Professional Documents

Culture Documents

D04B2

Uploaded by

Elisabet Carreras MarcosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D04B2

Uploaded by

Elisabet Carreras MarcosCopyright:

Available Formats

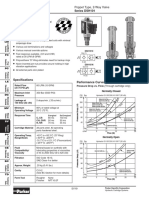

Catalog HY15-3501/US Ball Type Check Valve

Technical Information Series D04B2

CV

General Description

Valves

Ball Type Check Valve. For additional

Check

information see Technical Tips on pages CV1-CV4.

SH

Features

• Low leakage - less than 3 drops/min.

Shuttle

Valves

• Ball type construction for cost effective design

LM • Single and dual pilot pistons available to create pilot

to open check

Load/Motor

(2)

Out

Controls

• Range of cracking pressures available

• Good contamination tolerance

FC • All external parts zinc plated (1) In

Controls

(1) (2)

Performance Curve

Flow

Pressure Drop vs. Flow (Through cartridge only)

PC PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt) Free Flow

290 20

Pressure

Controls

Pressure Drop ( P)

218 15

LE Dimensions Millimeters (Inches)

145 10

Elements

31.8 8

D04B2-0.2

Logic

(1.25) (0.31)

73 5

(2) Out

DC

0

Directional

LPM 40 80 120 160 (1)

Controls

0

GPM 10.6 21.1 31.7 42.3 In

Flow (Q)

MV Specifications

26 AF Hex.

7/8" - 14 UNF 50 Nm

Rated Flow 160 LPM (42 GPM) (37 lb. ft.)

Manual

Valves

Torque

Nominal Flow @ 90 LPM (24 GPM)

7 Bar (100 PSI)

SV

Maximum Inlet 420 Bar (6000 PSI) Ordering Information

Solenoid

Pressure

Valves

Leakage at 3 drops/min. D04B2

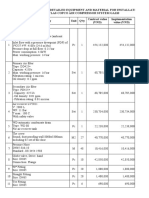

PV 150 SSU (32 cSt) Ball Type Cracking Seals Body Port

Check Valve Pressure Material Size

Proportional

Cartridge Material Steel operating parts,

Valves

hardened steel ball. Code Cracking Pressure Code Body Material

0.0 0.0 Bar (0 PSI) Omit Steel

Operating Temp. -40°C to +93.3°C (Nitrile, Buna-N)

CE Range/Seals (-40°F to +200°F) 0.2 0.2 Bar (3 PSI) Std. A Aluminum

-31.7°C to +121.1°C (Fluorocarbon) 1.0 1.0 Bar (15 PSI)

Electronics

(-25°F to +250°F) 2.1 2.1 Bar (30 PSI) Code Port Size Body Part No.

Coils &

3.4 3.4 Bar (50 PSI) Omit Cartridge Only

Fluid Mineral-based or synthetic with

Compatibility/ lubricating properties at viscosities 6.9 6.9 Bar (100 PSI) 4P 1/4″ NPTF (B10-2-*4P)

BC Viscosity of 45 to 2000 SSU (6 to 420 cSt) 10.0 10.0 Bar (145 PSI) 6P 3/8″ NPTF (B10-2-*6P)

8P 1/2″ NPTF (B10-2-*8P)

15.0 15.0 Bar (217 PSI)

Bodies &

Cavities

Filtration ISO code 16/13, 6T SAE-6 (B10-2-*6T)

SAE Class 4 or better T6T SAE-6 (B10-2-T6T)†

Code Seals / Kit No. 8T SAE-8 (B10-2-*8T)

Approx. Weight .08 kg (.18 lbs.) N Nitrile, Buna-N / T8T SAE-8 (B10-2-T8T)†

TD

(SK30516N-1) 6B 3/8″ BSPG (B10-2-6B)†

Technical

Cavity C10-2 V Fluorocarbon / * Add “A” for aluminum,omit for steel.

(See BC Section for more details) (SK30516V-1) † Steel body only.

