Professional Documents

Culture Documents

Phipl PCM U00 00

Uploaded by

pavan patil0 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

PHIPL_PCM_U00_00

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pagePhipl PCM U00 00

Uploaded by

pavan patilCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

5

1 2

2

7

1

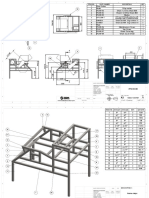

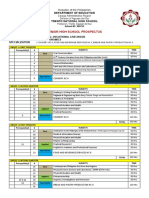

UNIT NO. UNIT NAME MATERIAL DRAWING NO. QTY.

1 Guide Bar AL PHIPL_PCM_U01_00 1

2 UCF BEARIN STD PHIPL_PCM_U02_00 2

3 Pinion M3 EN8 PHIPL_PCM_U03_00 1

9

1

4 Rack M3 EN8 PHIPL_PCM_U04_00 1

5 Air Cylinder STD PHIPL_PCM_U05_00 1

1

8 1 6 Rack Guide EN8 PHIPL_PCM_U06_00 1

1 3

6 1 7 Cylinder Mtg Plate MS PHIPL_PCM_U07_00 1

1

4 8 Rest Plate MS PHIPL_PCM_U08_00 1

1

9 Rib MS PHIPL_PCM_U09_00 1

NAME DATE

JAGRUTI TECHNICAL SERVICES

DESIGNED BY PAP 02-12-2022 PVT.LTD.PUNE 411026.

CHECKED

TITLE

ENG APPR

MGR APPR

BALLOONING

MACHINING TOLERANCE FOR UNTOLERANCE DIMENSIONS DEVIATION FOR LINEAR DIMENSIONS

MATERIAL QUANTITY HARDNESS SIZE DWG NO REV

1. DOWEL TO TAPPED HOLE. +0.1 RANGE OF NOMINAL DIMENSION - 01 HRD- A3 PHIPL_PCM_U00_00 0

NOTE - 2. EDGE TO TAPPED OR CLEARANCE HOLE. +0.1 ABOVE 0.5 6 30 120 315 1000 NOTES:- FILE NAME:

1.ALL DIMENSIONS ARE IN MM.

1. ALL DIMENSIONS ARE IN MM. 3. TAPPED TO TAPPED HOLE. +0.1 UPTO 6 30 120 315 1000 2000 2.DO NOT SCALE DRAWING.

2. REMOVE ALL SHARP EDGES. 4. CLEARANCE HOLE TO CLEARANCE HOLE. +0.2 TOLERANCE +0.1 +0.2 +0.3 +0.5 +0.8 +1.2

3.IF IN DOUBT ,ASK TEAM MEMBER. SCALE: WEIGHT: SHEET NO.- 01

You might also like

- 01.17510.0003 - VDB027 - Rev 00 - ADocument504 pages01.17510.0003 - VDB027 - Rev 00 - AThiagoNo ratings yet

- Glass Crusher CompleteDocument16 pagesGlass Crusher CompleteKhalil Al MahdiNo ratings yet

- 3-A Sanitary Standard For Pipeline Product Recovery Equipment Using Projectiles, Number 101-00Document23 pages3-A Sanitary Standard For Pipeline Product Recovery Equipment Using Projectiles, Number 101-00CHRISTIAN ZAVALA100% (1)

- Lewis Acid-Base Concept: Chapter 13 EDTA TitrationsDocument23 pagesLewis Acid-Base Concept: Chapter 13 EDTA TitrationsEdin AbolenciaNo ratings yet

- stm32 Discovery SchematicDocument4 pagesstm32 Discovery SchematicAli BarakatNo ratings yet

- Rda8810Nl&P&Pl Reference Design SchematicDocument9 pagesRda8810Nl&P&Pl Reference Design SchematicNileshNo ratings yet

- 2BT061 - V1 03 - DL (150121)Document22 pages2BT061 - V1 03 - DL (150121)Riza VirsadaNo ratings yet

- Diagrama ConexionesDocument1 pageDiagrama ConexionesfarospcNo ratings yet

- Acer Aspire - 5338 - 5736G - 5738 - 5738G - 5738DG - 5738 1 08245-1 - JV50-MV - 01 - Finger - Print - BoardDocument1 pageAcer Aspire - 5338 - 5736G - 5738 - 5738G - 5738DG - 5738 1 08245-1 - JV50-MV - 01 - Finger - Print - BoardffffNo ratings yet

