Professional Documents

Culture Documents

Risk Assessment Proc - 1

Uploaded by

bilo1984Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Proc - 1

Uploaded by

bilo1984Copyright:

Available Formats

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 1 of 35

IRAQI DRILLING COMPANY

IDC

HAZARD/ ASPECT

IDENTIFICATION, RISK/ IMPACTS

ASSESSMENT AND CONTROL

Nov. 2015

Aug,2015 A OGS HSE Mgr. General Manager

Issue Date ISSUE Prepared BY Approved BY Authorized

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 2 of 35

REVISION RECORD

Revision Date Description of Changes

Number

0 Aug,2015 Issued as draft for review and comment

1 Nov, 2015 Issued for implementation

The custodian of this procedure is the IDC HSE Manager and any

suggested changes to this procedure or queries about the applicability

of it should be addressed to him. He is also responsible for co-

ordinating periodic reviews of this procedure, which will take place every

two years.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 3 of 35

TABLE OF CONTENT

1- PURPOSE

2- SCOPE

3- DEFINITIONS

4- REFERENCES

5- RESPONSIBILITIES

6- PROCEDURE

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 4 of 35

1- PURPOSE

1.1. This procedure covers all activities within IDC activities, including

contractor’s personnel working for IDC. Contractors with their own HSE

arrangements must also comply with this procedure as a minimum.It

follows the general principles of international management systems.

1.2. The purpose of this procedure is to ensure that all staff in IDC operations

or offices are aware of, and understand, the importance of their

responsibilities for hazard identification, risk assessment and risk control

with respect to health, safety and environmental Aspects & Impacts

management.

1.3. Effective risk control will enable IDC to minimise the frequency and

severity of accidents/incidents and ill health, and minimise the

environmental impact of its activities.

1.4. The objectives of this procedure are:

1.4.1. To provide a consistent approach to HSE hazard and risk

management throughout all activities of the Company in order to

minimise HSE risks;

1.4.2. To provide a structured process for HSE risk screening, assessment

and control.

1.5. This procedure is also developed to meet the requirements of HSE

Legislation for ISO 14001:2004 & OHSAS 18001:2007.

2. SCOPE

2.1. This procedure covers all IDC operations, including activities in

offices, warehouse premises and in the Rig (s). As these operations

will have differing organisational structures, it is necessary to use

generic terms for the personnel having responsibilities for risk

screening and assessment. In order to provide clarity, these generic

terms are defined below with examples.

2.2. Further guidance may be obtained from the HSE commission if

required. In certain locations, all of the levels of supervision

described in this procedure may not be in place and the same person

may, therefore, have more than one set of responsibilities.

2.3. All personnel are responsible for working with due regard to health,

safety and the environment, especially those with responsibility for

others, e.g.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 5 of 35

Line Supervisor: The immediate supervisor of the person(s) who will

perform the activities for which the risk screening

and assessment is being conducted.

Line Manager: The manager of the department where the risks of

the activity are being screened and assessed

example, drilling operations manger, maintenance

manager, transportation, general services and

medical.

General Manager: The manager of the relevant Division for the

activities being considered example, operations,

HSE, maintenance, contracts and administration.

3. DEFINITIONS

3.1. General

Hazard: Something with the potential to cause harm,

loss or environmental impact, whether by

injury, illness or damage.

Probability: The likelihood of a hazard being realized.

Hazard Effect: The extent of the consequences (severity),

which could result from the hazard being

realized.

Risk: Risk is the product of the probability and the

hazard effect.

Significant: Indicates that a hazard or risk is anything

other than trivial.

Significant Risk: One which requires some form of positive

safeguard or control measure to eliminate, or

reduce it to an acceptable level;

Control Measure: A precautionary measure, which prevents or

reduces a risk. Control Measures can

include physical, procedural, and human

systems.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 6 of 35

4. REFERENCES

ISO 14001 14001:2004 & OHSAS 18001:2007 / clause 4.3.1

5. RESPONSIBILITIES

5.1. Company General Manager

5.1.1. The General Manager shall ensure that HSE risk screening and

assessments are carried out for all activities.

