = 8.6 in. O.K.

6. Use 2#4 each side

7. Maximum spacing = [(10*12-5*12)/2 –3 (cover)]/2=13.5 in. O.K.

4. Designing column dowels.

1. The bearing capacity of concrete at column base is

2. Pc = (0.7)(0.85)(3)(18)(12) = 385.6 kips

3. The factor column load is

4. Pu = (1.4)(100)+ (1.7)(60) = 242 kips < 385.6 kips

5. Use minimum dowel area ,

6. As,min = (0.0005)(18)(12) = 1.08 in2

ALLAN B. BENOGSUDAN Page 49/27 4/13/2022 / 1:09 PM

50

7. Use 4 - #5 dowels As = 1.2 in2

8. The footing is shown in below

7. Design of wall footings

Critical sections of wall footings:

Shear:

1. Footing supporting a masonry wall: at ¼ thickness from the face of wall.

ALLAN B. BENOGSUDAN Page 50/27 4/13/2022 / 1:09 PM

51

2. Footing supporting a concrete wall: at one effective section from the face of wall.

Moment: at face of wall:

Figure 2.4 critical shear section of masonry wall footing and concrete wall footing.

Design procedure:

Service load design:

1. Design footing width based on service load. If wall footing is an exterior wall, check required frost

depth.

Reinforced concrete design:

2. Determine footing depth and check direct shear stress at critical section.

3. Design transverse reinforcements based on factored moment.

4. Design longitudinal reinforcements for temperature and shrinkage.

Example 10: Design of a wall footing

Given:

Wall loads:

Live load: 36.5.5 kN/m

Dead load:43.8 kN/m

Wall type: 8” concrete masonry wall

Soil information:

Allowable soil bearing capacity: 2500 psf

Required frost depth: 18”

Unit weight of soil: 100 pcf

ALLAN B. BENOGSUDAN Page 51/27 4/13/2022 / 1:09 PM

52

Materials used:

Concrete strength at 28 day = 3000 psi

Yield strength of rebars = 60 ksi

Requirement: Determine width, depth, and reinforcement.

Solution:

Service load design:

1. Determine width of footing:

Assume that the footing depth is 10 inch with 8” overburden soil. The bottom of footing is at 18” below ground

surface that meet frost depth requirement.

The net soil bearing capacity is

p = 2500 – 15*10/120 – 100*8/12 = 2308 psf

The required footing width is

B = (2500 + 3000) / 2308 = 2.4 ft=29” Use 2’6” =30” width

Reinforced concrete design

2. Check direction shear

The ultimate footing pressure,

pu = (1.4 x 3 + 1.7 x 2.5 ) / 2.5 = 3.38 kips/ft

The effective depth of footing,

d = 10" - 3" (cover) - 0.25" (half of bar size) = 6.75"

The distance from critical section to the edge of the wall is

l = 30/2 - 4 (half of wall)+2” = 13"

The direct shear stress at critical section is

vu = (3.38)(1000)(13/12)/(6.75*12) = 45 psi

The shear strength of concrete is

vc = (0.85)(2 2500) = 85 psi > 45 psi O.K.

3. Design transverse reinforcement:

The distance from critical section of moment to the edge of the wall is

l = 15-4 = 11"

The ultimate moment at critical section is

Mu = (3.38)(11/12)2 / 2 = 1.42 k-ft/ft

Use trial method for reinforcement design

Assume a = 0.1".

ALLAN B. BENOGSUDAN Page 52/27 4/13/2022 / 1:09 PM

53

Calculate new a,

= 0.1” assumed

The reinforcement ratio is

The minimum reinforcement,

> min =(4/3)*0.0005=0.0007

Use min =0.0007

As = (0.0007)(8.75)(12) = 0.074 in2

Use #4 at 18" spacing, As = 0.15 in2

4. Design longitudinal reinforcement

The temperature reinforcements at longitudinal direction is

As = (0.002)(12)(2.5)(8.75) = 0.525 in2

Use 3 - #4, spacing, As = 0.66 in2

The footing reinforcements is as shown below.

