Professional Documents

Culture Documents

Arif Tools

Uploaded by

Mahamud HasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arif Tools

Uploaded by

Mahamud HasanCopyright:

Available Formats

Program : B.Sc.

Hon’s in AMT

Year: 2022 Section: AMT Europium

Course Code: AMT-309 ,

Course Title: Tools and techniques of merchandisers

Course Teacher: Ms. Shabnum Mustari

Name: Arif Hosen

Student ID: AMT 2001016024

(i) Details of sample program:

Now, we're discussing about Sample program. In “Garment Industry” there are

many sample use in different buyer.Moreover,buyer wants several types sample

place order to factory.According to buyer requirement factory make variety of

sample.In addition,different buyer different types of sample. Showing some

samples of garments industry in following

1.Proto Sample: Basically, it is the first step sample for order confirmation in

garments industry. Merchandiser presents to buyers proto sample for ordering.

If buyer chose proto sample or need any comments they put into garments or

asked 2 nd time proto sample. Buyers see what looking it & how to adjust

current or further market. Proto sample made by sampling department in

garments industry. Before making proto sample product department must be

careful about proto sample because it is the first view or eyesight in buyer for

order confirming. Every buyer has own requirement for proto sample. Some

buyers want all actual fabric & trims in proto sample & some buyer wants

available fabric & trims in proto stage. So we must take care about proto sample

in the below points.

e must take care about proto sample in the below points.

1.Style or Design.

2.Fittings.

3.Fabric & trims

4.Wash

5.FOB

Normally, proto sample make 3 pcs in the following reasons.

1.1Pc for Buyer or Customer.

2.1Pc for Buying House Merchandiser Counter.

3.1 Pc for Vendor or Garments Merchandiser

2.Fit Sample: Main purpose of fit sample is how to fittings in a body. In modern

times without fitting a garments can not sell into market so fitting of a garments

is the very important part of modern technology in garments sector. Once upon

approval proto sample then the start fit sample. Fit sample is more concern

about accurate pattern. Now days, some of buyers in the world is working now

zero tolerance for a garments body. Every Size has an own accurate pattern.

After making fit sample a technical manager must be wear to dummy to see

what the fitting of a garments body. So, for fit sample a merchandiser &

manager must be cheek in the below points

. 1.Block patter.

2.Adjusted Measurement

3.Wear to fitting.

4.Wash method.

5.Fabric type.

3.PP Sample: PP is called “Pre-production” sample in garments Sector.

Basically, it is the green signal to bulk production. Once upon Fit sample

approval vendor Merchandiser send to buyer PP sample for production

approval. All fabric & trims needed actual for making Pre Production

sample.Without PP sample approval it can not go to bulk production. It is the

important approval before bulk production. A smart merchandiser must be

careful when send PP sample to buyer in the following Points & show PP

sample during Pre-Production meeting.

1.Actual pattern.

2.Actual Fabric & trims.

3.Actual Wash.

4.Fittings.

5.Actual Printing & embroidery.

6.Actual Workmanship.

4.Size Set Sample: Size set sample is the very important sample before

production. Size set sample make all size with update graded nest pattern. The

main purpose is the cheek standard quality as per buyer & fit of the garments.

Manufacturer present to buyer QC before production. Without Size set approval

manufacturer can not go to bulk production. Sometimes size set makes jump

size like S, L, XXL instead of all size.Buyer QC cheek properly standard quality

& fitting of the garments. Normally, Vendor make 2-3 set size set sample.

Before Size make technical department must be careful below points.

1.Size makes ensure.

2.Update pattern Use.

3.Fabric & trims properly cheek

. 4.Wash method cheek in garments.

5.Cheek Quality of Sewing.

6.Cheek finishing items.

5.Top Sample : TOP means “Top of production”. When bulk production is

running then few pieces are taken out middle of the production as per buyer

requirement size. The main reasons are buyer cheek what is the actual quality

follow up in production against Pre-production sample. Without TOP approval

buyer cant not permits the shipment so it is the very important sample for

shipment.

6.Shipmemt Sample: When any style going on finishing buyer ask shipment

sample to cheek properly finishing quality & items what vendor used. And also

buyer keep this sample in further reference can be repeated order aspect of

business feedback in market. Moreover, vendor also needed to keep in future

when buyer asked for repeated order or wanted reference. When kept shipment

sample in future reference a smart merchandiser must careful below points

1.Properly tags.