Data

CV11 Parker Hannifin Corporation

Hydraulic Cartridge Systems

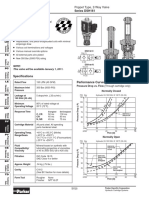

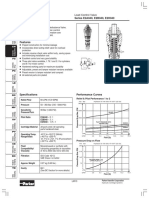

Catalog HY15-3501/US Check Valve

Technical Information Series CVH121P

CV

General Description

Valves

Cartridge Style Check Valve. For additional information

Check

see Technical Tips on pages CV1-CV4.

SH

Shuttle

Features

Valves

• Hardened, precision ground parts for durability

• Fully guided poppet for smooth operation LM

Load/Motor

• All external parts zinc plated

Controls

Out

(2)

Performance Curve FC

Pressure Drop vs. Flow (Through cartridge only) In Out

Controls

(1) (2) In (1)

Flow

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

100 6.9

Free Flow PC

Pressure Drop ( P)

80 5.5

Pressure

Controls

60 4.1

40 2.8 LE

Dimensions Millimeters (Inches)

Elements

20 1.4

Logic

Ø 22.2 40.1 9.0

0 (1.58) (.35)

LPM 30 61 91 121

(.87)

0 DC

GPM 8 16 24 32 (2)

Directional

Flow (Q)

Controls

(1)

MV

1-1/4" Hex.

Specifications 1-1/16-12 UNF-2A

76 Nm

Manual

Valves

Thread

(56 lb. ft.)

Rated Flow 121 LPM (32 GPM) Torque

Maximum Inlet 350 Bar (5000 PSI) SV

Pressure

Solenoid

Ordering Information

Valves

Leakage at 5 drops/min. (.33 cc/min.)

150 SSU (32 cSt) at 350 Bar (5000 PSI)

Cartridge Material All parts steel. All operating parts CVH121P PV

Proportional

hardened steel.

12 Size Cracking Seals Body Port

Valves

Operating Temp. -40°C to +93.3°C (Nitrile) Check Valve Pressure Material Size

Range/Seals (-40°F to +200°F)

-31.7°C to +121.1°C (Fluorocarbon)

(-25°F to +250°F) CE

Electronics

Fluid Mineral-based or synthetic with Code Cracking Pressure Code Body Material

Coils &

Compatibility/ lubricating properties at viscosities Omit 1.7 Bar (25 PSI) Omit Steel

Viscosity of 45 to 2000 SSU (6 to 420 cSt) 65 4.5 Bar (65 PSI) A Aluminum

Filtration ISO code 16/13, BC

SAE Class 4 or better Code Seals / Kit No. Code Port Size Body Part No.

Bodies &

Cavities

Approx. Weight .14 kg (.30 lbs.) Omit Nitrile / Omit Cartridge Only

(SK12-2) 12P 3/4″ NPTF (B12-2-*12P)

Cavity C12-2 V Fluorocarbon / 8T SAE-8 (B12-2-*8T)

(See BC Section for more details) (SK12-2V) 12T SAE-12 (B12-2-*12T) TD

Technical

Form Tool Rougher None 12B 3/4″ BSPG (B12-2-*12B)

Finisher NFT12-2F *Add “A” for aluminum, omit for steel.

Data

CV12 Parker Hannifin Corporation

Hydraulic Cartridge Systems

You might also like

- Direct Acting Relief Valve Technical Specs and Dimensions Series RD102Document2 pagesDirect Acting Relief Valve Technical Specs and Dimensions Series RD102Ventas Control HidráulicoNo ratings yet

- Unloading Relief ValvesDocument6 pagesUnloading Relief ValvesStar SealNo ratings yet

- 190 - Series K2A005Document1 page190 - Series K2A005helderfgmNo ratings yet

- Cvsection cvh081pDocument1 pageCvsection cvh081pVentas Control HidráulicoNo ratings yet