ALLAN B. BENOGSUDAN Page 53/27 4/13/2022 / 1:09 PM

You might also like

- Determine footing sizes for columns with axial and eccentric loadsDocument6 pagesDetermine footing sizes for columns with axial and eccentric loadsBalamuruganNo ratings yet

- Spread FootingDocument15 pagesSpread FootingMary MarasiganNo ratings yet

- Shallow Foundation,,,, PDFDocument48 pagesShallow Foundation,,,, PDFJKDLJSJFLSNo ratings yet

- Design of Cantilever Retaining WallDocument23 pagesDesign of Cantilever Retaining WallD.V.Srinivasa RaoNo ratings yet

- Footing Design and AnalysisDocument53 pagesFooting Design and AnalysisAsad Ismail100% (1)

- Loading and Design of Box Culverts To EurocodesDocument35 pagesLoading and Design of Box Culverts To Eurocodeslnanescu83% (6)

- Isoloated Footing Design SampleDocument5 pagesIsoloated Footing Design SampleSaroj Acharya100% (1)

- Shallow Foundation Design and TypesDocument45 pagesShallow Foundation Design and Typescheligp1981No ratings yet

- اسس ٥Document11 pagesاسس ٥arno assassinNo ratings yet

- Shallow FoundationDocument33 pagesShallow FoundationAntony GodwinNo ratings yet

- Reinforced Concrete Design IIDocument52 pagesReinforced Concrete Design II'Izzad Afif100% (1)

- Bearing Capacity Technical GuidanceDocument16 pagesBearing Capacity Technical GuidanceJuan Manuel Velazquez GonzalezNo ratings yet

- Slab Raft Foundation PresentationDocument25 pagesSlab Raft Foundation PresentationOsarieme Osakue100% (1)

- Retaining WallDocument58 pagesRetaining WallSaurabhNo ratings yet

- FOUNDATIONS FOR SHALLOW STRUCTURESDocument29 pagesFOUNDATIONS FOR SHALLOW STRUCTURESBuoyancyNo ratings yet

- Combined FootingDocument12 pagesCombined FootingmyNo ratings yet

- Isolated footing design example step-by-step guideDocument6 pagesIsolated footing design example step-by-step guidetopukuet100% (1)

- Retaining WallDocument58 pagesRetaining WallPradnya Sikachi100% (1)

- Isolated Footing Design ExampleDocument7 pagesIsolated Footing Design ExampleBENNo ratings yet

- 4.design of FootingDocument34 pages4.design of FootingGladys LeonorNo ratings yet

- What is Plate Load TestDocument10 pagesWhat is Plate Load TestFOZCANNo ratings yet

- Pile FoundationDocument17 pagesPile Foundationritam1991No ratings yet

- Isolated Footing Design Example and Excel SheetDocument8 pagesIsolated Footing Design Example and Excel SheetSougata DasNo ratings yet

- Sound: Wall de IgnDocument36 pagesSound: Wall de IgnHundeejireenyaNo ratings yet

- Erc - Valve Pit CalculationDocument30 pagesErc - Valve Pit Calculationisaacjoe77No ratings yet

- Raft N Pile Footing DesignDocument84 pagesRaft N Pile Footing Designabdur rahman100% (1)

- Bearing Capacity and Failure Modes of Shallow FoundationsDocument56 pagesBearing Capacity and Failure Modes of Shallow FoundationsHaider Yousef0% (1)

- PondasiDocument24 pagesPondasiAnnisa AmaliaNo ratings yet

- Bearing N Settlement 3Document13 pagesBearing N Settlement 3U4rayNo ratings yet

- Isolated Footing Design Example and Excel SheetDocument7 pagesIsolated Footing Design Example and Excel SheetAmjid AfridiNo ratings yet

- Shallow Foundation NotesDocument52 pagesShallow Foundation NotesBAMSNo ratings yet

- Ans Struktur PondasiDocument77 pagesAns Struktur PondasiRujak CingurNo ratings yet

