Professional Documents

Culture Documents

US4152528

Uploaded by

anhchangcodon88Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US4152528

Uploaded by

anhchangcodon88Copyright:

Available Formats

United States Patent (19) 11 4,152,528

Strahorn 45 May 1, 1979

54 PROCESS FOR EXTRACTING PHENOL

FROM PHENOL-WATER MIXTURES OTHER PUBLICATIONS

w Zlatin et al. Chem. Abs. vol. 59, 13683e (1963).

(75) Inventor: David F. Strahorn, Oakland, Calif. Aunicky Chem. Abs. vol. 63, 393e (1965).

73 Assignee: Chevron Research Company, San Ivonon et al. Chem. Abs. vol. 54, 15905 (1960).

Francisco,9 Calif. Primary Examiner-Werren B. Lone

(21) Appl. No.: 788,104 Attorney, Agent, or Firm-D. A. Newell; R. H. Davies;

22 Filed: Apr. 15, 1977 W. D. Reese

51) Int. Cl. .............................................. coTC 37/34 ABSTRACT

52 U.S.C. ..................................... 568/749; 568/761 A process is provided for extracting phenol from phe

58 Field of Search ........... 260/621 A, 621 B, 627 R, nol-water mixtures using a hydrocarbon-extracting me

260/624 A, 626 R, 627; 568/749, 761 dium having an improved extraction coefficient. The

extracting medium comprises a mixture of a hydrocar

56) References Cited bon component containing at least a substantial amount

U.S. PATENT DOCUMENTS of an aromatic hydrocarbon for example benzene, and a

2,807,654 9/1959 Grimmett ........................ 260/627 R ketone component, for example 2-butanone.

2,928,882 3/1960 Hall ......... ... 260/627 R

3,155,734 1 1/1964 Merkel ............................. 260/621 R 6 Claims, 1 Drawing Figure

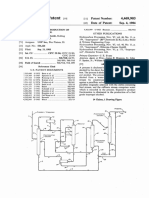

PARTITION COEFFICIENTs' For

BENZENE-2-BUTANONE (B-2-B) MIXTURES

AT 22 C

H

2

2

L

L

l

O

s

2

9.

a

W. / 2 - BUTANONE

WT. /o. PHENO IN B-2-B MXTURES

( ) Ks WT. W. PHENOL IN WATER PHASE.

U.S. Patent May 1, 1979 4,152,528

PARTITION COEFFICIENTs' FOR

BENZENE-2 - BUTANONE (B-2-B) MIXTURES

A 22 C

2O 4O 6O 8O OO

WT. A 2 - BUTANONE

WT. A. PHENO N B-2-B MIXTURES

K wt. i. PHENON WATER PHASE

4, 152,528

1. 2

PROCESS FOR EXTRACTING PHENOL FROM EMBODIMENT

PHENOL-WATER MIXTURES In a preferred embodiment phenol is recovered from

BACKGROUND OF THE INVENTION

an aqueous phenolic process stream produced in refin

ing a petroleum stock. A typical such stream is a stream

This invention relates to an improved process for stripping condensate containing, in parts by weight,

extracting phenol from a phenol-water mixture. More about 1 part of phenol and about 99 parts of water. In

particularly, it relates to carrying out the aforemen the embodiment, this stream is contacted with recycled

tioned extracting using an extracting medium compris extracting medium which is a 50/50 (volume) mixture

ing an aromatic hydrocarbon component and a ketone O of benzene and 2-butanone containing about 1000 ppmw

component. of phenol. The contacting is carried out in an ordinary

The recovery of phenol from aqueous phenolic mix countercurrent extracting column at a volume ratio of

tures using benzene as the extracting solvent, for exam extracting medium to aqueous phenol of about 0.05. The

ple from (1) tar water, (2) aqueous phenolic wastes, and resulting aqueous raffinate phase contains less than 100

(3) aqueous coke-oven wastes, is described in articles by

15 ppmw of phenol. In order to achieve a comparable

(i) B. I. Ivanov et al., (ii) L. I. Zlatin et al. and (iii) Zd extraction of the phenol from the water using benzene

alone as the extracting medium, it would be necessary

Aunicky. These articles are cited in the Chemical Ab to use per volume of feed a volume of benzene having

stracts of the American Chemical Society at Vol. less than 300 ppmw of phenol which is at least a factor