5.1.2. They shall ensure that actions and controls arising from the

assessments are implemented.

5.1.3. They shall also ensure that suitable and adequate resources of

funding and personnel are made available to conduct the HSE risk

assessments, to implement actions and controls arising from the

assessments, and for training of personnel.

5.2.Department General Managers

Each commission General Manager should ensure that:

5.2.1. HSE risk screening and assessments are conducted for all intended

activities within their remit prior to performing the activity.

5.2.2. All controls and actions arising from such HSE risk screenings and

assessments, including procedures, are developed and

implemented, and monitor the progress of implementation.

5.2.3. HSE risk screening and assessment objectives and targets are set

annually for all personnel in their Division.

5.2.4. Line managers/supervisors are fulfilling their responsibilities in

accordance with the procedure in hand.

5.2.5. All appropriate company and contractor personnel understand all

controls, procedures and precautions that apply to the activities to be

carried out and are trained as necessary.

5.3.Line Manager

Line Managers shall:

5.3.1. Initiate and ensure risk screening/assessment is conducted prior to

any activity under their responsibility;

5.3.2. Formulate a team, including a member from HSE, to conduct the

required risk screening/ assessment exercise for all activities;

5.3.3. Follow up the development and implementation of required controls.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 7 of 35

5.4. Line Supervisors

Line supervisors are required to:

5.4.1. Lead task specific risk assessment

5.4.2. Develop and implement controls

5.4.3. Participate in risk screening teams

5.4.4. Report any impediments to Line Managers

5.5.Role of the HSE Commission.

In addition to the responsibilities described above, the HSE commission will

also be responsible for providing assistance and/or advice in the following

areas:

5.5.1. Developing the scope of HSE risk/Aspect screening and

assessments;

5.5.2. Participating as required in HSE risk/Aspect screening and

assessments and advising on the suitability of control measures

and their implementation;

5.5.3. Reviewing any work produced by external consultants on behalf of

the commissioning Department; and

5.5.4. Assisting with the preparation or review of specific procedures, HSE

plans or briefing documentation.

5.5.5. HSE follow up section to follow up the updating of risk/Aspect

registers

6. PROCEDURE

6.1. FORMULATING THE TEAM

6.1.1. High Level Risk Assessment

6.1.1.1. High Level Risk Assessment should be conducted for all

departmental major activities e.g. rig move , mast raising or

lowering ,equipment modifications, coil tube , perforation testing

high pressure equipment etc., require a separate risk screening

exercise prior to the initiation. The operations Manager in

conjunction with HSE Manager should plan the exercise by

splitting the job into discrete sub-activities and identifying the

required expertise in the team, which will be doing the

assessment.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 8 of 35

6.1.1.2. In general, these high level risk assessment teams should be

led by the Department manager and include line manager and

rig manger of the proposed activity along with a member of the

HSE Dept. and any other expertise that is thought necessary.

6.1.2. Task Related Risk Assessment

6.1.2.1. Task related risk assessments include specific activities e.g

scaffold erection, material handling, loading/offloading,

transportation etc,. The rig manager in this case should

formulate a team led by the supervisor of the specific activity

and including a member of the HSE Dept. along with anybody

specific to the task if deemed necessary.

6.2. RISK SCREENING AND ASSESSMENT PROCESS

6.2.1. Risks/Aspect arise from the interaction of people, equipment,

materials and the work environment. The intent of the risk/Aspect

screening and assessment process is to systematically identify the

hazards, their probability of occurrence and their potential

consequences, screen and assess the risks, develop and

implement control measures, which minimise the risk, and record

the findings of the process.

6.2.2. The Risk Screening and Assessment process consists of five

essential steps.

6.2.2.1. Identify the Hazards/Aspects

6.2.2.2. Evaluate the Risk/Impact

6.2.2.3. Analyse the Risk/Impact

6.2.2.4. Reduce/Control the Risk/Impact

6.2.2.5. Record and Review

6.2.3. The process addresses three fundamental questions:

(a) What can go wrong and how often?

i.e. Identify the hazards and the likelihood of occurrence.