- Desain PondasiDocument156 pagesDesain PondasiHerliansyah HerryNo ratings yet

- Combined FootingDocument12 pagesCombined FootingmyNo ratings yet

- Bearing Capacity Calculations for Shallow and Deep FoundationsDocument16 pagesBearing Capacity Calculations for Shallow and Deep Foundationsአድሜ ልስልሱNo ratings yet

- Boring Log Sample ComputationDocument18 pagesBoring Log Sample ComputationMARK VINCENT NAVARRO80% (5)

- Mat FoundationDocument19 pagesMat FoundationJoshua Cala100% (1)

- Bearing Capacity NotesDocument6 pagesBearing Capacity NotesKhaled AbdelbakiNo ratings yet

- Lecture 26 - Footings: August 8, 2003 CVEN444Document195 pagesLecture 26 - Footings: August 8, 2003 CVEN444sandycivilpgNo ratings yet

- Isolated Footing Design Example and Excel SheetDocument6 pagesIsolated Footing Design Example and Excel SheetshakeelNo ratings yet

- RwallDocument51 pagesRwallandualemNo ratings yet

- Bearing Capacity From SPT Numbers PDFDocument22 pagesBearing Capacity From SPT Numbers PDFKA25 Consultant100% (1)

- PILE Foundations: Foundation Engineering Bearing Capacity CalculationDocument15 pagesPILE Foundations: Foundation Engineering Bearing Capacity CalculationAndrick AlvarezNo ratings yet

- Types of Foundations: Shallow Foundation Deep FoundationDocument28 pagesTypes of Foundations: Shallow Foundation Deep FoundationLeung Wai YipNo ratings yet

- Types of FoundationDocument28 pagesTypes of FoundationraniepaulNo ratings yet

- Design of Cantilever Retaining WallDocument38 pagesDesign of Cantilever Retaining WallGajula Pavan100% (1)

- Reinforced Concrete Footing DesignDocument13 pagesReinforced Concrete Footing DesignMike MatshonaNo ratings yet

- Perhitungan Struktur Shelter - Meyerhoff AnlyDocument73 pagesPerhitungan Struktur Shelter - Meyerhoff AnlyTaufik GunawanNo ratings yet

- Design of Combined - Strap Footings (16-18)Document58 pagesDesign of Combined - Strap Footings (16-18)Waqas QureshiNo ratings yet

- Bearing CapacityDocument59 pagesBearing CapacityAryan Arora67% (3)

- Rigid Pavement Design: 29.1.1 Modulus of Sub-Grade ReactionDocument9 pagesRigid Pavement Design: 29.1.1 Modulus of Sub-Grade Reactionnageshkumarcs100% (1)

- Cantilever Retaining Wall - RameswaramDocument23 pagesCantilever Retaining Wall - RameswaramD.V.Srinivasa RaoNo ratings yet

- Box Culvert at Chainage 83 10 M XLSX Depth 4 1 MDocument18 pagesBox Culvert at Chainage 83 10 M XLSX Depth 4 1 MMario Sajulga Dela Cuadra100% (1)

- Design of Colum Bases 12Document5 pagesDesign of Colum Bases 12radhe soniNo ratings yet

- Shallow Foundations: o o o o oDocument11 pagesShallow Foundations: o o o o otoluca28No ratings yet

- .Uk-Abutment Design Example To BD 30Document30 pages.Uk-Abutment Design Example To BD 30OscarKonzultNo ratings yet

- Bearing Capacity of SoilDocument10 pagesBearing Capacity of SoilaminjolesNo ratings yet

- Pressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910From EverandPressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910No ratings yet

- Module 1 Ce007Document5 pagesModule 1 Ce007ANGELICA SAHAGUNNo ratings yet

- FDN Engg Manual (4-13-2022)Document26 pagesFDN Engg Manual (4-13-2022)ANGELICA SAHAGUNNo ratings yet

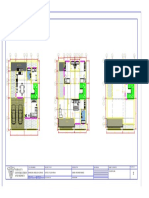

- Lot PlanDocument1 pageLot PlanANGELICA SAHAGUNNo ratings yet

- Floor PlanDocument1 pageFloor PlanANGELICA SAHAGUNNo ratings yet

- Condition RatingDocument23 pagesCondition RatingChris RodopoulosNo ratings yet

- Design of Reinforced Concrete BeamsDocument5 pagesDesign of Reinforced Concrete BeamsIbrahim AlmohannaNo ratings yet