2.Date & time mention in sample.

3.Wash method mention in sample.

4.Fabric & trims information in tag.

5.Store in suitable place & hang properly

7.Salesman Sample: Salesman Sample is the very important sample to feedback

or comments from customers in market. Basically, it is present or hang on

departmental store to get actual information from customers comments or

feedback from market trend. So, this sample made by vendor as tested order.

Salesman sample made by actual fabric & trims. So, buyers predict sales

forecast on market trend & gets actual response from customers.Sampleman

sample put on retail departmental store. When vendor makes salesman sample

need to more careful about quality. It can be 200-300 pcs & buyer pay for this

samples.

8.Original Sample: Original Sample is the sample which sample buyer give to

manufacturer for development is called original sample. Buyers always realize

which sample is fruitful for business & develop it by manufacturer. When a

smart merchandiser gets original sample from buyers he must thinks & realize

below points.

1.Cheek properly sample design & style.

2.Cheek fabric & trims quality.

3.Cheek block pattern

4.Cheek wash method.

5.Sourcing fabric & trims.

6.Costing idea generate.

9.Photo-Shoot Sample: Photo shoot sample used who has own retail chain

stores throughout country. Generally, it is called catalog buyer. This type of

buyer use model in their sales promoting & grow up in their business market.

They have their own product represent style, color, price to customers by photo

shoot model. These photos then will be printed or used in the catalogs,

advertisements, bill boards and on the inner packing. For this reason buyer need

some photo sample from manufacture. A smart merchandiser sends to photo

sample to buyer he must take care below important points:

1. Cheek size & color as per requirement.

2. Cheek fabric & trims quality.

3. Price & hang tag attached in garments body.

4. Cheek visible appearance.

10. Fabric Sample : Normally, this type of sample just buyer wants & cheek

fabric quality & nature like as fiber content, construction, hairiness, smooth,

comfortable. Before place fabric order buyer wants fabric sample from vendor.

So Merchandiser need make properly fabric sample & send to buyers for

approval place fabric order to suppliers. Before send this sample you should

cheek below points

1.Fabric weight.

2.Fabric content.

3.Fabric constructions.

4.Fabric hand feel.

5.Fabric width

(ii) Explain the duties and responsibilities/ role /

function/ activity/ job restriction of merchandiser in

RMG:

Merchandising Duties and Responsibilities in

Garments Factory:

Merchandising plays the most important role in the apparel industry,

merchandising general procedures are sourcing garments order,

making a sample, price negotiation, price confirmation, order

confirmation, fabrics-trims, and accessories booking, Fabrics-trims and

accessories in-house and arrange QC file. Merchandising fills up the

gap between garments manufacturers and buyers. So, if you are a

stakeholder of the apparel industry then you must have the idea of

merchandising duties and responsibilities in a garments factory.

Some Merchandising Duties and Job Responsibilities in the Apparel

Industry given blew:

1. Product development and price offer to the client.

2. Price confirms with the client and provides PI to the client for

master L/C.

3. Within a short time to collect all order concern document to the

buyer for necessary action.

4. Collect PI for open BTB L/C to arrange the all related materials.

5. To follow-up T & A on a regular basis to ensure on-time delivery

with the right quality and quantity.

6. Lab dip, trims, bulk fabric color, and quality submit to the buyer

for approval.

7. Arrange all materials to make the required

8. Closely monitoring the sampling approval process and on-time

provide to the client for approval and arrange approval for the go-

ahead.

9. Critical path analyzes and meeting with the buyer.

10. PP meeting with the buyer.

11. Size set submits to the buyer and arranges approval for bulk

production.

12. To in-house require materials on time to production

according to T & A.

13. To collect an inventory report from the store.

14. Update factory production and the quality team about every

message of buying a house

15. Sent the required materials (trims, fabric, etc.) third-party

test and provide the report to the client.

16. Regular basis checks with the quality department and makes

ensure correct quality.

17. Make a schedule for inspection with the buyer inspection

team.

18. Space booking to the shipping line and goods handover on

time.