54:15905i, Vol. 59:13683e and Vol. 63:393e, respec 20 of about 10 greater than the volume of the 50/50 ben

tively. However, the phenol extraction coefficient for zene-ketone extracting medium.

the benzene-water system is small, for example it is less By "liquid-liquid extracting conditions' as used

than 5. The lower the coefficient, of course, the larger herein is meant by definition efficient contacting of at

is the number of extraction stages which must be used least two liquid phases carried out under conditions of

for an effective recovery of phenol in an extracting 25 temperature and pressure at least sufficient to maintain

process and the larger is the amount of solvent which said liquid phases.

must be processed. Accordingly, there is a need for a Liquid-liquid extracting conditions are known and

phenol extracting medium having an improved extrac used in the extracting art, and such are contemplated for

tion coefficient. use in the usual way herein. Representative conditions,

It is an object of this invention to provide an extract 30 methods and equipment suitable for use in liquid-liquid

ing medium having an improved extraction coefficient. extracting for directly contacting separable liquid pha

A further object is to provide an improved process for ses for the purpose of causing transfer of a dissolved

recovering phenol from water-phenol mixtures using substance, for example, phenol as herein, are described

such a medium. in Perry's Chemical Engineers' Handbook, 4th Ed., R.

35 H. Perry, C. H. Chilton and S. D. Kirkpatrick, co-edi

SUMMARY OF THE INVENTION tors, McGraw-Hill Book Company, New York, Sec

In the process for extracting phenol from a liquid tions 21-10 to 21-34. Other leading references are also

phase comprising phenol and water by contacting said cited in the above Handbook.

phase under liquid-liquid extracting conditions with an EXAMPLES

extracting medium thereby producing an aqueous raffi In a series of runs which were carried out under

nate phase and an organic extract phase, an improve ambient conditions, that is, at a temperature of about 22

ment is provided comprising: (1) using as said medium a C. and a pressure of 1 atmosphere, the phenol partition

liquid mixture containing a hydrocarbon component, coefficients for water and a series of ketone-modified

and a ketone component, said hydrocarbon component 45 hydrocarbon extracting phases were determined. The

containing (a) at least about 25 weight percent of at least extracting phases used in these examples were benzene

one aromatic hydrocarbon selected from the group and a benzene solution containing a range of 2-butanone

consisting of (i) benzene, and (ii) lower alkyl-substituted contents. The results from these runs are shown in the

benzenes containing less than 4 alkyl substituent groups, FIGURE. These results illustrate that while benzene or

and (b) a remainder, if any, selected from the group 50 2-butanone individually exhibit phenol partition coeffi

consisting of non-aromatic hydrocarbon solvents; said cients of a relatively low order, for example of less than

ketone component being at least one ketone selected about 3 or 5, mixtures of benzene and 2-butanone ex

from the group consisting of ketones composed of car hibit, in the partition of phenol between water and the

bon, hydrogen and oxygen and having a carbon atom organic extracting medium, partition coefficients which

content in the range from 3 to about 7; and said medium 55 are receptional. From the FIGURE it is notable that the

containing at least sufficient of said ketone to produce, addition of but a minor amount of 2-butanone, for exam

in extracting phenol from water, a phenol extraction ple as little as 10 weight percent, to benzene about dou

bles the partition coefficient. The coefficient for a 50/50

coefficient for said medium which is at least a factor of

about 2 greater than the phenol extraction coefficient mixture, relative to that for benzene alone, is larger by

for said hydrocarbon component; and (2) separating 60 about a factor of 20

said raffinate and extract phases. Process Parameters

DESCRIPTION OF THE DRAWING (A) Extracting Medium

The FIGURE is a curve showing the enhancement of 65 The hydrocarbon solvents suitable for use herein may

the phenol extraction coefficient resulting from the vary widely and, in general, must exhibit an appreciable

addition of 2-butanone to the benzene in a benzene aromatic character, for example as exhibited by a hy

water system. drocarbon mixture having an aromatic hydrocarbon

4,152,528

3 4.