- CVLE 322 Reinforced Concrete Design I: Course Syllabus - Spring 2015 2016Document3 pagesCVLE 322 Reinforced Concrete Design I: Course Syllabus - Spring 2015 2016Gempf GisNo ratings yet

- Thin Slender Concrete Rectangular Walls in Moderate Seismic Regions With A Single Reinforcement Layer2020journal of Building Engineering PDFDocument12 pagesThin Slender Concrete Rectangular Walls in Moderate Seismic Regions With A Single Reinforcement Layer2020journal of Building Engineering PDFLeonardo Chavez VillamizarNo ratings yet

- 3 Final Plates PDFDocument48 pages3 Final Plates PDFAriane Joyze BronzalNo ratings yet

- ACI E-706 Spall Repair of Horizontal Concrete SurfacesDocument6 pagesACI E-706 Spall Repair of Horizontal Concrete SurfacesmirzaNo ratings yet

- BCA Requirements and Good Practices For CONQUAS Preparation PDFDocument121 pagesBCA Requirements and Good Practices For CONQUAS Preparation PDFALFREDO JR. ARIOS CLARO100% (3)

- Ehe EngDocument551 pagesEhe EngMohamed OumlkhirNo ratings yet

- 4 Joints in BuildingsDocument18 pages4 Joints in BuildingsDipeshNo ratings yet

- PIP STE05121 Application of ASCE Anchorage Design For PetrochemicalDocument66 pagesPIP STE05121 Application of ASCE Anchorage Design For Petrochemicalbabakfun2000No ratings yet

- FE BEAM DESIGN REVIEWDocument50 pagesFE BEAM DESIGN REVIEWev xvNo ratings yet

- Kurukshetra University Scheme of Studies for Civil EngineeringDocument9 pagesKurukshetra University Scheme of Studies for Civil EngineeringGourav RanaNo ratings yet

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Document5 pagesSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- DS Factory Construction ScheduleDocument5 pagesDS Factory Construction ScheduleYe Yint100% (1)

- Advanced Design - IntroductionDocument20 pagesAdvanced Design - Introductionkaye jeonNo ratings yet

- Final Internship Report NewDocument68 pagesFinal Internship Report NewMahanthesh kori100% (1)

- DPWH Minimum Test Requirements PDFDocument30 pagesDPWH Minimum Test Requirements PDFWilliam100% (4)

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Major Project Report ON Building Construction and TechniquesDocument55 pagesMajor Project Report ON Building Construction and Techniquesashi ashi100% (1)

- DFI-ADSC Micropile Guide SpecDocument39 pagesDFI-ADSC Micropile Guide Specpk100% (2)

- UntitledDocument49 pagesUntitledErwin SusantoNo ratings yet

- Is 456 - PPTDocument41 pagesIs 456 - PPTtarang shethNo ratings yet

- Study of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqDocument10 pagesStudy of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqIAEME PublicationNo ratings yet

- Ductile Detailing Useful ReferencesDocument6 pagesDuctile Detailing Useful ReferencesMandar NadgaundiNo ratings yet

- Annex J - Concrete Pouring PermitDocument2 pagesAnnex J - Concrete Pouring PermitSymbian ToniNo ratings yet

- Concrete Coring (Eng) PDFDocument2 pagesConcrete Coring (Eng) PDFSanchai_SaNo ratings yet

- Design of RC ShellsDocument9 pagesDesign of RC Shellscacrcarlos100% (1)

- Civil Interview QuestionsDocument6 pagesCivil Interview QuestionsSonam Rinchen BhutiaNo ratings yet

- 00 List of StandardsDocument2 pages00 List of StandardsDeepak GuptaNo ratings yet

- BILFINGER TEBODIN Cost Analysis CEE 2019Document24 pagesBILFINGER TEBODIN Cost Analysis CEE 2019acuzungeceNo ratings yet