(b) What would happen if something did go wrong?

i.e. Identify the consequences.

The product of the answer to these first two questions establishes the initial

potential risk/impact from the activity.

(c) What can be done to prevent or minimise this risk/Impact?

i.e. Identify and implement the control measures needed.

Each step of the assessment process should be completed before going onto

the next.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 9 of 35

6.3.Identify the Hazards/Aspects

This is the starting point for the risk/Aspect assessment and requires

consideration of all the tasks that are likely to be carried out.

In order to assess the risks/impacts associated with the tasks, a manageable

level of detail is required and this may require the task to be broken down into

discrete steps.

6.3.1. Definition of Tasks

Each task should be identified in terms of:

6.3.1.1. Activities

6.3.1.2. Use of equipment

6.3.1.3. Use of materials/substances

6.3.1.4. Workplace

This should help to build up, in time, an inventory of tasks that Departments

conduct and the type of work carried out in the different workplace areas.

6.3.2. Record the Hazards

6.3.2.1. Once all the tasks have been identified, an inventory

should be drawn up, which lists all the tasks carried out in

each workplace area. These tasks may be considered as

routine, non-routine or generic, and should be fed forward

for risk assessment.

6.3.2.2. To ensure that all hazards /Aspects are identified at this

stage, typical risk screening key words are given in

Appendix 1 and hazard/Aspects identification checklist

tables are provided for guidance in Appendix 2. The

checklists given are not exhaustive and should be

updated each time a new hazard is identified.

6.3.2.3. Look for what could reasonably be expected to cause

harm. Ignore the trivial and concentrate on significant

hazards, which could result in serious harm or affect

several people. Manufacturer instructions and material

data sheets can help put risks in perspective.

6.3.3. Evaluate the Risks

6.3.3.1. Decide who may be harmed and how. Think also about people

who may not be at the work place at the time, e.g. cleaners,

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 10 of 35

visitors, contractors, and members of the public, etc. Is there any

chance that they might be harmed by the activities?

6.3.3.2. Consider the probability of realization of the hazards. Typical

factors which may affect the analysis of probability include:

6.3.3.2.1. The number of times the situation occurs;

6.3.3.2.2. Duration of exposure;

6.3.3.2.3. Quantities of materials involved;

6.3.3.2.4. Environmental conditions, e.g. lighting, temperature;

6.3.3.2.5. Competence of people involved;

6.3.3.2.6. Condition of equipment.

6.3.3.3. Estimate the hazard/Aspect effects, i.e. the consequence of the

risks arising from the hazards. The assessed severity rating of

the hazard effects, with or without any control measures in place,

should be entered on the Risk Assessment form as a number

using the Consequence (Severity) Rating Guidance shown in

Table 1.

6.3.3.4. Severity ratings for environment and asset damage are also

shown for completeness.

6.3.3.5. Consider whether existing precautions are adequate or more

should be done.

6.4. Analyse the Risks

6.4.1. Analyse the initial Risk Rating (Risk Rating With Existing Control

Measures) by multiplying the consequence number by the likelihood

number, to provide a risk rating (or ranking) for each hazard. This

number, on a scale of 4 to 100, should be entered in the Risk/impact

column on the Risk Assessment Form (Appendix 6).

6.4.2. The numbers in the Risk/impact column provide an indication of

priority and of the extent of the risk without any specific control

measures.

6.4.3. The objective of this process is not to arrive at a certain number but

to provide a systematic method of ensuring that consequence and

likelihood ratings are analysed carefully and a record made of the

analysis for future reference and review.

6.4.4. The next step is to consider the existing control measures and

additional control measures needed to control, reduce and minimise

the risk for each identified hazard.

6.4.5. The preferred hierarchy for the control measures is described in

Section 5.4 below.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 11 of 35

6.4.6. The control measures may address the consequence, the likelihood

or both. The required control measures for each hazard should be

recorded alongside each hazard on the Risk Assessment Form.