content of at least about 25 volume percent, preferably are in the range from about 10 C. to 50° C. and most

in the range of from about 40 to 65. As may be noted preferably about the ambient temperature.

from the FIGURE, excellent results, in terms of an

improved phenol partition coefficient, are achieved (D) Extracting Medium to Phenolic Water Volume

when the hydrocarbon components consist essentially Ratio

of aromatic hydrocarbons. However, for practical rea The extracting medium to phenolic water volume

sons, including (1) cost and/or (2) concurrent coextrac ratio may vary widely, depending upon the particular

tion of non-aromatic hydrocarbons from the phenolic extracting medium being employed and the phenol

aqueous phase, a diluted aromatic hydrocarbon extract content of the phenolic water phase. At least sufficient

ing phase will frequently be that of choice for use O of the extracting medium must be employed in the con

herein, especially where the process is being carried out tacting to result in the required aqueous raffinate phase

in a continuous mode. Where the hydrocarbon compo and an organic extract phase, that is, sufficient to satisfy

nent contains a non-aromatic diluent, the latter may be ordinary liquid-liquid extracting conditions. In general,

any known normally liquid non-aromatic hydrocarbon satisfactory volumetric operating ratios are in the range

solvent or fraction thereof. Representative diluents 15

from about 0.05 to 15 and preferably 0.1 to 1.

include paraffinic and olefinic petroleum fractions, hex

ane, hexene, cyclohexane, cyclohexene, heptane, hep Apparatus

tene, and the like hydrocarbon solvents, and paraffinic

and olefinic components and fractions thereof which Any suitable form of apparatus may be used. In gen

are normally present in substantially aromatic product 20 eral, the various means customarily employed in extrac

streams ordinarily recovered in a petroleum refinery. tion processes to increase the contact area between the

The aromatic hydrocarbons comprising benzene and two separate liquid phases can be employed. Thus the

alkyl-substituted benzenes and mixtures thereof are apparatus used in the present process can comprise a

preferred for use as the extracting medium or as compo single extraction zone or multiple extraction zones

nents thereof in the present process. Preferably, the 25 equipped with (a) shed rows or stationary devices to

aromatic component of the extracting medium contains facilitate contacting; (b) orifice mixers; or (c) effective

at least one hydrocarbon selected from the group con stirring devices such as mechanical agitators, jets of

sisting of benzene and lower alkyl (alkyl groups con restricted internal diameter, turbomixers, and the like.

taining less than 4 carbon atoms), substituted benzenes Apparatus suitable in the batch- or continuous-type

containing less than 4 alkyl substituent groups. Repre 30 manner, the latter being preferred, may be employed. A

sentative aromatic components include benzene, tolu continuous countercurrent operation employing a liq

ene, the xylenes, ethylbenzene, cumene and mixtures uid-liquid contacting tower is a preferred mode.

thereof. Benzene and toluene are preferred. Reasonable variation and modification are possible

(B) Ketone Component within the scope of the disclosure, the drawing and the

The ketone component of the extracting medium may

35 appended claims to the invention, the essence of which

be 2-butanone, 2-pentanone, 3-pentanone, acetone and is that there has been provided a method for improving

the like ketones and mixtures thereof, that is, there may

the extraction of phenol from a phenol-water mixture

by increasing the phenol partition coefficient of a hy

be at least one ketone selected from the group consisting drocarbon extracting medium by adding a suitable ke

of ketones composed of carbon, hydrogen and oxygen tone to the medium.

and having a carbon atom content in the range from 3 to What is claimed is:

about 7. In addition to the aforenamed ketones, repre 1. In the process for extracting phenol from a liquid

sentative ketones suitable for use herein include cyclo phase comprising phenol and water by extracting said

hexanone, cyclopentanone, methyl-substituted cyclo phase under conventional liquid-liquid extracting con

hexanone or cyclopentanone, isopropylmethyl, ethyl 45 ditions with an extracting medium thereby producing

isopropyl and the like acyclic ketones. 2-butanone is a an aqueous raffinate phase and an organic extract phase,

preferred ketone component for use herein. said conditions including a temperature of 10-50 C.,