19. Confirm on time and smooth shipment to the buyer

20. If in case fail on-time delivery or correct quality than make

a decision and discuss with the head of department or high

authority and finalized.

21. Time to time reporting to the head of the department

22. Reporting to the high authority in need basis.

23. Send a document for an issue inspection certificate.

24. If in case need than follow up payment issue.

Roles of a Merchandiser in the Garment

Industry:

An apparel merchandiser has to interact with so many departments

during merchandising his product. The merchandiser’s role is to oversee the

order right from the time the order is received from the buyer till calculating the

account profitability and shipment. A garments merchandiser to complete the

order coordinates with the buyer, various departments within the organization,

suppliers, and job worker’s logistics outside the company.

Role of Merchandiser with Buyer and Sampling Department:

The merchandise in the initial stages of order receipt and confirmation

coordinates with the buyer and sampling department for various approvals.

Role of Merchandiser with Buyer:

A garment merchandiser receives the tech pack from the buyer [inquiry]. He has

to work with various departments and prepare a validity report and a feasible

quote. The quote will be intimated to the buyer, price is negotiated and confirmed.

The purchase order is then sent by the buyer along with the LC. At the various

stages of samples, prints embroideries, and accessories are sent to the buyer for

approval. Once the entire approval phase is over goods are produced and shipped.

Role of Merchandiser with Sampling department:

Here garments merchandiser arranges for approval of the first sample it may be

in just one size, preproduction sample may be in jumping size or entire size set,

embroidery, print approval, and placement approvals are also finalized in the

sampling stage. The measurement chart is also checked and confirmed upon any

increase in measurement will lead to an upcharge. The paper pattern is also

completed with all revisions asked by the Buyer. The fabric [Knit downs, bit

looms, and first taka] and accessories are approved at this stage.

Role of Merchandiser with Purchase Department:

The purchase department is divided into two departments such as fabric and

accessories. Working procedure of both departments have discussed the below:

The working procedure with the fabric department:

A garment merchandiser receives the fabric requirement from the buyer. The

parameters to keep in mind are the content, fabric count and construction, weight

/G.S.M, design of the fabric, fabric quality, color, etc. The buyer will send an

image of the fabric design to the garment merchandiser and it is replicated by the

fabric manager along with the suppliers into actual. Garment merchandiser

coordinated with the fabric manager for bit looms and knit downs, then it is sent

to the buyer for approval. On receipt of approval, the first take of around 10-15

meters or 3kgs -5kgs of knit down is asked from the fabric supplier as the case

may be. The pre-production size set is sent to the buyer with all actual print,

embroidery, and accessories. Once the bit looms or knit downs are approved the

price is negotiated and bulk order is placed. The optimum width/dia required is

ascertained in co-ordination with the lectra and production department. In the

case of dying of fabrics again the buyer’s standard should be kept in mind. In

Germany, Azo dyes are forbidden. If the quantities are too small for

manufacturing the stock lots can be offered. Sourcing, Pricing, Right and Timely

deliveries are the main goal of the fabric manager and the garment merchandiser.

Generally, an excess of 5% is ordered then the actual required quantity but this

can vary from organization to organization and the size of the order.

The working procedure with accessories department:

Garment merchandiser receives details of trimmings and accessories required

from the buyer. The parameters to keep in mind are content, dimension, color,

size, logo, etc. e.g. some buyers want nickel-free metallic accessories. If the items

as required by the buyer are not available in the market then options can be

proposed to the buyer. Once the trimmings and accessories are approved the price

is negotiated and bulk order is placed. Sourcing, Right and Timely deliveries are

the main goal of the accessories manager and the garment merchandiser.

Generally, an extra 3% is ordered then the actual required quantity but this can

vary from organization to organization and the size of the order.

Role of garment merchandiser with store department:

A copy of the purchase order with all details for fabric, trimmings, and

accessories are given to the stores. Once the goods are in-house, the store manager

will send a sample to the garment merchandiser and the respective manager for

approval, on receipt of approval of the same the goods will be in-warded. Here

the store manager has totally the quantity ordered against the quantity received

along with the price. Any deviation will have to be reported to the fabric or

trimmings and accessories manager. Garment merchandiser sends the sample of

the bulk fabric and accessories to the buyer for approval. With the help of the

purchase order, the stores understand what quantities are to be dispatched. At the

end of the order, all balance accessories should reach the stores.