Appendix 2 provides guidance on the type of control measures that

can be employed for the various hazards.

6.4.7. Residual Risk – to assess the residual risk that remains with the

control measures in place, new hazard effect (consequence) and

likelihood ratings are selected from the scales shown in Tables 2 and

3, respectively, with the inclusion of the control measures. The

product of these two ratings provides a measure of the Residual Risk

and completes the risk analysis stage. The information provided in

the Residual Risk box is used in the next stage of the risk/impact

assessment to evaluate whether the risk is adequately controlled or

not.

6.4.8. Risk/impact Evaluation - this is the final step in the risk assessment

process and will require the assessor to decide if the hazards

identified have been controlled to a suitable level. The risk analysis

stage took into account the control measures currently applied to the

hazard and, therefore, the result of the analysis indicates the amount

of risk that remains, or the residual risk. From this analysis, the risk

matrix shown below in Table 3 indicates whether the residual risk of

each hazard is:

6.4.8.1. Trivial - (T)

6.4.8.2. Adequately controlled - (A)

6.4.8.3. Moderately controlled - (M)

6.4.8.4. Intolerable – (I)

6.4.9. Record the results in the final (right hand) column of the Risk

Assessment forms (IDCHSEF1.1) & Environmental impact

Assessment form(IDCHSEF1.2).

6.4.10. This risk rating assessment will assist in deciding priorities for

action and in deciding the authorisation levels for the work

commensurate with the risk.

6.4.11. In general, high risks may require the provision of considerable

additional resources involving special equipment, training, high

levels of supervision, and consideration of the most effective

methods of eliminating or controlling hazards.

6.4.12. Some situations may require special consideration, including:

6.4.12.1. if the task is new, complex or unfamiliar

6.4.12.2. if the task is unusual or occasional

6.4.12.3. if it is impractical to comply with normal industry standards

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 12 of 35

6.4.12.4. if previously used safeguards are not appropriate for this activity

6.4.13. There may be a need to consider alternative engineering

solutions to eliminate the risk from the task, if no suitable

combination of control measures can be found, which would

reduce risks to an acceptable level.

6.4.14. Lower level risks may be considered as acceptable but actions

should still be taken to try to reduce these risks further if possible

within reasonable limits.

6.5. Reduce / Control Risk

Use the following hierarchy to reduce risks to acceptable levels:

6.5.1. Elimination or Substitution

Eliminate the hazard; e.g. use of lifting equipment instead of manual

handling

6.5.2. Hazard Reduction

Reduce the hazard with an alternative; e.g. use low impact type of

chemicals instead of high impact ( toxic or allergic chemicals

6.5.3. Segregation

Isolate the hazard from people; e.g. fencing of excavations, machine

guards.

6.5.4. Control

Control the hazard by introducing suitable measures, which may be in

either or both of the following two categories;

6.5.4.1. Personal controls - competence based (e.g. well

trained staff)

6.5.4.2. Organisational controls - rule based (e.g. adherence to

work procedures)

6.5.5. Controls should be introduced using the following preferred

sequence:

(a) Procedures, such as permit to work, emergency response,

etc.

(b) training and instruction

(c) supervision

(d) maintenance

6.5.6. Mitigation

Provide personal protective equipment (PPE) as necessary, e.g. hard

hats, boots, gloves, harnesses to prevent falls from height, etc.

Typical control measures are provided in Appendix 3.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 13 of 35

6.5.7. When considering what control measures are already provided or

need to be provided, to control or reduce the risk/impact , the risk

assessor must take into account the possibility of control measures

not being implemented because of human error, lack of

maintenance, difficulty in compliance, complexity of instructions,

etc.

6.5.8. It is essential to discover how the task is actually carried out and

base the assessment on this, rather than assessing the likelihood on

how the task is supposed to be carried out.

