Professional Documents

Culture Documents

Lmsection E2x040

Uploaded by

Jhon MontenegroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lmsection E2x040

Uploaded by

Jhon MontenegroCopyright:

Available Formats

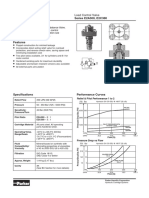

Catalog HY15-3502/US Load Control Valve

Technical Information Series E2A040, E2B040, E2H040

CV

General Description

Threaded Cartridge Style Counterbalance Valve.

Valves

Check

Pilot assisted, designed for motion control

applications. For additional information see

SH Technical Tips on pages LM1-LM4.

Shuttle

Valves

Features

LM • Poppet construction for minimal leakage

• Incorporates direct acting relief valve for overload

Load/Motor

protection

Controls

(3)

• Includes reverse check valve within body, saving space

and minimizing installation cost

FC • Excellent control and very good stability (1)

• Three pilot ratios available, 1.75:1 and 3:1 for cylinders

(3)

(2)

Controls

and 8:1 for motor control

Flow

• Hardened working parts for maximum durability

(2) (1)

PC • Adjustable, preset and tamper resistant versions available

• Preset version is tamper resistant and compact

•

Pressure

All external parts zinc plated

Controls

LE

Elements

Logic

DC Specifications Performance Curves

Directional

Relief & Pilot Performance 1 to 2

Controls

Rated Flow 60 LPM (15.9 GPM)

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

5800 400

Pressure 50 - 350 Bar (725 - 5000 PSI)

MV

Pressure Drop Bar, PSI

Sensitivity: 99 Bar (1435 PSI) 4350 300

Pressure/Turn RELIEF

Manual

Valves

Pilot Ratio E2A040 - 8 : 1 2900 200

SV E2B040 - 3 : 1

E2H040 - 1.75 : 1 PILOT PRESSURE WITH

E2H040

Solenoid

100 BAR LOAD

Valves

1450 100

Cartridge Material All parts steel. All operating E2B040

parts hardened steel.

E2A040

PV 0

LPM 10 20 30 40 50 60

Proportional

Operating Temp. -40°C to +93.3°C (Nitrile) 0

Range/Seals (-40°F to +200°F) GPM 2.6 5.3 7.9 10.6 13.2 15.9

Valves

Flow (Q)

-31.7°C to +121.1°C (Fluorocarbon)

(-25°F to +250°F) Pressure Drop vs Flow

CE PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

Fluid Mineral-based or synthetic with 290 20

Electronics

Compatibility/ lubricating properties at viscosities

PressurDrop Bar, PSI

Coils &

Viscosity of 45 to 2000 SSU (6 to 420 cSt) 218 15

BC Filtration ISO Code 16/13,

145 10

SAE Class 4 or better

PILOTED OPEN 1 to 2

Bodies &

Cavities

& FREE FLOW 2 to 1

Approx. Weight 0.27 kg (0.60 lbs.) 73 5

TD Cavity 68-1 0

(See BC Section for more details) LPM 10 20 30 40 50 60

0

Technical

GPM 2.6 5.3 7.9 10.6 13.2 15.9

Flow (Q)

Data

LM19 Parker Hannifin Corporation

Hydraulic Cartridge Systems

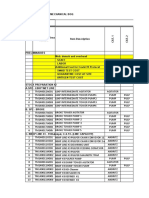

Catalog HY15-3502/US Load Control Valve

Technical Information Series E2A040, E2B040, E2H040

CV

Dimensions Millimeters (Inches)

Valves

Check

'Z'

14 5 AF Hex socket

(0.55) max SH

Shuttle

Valves

17 AF Hex

12 Nm

9 lb ft

torque LM

'Z'

Load/Motor

28.5 'Y' 1.125 AF Hex

Controls

(1.12) 23.25 54 Nm

(0.92) 40 lb ft

torque

FC

M24 x 1.5

Controls

(3)

Flow

PC

64

(2.52) (2)

Pressure

Controls

(1)

LE

Elements

Logic

DC

Directional

Controls

Ordering Information

MV

E2 040 MK3

Manual

Valves

Load Pilot Adjustment Cracking Seals

Control Ratio Style Pressure

Valve

SV

Code Pilot Ratio Code Cracking Pressure Order Bodies Separately

Solenoid

Valves

A 8:1 Omit for no setting (Standard)*

B 3:1 Specify setting if required LB10

H 1.75 : 1 Y: Setting must be specified

Line Body Porting Body PV

*Standard valve is set to crack at 215 Bar

Proportional

Material

(3120 PSI). Valve to be set to 1.3 times

Code Adjustment Style / Kit No. maximum load induced pressure.