Role of Merchandiser with Testing Department:

Testing is generally outsourced there are companies like Texanlab in India that

are sometimes nominated by the buyer. Some huge companies conduct basic tests

in house. Fabric, trimmings, and accessories are tested as per the parameters given

by the buyer. The buyer lays down a tolerance range for acceptance of goods.

Testing of Fabric:

Fabric tests are conducted at various stages as per the requirement of the buyer.

Fabric is tested for strength, width, length, shrinkage, thickness, count,

colorfastness, etc

Testing of Fibre:

Fiber is tested for strength, maturity, trash content elasticity, length, fineness

Testing of Yarn:

Yarn is tested for strength, count, twist, yarn hairiness, yarn crimps, rigidity

Testing of Accessories:

Accessories are tested for content, color fastness any other requirements by the

buyer.

Role of garment merchandiser with EDP [Electronic Data Processing]

department:

A garment merchandiser should be in synch will and all departments regarding

the process of each order. The EDP department feeds this data so that at a click

one gets information on the status of the order and the functioning of various

departments. Also if the performance is within the time frame available. There

are many software packages available e.g. SAP for this work.

Role of garment merchandiser with HR Department:

A garment merchandiser should inform the HR [Human Resource] in case of

manpower, godowns, local transport requirement, local permits, manpower

movements required.

Role of Merchandiser with Production Department:

The merchandiser on the receipt of the order will intimate the production

department. Garments production department will plan whether to produce in-

house or to outsource through other job workers. Production samples are

submitted to the garments merchandiser for buyers’ approval in sizes mentioned

in the LC. Garments merchandiser coordinates daily with the production

department on the progress of the order and clarification of doubts if any. It is the

duty of the garments merchandiser to follow-up on the patterns, fabric-approved

samples for bulk production, and accessories, and all of those should reach the

designated factory in time. After the order is completed, the garments

merchandiser tallies as per inward, outward, and what was consumed and what is

left is exactly as per plan. In case of shortages and excess utilization or rejects

have to be justified in the validity report and balance goods are sent to the stores

by the garments merchandiser and the garments production department.

Generally, the buyer accepts 3% extra of the total good ordered while others do

not accept extra quantities.

Quality Department:

A garment merchandiser should be aware of the company goals and quality

standards along with the quality standards acceptable limit to each buyer. The

Production Manager along with his production team and quality checkers

maintains the quality standards. Based on the style and volume, the production

manager will install check points to maintain quality levels.

Role of garment merchandiser with packing department:

A garment merchandiser co-ordinates with the packing department to pack the

goods as per the style, ratio and carton quality and size, marking details received

by the buyer .e.g. if the buyer wants goods packed in individual poly-bags or

individually packed and then ratio packed in a master poly-bag, etc. The garment

merchandiser needs to understand the importance of adhering to packing details

received from the buyer. The storage and labor cost in foreign countries is very

high. Where and how to store the goods is preplanned by the buyer to have

effective space utilization. According to the order received packing details are

given so that it becomes easy to remove the designated carton and dispatch where

there is a requirement.

Role of garment merchandiser with the commercial department:

A garment merchandiser should provide a copy of all the purchase orders raised

against a particular order to the accounts department to co-ordinate with all

departments, garment merchandiser, supplier for excess, shortage or variance of

price, etc. Bank transfers, L/C negotiation, allocation of funds are done by the

accounts department. The accounts department negotiates with the bank for

payment depending on the type of L/C. Once the order is completed the

documents as required by the buyer are submitted to the bank and payments are

received.

Role of garment merchandiser with shipping department:

A garment merchandiser co-ordinates with the shipping department for vessel

booking, transport, etc, and completion of documents for shipping the order on

completion of the order all documents are submitted to the accounts department

for realizing of funds from the buyer.

Contract profitability:

At the end of the order, the clothing merchandiser will compare the actual and

budgeted costs to ascertain contract profitability. It is on this basis that the

performance of the merchandiser is assessed along with time and action planned

and executed.