6.6. Record the Findings

6.6.1. For each of the more significant hazards identified, e.g. fire, electric

shock, etc, write down the control measures to be used to manage

the risk from the hazard, e.g. for fire, controls including evacuation

and emergency response procedures, fire extinguishers, etc.

6.6.2. Once the risk/ impact assessments have been completed, a Work

Plan should be prepared for the more complex activities. A sample

plan is indicated in Appendix 5.

6.7. Monitor and Review

If there is any significant change to the hazards or consequences, the

risk assessments should be revised and the database updated. Risk/

Aspect assessments registers should be reviewed annually.

7. FORMS

- RISK ASSESSMENT FORM HSEF-1.1

- ASPECT & IMPACT FORM HSEF-1.2

APPENDICES

- APPENDICES #1 RISK SCREENING KEY WORDS

- APPENDICES #2 HAZARD CHECKLISTS

- APPENDICES #3 CONTROL MEASURES GUIDANCE

- APPENDICES #4 RISK ASSESSMENT EXAMPLE

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 14 of 35

TABLE 1 – HAZARD EFFECT (CONSEQUENCE) RATING GUIDANCE

Hazard Outcome R

Consequence Consequence Consequence A

(Asset Damage) (Environmental Damage) T

(Injury) I

(Loss of Reputation)

N

G

Extensive damage. Massive leak/spill.

Multiple fatalities, Downtime. Substantial or Major public concern. 10

total loss of rig or Reputation destroyed.

location. Major clean up. e.g. well

blowout.

Single fatality or Major damage. Massive leak/spill.

permanent disability, downtime ,shutoff one Reputation badly damaged.

e.g. cancer caused by IDC locations Non-conformance with 8

release of carcinogenic regulations.

substance, or asthma.

Major injury, lost time Localised damage. Localised leak/spill.

accident >3 days, e.g. Reputation in media 6

falling from height, Major Equipment

spotlight.

broken bones, damaged

Non-conformance with

temporary health regulations.

effect.

Minor injury, e.g. Minor damage. Minor leak/spill. Public

sprains, burn with Parts replacement, concern. Small loss of 4

caustic chemical, back e.g. pump or compressor reputation. No lasting

or limb strain. failure. effect.

Slight injury / First Aid Slight damage to Slight leak. Spill minimal.

Case, e.g. finger cut. equipment. Minimal cost. No loss of reputation. 2

Minimal or no downtime, Effect contained locally,

e.g. minor vehicle e.g. leak from a chemical

damage. drum.

Note that the use of numbers for consequence rating from the above scale

does not make the risk assessment quantitative. It merely provides a

shorthand way of recording the judgement of consequence (severity) and the

priority for control measures. The person carrying out the risk assessment

should not become too obsessed with the figures; part of the purpose of the

risk assessment is to identify the control measures that need to be

implemented. These figures are designed to assist with the prioritisation of

such measures.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 15 of 35

TABLE 2 - LIKELIHOOD RATING GUIDANCE

Table 2 Likelihood

Likelihood Rating Guidance Rating

Imminent or Acute

Harm from a hazard is imminent or acute if no control measures are

provided at all and/or if one or more of the following factors also apply:-

a) The hazard is a cause of large numbers of injuries or ill health in

national or location statistics;

b) People are exposed to the hazard continuously; 10

c) The hazard is difficult to see e.g. H2S gas;

d) Health, Safety and Environment is not considered high priority by

those involved, including manager and supervisors, e.g. non-adherence to

PTW.

Very Likely

Harm is very likely if the control measures provided depend on an individual

using them on every occasion (e.g. personal protective equipment, PTW 8

system) or if training and supervision are minimal, and/or if one or more of

the above factors are present.

Likely

Harm is likely if the control measures provided depend on an individual

using them or adjusting them on every occasion (e.g. portable gas 6

detectors, safe working procedures), or if training is provided and work

supervised, and/or if any of the factors given for certain or imminent harm

also apply.

Possible

Harm may happen if control measures include measures that do not

depend on the operator but can break down or be removed or defeated

(e.g. pressure safety valve), or if there is no defined system of maintenance 4

or supervision of the control measures. The hazard is a potentially

significant cause of injury or ill health, or for which a number of people are

often exposed.