Valves

Z Screw Adjust (Standard) Code Porting

T Tamper Resistant (TC1125) Code Seals / Kit No. 251 1/2″ BSP (main) 1/4″ BSP (aux)

Y Non Adjustable Preset N Nitrile, Buna-N (Std.) / 253 1/2″ SAE (main) 1/4″ SAE (aux) CE

Electronics

(SK30059N-1) 259 1/2″ BSP Dual Cavity

Coils &

V Fluorocarbon / 261 1/2″ SAE Dual Cavity

(SK30059V-1)

Code Body Material BC

A Aluminum

Bodies &

Cavities

S Steel

TD

Technical

Data

LM20 Parker Hannifin Corporation

Hydraulic Cartridge Systems

You might also like

- Uen R 62710001Document274 pagesUen R 62710001Jhon Montenegro100% (1)

- Topside Module Design PDFDocument24 pagesTopside Module Design PDFKandousi YassineNo ratings yet

- COSH ManualDocument281 pagesCOSH ManualLeo Buquiran AcabalNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Staad Tut1Document58 pagesStaad Tut1gundulp100% (1)

- S00-2 Weights and Dimensions DS311 (@)Document66 pagesS00-2 Weights and Dimensions DS311 (@)Jhon Montenegro100% (1)

- Rheinzink Standing Seam TechnologyDocument106 pagesRheinzink Standing Seam TechnologyAndrei TeacăNo ratings yet

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- Industrial Sliding DoorsDocument40 pagesIndustrial Sliding DoorsAnonymous CPEha1db7UNo ratings yet

- Soil Nailing ReportDocument37 pagesSoil Nailing Reportavinash chechaniNo ratings yet

- 11kV ChecklistDocument2 pages11kV Checklistsofyan_shah25% (4)

- S04-1 SBH Bolting Head (D)Document86 pagesS04-1 SBH Bolting Head (D)Jhon MontenegroNo ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- Load Control ValvesDocument18 pagesLoad Control ValvesMusa ArysNo ratings yet

- Lmsection E6x060Document2 pagesLmsection E6x060Ηρακλης ΤσαπραζηςNo ratings yet

- Series E2A300, E2C300 General Description Technical InformationDocument2 pagesSeries E2A300, E2C300 General Description Technical InformationJorge de oliveiraNo ratings yet

- Pcsection prh081Document2 pagesPcsection prh081Taller PahrNo ratings yet

- Series B02E3F Technical Information General DescriptionDocument13 pagesSeries B02E3F Technical Information General DescriptionhoiNo ratings yet

- Parker - Valvulas Insertables de PresionDocument20 pagesParker - Valvulas Insertables de PresionElisabet Carreras MarcosNo ratings yet

- A04B2Document2 pagesA04B2Elisabet Carreras MarcosNo ratings yet

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- Unloading Relief ValvesDocument6 pagesUnloading Relief ValvesStar SealNo ratings yet

- Datasheet Rah101Document4 pagesDatasheet Rah101Carlos AntunaNo ratings yet

- RD 102Document2 pagesRD 102Ventas Control HidráulicoNo ratings yet

- Ekomat - WE4 10 Englisch PDFDocument10 pagesEkomat - WE4 10 Englisch PDFharianaNo ratings yet

- Series DSH081 and DSH091 Technical Information General DescriptionDocument4 pagesSeries DSH081 and DSH091 Technical Information General DescriptionEugeniu CebotariNo ratings yet

- 4/2 and 4/3 Directional Control Valve, Hydraulically OperatedDocument2 pages4/2 and 4/3 Directional Control Valve, Hydraulically OperatedVito LaudicinaNo ratings yet

- Ball Segment Valve Si-111 EN Type KVTF and KVXF PN 50Document4 pagesBall Segment Valve Si-111 EN Type KVTF and KVXF PN 50Nicole Andre Tapia SegoviaNo ratings yet

- Datasheet RPE4-10 Ha4039 enDocument10 pagesDatasheet RPE4-10 Ha4039 enwilliamNo ratings yet

- Series DPR103C Technical Information General Description: Proportional ValvesDocument4 pagesSeries DPR103C Technical Information General Description: Proportional ValvesHenry CorreaNo ratings yet