Speech from the writer:

If anybody follows this article carefully then he will be definitely able to answer

the following questions in the interview:

1. What is the role of a merchandiser in an organization?

2. How does a merchandiser help in the growth of the organization?

3. Explain the merchandiser role of anyone department?

4. Why is it important for buyers to know buyer quality standards?

5. Why is it essential to take approvals from the buyer at every stage?

You might also like

- Tools &technic MahamudDocument12 pagesTools &technic MahamudMahamud HasanNo ratings yet

- Tools and Techniques - Final.2022Document11 pagesTools and Techniques - Final.2022Mahamud HasanNo ratings yet

- Basic Knowlage of MarchandisingDocument10 pagesBasic Knowlage of Marchandisingtextile028No ratings yet

- Chronological Process of MerchandisingDocument6 pagesChronological Process of MerchandisingAlamesuNo ratings yet

- Internship Report On Marchandising in Garments IndustryDocument47 pagesInternship Report On Marchandising in Garments IndustryHimuSunNo ratings yet

- Garments Merchandising GuideDocument49 pagesGarments Merchandising Guiderkhan9392No ratings yet

- Standard Operating Procedures For Garment Merchandising?: The Chronological Process of Merchandising Is The FollowingDocument6 pagesStandard Operating Procedures For Garment Merchandising?: The Chronological Process of Merchandising Is The FollowingAhmed KarimNo ratings yet

- Sampling Process at An Export HouseDocument12 pagesSampling Process at An Export HouseMayur Somvanshi100% (1)

- Apparel Manufacturing ProcessesDocument16 pagesApparel Manufacturing Processesmmiks2008No ratings yet

- Vital Role of Sampling in Garment ManufacturingDocument5 pagesVital Role of Sampling in Garment ManufacturingHasan TarekNo ratings yet

- Types of textile samplesDocument11 pagesTypes of textile samplesNaimur RahmanNo ratings yet

- Apparel Manufacturing PDF FreeDocument16 pagesApparel Manufacturing PDF Freeole.msfashionNo ratings yet

- HTTPS://WWW - Scribd.com/doc/142923696/tazreen Fire Tragedy ReportDocument95 pagesHTTPS://WWW - Scribd.com/doc/142923696/tazreen Fire Tragedy ReportJIBONNo ratings yet

- Essential roles and responsibilities of a garment merchandiserDocument4 pagesEssential roles and responsibilities of a garment merchandiserKiron KaysarNo ratings yet

- Garment MerchandisingDocument16 pagesGarment MerchandisingaontuNo ratings yet

- Buying TriburgDocument9 pagesBuying TriburgSupriya NandaNo ratings yet

- Activities and Importance of Sample RoomDocument18 pagesActivities and Importance of Sample RoomChuong Nguyen100% (1)

- The Different Types of Samples Made by The Apparel Manufacturers Are Listed BelowDocument5 pagesThe Different Types of Samples Made by The Apparel Manufacturers Are Listed BelowbronicNo ratings yet

- Garment Industry DepartmentsDocument61 pagesGarment Industry DepartmentsIndu Vikasini100% (3)

- Merchandising Job DescriptionDocument2 pagesMerchandising Job DescriptionAhmed KarimNo ratings yet

- 14 Types of Garment Samples ExplainedDocument7 pages14 Types of Garment Samples ExplainedNitin VermaNo ratings yet

- Chan FDDocument16 pagesChan FDChanpreet KaurNo ratings yet

- 14 Different Types of Garment SamplesDocument5 pages14 Different Types of Garment SamplesSnigdhojit BijonNo ratings yet

- 14 Different Types of Garment SamplesDocument5 pages14 Different Types of Garment SamplesSnigdhojit BijonNo ratings yet

- TechpackDocument27 pagesTechpackShalini Yadav33% (3)

- Internship ReportDocument13 pagesInternship ReportBrian MolinaNo ratings yet

- Garments Merchandising: General Duties of A MerchandiserDocument6 pagesGarments Merchandising: General Duties of A MerchandiserMoshtak AhmedNo ratings yet

- SAMPLESDocument9 pagesSAMPLESM. Zubair Alam SiddiquiNo ratings yet

- India's Textile Industry: An Overview of the Garment SectorDocument49 pagesIndia's Textile Industry: An Overview of the Garment SectorInvincible Thakur VijayNo ratings yet

- Mod 3 MerchandisingDocument18 pagesMod 3 MerchandisingJerin JosephNo ratings yet