- 2BU001 V2.01 DL S56 DualDocument20 pages2BU001 V2.01 DL S56 DualRiza VirsadaNo ratings yet

- Compal LS-5502P Function BoardDocument1 pageCompal LS-5502P Function BoardLive After DeathNo ratings yet

- Lenovo b450 La14-48.4dm04.011 - Nvidia n10m-Gs SW BoardDocument1 pageLenovo b450 La14-48.4dm04.011 - Nvidia n10m-Gs SW BoardComercial D LucasNo ratings yet

- Volvi2 - Usb BD - 1 - 0703Document1 pageVolvi2 - Usb BD - 1 - 0703Francisco RomeroNo ratings yet

- Lns125-I Mio M3 Leg Shield PDFDocument2 pagesLns125-I Mio M3 Leg Shield PDFTeguhNugrohoNo ratings yet

- Ford Galaxy SMAXDocument14 pagesFord Galaxy SMAXAdolfo BelloNo ratings yet

- SM30 - Media Key - Rev SaDocument1 pageSM30 - Media Key - Rev SajjoaquimmartinsNo ratings yet

- Parts Catalogue OP16TDocument68 pagesParts Catalogue OP16Ttiaingrid073No ratings yet

- GPD150 N-Max SeatDocument1 pageGPD150 N-Max SeatThe MainstreamNo ratings yet

- 11/3/2019 8:41 PM C:/Users/User/Desktop/MUGILESH PUO/GUTTER PROJECT/BOARD - BRDDocument1 page11/3/2019 8:41 PM C:/Users/User/Desktop/MUGILESH PUO/GUTTER PROJECT/BOARD - BRDPedang TunggalNo ratings yet

- GDR155-R Aerox ExhaustDocument1 pageGDR155-R Aerox Exhaustady firansyahNo ratings yet

- SM-A600FN/F/GN/G document block diagramDocument32 pagesSM-A600FN/F/GN/G document block diagramKamKamikazeNo ratings yet

- Manual Service Mx5203ms 20Document1 pageManual Service Mx5203ms 20yudiw74No ratings yet

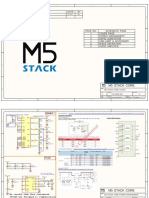

- M5 STACK CORE COVER PAGEDocument6 pagesM5 STACK CORE COVER PAGED RuNo ratings yet

- dm8603 DemoboardDocument6 pagesdm8603 DemoboardAli HarfoushNo ratings yet

- Sualaptop365.edu - VN - X200 - MLB - C1 051-0886 Ra00Document54 pagesSualaptop365.edu - VN - X200 - MLB - C1 051-0886 Ra00Algis SimonaviciusNo ratings yet

- Dell Inspiron 1545 - WISTRON DR1 ROBERTS - NEW CARD BOARD - REV SB PDFDocument1 pageDell Inspiron 1545 - WISTRON DR1 ROBERTS - NEW CARD BOARD - REV SB PDFRamon PortellaNo ratings yet

- Teste PDFDocument1 pageTeste PDFRamon PortellaNo ratings yet

- Asdfasfasdfasdfwer324ewr PDFDocument1 pageAsdfasfasdfasdfwer324ewr PDFRamon PortellaNo ratings yet

- DR1 New Card Board ProjectDocument1 pageDR1 New Card Board Projectmanish_iitrNo ratings yet

- LP008Document20 pagesLP008Rojas RudyNo ratings yet

- VXN155 Vixion R Front Brake CaliperDocument1 pageVXN155 Vixion R Front Brake CaliperShade CormacNo ratings yet

- Va1027 0Document1 pageVa1027 0陆军No ratings yet

- Power OnDocument4 pagesPower OnAlexander MolinaNo ratings yet

- Parts Reference List: Laser PrinterDocument25 pagesParts Reference List: Laser PrinterarieessNo ratings yet

- 820 3213PDFDocument15 pages820 3213PDFayo bermainNo ratings yet

- Lns125-I Mio M3 Seat PDFDocument1 pageLns125-I Mio M3 Seat PDFTeguhNugrohoNo ratings yet

- PT 100 02 3dpower Turbine DrawingsDocument9 pagesPT 100 02 3dpower Turbine DrawingsJoseNo ratings yet