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- Catalog HY15-3502/US - Technical specifications and performance curves for Parker Hannifin DSL082 series 2-way spool valvesDocument2 pagesCatalog HY15-3502/US - Technical specifications and performance curves for Parker Hannifin DSL082 series 2-way spool valvesDaniel MarNo ratings yet

- Pcsection prh081Document2 pagesPcsection prh081Taller PahrNo ratings yet

- Series B02E3F Technical Information General DescriptionDocument13 pagesSeries B02E3F Technical Information General DescriptionhoiNo ratings yet

- Valvula Parker Dsh08Document13 pagesValvula Parker Dsh08Jorge MendozaNo ratings yet

- Lmsection E6x060Document2 pagesLmsection E6x060Ηρακλης ΤσαπραζηςNo ratings yet

- 2 Way Poppet Type Bi-Directional Solenoid ValveDocument16 pages2 Way Poppet Type Bi-Directional Solenoid ValveJonathan GiraldoNo ratings yet

- Series CDP103 / CDPH103 Technical Information General DescriptionDocument2 pagesSeries CDP103 / CDPH103 Technical Information General DescriptionAosama A135790No ratings yet

- Cat Valvula PARKER.p65Document2 pagesCat Valvula PARKER.p65Felipe VenturiniNo ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- Datasheet 2RJV1-06 Ha5021 enDocument4 pagesDatasheet 2RJV1-06 Ha5021 enangel silvaNo ratings yet

- 125 PV 4714Document1 page125 PV 4714Pratik SangamNo ratings yet

- 155 - Series DSH103Document2 pages155 - Series DSH103gerardo floresNo ratings yet

- Svsection 2w2p dsh161Document2 pagesSvsection 2w2p dsh161essamNo ratings yet

- PBS2CDocument2 pagesPBS2CMarusya KlimovaNo ratings yet

- Parker - Valvulas Insertables de PresionDocument20 pagesParker - Valvulas Insertables de PresionElisabet Carreras MarcosNo ratings yet

- Hydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsDocument2 pagesHydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsVito LaudicinaNo ratings yet

- Threaded Cartridge ValvesDocument3 pagesThreaded Cartridge ValvesJose LibrerosNo ratings yet

- Datasheet RPH3-06 Ha4006 en Hydraulic Operated DCVDocument2 pagesDatasheet RPH3-06 Ha4006 en Hydraulic Operated DCVPritesh KoratNo ratings yet

- RAH101Document3 pagesRAH101Elisabet Carreras MarcosNo ratings yet

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- 2 Way Poppet Type Solenoid ValveDocument16 pages2 Way Poppet Type Solenoid ValveFrancisco Javier BurgosNo ratings yet

- Lmsection E2x040Document2 pagesLmsection E2x040Jhon MontenegroNo ratings yet

- A04B2Document2 pagesA04B2Elisabet Carreras MarcosNo ratings yet

- Bray Sizing - OVS 5682Document16 pagesBray Sizing - OVS 5682crvitor1No ratings yet

- Datasheet SC5H-Q3 I Ha5217 enDocument2 pagesDatasheet SC5H-Q3 I Ha5217 enPritesh KoratNo ratings yet

- Pressure Relief Valve, Poppet Type, Direct ActingDocument2 pagesPressure Relief Valve, Poppet Type, Direct ActingRicham HamzeNo ratings yet

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviNo ratings yet

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- Cassapa SVP-02-T-A PDFDocument8 pagesCassapa SVP-02-T-A PDFRNo ratings yet

- Load Control ValvesDocument18 pagesLoad Control ValvesMusa ArysNo ratings yet

- Pressure Reducing Valve Technical Specs and DimensionsDocument2 pagesPressure Reducing Valve Technical Specs and DimensionsRamiro Di PintoNo ratings yet

- 4/2 and 4/3 Directional Control Valve Solenoid GuideDocument4 pages4/2 and 4/3 Directional Control Valve Solenoid GuideRichard MarcolinNo ratings yet

