Professional Documents

Culture Documents

Institutional Assessment Tools

Institutional Assessment Tools

Uploaded by

MaximalistaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Institutional Assessment Tools

Institutional Assessment Tools

Uploaded by

MaximalistaCopyright:

Available Formats

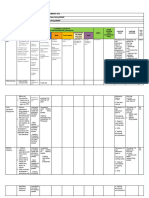

Evidence Plan

Competency ELECTRICAL INSTALLATION AND MAINTENANCE NC II

standard:

Unit of PERFORM ROUGHING-IN ACTIVITIES, WIRING AND

competency: CABLING WORKS FOR SINGLE PHASE DISTRIBUTION,

POWER, LIGHTING AND AUXILIARY SYSTEM.

Ways in which evidence will be collected:

[tick the column]

Third party Report

Demonstration &

Observation &

Portfolio

Written

The evidence must show that the trainee…

*Interpret correct drawing based on job

/ / /

requirements

Determine correct quantities of conduit, fittings

/ /

and materials as per job requirements

Select tools, and equipments as per job

/ /

requirements

*Installed and assemble conduit ensuring that

fittings are fully inserted ,tightened and / /

threaded as per job requirements

Conduit is bent with bends not exceeding 90˚

/ /

as per standard and job requirements

*Installed wire ways and cable tray / /

*Prepare cable pulling, wiring installation and

/ /

lay-out

Follow safety procedures in line with standard

/ /

operating procedures (SOPs)

*Installed auxiliary terminal cabinet and

/ /

distribution panel

*Notified completion of work / /

NOTE: *Critical aspects of competency

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

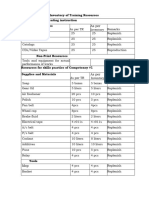

TABLE OF SPECIFICATION

Objectives/Content # of items/

Knowledge Comprehension Application

area/Topics % of test

1. Install electrical

metallic/non- 1 ITEM 1 ITEM 2 ITEM

20%

metallic (PVC 5% 5% 10%

conduit)

2. Install wire ways 1 ITEM 1 ITEM 1 ITEM

and cable trays 15%

5% 5% 5%

3. Install auxiliary 1 ITEM 1 ITEM 2 ITEM

terminal cabinet and 20%

distribution panel 5% 5% 2%

4. Prepare for cable 1 ITEM 1 ITEM 1 ITEM

pulling and 15%

installation 5% 5% 5%

5. Perform wiring 1 ITEM 1 ITEM 2 ITEM

and cabling lay out 20%

5% 5% 10%

6. Notify completion 1 ITEM 1 ITEM

of work 0 10%

5% 5%

5 ITEMS 6 ITEMS 9 ITEMS 20 ITEMS

TOTAL

25% 30% 45% 100%

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

Written Test

TEST I -MULTIPLE CHOICES: Choose the correct answer and

encircle its letter.

1. A conduit informally called Greenfield or flex. Is made by the helical

coiling of a self-interlocked ribbed strip of aluminum or steel, forming a

hallow tube through which wires can be pulled. It is used primarily in dry

areas where it would be impractical to use EMT.

a. EMT (Electrical Metallic tubing) b. RMC (Rigid Metal Conduit)

c. FMC (Flexible Metallic Conduit) d. ENT (Electrical nonmetallic conduit)

2. The conduit is allowed to bend, but should not exceed the maximum

tolerance of.

a. 30˚ b. 45˚ c. 180˚ d. 90˚

3. The equipment needed to install metallic and non-metallic conduits are:

a. Electric power drill, Portable Grinder

b. Heat gun, Pipe Thread maker

c. Pipe bender

d. All of the above

4. What specific Instructions must be followed in installation of conduit

fittings, couplings and elbows?

a. Inserted as per job requirements.

b. Fully inserted, tightened and properly installed as per job

requirements.

c. Installed and constraint as per job requirements.

d. None of the above.