- Am 1Document34 pagesAm 1Karan VermaNo ratings yet

- Apparel Merchandising 2020Document101 pagesApparel Merchandising 2020Nidhi ChadhaNo ratings yet

- Pre ProductionDocument8 pagesPre ProductionKARISHMA RAJNo ratings yet

- Garments Merchandising & Export ProcedureDocument4 pagesGarments Merchandising & Export ProcedureTanbir Ahsan RubelNo ratings yet

- Type of SamplesDocument4 pagesType of SamplesM. Zubair Alam SiddiquiNo ratings yet

- ASGNMNT Merchandising FunctionsDocument6 pagesASGNMNT Merchandising FunctionsAnju VijayanNo ratings yet

- Process Flow Chart of Garments Sample MakingDocument5 pagesProcess Flow Chart of Garments Sample MakingRana Muhammad Arif Khan100% (1)

- Process Flow and Activities of Garment Sample MakingDocument5 pagesProcess Flow and Activities of Garment Sample MakingRana Muhammad Arif KhanNo ratings yet

- Execution of Balk ProductionDocument4 pagesExecution of Balk ProductionAshraful MithuNo ratings yet

- Role of A Merchandiser in A Garment Industry/ Export House: Ms. Lipsa MohapatraDocument58 pagesRole of A Merchandiser in A Garment Industry/ Export House: Ms. Lipsa MohapatraBhaswati PandaNo ratings yet

- Apparel Manufacturing ProcessDocument46 pagesApparel Manufacturing Processroselyn ayensa100% (1)

- Sample Room ActivitiesDocument16 pagesSample Room ActivitiesMianAbrarAnjumNo ratings yet

- Sampling ProcessDocument9 pagesSampling ProcessSauumye ChauhanNo ratings yet

- Fashion Buying CycleDocument10 pagesFashion Buying CycleAbhishek Kumar100% (9)

- Types of Samples For Completing A Garments OrderDocument14 pagesTypes of Samples For Completing A Garments OrderGR FaisalNo ratings yet

- Duties of Merchandiser in Readymade Garment IndustryDocument2 pagesDuties of Merchandiser in Readymade Garment IndustryJyoti MeherNo ratings yet

- Traning ReportDocument80 pagesTraning ReportAmar Nath Prasad100% (1)

- Subject: Apparel MerchandisingDocument6 pagesSubject: Apparel MerchandisingsatexNo ratings yet

- Short Notes On Bulk ProductionDocument4 pagesShort Notes On Bulk ProductionBashir ahmedNo ratings yet

- Role of Different Samples in The Export Oriented Apparel IndustryDocument7 pagesRole of Different Samples in The Export Oriented Apparel Industrymehedi_mollah50% (2)

- Concepts of Knit Garments Merchandising: March 2014Document9 pagesConcepts of Knit Garments Merchandising: March 2014Naveen NaviNo ratings yet

- Sampling Stages in Apparel ManufacturingDocument2 pagesSampling Stages in Apparel ManufacturingM. Zubair Alam SiddiquiNo ratings yet

- Khushboo PriyambadaDocument121 pagesKhushboo PriyambadanguyendaibkaNo ratings yet

- Concepts of Knit Garments Merchandising: March 2014Document9 pagesConcepts of Knit Garments Merchandising: March 2014s.m.arunNo ratings yet

- Roles of A Merchandiser in Garment IndustryDocument5 pagesRoles of A Merchandiser in Garment IndustryRakib Hasan V PNo ratings yet

- Quality Control for Fashion Start-ups with Chris Walker: Overseas Apparel Production Series, #3From EverandQuality Control for Fashion Start-ups with Chris Walker: Overseas Apparel Production Series, #3Rating: 5 out of 5 stars5/5 (1)

- Understanding Statistics and CorrelationDocument11 pagesUnderstanding Statistics and CorrelationMahamud HasanNo ratings yet

- ArifDocument17 pagesArifMahamud HasanNo ratings yet

- AlokDocument20 pagesAlokMahamud HasanNo ratings yet

- HUM 207, Mid, Fall21Document2 pagesHUM 207, Mid, Fall21Mahamud HasanNo ratings yet