- Rneh5 16Document4 pagesRneh5 16Shirdish PatilNo ratings yet

- Series B10-2 - Technical Information General Description Performance CurveDocument2 pagesSeries B10-2 - Technical Information General Description Performance CurveLuis Fernando Ramírez PromotorNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- C16601 Proinert®2 Selector ValveDocument2 pagesC16601 Proinert®2 Selector Valvevld20082No ratings yet

- Parker GP0130 (Valvula Poporcional LC1)Document2 pagesParker GP0130 (Valvula Poporcional LC1)Daniel AguirreNo ratings yet

- Hanbell Spec Sheet RC2-200BDocument1 pageHanbell Spec Sheet RC2-200BMuhammadAsim100% (1)

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- Pressure Relief Valve, Poppet-Type, Direct-Acting: M28x1.5 - Q 50 L/min (13 GPM) - P 320 Bar (4600 PSI)Document2 pagesPressure Relief Valve, Poppet-Type, Direct-Acting: M28x1.5 - Q 50 L/min (13 GPM) - P 320 Bar (4600 PSI)Richam HamzeNo ratings yet

- VIN Solenoid Valve DSL103seriesDocument14 pagesVIN Solenoid Valve DSL103seriesAndres Cardenas MoyaNo ratings yet

- VÁLVULA RETENÇÃO 2RJV1-06 - M - Ha5021 - ENDocument2 pagesVÁLVULA RETENÇÃO 2RJV1-06 - M - Ha5021 - ENadornelsidneyNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Ficha de Datos UR 219Document4 pagesFicha de Datos UR 219mcuestaNo ratings yet

- Pressure ControlsDocument56 pagesPressure Controlsapi-3854910100% (1)

- Quick Coupling DatasheetDocument1 pageQuick Coupling DatasheetfaridferdiansyahNo ratings yet

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 pagesMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoNo ratings yet

- 2-Flow ControlDocument4 pages2-Flow ControlIslam ElhabsheNo ratings yet

- ROE3-042S5 (S6) : 2/2 Directional Valve, Solenoid Operated, Poppet Type, Blocking, Direct ActingDocument2 pagesROE3-042S5 (S6) : 2/2 Directional Valve, Solenoid Operated, Poppet Type, Blocking, Direct ActingDeutsch themeNo ratings yet

- Data Sheet AgitatorDocument10 pagesData Sheet AgitatorEdi KurniawanNo ratings yet

- Ec 0411 PDFDocument7 pagesEc 0411 PDFmhasansharifiNo ratings yet

- Pulsar VPL Series (Non-Compensated) General Description Technical InformationDocument4 pagesPulsar VPL Series (Non-Compensated) General Description Technical InformationMarcos SuarezNo ratings yet

- 2/2 Directional Valve Solenoid Operated Spool TypeDocument2 pages2/2 Directional Valve Solenoid Operated Spool TypeRamiro Di PintoNo ratings yet

- Parker - Valvulas Insertables de PresionDocument20 pagesParker - Valvulas Insertables de PresionElisabet Carreras MarcosNo ratings yet

- BCsectionDocument71 pagesBCsectionAmir WassimNo ratings yet

- BCsectionDocument71 pagesBCsectionAmir WassimNo ratings yet

- E2b060series Overcenter ParkerDocument11 pagesE2b060series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- E2b040series Overcenter ParkerDocument11 pagesE2b040series Overcenter ParkerElisabet Carreras MarcosNo ratings yet

- Cat. Hy15-3502-R PDFDocument659 pagesCat. Hy15-3502-R PDFRuddy Ral100% (1)

- RAH101Document3 pagesRAH101Elisabet Carreras MarcosNo ratings yet

- A04B2Document2 pagesA04B2Elisabet Carreras MarcosNo ratings yet

- Estudio 2505hDocument162 pagesEstudio 2505hElisabet Carreras MarcosNo ratings yet

- 112-DS-6000-4 (5 of 5) - P&ID Typical Details Standard DrawiDocument5 pages112-DS-6000-4 (5 of 5) - P&ID Typical Details Standard Drawiusaid saifullahNo ratings yet