5. The blade tip of this kind is wedge-shaped and resembles a negative

sign.

a. Philips screw b. Flat screw driver

c. Insulators d. Stubby screw

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

6. Used for cutting and holding fine wires. Can reach tight space or small

opening where others cannot.

a. Wire stripper b. Diagonal pliers

c. Long nose pliers d. Electrician knife

7. These are made from metals with insulators in the handle and are used

for cutting, twisting, bending, holding, gripping wires and cables.

a. Pliers b. mallet

c. Claw hammer d. Side cutter

8. Is a component of an electricity supply system that divides an electrical

power feed in to subsidiary circuits, while providing a protective fuse or

circuit breaker for each circuit in a common enclosure.

a. Multi tester b. Distribution board or Panel board

c. Mother board d. PCB

9. What specification (ampere) of circuit breaker is needed after installing a

special purpose outlet (SPO)?

a. 30 amp b. 20 amp

c. 15 amp d. 60 amp

10. A class type of hardhat that tested at 2200 volts.

a. Type I hard hat b. General class

c. Electrical class d. Conductive class

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

TEST II – TRUE OR FALSE

Direction: Write T if the statement is TRUE and Write F if it is FALSE.

_________11. A protective device used to automatically blow or cut off the

flow of electrical current when trouble in the circuit such as short circuit or

overload occurs is called circuit breaker.

_________12. Cable pulling is the moving of length of cable from one place to

another to install a connection of some type between designated areas.

_________13. A cable tray is a tube used to protect and route electrical

wiring in building or structure.

_________14. Reading and interpreting electrical drawing, familiarize all

electrical symbols will not help you to complete wiring installation as per job

requirements.

_________15. There are three ways to show electrical circuits. They are

wiring diagram, schematic diagram and pictorial diagram. The two most

commonly used are wiring diagram and schematic diagram.

Test III – IDENTIFICATION

Direction: Identify the following question.

___________16. It is galvanized steel tubing with a tubing wall that is thick

enough to allow threading.

___________17. A rectangular shaped metallic or non-metallic material in

which flush type convenience outlet and switch are mounted or attached.

___________18. Sometimes called thin wall, it is less costly and lighter than

GRC.

___________19. A pocket size tools use to test the line wire or circuit if there

is flow of current in it.

___________20. These are tools used in driving or pounding and pulling out

nails, they are made of hard steel, wood, plastic or rubber.

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

Answer Key

Test I. Multiple Choice

1. C

2. D

3. D

4. B

5. B

6. C

7. A

8. B

9. A

10. B

Test II. True or False

1. T

2. T

3. F

4. F

5. T

Test III – IDENTIFICATION

1. Galvanized Rigid Conduit

2. Utility box

3. Electrical Metallic Tubing

4. Screw tester/ Circuit tester

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

5. Hammer

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

Performance Test

Specific Instruction for the Candidate

Qualification ELECTRICAL INSTALLATION AND

MAINTENANCE NC II

Unit of Competency PERFORM ROUGHING-IN ACTIVITIES,

WIRING AND CABLING WORKS FOR

SINGLE-PHASE DISTRIBUTION,

POWER, LIGHTING AND AUXILIARY

SYSTEMS

General Instruction:

Given the following tools, materials and equipments you should be able

to perform roughing-in activities, wiring and cabling works for single-phase

distribution, power, lighting and auxiliary systems as per job requirements.

Specific Instruction:

1. Ensure that the fittings are fully inserted and tightened as per job

requirements.

2. Install Conduit coupling and elbows are properly installed as per

job requirements.

3. Interpret correct drawing as per job requirements.

4. Install wire ways and cable trays are properly installed as per job

requirements.

5. Select correct quantities of materials as per job requirements.

6. Install auxiliary terminal cabinet as per job requirements.

7. Set up cable lay out and installation equipment in accordance with

manufacturers and job requirements.

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

8. Identify cable pulling and installation requirements and constraints

from plan and site inspection as per job requirements.

9. Observe bending radius and loops tolerance for cable materials at

all times.

10. Proper pulling materials are installed and tensioned to required

specification.

11. Final checking are made to ensure that work conforms with

instruction and job requirements.

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

QUESTIONING TOOL

Questions to probe the candidate’s underpinning Satisfactory

knowledge response

Extension/Reflection Questions Yes No

1. Why do you need to familiarize the different tools,

materials and equipments?

Answer; To easily locate and prepare the materials, tools

and equipments needed as per job requirements.