- Invoice 138Document1 pageInvoice 138Mahamud HasanNo ratings yet

- Shabnam MusariDocument13 pagesShabnam MusariMahamud HasanNo ratings yet

- FLG 212 Study GuideDocument19 pagesFLG 212 Study GuidecynthiaNo ratings yet

- Annual Reading Plan - Designed by Pavan BhattadDocument12 pagesAnnual Reading Plan - Designed by Pavan BhattadFarhan PatelNo ratings yet

- A Review of High School Economics Textbooks: February 2003Document27 pagesA Review of High School Economics Textbooks: February 2003Adam NowickiNo ratings yet

- The History of Coins and Banknotes in Mexico: September 2012Document35 pagesThe History of Coins and Banknotes in Mexico: September 2012Mladen VidovicNo ratings yet

- Invoice Request for Digitize Global InovasiDocument1 pageInvoice Request for Digitize Global InovasiAsa Arya SudarmanNo ratings yet

- Ultra Structure of Plant Cell 1Document18 pagesUltra Structure of Plant Cell 1Kumaran JothiramNo ratings yet

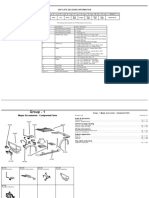

- #5130 Long Dress With Short Sleeves InstructionDocument2 pages#5130 Long Dress With Short Sleeves Instructionmr kdramaNo ratings yet

- Teaching English as a Second Language in Four PhasesDocument18 pagesTeaching English as a Second Language in Four PhasesVia Johnson100% (1)

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- GFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportDocument21 pagesGFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportRayane LimaNo ratings yet

- Synchronous Motor - InstruDocument12 pagesSynchronous Motor - InstruMohit IndurkarNo ratings yet

- CENELEC RA STANDARDS CATALOGUEDocument17 pagesCENELEC RA STANDARDS CATALOGUEHamed AhmadnejadNo ratings yet

- Readings On The History and System of The Common Law - Roscoe PoundDocument646 pagesReadings On The History and System of The Common Law - Roscoe PoundpajorocNo ratings yet

- (Drago) That Time I Got Reincarnated As A Slime Vol 06 (Sub Indo)Document408 pages(Drago) That Time I Got Reincarnated As A Slime Vol 06 (Sub Indo)PeppermintNo ratings yet

- Cooling Tower FundamentalsDocument17 pagesCooling Tower FundamentalsGaurav RathoreNo ratings yet

- BLADED - Theory Manual PDFDocument134 pagesBLADED - Theory Manual PDFdavidlokito100% (2)

- NWQSR - BodyDocument56 pagesNWQSR - BodyRonnie EncarnacionNo ratings yet

- Tecnológico de Monterrey Experiment on Matter and EnvironmentDocument6 pagesTecnológico de Monterrey Experiment on Matter and EnvironmentEvelyn Montserrat Gómez ZentenoNo ratings yet

- Panasonic SA-HT878Document82 pagesPanasonic SA-HT878immortalwombatNo ratings yet

- Luxand FaceSDK DocumentationDocument117 pagesLuxand FaceSDK DocumentationrdhartzNo ratings yet

- Green Tree PythonDocument1 pageGreen Tree Pythonapi-379174072No ratings yet

- Beef & Dairy 2016Document36 pagesBeef & Dairy 2016The Standard NewspaperNo ratings yet

- Main Application of Fans and BlowerDocument5 pagesMain Application of Fans and Blowermissy forlajeNo ratings yet

- Brake CMMDocument262 pagesBrake CMMvishalsachanameNo ratings yet

- Ic T7HDocument36 pagesIc T7HCarlos GaiarinNo ratings yet

- Workbook. Unit 3. Exercises 5 To 9. RESPUESTASDocument3 pagesWorkbook. Unit 3. Exercises 5 To 9. RESPUESTASRosani GeraldoNo ratings yet

- Automation & Artificial Intelligence: Robots and Their ApplicationsDocument93 pagesAutomation & Artificial Intelligence: Robots and Their ApplicationsManal AndhereNo ratings yet

- Aimt ProspectusDocument40 pagesAimt ProspectusdustydiamondNo ratings yet

- Netutils ToturialDocument35 pagesNetutils ToturialLuis SanchoNo ratings yet

- Latest Information Technology Trends 2023Document5 pagesLatest Information Technology Trends 2023Salveigh C. TacleonNo ratings yet