- AntMiner ControlBoard XC7010 V1.01控制板-S9Document15 pagesAntMiner ControlBoard XC7010 V1.01控制板-S9Satvik HardatNo ratings yet

- Compal LS-5659P r10 BTN BoardDocument1 pageCompal LS-5659P r10 BTN BoardQuenitoLucianoJoãoNo ratings yet

- Kim Uno Rev1 SchematicDocument1 pageKim Uno Rev1 SchematicweaponNo ratings yet

- P139 en in R42a 314 653Document6 pagesP139 en in R42a 314 653Cata CatalinNo ratings yet

- Ball Valves Female Female DrawingDocument1 pageBall Valves Female Female Drawingmanoj_sitecNo ratings yet

- A 01 CylinderDocument2 pagesA 01 CylindereeonNo ratings yet

- Moppet finger unloader assembly parts listDocument1 pageMoppet finger unloader assembly parts listYurizki LhzNo ratings yet

- NAV50 Schematics Document I/O Board (USB/Card Reader/Audio/WLANDocument10 pagesNAV50 Schematics Document I/O Board (USB/Card Reader/Audio/WLANQuenitoLucianoJoãoNo ratings yet

- Gambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganDocument1 pageGambar 33 Cowling 1: Nomor Refere Nomor Part Nama Part KeteranganHarris Jum'aniandaNo ratings yet

- CVC Technologies, IncDocument1 pageCVC Technologies, IncYacine MokhtariNo ratings yet

- Documentación Del Sistema de PaletizadoDocument1,184 pagesDocumentación Del Sistema de PaletizadoAnalista Control de CalidadNo ratings yet

- WQT 03Document1 pageWQT 03ruhul01No ratings yet

- SM-A107F Esquematico Completo Anibal Garcia IrepairDocument72 pagesSM-A107F Esquematico Completo Anibal Garcia IrepairOSCAR EDDY MALLCU MENDOZANo ratings yet

- Compal LS-5656P r10 PWR BoardDocument1 pageCompal LS-5656P r10 PWR BoardQuenitoLucianoJoãoNo ratings yet

- GPD155 All New Nmax 155 FenderDocument1 pageGPD155 All New Nmax 155 Fenderyoiki.amruNo ratings yet

- Nordic Semiconductor ASA: nRF9160 Development Kit (PCA10090)Document13 pagesNordic Semiconductor ASA: nRF9160 Development Kit (PCA10090)Thanga raj100% (1)

- DCNTLP 056 06Document2 pagesDCNTLP 056 06frankcengelNo ratings yet

- Product Specification - Nisan Plastic - Alupet RollsDocument1 pageProduct Specification - Nisan Plastic - Alupet RollsHiba NaserNo ratings yet

- Fuente de Laboratorio de Alta CorrienteDocument2 pagesFuente de Laboratorio de Alta CorrienteJulian Javier Canul PoolNo ratings yet

- MQ13-02-DR-3210-IN5911 0: Field / Campo Electrical Room / Sala ElectricaDocument2 pagesMQ13-02-DR-3210-IN5911 0: Field / Campo Electrical Room / Sala ElectricaLuis MantillaNo ratings yet

- TEX30-LCD: User ManualDocument25 pagesTEX30-LCD: User ManualJose Hugo Sosa Salas100% (1)

- RVR Tex702Document44 pagesRVR Tex702mendezp2410No ratings yet

- TP BTN LS 6743Document2 pagesTP BTN LS 6743Ricardo MeloNo ratings yet

- Strength Characteristics of Expansive Soils Using Epoxy Resin and Silty SoilDocument4 pagesStrength Characteristics of Expansive Soils Using Epoxy Resin and Silty SoilsonofalexanderNo ratings yet

- Harare Institute of TechnologyDocument5 pagesHarare Institute of Technologyntando ndlovuNo ratings yet

- Prasetyawan 2020Document9 pagesPrasetyawan 2020Tania CanchanyaNo ratings yet

- Class 2 NSO Preparation Free Sample Test: Aabbaa Ababab Abbabb Aababb A. B. C. DDocument11 pagesClass 2 NSO Preparation Free Sample Test: Aabbaa Ababab Abbabb Aababb A. B. C. DamarpreetsethiNo ratings yet