The amount of ketone desirably present in the ex and pressure at least sufficient to maintain said liquid

tracting medium varies depending upon a number of phases, the improvement comprising: (1) using as said

factors, including the kind and amount of aromatic

hydrocarbon in the hydrocarbon component, the par 50 medium a liquid mixture containing a hydrocarbon

component, and a ketone component, said hydrocarbon

ticular ketone component employed and the tempera component containing at least 25 weight percent of

ture at which the extracting is carried out. In general, an

improved extracting medium is obtained when this me aromatic hydrocarbon being selected from the group

dium contains an amount of ketone in the range from 55

consisting of benzene and alkyl-substituted benzenes

about 5 to 90 weight percent. Preferably the medium containing less than 4 alkyl substituent groups, said

contains by weight an amount of the ketone in the range alkyl groups containing less than 4 carbon atoms; said

from about 20 to 80%, and more preferably 40 to 65%. ketone component being at least one aliphatic ketone

selected from the group consisting of aliphatic ketones

(C) Temperature and Pressure composed of carbon, hydrogen and oxygen and having

60

The temperature and pressure combinations suitable a carbon atom content in the range from 3 to 7; said

for use herein are in general those sufficient to maintain medium containing an amount of said ketone, in the

the liquid phases herein in the liquid phase. Preferably range 20-80 weight percent, sufficient to produce, in

the contacting, in order to avoid use of costly pressure extracting phenol from water, a phenol extraction coef.

equipment, is carried out at atmospheric pressure. Suit 65 ficient for said medium which is at least a factor of

able temperatures in this case will, of course, be below about 2 greater than the phenol extraction coefficient

the boiling point of the lowest-boiling component in the for said hydrocarbon component; and (2) said condi

extracting system. Preferred contacting temperatures tions including using a volume ratio of extracting me

4,152,528 6

5

dium to phenolic water in the range of from about 5. A process as in claim 2 wherein said amount of

0.05-15 to 1, respectively. ketone is in the range of from about 40 to 65 weight

2. A process as in claim 1 wherein: percent.

(a) said aromatic hydrocarbon group is benzene and 6. A process as in claim 1 wherein:

toluene; 5 (a) said contacting medium is about a 50/50 (volume)

(b) said hydrocarbon component contains an amount mixture of benzene and 2-butanone;

by volume of said aromatic hydrocarbon in the (b) said contacting is carried out using an extracting

range of from about 40 to 65 percent. medium to phenolic water volume ratio of about 3;

3. A process as in claim 2 wherein said ketone is and

2-butanone. 10 (c) said raffinate per million parts by weight has a

4. A process as in claim 1 wherein said volume ratio phenol content skwhich

is

is less than about 1000.

is

is in the range of from about 0.1-1 to 1, respectively.

15

20

25

30

35

45

50

55

65

You might also like

- BS7-Touch Screen PanelDocument96 pagesBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)

- 2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20Document10 pages2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20mgalphamrn100% (1)

- GRE Minger 1982Document4 pagesGRE Minger 1982anhchangcodon88No ratings yet

- Us 7371903Document4 pagesUs 7371903Rafi Theda PrabawaNo ratings yet

- Articulo 3Document20 pagesArticulo 3AnaNo ratings yet

- United States Patent (19) : Imuro Et AlDocument5 pagesUnited States Patent (19) : Imuro Et AlgopalNo ratings yet

- US4684750Document4 pagesUS4684750Deep PatelNo ratings yet

- US4767543Document6 pagesUS4767543Baba DookNo ratings yet

- Hydroxylation of Benzene To Phenol Via Hydrogen Peroxide in Hydrophilic Triethylammonium Acetate Ionic LiquidDocument5 pagesHydroxylation of Benzene To Phenol Via Hydrogen Peroxide in Hydrophilic Triethylammonium Acetate Ionic LiquidshivanshNo ratings yet