Unlikely

The circumstances under which harm may happen will reduce to harm

being unlikely if there is a defined system of supervision and maintenance,

and/or if training is provided and repeated regularly. Other factors making 2

harm unlikely include hazards, which are a cause of few injuries or cases of

ill health, or for which a few people are occasionally exposed.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 16 of 35

TABLE 3 - RISK MATRIX

Consequence

Slight Injury Minor Major Injury Single Fatality Multiple

First Aid Injury Lost Time Fatalities

> 3 days

Short Term Minor Health Temporary Permanent

Health Effect Effect Health Effect Disability

Slight Leak Minor Leak Local Leak Massive Leak Massive

Leak

Likelihood 2 4 6 8 10

Imminent 10 20 40 60 80 100

Very Likely 8 16 32 48 64 80

Likely 6 12 24 36 48 60

Possible 4 8 16 24 32 40

Unlikely 2 4 8 12 16 20

4 – 8 (T) Trivial / Tolerable Risk

No action necessary provided control measures are maintained.

12 – 24 (A) Adequately Controlled Risk

Risk is tolerable when control measures identified are implemented and

maintained.

32 – 48 (M) Moderately Controlled Risk

Further Risk Reduction Measures must be considered.

60 – 100 (I)

Intolerable Risk

Risk unacceptable. Seek specialist advice/support.

The results of the risk analyses indicate the extent of the risks. The number

in each box is the risk rating number entered on the risk assessment form,

arrived at by multiplying together the hazard effect (severity) and likelihood

numbers. The higher the number, the higher is the risk rating.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 17 of 35

Appendix 1 RISK SCREENING KEY WORDS

Leadership Personnel Health Safety

Policy Drugs/Alcohol Substances Fire

Commitment Selection Asbestos Explosives

Communications Training Noise Road

travel

Top-down Motivation Poisons Air travel

Elitism Competence Carcinogens Sea travel

Standards Culture Stress

Drowning

Guidance Temporary Biological Electricity

Targets Experience Wild animals Hot work

Information Language Sewage

Confined Spaces

Lessons Literacy Food/Water Heights

Planning Quality Ergonomics Excavation

Organisation Quantity Lighting Diving

Control Certification Vibration Rigging

Responsibility Size/Strength VDUs Hoisting

Feedback Supervision Radiation

Scaffolding

Openness Stand-ins Hot/Cold Power tools

Remote Pressure

Terrain Steam

Long hours Machinery

Guarding

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 18 of 35

Environment Engineering/Change Contractors

Purchasing

Weather Change Contract type QA/QC

Seasons Modifications Contractor quality Purchase orders

Waste Corrosion Experience Specifications

Disposal Erosion QA/QC Receipt

Energy/Resource Stress Planning Inspection

Emissions Metal fatigue Qualification Storage

Discharges Structure Schedule Handling

Water Quality Personnel Segregation

EIA/Regulations Design Communications Inventory

Spills Technical Critical parts

Permits Maintenance Number Spares

Geography Specifications Sub-contractor

Local sensitivities Standards Temporary/Casual HSE equipment

Water intake Inspection Discipline Scrap

Conservation Documentation Enforcement Transportation

Leisure Technical authority Monitoring Insurance

History Audit Local purchasing

Flora/Fauna

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 19 of 35

APPENDIX 1 RISK SCREENING KEY WORDS

(continued)