2. What are the requirements needed before starting the

installation process?

Answer; Observe OHS; Verify the availability of materials,

tools and equipments.

3. Why do we have to familiarize in all electrical symbols

and interpret the correct drawing?

Answer; To easily follow the correct cable lay out, wiring,

conduit, cable tray, wire ways and distribution panel and

auxiliary terminal cabinet installation as per job

requirements.

4. Why do we have to read and understand the manual or

guide?

Answer; To easily follow and perform the correct

procedures.

Safety Questions

5. Why do we have to strictly follow the OHS?

Answer; To avoid incidents in the work place

6. Is it necessary to verify the sizes of conductor to be

use? And Why?

Answer; Yes, following the correct use of conductor as per

standard will avoid overloaded of electrical current.

7. Why do we need to replace substandard materials?

Answer; To avoid short circuit.

8. Is it necessary to double check GFCI before use? And

Why?

Answer; Yes, To avoid sudden electrical shock, and

equipment damage.

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

Contingency Questions

9. What will you do, if you see or encounter fire in the

workplace?

Answer; Sound the alarm and use the correct type of fire

extinguisher to extinguish the fire.

10. How can we be sure that the tools are in good and safe

condition and materials are the correct as per job

requirements?

Answer; Insulation of tools must be thoroughly checked to

ensure it is safe for electrical use and double check

materials labelling and specification.

11. Why do we need to check wiring of electrical

equipment regularly?

Answer; To prevent fire.

12. What will you do if you encounter someone is

electrocuted?

Answer; Switch off the source of electricity and immediately

call emergency.

Job Role/Environment Questions

13. Why do we need to keep working area clean?

Answer; To prevent/avoid Hazard and Risk

14. Why is it so important segregate materials/things in

work area?

Answer; To easily locate materials needed and avoid delay

in actual performance

15. Why do we need to dispose unnecessary items?

Answer; Maintaining cleanliness of the work area can avoid

exposure to hazard and risk

Rules and Regulations

16. Why do we need to get involved in OHS management?

Answer; To foster a safe working environment

17. Why is it so important to follow the standard

procedure of training?

Answer; In order for us to easily achieve the goals of the

training

18. Why is it so important to follow the standard

procedures of job requirements?

Answer; Compliance to standard procedures ensured the

quality and safety of work.

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

19. Why do we need to follow the rules and regulations of

training Industry or Institution?

Answer; Compliance with rules and regulations showed

respect and attitude of candidate who can easily achieve

the objectives of training.

20. Give at least two (2) precautionary measures while on

the training?

Answer; 1. Observe OHS and use of PPE

2. Remove any metal accessories from your body

to avoid statics or electrical shock.

The candidate’s underpinning Satisfactory Not

knowledge was: Satisfactor

y

ELECTRICAL Date Developed: Document No.

Oct. 2019 to Feb. 2020 Issued by:

INSTALLATION

Date Revised:

AND

MAINTENANCE Developed by:

NC II ARTHURO G. RAMOS

Revision # 01

You might also like

- Evidence PlanDocument13 pagesEvidence PlanRobert Rosales Respicio100% (1)

- Barangay Health Services NC IIDocument114 pagesBarangay Health Services NC IIRizaNo ratings yet

- CSS 21st CenturyDocument62 pagesCSS 21st Centuryirish ragasa100% (1)

- 3 EimDocument115 pages3 EimCzar Ina100% (2)

- 4B. Tna-VDocument3 pages4B. Tna-VJohn Lester M. Dela Cruz100% (1)

- Philippine Electronics and Communication Institute of TechnologyDocument1 pagePhilippine Electronics and Communication Institute of TechnologyJay-Ar Cuevas Salve100% (1)

- Training Activity MatrixDocument3 pagesTraining Activity MatrixEmil D. Padullon100% (1)

- Supervise Work-Based LearningDocument43 pagesSupervise Work-Based LearningLiezelNo ratings yet

- Sample CBLMDocument17 pagesSample CBLMJericho Padilla100% (1)