- The Standard Penetration Test - Its Application and Interpretation - Stroud-1989Document21 pagesThe Standard Penetration Test - Its Application and Interpretation - Stroud-1989Rajeev Kusugal67% (3)

- A Critical Assessment of Positivism and Normativism in EconomicsDocument7 pagesA Critical Assessment of Positivism and Normativism in EconomicsSAMEEKSHA SUDHINDRA HOSKOTE 2133361No ratings yet

- Cookery Fbs BPP NC IIDocument2 pagesCookery Fbs BPP NC IISheryl PanesNo ratings yet

- Labomed Prima DNT SeriesDocument5 pagesLabomed Prima DNT SeriesCarlos EstradaNo ratings yet

- Q2 Grasps G9 - Tle Ap ScienceDocument5 pagesQ2 Grasps G9 - Tle Ap ScienceJC LaraNo ratings yet

- Bus MathDocument100 pagesBus MathApple Michaela Asiatico PaloNo ratings yet

- Sist en 10327 2004Document11 pagesSist en 10327 2004Adrià DraperNo ratings yet

- CAPE Biology 2005 U1 P1Document19 pagesCAPE Biology 2005 U1 P1Reshana SimonNo ratings yet

- Risk Assesment Train StationDocument2 pagesRisk Assesment Train StationCharlie ParkesNo ratings yet

- Instructions: Ashoka University Ma Economics Entrance ExaminationDocument10 pagesInstructions: Ashoka University Ma Economics Entrance ExaminationJayesh RaghuwanshiNo ratings yet

- Pengaruh Pembebasan Tanah Terhadap Keterlambatan Proyek Pembangunan Jalan Tol Cinere - Jagorawi Seksi II BDocument8 pagesPengaruh Pembebasan Tanah Terhadap Keterlambatan Proyek Pembangunan Jalan Tol Cinere - Jagorawi Seksi II BAgsartika YuniNo ratings yet

- National Air Quality Index (IND-AQI) for IndiaDocument40 pagesNational Air Quality Index (IND-AQI) for IndiaRAHUL KUMARNo ratings yet

- Finnish National Annex TO EN 1990-A2 Basis of Structural Design Annex A2: Application For Bridges (Normative)Document22 pagesFinnish National Annex TO EN 1990-A2 Basis of Structural Design Annex A2: Application For Bridges (Normative)chong pak limNo ratings yet

- Coffey Mining MapInfo Advanced 2009Document58 pagesCoffey Mining MapInfo Advanced 2009Ahmed GhoneimNo ratings yet

- D.5 Test Yourself QuestionsDocument2 pagesD.5 Test Yourself QuestionsTaeha KimNo ratings yet

- Esti Mystery 454 Hats and Hat and HatsDocument19 pagesEsti Mystery 454 Hats and Hat and HatsKor16No ratings yet

- Study of Transparent Concrete: Presented ByDocument17 pagesStudy of Transparent Concrete: Presented ByGaurav JainNo ratings yet

- Jurnal Aset (Akuntansi Riset) : Locus of Control, Tekanan Ketaatan Dan Kompleksitas Tugas Terhadap Audit JudgmentDocument12 pagesJurnal Aset (Akuntansi Riset) : Locus of Control, Tekanan Ketaatan Dan Kompleksitas Tugas Terhadap Audit JudgmentSukma ApriyantiNo ratings yet

- The Essence of Architecture as a Territorial EntityDocument11 pagesThe Essence of Architecture as a Territorial Entitymercyella prasetyaNo ratings yet

- Testy Dlja Podg K Egje Po Angl Jaz Macmillan Exam Skills KN Uchitelja 2015 64cDocument66 pagesTesty Dlja Podg K Egje Po Angl Jaz Macmillan Exam Skills KN Uchitelja 2015 64cDaria StryapshinaNo ratings yet

- The Communicative Purpose of The Text: Generic Human Generic Non-Human Participants Passive Voice. Time ConjunctionsDocument2 pagesThe Communicative Purpose of The Text: Generic Human Generic Non-Human Participants Passive Voice. Time ConjunctionsFitriaNo ratings yet

- Poster v2Document1 pagePoster v2Radhakrishna BarNo ratings yet

- DS3400 User's GuideDocument174 pagesDS3400 User's Guidecesco_78No ratings yet

- Multiplication of DecimalsDocument28 pagesMultiplication of DecimalsPaolo P. VinuyaNo ratings yet