- United States Patent (19) : Benedetto Calcagno Fulvio Attorney, Agent, or Firm-Sughrue, Mion, ZinnDocument5 pagesUnited States Patent (19) : Benedetto Calcagno Fulvio Attorney, Agent, or Firm-Sughrue, Mion, ZinnmasyNo ratings yet

- US5625109 Liquid Phase Dehydration of Tertiary Butyl AlcoholDocument6 pagesUS5625109 Liquid Phase Dehydration of Tertiary Butyl AlcoholNuzulina FitriNo ratings yet

- Fenoles Termofilico ReactorDocument8 pagesFenoles Termofilico ReactorElberPugaNo ratings yet

- United States Patent ToDocument8 pagesUnited States Patent ToAwat MuhammadNo ratings yet

- Solvents SDocument3 pagesSolvents SLorenaNo ratings yet

- 2008 The Rule of Phenols From Bagasse Vacuum Pyrolysis Bio-Oil in Cupper Sulfured Ore FlotationDocument6 pages2008 The Rule of Phenols From Bagasse Vacuum Pyrolysis Bio-Oil in Cupper Sulfured Ore Flotationmuhammad noorNo ratings yet

- Separación de AzeotropoDocument2 pagesSeparación de AzeotropoLaura GarciaNo ratings yet

- US4152217Document9 pagesUS4152217SekarNTutyNo ratings yet

- Determination of Boron in Fertilizers by Atomic AbsorptionDocument3 pagesDetermination of Boron in Fertilizers by Atomic AbsorptionRenato Diaz FrigerioNo ratings yet

- Us 3625879 PatentDocument8 pagesUs 3625879 PatentJuPe Juniawan PrakosoNo ratings yet

- United States Patent: Benzene From Pyrolysis Naphtha Produced by High-TemperaDocument8 pagesUnited States Patent: Benzene From Pyrolysis Naphtha Produced by High-TemperalandagoNo ratings yet

- United States Patent To: 58) Field of Search ........ 260/671 P, 672 T, 671 R, 260/671 CDocument7 pagesUnited States Patent To: 58) Field of Search ........ 260/671 P, 672 T, 671 R, 260/671 CmasyNo ratings yet

- US4285881Document4 pagesUS4285881Thomas MarshallNo ratings yet

- Nov. 15, 1955 J. T. Rutherford 2,723,995: (NH4) 2SO4Document3 pagesNov. 15, 1955 J. T. Rutherford 2,723,995: (NH4) 2SO4sefssefNo ratings yet

- Paten 5 Us5998677Document7 pagesPaten 5 Us5998677Jihan FauziyahNo ratings yet

- A-Phenyltropic Acid and Basic Esters.-Catalyzed Reactions of oYDiphenyl-p-propiolactoneand of 2 2-Diphenyl-3-Bromo - and Chloropropanoic AcidsDocument4 pagesA-Phenyltropic Acid and Basic Esters.-Catalyzed Reactions of oYDiphenyl-p-propiolactoneand of 2 2-Diphenyl-3-Bromo - and Chloropropanoic AcidsTHEUSER0001No ratings yet

- United States PatentDocument4 pagesUnited States Patentwiam wiamNo ratings yet

- United States Patent (19) : 11) Patent Number: 5,606,102 (45) Date of Patent: Feb. 25, 1997Document9 pagesUnited States Patent (19) : 11) Patent Number: 5,606,102 (45) Date of Patent: Feb. 25, 1997Dian Agung SatyanagaraNo ratings yet

- Water Research, 10, 11, 985-90, 1976Document6 pagesWater Research, 10, 11, 985-90, 1976prashantNo ratings yet

- United States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GDocument9 pagesUnited States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GFebrian Dimas Adi NugrahaNo ratings yet

- Ba Patent 1Document6 pagesBa Patent 1Firdaus ImamNo ratings yet

- By Harry D. Baernstein (From Industrial: The Hygiene Laboratory, National Institute of Health, Bethesda, Maryland)Document9 pagesBy Harry D. Baernstein (From Industrial: The Hygiene Laboratory, National Institute of Health, Bethesda, Maryland)IsakayogaNo ratings yet