- Aircraft Maintenance ManualDocument118 pagesAircraft Maintenance ManualcleberNo ratings yet

- Mech Acople Flexible Mod 1nDocument1 pageMech Acople Flexible Mod 1nJONY ROBERT SILVA AGUILARNo ratings yet

- Compress Ible FlowsDocument47 pagesCompress Ible FlowsAdeniyi AleseNo ratings yet

- Hydraulic FlangesDocument60 pagesHydraulic FlangesHotnCrispy CrispyNo ratings yet

- Drillmax Float Valve BrochureDocument16 pagesDrillmax Float Valve BrochureMoni FraileNo ratings yet

- Project Datasheet for Echo Compressor Bleed RingDocument6 pagesProject Datasheet for Echo Compressor Bleed RingTamyizudin Kodri100% (1)

- HP Quiz - IIDocument4 pagesHP Quiz - IISaravanan AkNo ratings yet

- MEP CompanyDocument24 pagesMEP Companyniteen_mnnitNo ratings yet

- Bonomi Euroblock Check ValveDocument1 pageBonomi Euroblock Check ValveBrandon TrocNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Daftar Produk CEUDocument1 pageDaftar Produk CEUZulfan STNo ratings yet

- 221120004-22-MKO 412-2013-KW7I-03-pertemuan Ke 3Document9 pages221120004-22-MKO 412-2013-KW7I-03-pertemuan Ke 3ER IalNo ratings yet

- Mas Rollpro Technologies PVT LTD: General ArrangementDocument1 pageMas Rollpro Technologies PVT LTD: General ArrangementJagdish MishraNo ratings yet

- Rotry Vane Compressors For Vehicle Applications V1.0Document43 pagesRotry Vane Compressors For Vehicle Applications V1.0naing linNo ratings yet

- Cve 305-1,2,3Document56 pagesCve 305-1,2,3Abdurrahman AdigunNo ratings yet

- Free Floating Lever Air/Gas Vents Installation and Operation ManualDocument7 pagesFree Floating Lever Air/Gas Vents Installation and Operation ManualhanshanantaNo ratings yet

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BDH) Service Repair Manual (BDH00001 and Up) PDFDocument26 pagesCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BDH) Service Repair Manual (BDH00001 and Up) PDFfkdmma20% (5)

- D160610-Appendix ConfirmedDocument8 pagesD160610-Appendix ConfirmedNguyễn Đức CườngNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- Pipesim 2015 GL CCEDocument7 pagesPipesim 2015 GL CCELuffy's Fights100% (1)

- Parts BOP FORUMDocument6 pagesParts BOP FORUMAdrian CristianiNo ratings yet

- Chapter 3 Gas TurbineDocument120 pagesChapter 3 Gas TurbineGloria Del Carmen Muñoz100% (2)

- WJMDocument6 pagesWJMAldianivo Nur FaizNo ratings yet

- Oil and Gas Processing Systems: Offshore Standard DNV-OS-E201Document51 pagesOil and Gas Processing Systems: Offshore Standard DNV-OS-E201TIZIANO CIVIDINONo ratings yet

- Port Ps PDFDocument2 pagesPort Ps PDFluisNo ratings yet

- Diaphragma Pump PD20P-X-X-B DatasheetDocument2 pagesDiaphragma Pump PD20P-X-X-B DatasheetsugiantoNo ratings yet

- Water Flow Meter TypesDocument2 pagesWater Flow Meter TypesMohamad AsrulNo ratings yet

- Measuring Volume Flow Rate Using Venturi MeterDocument4 pagesMeasuring Volume Flow Rate Using Venturi Meterlya AhmedNo ratings yet

- LPB 2523/TC/38/BSIII/SRT 6.14/G1150/TML BOGIE SUSPENSION (PARTS LISTDocument330 pagesLPB 2523/TC/38/BSIII/SRT 6.14/G1150/TML BOGIE SUSPENSION (PARTS LISTnilesh asthanaNo ratings yet