- F11 - CBC Auto NC-1Document46 pagesF11 - CBC Auto NC-1Ait BiñanNo ratings yet

- Competency Based Learning Material: S: P F & B Q: F P NC Ii U C: I E P P M T: I E P PDocument51 pagesCompetency Based Learning Material: S: P F & B Q: F P NC Ii U C: I E P P M T: I E P PErethro CytesNo ratings yet

- Institutional Assessment ToolDocument13 pagesInstitutional Assessment ToolIris Daphne Badoy100% (1)

- Core 1 Session PlanDocument4 pagesCore 1 Session PlanOphir AycochoNo ratings yet

- Training Activity MatrixDocument5 pagesTraining Activity MatrixALWIN P. INGUANo ratings yet

- CBLM Basic 1Document68 pagesCBLM Basic 1Rico EsponillaNo ratings yet

- Data Gathering Instrument For TraineeDocument6 pagesData Gathering Instrument For TraineeRinalyn G. CanetesNo ratings yet

- Facilitate Learning SessionDocument8 pagesFacilitate Learning SessionJoviner Yabres LactamNo ratings yet

- TRB EimDocument9 pagesTRB EimMay EsbanNo ratings yet

- Session Plan - All BasicDocument15 pagesSession Plan - All BasicFernando PradoNo ratings yet

- Application Form With Admission SlipDocument2 pagesApplication Form With Admission SlipEelha Adad AleemanNo ratings yet

- Integrated-CLM CORE SMAWDocument3 pagesIntegrated-CLM CORE SMAWMICHELLE BITALASNo ratings yet

- 5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalDocument35 pages5 Yoyoy 2 - CBLM Common Using Hand ToolsfinalGlaiza Magistrado MonteNo ratings yet

- CBLM Practice Career ProfessionalismDocument57 pagesCBLM Practice Career ProfessionalismBhel OpmeitneubNo ratings yet

- Perform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Document7 pagesPerform Pre and Post Operation Procedures On Vehicles Under Lto Restricition Codes 6 To 8Jason MandelaNo ratings yet

- Inventory of Training ResourcesDocument3 pagesInventory of Training ResourcesKarlo Asico100% (1)

- Pvsi NC Ii CBLM Core Competency 5 Perfor PV Systems Testing and CommissioningDocument128 pagesPvsi NC Ii CBLM Core Competency 5 Perfor PV Systems Testing and CommissioningFRANCIS BERJA100% (1)

- TESDA Circular No. 107-2021Document31 pagesTESDA Circular No. 107-2021Wayne ManabatNo ratings yet

- Cbc-Competency Based Curriculum EpasDocument91 pagesCbc-Competency Based Curriculum EpasMapili Amigo Gen100% (1)

- Basic4 Practice Occupational Health and Safety ProceduresDocument92 pagesBasic4 Practice Occupational Health and Safety ProceduresDreana MarshallNo ratings yet

- Instruction:: TESDA-SOP-CACO-07-F22 To Be Filled Out by Processing OfficerDocument1 pageInstruction:: TESDA-SOP-CACO-07-F22 To Be Filled Out by Processing OfficerMaryrose MacabuhayNo ratings yet

- F11 CBC Eim NC IiDocument63 pagesF11 CBC Eim NC IiMarveneth Nawong100% (1)

- INVENTORY of TRAINING RESOURCESDocument4 pagesINVENTORY of TRAINING RESOURCESCharis AbadNo ratings yet

- CBC New-BPPDocument61 pagesCBC New-BPPRegean EllorimoNo ratings yet

- SESSION PLAN NC III AGRI-CROPS (Control Weeds)Document4 pagesSESSION PLAN NC III AGRI-CROPS (Control Weeds)Ruebenson Acabal100% (1)

- f01 Training Activity MatrixDocument2 pagesf01 Training Activity MatrixEmmer100% (1)

- CBC EIM 21stDocument94 pagesCBC EIM 21stSpti Manpower100% (3)

- 2a. TESDA-OP-CO-01-F11 CBC EIM NC II FINAL AND CONSOLIDATEDDocument67 pages2a. TESDA-OP-CO-01-F11 CBC EIM NC II FINAL AND CONSOLIDATEDRommel SelgaNo ratings yet