- MTT655 W2 ExtrusionDocument13 pagesMTT655 W2 ExtrusionCitra Adelina SitorusNo ratings yet

- Patente CumenoDocument6 pagesPatente CumenoMaria PaulaNo ratings yet

- 1 s2.0 037673889080010J MainDocument16 pages1 s2.0 037673889080010J MainAnca Maria CimbruNo ratings yet

- Reactor AnaeróbicoDocument8 pagesReactor AnaeróbicoLuis BejaranoNo ratings yet

- United States Patent (19) : 51 Int. Cl. ...................... Conc29/86, Conc29/80, No!", Deutsche Texaco AGDocument7 pagesUnited States Patent (19) : 51 Int. Cl. ...................... Conc29/86, Conc29/80, No!", Deutsche Texaco AGArka Krisna PratamaNo ratings yet

- @ Gradeff US3869517 1975 Process For Preparing Hydroxy Citronellal Via 1,1-DiacetatesDocument10 pages@ Gradeff US3869517 1975 Process For Preparing Hydroxy Citronellal Via 1,1-DiacetatesLouisNo ratings yet

- Patente II ButadienoDocument4 pagesPatente II Butadienomanuel lozanoNo ratings yet

- Patente ButanonaDocument6 pagesPatente ButanonaAgustina VaiNo ratings yet

- Shell 50s Ipa To PeroxideDocument8 pagesShell 50s Ipa To PeroxideKevin ApteNo ratings yet

- DestilaciónDocument22 pagesDestilaciónMischel Pamela Cardenas LopezNo ratings yet

- 54754-Article Text-89653-1-10-20100526Document7 pages54754-Article Text-89653-1-10-20100526nurizzaatiNo ratings yet

- Us20150218435a1 Nano-SurfactantsDocument13 pagesUs20150218435a1 Nano-SurfactantsFederico ArqueroNo ratings yet

- Liotta 1989Document4 pagesLiotta 1989NikaNo ratings yet

- Estimation of Biological Kinetic Parameters From An Analysis of The BOD Curve of Waste Waters-Effects of A Chemical PreoxidationDocument15 pagesEstimation of Biological Kinetic Parameters From An Analysis of The BOD Curve of Waste Waters-Effects of A Chemical PreoxidationAnita Saucedo GomezNo ratings yet

- Joya Us4569799Document9 pagesJoya Us4569799Agustin CantilloNo ratings yet

- Us 6479707Document4 pagesUs 6479707jdedfvNo ratings yet

- Aldehyde and Ketone Condensation Catalyzed by Boric Acid: Mrs. L. For I11 (Cis, Trans, Trans), I11 (Cis, Cis, Cis)Document3 pagesAldehyde and Ketone Condensation Catalyzed by Boric Acid: Mrs. L. For I11 (Cis, Trans, Trans), I11 (Cis, Cis, Cis)EMMANUEL BETANCUR ZAPATANo ratings yet

- Case 1982Document4 pagesCase 1982Sebastian Ortiz BuitragoNo ratings yet

- AttachmentDocument5 pagesAttachmentyentilNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,525,005 B2Document7 pagesUlllted States Patent (10) Patent N0.: US 7,525,005 B2nokarajuNo ratings yet

- Palma 2007Document5 pagesPalma 2007AlejandraTurriagoNo ratings yet

- United States PatentDocument5 pagesUnited States PatentRefi RahmanNo ratings yet

- Transformation of Phenol Into Phenylalanine by A Methanogenic ConsortiumDocument6 pagesTransformation of Phenol Into Phenylalanine by A Methanogenic ConsortiumCao Thị Vân GiangNo ratings yet

- Phosphorus in FertilizDocument2 pagesPhosphorus in Fertilizkaren capoteNo ratings yet

- Anaerobic Packed-Bed Reactor For Bioremediation ofDocument6 pagesAnaerobic Packed-Bed Reactor For Bioremediation ofSandraMeirellesNo ratings yet

- Improved Pervaporation Performance of Locally-Produced Chitosan Membranes Mohd Ghazali Mohd Nawawi and Hashim HassanDocument8 pagesImproved Pervaporation Performance of Locally-Produced Chitosan Membranes Mohd Ghazali Mohd Nawawi and Hashim Hassanapi-26678889No ratings yet