- Toyota 1ND-TV InglesDocument41 pagesToyota 1ND-TV InglesLuis ANGELNo ratings yet

- VSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedDocument2 pagesVSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedCarlos Andrés CuelloNo ratings yet

- Belimo R3..-S.. Datasheet En-GbDocument3 pagesBelimo R3..-S.. Datasheet En-GbLaurentiu LapusescuNo ratings yet

- Válvula Cilindro Inclinación Grúa Effer 120Document2 pagesVálvula Cilindro Inclinación Grúa Effer 120Sergio BelmarNo ratings yet

- 2 Way Poppet Type Bi-Directional Solenoid ValveDocument16 pages2 Way Poppet Type Bi-Directional Solenoid ValveJonathan GiraldoNo ratings yet

- D04B2Document2 pagesD04B2Elisabet Carreras MarcosNo ratings yet

- SQX62UDocument12 pagesSQX62UboroumandNo ratings yet

- Technical Data Sheet R3..-S..: Type OverviewDocument3 pagesTechnical Data Sheet R3..-S..: Type OverviewMohammed AttounNo ratings yet

- 059006XYZ RE18310-13rextonDocument2 pages059006XYZ RE18310-13rextonBryan Edu Curay ZavalaNo ratings yet

- Preliminary - MITTEN HPU Only Rev DDocument120 pagesPreliminary - MITTEN HPU Only Rev DFabyano BrittoNo ratings yet

- LM50B/LM50C SOT-23 Single-Supply Centigrade Temperature SensorDocument8 pagesLM50B/LM50C SOT-23 Single-Supply Centigrade Temperature SensorBadriNo ratings yet

- RAH101Document3 pagesRAH101Elisabet Carreras MarcosNo ratings yet

- Threaded Cartridge ValvesDocument3 pagesThreaded Cartridge ValvesJose LibrerosNo ratings yet

- LMUDocument5 pagesLMUCarlos España CurielNo ratings yet

- Oilflowmeter Electronic FRLDocument6 pagesOilflowmeter Electronic FRLDimas Agil Roeseno KambunaNo ratings yet

- Single Counterbalance: DescriptionDocument2 pagesSingle Counterbalance: DescriptionAtaa AssaadNo ratings yet

- Contamination CodesDocument18 pagesContamination CodesMarlon GarciaNo ratings yet

- Features Specifications: Oil ControlsDocument2 pagesFeatures Specifications: Oil ControlsBruno OliveiraNo ratings yet

- Series D1FS Technical Information: General DescriptionDocument4 pagesSeries D1FS Technical Information: General Descriptionvdmoorthy123No ratings yet

- VSO-SE-DL 055211X03Z Pilot Operated Check SingleDocument2 pagesVSO-SE-DL 055211X03Z Pilot Operated Check SingleCarlos Andrés CuelloNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHlaing MyintNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Dual Counterbalance: DescriptionDocument2 pagesDual Counterbalance: DescriptionMichalNo ratings yet

- Datasheet RPE3-06 Ha4010 EN 01Document10 pagesDatasheet RPE3-06 Ha4010 EN 01angel silvaNo ratings yet

- 290 MotorizedDocument3 pages290 MotorizedM. Gerardo SanchezNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- Series 4D01 (Denison) Characteristics: Directional Control ValveDocument6 pagesSeries 4D01 (Denison) Characteristics: Directional Control ValveKhaled MahranNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- CHM Van 1 Chieu ĐKDocument2 pagesCHM Van 1 Chieu ĐKVăn Công LêNo ratings yet

- Yoshutake GP-2000 P Reducing VDocument17 pagesYoshutake GP-2000 P Reducing VChirasak PaksasornNo ratings yet

- Flowmeters & Monitors: A Range of Cost Saving SolutionsDocument2 pagesFlowmeters & Monitors: A Range of Cost Saving SolutionsDragan LazicNo ratings yet

- Azbil Control ValveDocument8 pagesAzbil Control ValveAwang FaisalNo ratings yet

- AB31-41-42-Katalog-en-130111 Valvula de Prueba de Fuga PDFDocument14 pagesAB31-41-42-Katalog-en-130111 Valvula de Prueba de Fuga PDFAlejandro Alex EnriquezNo ratings yet

- PBS2CDocument2 pagesPBS2CMarusya KlimovaNo ratings yet

- SS2 8110 0600 07Document4 pagesSS2 8110 0600 07rullycosta85No ratings yet

- TESCCOOM 54-52: SpecificationsDocument4 pagesTESCCOOM 54-52: SpecificationsMFERRNo ratings yet