- INSTRUCTION: Put A Tick ( ) Mark On The Appropriate Column. Write YourDocument3 pagesINSTRUCTION: Put A Tick ( ) Mark On The Appropriate Column. Write YourGejel MondragonNo ratings yet

- Tm1 Pre-Test Answer SheetDocument2 pagesTm1 Pre-Test Answer SheetJayson Deocareza Dela Torre100% (1)

- Kleah PorfolioDocument84 pagesKleah PorfolioKleah OrtuosteNo ratings yet

- CBC - Smaw NC IDocument56 pagesCBC - Smaw NC ILeo Loquinario Jr.No ratings yet

- CBLM SampleDocument48 pagesCBLM SampleMieflor PatilanoNo ratings yet

- Maintain - Training - Facilities Muah MuahDocument19 pagesMaintain - Training - Facilities Muah MuahSalvador MiraNo ratings yet

- Competency-Based-Curriculum-EIM-NC-II-Blended FooterDocument87 pagesCompetency-Based-Curriculum-EIM-NC-II-Blended FooterDiana DainaNo ratings yet

- CBLM FinalDocument56 pagesCBLM FinalGaygo Gaygo75% (4)

- Tm1 Answer WrittenDocument6 pagesTm1 Answer WrittenHarris MalakiNo ratings yet

- Self Assessment Check On EPasDocument9 pagesSelf Assessment Check On EPasAra CNo ratings yet

- CBC - Carpentry NciiDocument69 pagesCBC - Carpentry NciiMayciel Jaralve Tuyac-HipulanNo ratings yet

- Driving NC IiDocument8 pagesDriving NC IiMiko Salvacion BrazaNo ratings yet

- Sag Eim NciiDocument2 pagesSag Eim NciiBon CalderonNo ratings yet

- Progression & Achievement Chart For EIM NCIIDocument20 pagesProgression & Achievement Chart For EIM NCIIVincent LambanNo ratings yet

- Job SheetDocument2 pagesJob SheetSer Crz JyNo ratings yet

- 2023 TVET Program Registration in The New NormalDocument33 pages2023 TVET Program Registration in The New NormalfirstandlastnamexxNo ratings yet

- Self - Assessment Guide: CONROC205-0609 Carpentry NC IIDocument1 pageSelf - Assessment Guide: CONROC205-0609 Carpentry NC IIandi2akoNo ratings yet

- Competency-Based CurriculumDocument114 pagesCompetency-Based CurriculumMayAnn E DeGuzman100% (1)

- Tesda Portfolio OrderDocument2 pagesTesda Portfolio OrderLuis S Alvarez Jr100% (1)

- Plan Training SessionDocument14 pagesPlan Training SessionJP Sacro100% (1)

- Computer Systems Servicing NC Ii Shop Lay-Out: Quality Control Area and Distance Learning AreaDocument1 pageComputer Systems Servicing NC Ii Shop Lay-Out: Quality Control Area and Distance Learning AreaCandice SumayangNo ratings yet

- Sample Data Gathering InstrumentDocument5 pagesSample Data Gathering InstrumentMaximalistaNo ratings yet

- CBLM or Learning MaterialsDocument38 pagesCBLM or Learning MaterialsMaximalistaNo ratings yet

- Session PlanDocument10 pagesSession PlanMaximalistaNo ratings yet

- CS Form 100 - Revised September 2016Document2 pagesCS Form 100 - Revised September 2016MaximalistaNo ratings yet

- 2014 Issp-TemplateDocument19 pages2014 Issp-TemplateMaximalistaNo ratings yet

- Haiery Mae de Peralta - Social Media Content Calendar TaskDocument8 pagesHaiery Mae de Peralta - Social Media Content Calendar TaskMaximalistaNo ratings yet

- Microsoft Office 2019 KeyDocument2 pagesMicrosoft Office 2019 KeyMaximalistaNo ratings yet

- PDS BlankDocument5 pagesPDS BlankMaximalistaNo ratings yet

- Written Test D Myo Na TMDocument1 pageWritten Test D Myo Na TMMaximalistaNo ratings yet

- Achievement Chart RollyDocument4 pagesAchievement Chart RollyMaximalistaNo ratings yet