- Catalytic Removal of Phenol From Aqueous Solutions in A Trickle-Bed ReactorDocument7 pagesCatalytic Removal of Phenol From Aqueous Solutions in A Trickle-Bed ReactorFarah TalibNo ratings yet

- US4247729Document5 pagesUS4247729Muhammad Akbar FahleviNo ratings yet

- June 10, 1958: Continuous Hydrolysis of EpichlorohydrinDocument4 pagesJune 10, 1958: Continuous Hydrolysis of EpichlorohydrinAbdur Rochim Al IchwanNo ratings yet

- Use of An Effluent For Enhanced Oil Recovery: Subrata Borgohain Gogoi & Borkha Mech DasDocument5 pagesUse of An Effluent For Enhanced Oil Recovery: Subrata Borgohain Gogoi & Borkha Mech DasSirisha NNo ratings yet

- Crime Free Lease AddendumDocument1 pageCrime Free Lease AddendumjmtmanagementNo ratings yet

- WT Chapter 5Document34 pagesWT Chapter 5Wariyo GalgaloNo ratings yet

- Chapter 54 - Drugs Acting On The Upper Respiratory TractDocument13 pagesChapter 54 - Drugs Acting On The Upper Respiratory TractJonathonNo ratings yet

- 5L ReductionsDocument20 pages5L ReductionsCarlos Javier Orellana OrtizNo ratings yet

- 13 Alvarez II vs. Sun Life of CanadaDocument1 page13 Alvarez II vs. Sun Life of CanadaPaolo AlarillaNo ratings yet

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Ifm Product Innovations PDFDocument109 pagesIfm Product Innovations PDFJC InquillayNo ratings yet

- 1 Nitanshi Singh Full WorkDocument9 pages1 Nitanshi Singh Full WorkNitanshi SinghNo ratings yet

- Social Connectedness and Role of HopelessnessDocument8 pagesSocial Connectedness and Role of HopelessnessEmman CabiilanNo ratings yet

- Liquid Enema ProcedureDocument3 pagesLiquid Enema Procedureapi-209728657No ratings yet

- Snap Bore Ring PDFDocument8 pagesSnap Bore Ring PDFlaaliNo ratings yet

- The Power of PositivityDocument5 pagesThe Power of PositivityYorlenis PintoNo ratings yet

- Brain Slides SEMINAR 1 - 220606 - 142811 - 220606 - 223805Document32 pagesBrain Slides SEMINAR 1 - 220606 - 142811 - 220606 - 223805pang pangNo ratings yet

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDocument5 pagesKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNo ratings yet

- Chapter - 7 Materials HandlingDocument14 pagesChapter - 7 Materials HandlingTanaya KambliNo ratings yet

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocument29 pagesUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemNo ratings yet

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtDocument7 pagesHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganNo ratings yet

- Cooling Tower (Genius)Document7 pagesCooling Tower (Genius)JeghiNo ratings yet

- Community Medicine DissertationDocument7 pagesCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Installation Manual (DH84309201) - 07Document24 pagesInstallation Manual (DH84309201) - 07mquaiottiNo ratings yet

- Practical Cookery 14th Edition SAMPLEDocument16 pagesPractical Cookery 14th Edition SAMPLETendaiNo ratings yet

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 pagesTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNo ratings yet

- Kes MahkamahDocument16 pagesKes Mahkamahfirdaus azinunNo ratings yet

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDocument1 pageVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaNo ratings yet

- Gmail - RedBus Ticket - TN7R20093672Document2 pagesGmail - RedBus Ticket - TN7R20093672Bappa RoyNo ratings yet

- TelfastDocument3 pagesTelfastjbahalkehNo ratings yet

- Richard Teerlink and Paul Trane - Part 1Document14 pagesRichard Teerlink and Paul Trane - Part 1Scratch HunterNo ratings yet

- ME-317 Internal Combustion Engines - TurbochargingDocument21 pagesME-317 Internal Combustion Engines - TurbochargingHamzaJavedNo ratings yet