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 pagesMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoNo ratings yet

- Izn Two Stage CompressorDocument2 pagesIzn Two Stage CompressorLhexter Mhervin CoNo ratings yet

- Datasheet R930001664Document2 pagesDatasheet R930001664Анатолий РябухаNo ratings yet

- 2Document16 pages2nivas12155No ratings yet

- Electric Diagram PDFDocument95 pagesElectric Diagram PDFJhon MontenegroNo ratings yet

- 10-Ds311 Water Inflated Bolt Hydraulic Diagram - 77018750 - KDocument1 page10-Ds311 Water Inflated Bolt Hydraulic Diagram - 77018750 - KJhon MontenegroNo ratings yet

- 14-311 Range Airwater Options Hydraulic Diagram - 77018795 - PDocument1 page14-311 Range Airwater Options Hydraulic Diagram - 77018795 - PJhon MontenegroNo ratings yet

- 18 PCIR Action PlansDocument48 pages18 PCIR Action PlansJohanne Rhielle OpridoNo ratings yet

- SteelDocument24 pagesSteelsaranya rNo ratings yet

- Yadav Basti 1Document1 pageYadav Basti 1anvaya coNo ratings yet

- RAB MEIA MechanicalDocument362 pagesRAB MEIA MechanicalArif BinorikaNo ratings yet

- QUIZ 1 11 TPM Kode ADocument2 pagesQUIZ 1 11 TPM Kode AWejang AlvinNo ratings yet

- Sae J217-2016Document3 pagesSae J217-2016tiramisuweitaoNo ratings yet

- GYPROC LEEDv4 GenericBrochureDocument40 pagesGYPROC LEEDv4 GenericBrochureKoala Tube88No ratings yet

- Electrical Daily Report (January 2023)Document60 pagesElectrical Daily Report (January 2023)Inghon SilalahiNo ratings yet

- Impact of Technology in Construction ManagementDocument6 pagesImpact of Technology in Construction ManagementIJRASETPublicationsNo ratings yet

- 004 Dam Cross Section Optimization Collahuasi Copper Project ChileDocument10 pages004 Dam Cross Section Optimization Collahuasi Copper Project ChileAfuye Oluyemi IbiyinkaNo ratings yet

- Filling Station Case StudyDocument22 pagesFilling Station Case StudyTasnia ZahidNo ratings yet

- Beijing Urban Construction Group Co., LTD PT. Wijaya Karya (Persero) Tbk. PT. Pembangunan Perumahan (Persero) Tbk. Joint OperationDocument88 pagesBeijing Urban Construction Group Co., LTD PT. Wijaya Karya (Persero) Tbk. PT. Pembangunan Perumahan (Persero) Tbk. Joint Operationeryan arief ramadhanNo ratings yet

- Collet Catcher SubDocument1 pageCollet Catcher SubjasonNo ratings yet

- Calzeta, Erika Faye M.Document16 pagesCalzeta, Erika Faye M.Erika Faye CalzetaNo ratings yet

- Pulastic SP Track 160 (Indoors - Multi Directional)Document4 pagesPulastic SP Track 160 (Indoors - Multi Directional)Halil GüneyNo ratings yet

- Securedge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Document2 pagesSecuredge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Constantin GubavuNo ratings yet

- Villa Esperanto Dic18 EN PDFDocument12 pagesVilla Esperanto Dic18 EN PDFroyal_eagle04No ratings yet

- Firex II Teck Catalogue 1Document42 pagesFirex II Teck Catalogue 1mehmoodvNo ratings yet

- CP 653 BA Technical-information-ASSET-DOC-LOC-1540979Document1 pageCP 653 BA Technical-information-ASSET-DOC-LOC-1540979AdityaNo ratings yet

- AquaArm GepotechDocument3 pagesAquaArm GepotechSomnath ChakrabortyNo ratings yet

- CSSBI-Facts 5 - Understanding Limit States DesignDocument4 pagesCSSBI-Facts 5 - Understanding Limit States DesignFWICIPNo ratings yet

- Dibden Lane - Design and Access Statement - Greenvolt DevelopmentsDocument44 pagesDibden Lane - Design and Access Statement - Greenvolt DevelopmentsMark Watts-JonesNo ratings yet

- Vertical Pile Load Test Procedure - Kentledge MethodDocument1 pageVertical Pile Load Test Procedure - Kentledge MethodDharma Pratap LamgadeNo ratings yet