Operating/Technical Emergency Monitoring Security

Simultaneous Fire/Explosion Audit Terrorism

Start up Spill/Leak Auditor

Bomb

Shut down Dispersion Technical Threat

Isolations Structural Limits Theft

One-off Well control Permit Fraud

Unusual Power Review

Lighting

Assemble Collision Inspection Camera

Dismantle Weather General Hi-jack

Specialist Earthquake Critical

Politics

Expert Flood Hygiene Religion

Shift changes Landslide Environment Revenge

Overhaul Communications Analysis Sabotage

Workover Epidemic Loss Invasion

Procedures Medevac Statistics War

Practices Heart attack Reporting Riot

Instructions Fatality Verification Weapons

Guidelines Media Follow-up Abduction

Support Feedback Hostage

Lost Extortion

Facilities

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 20 of 35

APPENDIX 2 HAZARD CHECKLISTS

1. Rigs and Equipment (including non-powered hand tools)

2. Materials and Substances

3. Place of Work

4. The Working Environment

5. The Method of Work

6. Work Organisation

7. Hazards - Other Types

HAZARD CHECKLIST - 1

Hazards Associated with Plant and Equipment (including non-powered hand tools)

Category Type of Harm Examples of Hazards

Thermal Burns Hot / cold surface:

Fires Blow torch

Scalds Welding flame/arc

Frostbite Refrigerant

Steam

Radiation Ionising: X Rays

- Burns Alpha or Beta Rays

- Cancers Naturally occurring radioactive material

- Blood disorders Low Scale Activity

- Sickness Neutrons

Non-ionising: Micro wave

- Burns Radio frequency

- Melanomas Laser

- Cataracts Ultra violet

- Static shock Infra red

- Induced body currents Electromagnetic (transformers, power

cables)

Noise Hearing loss Machine tools/equipment

Deafness Hand tools

Tinnitus Compressors

Pneumatic tools/equipment

Vibration Vibration white finger Pneumatic drill

Whole body effects Operation of machinery

Circulatory disorders

Overload/defective Crushing Crane overload

due to mechanical Chain sling

failure Eye bolt overload

Scaffold overload

Display screen Eyestrain Poor layout of work station

equipment Headaches Poor furniture

Muscular discomfort Poorly sited screens

Work related upper limb Illegible text

Disorders

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 21 of 35

HAZARD CHECKLIST - 2

Hazards Associated with Materials and Substances

Category Type of Harm Examples of Hazards

Fire/Explosion Burns Hydrocarbons

Combustion Dehydration Timber stack

(e.g. scaffold board store)

Paper store

Grease

Oily rags

Plastic foam

Flammable Burns Hydrocarbon gases, condensate, oils

substances Dehydration Bottled hydrocarbon gases (e.g.

acetylene)

Lubricants

Diesel

Methanol

Paint/thinners/solvents

Hydrogen (e.g. battery room)

Aromatic hydrocarbons (benzene,

toluene, etc)

Oxidising Burns Explosive material

Substances Pyrotechnics (e.g. flares)

Detonators

Health Hazards Acute: Hydrogen Sulphide

Toxic Material - Respiratory irritation Benzene

- Chemical asphyxiation Methanol

- Nervous system effects Isocyanates

- Narcotic effects Corrosion Inhibitors

- Damage to eye Dust

Chronic :- Paints

- Anaemia Degreasing Solvents

- Leukaemia Anaerobic sealant

Primers

Corrosive Material Acute: Sulphuric acid

- Skin, eye, Caustic soda

- Respiratory irritation Hydrochloric acid

- burns Bleaches

- ulceration

- tissue destruction

Irritant Material Acute: Man made-

- Skin, eye and respiratory irritant: mineral fibre

- dermatitis Cement Dust

Sodium hypochlorite

(continued on next page /………)

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 22 of 35

HAZARD CHECKLIST – 2 (continued)

Hazards Associated with Materials and Substances

Category Type of Harm Examples of Hazards

Sensitising Acute:

Materials - respiratory and skin allergic reactions Isocyanates

after sensitisation Gluteraldehyde (biocide)

Terpene

Welding/soldering fumes

Possible Chronic:

Carcinogens - skin, lung cancers Asbestos

- asbestosis, mesothelioma Polyaromatic hydrocarbons

- dermatitis Used engine oil

Asphyxiants Acute (suffocation) and chronic effects Nitrogen

on health Carbon dioxide

Argon

Biological Acute:

- Legionnaires disease Bacterial

- gastro-intestinal disorders Viral

- food poisoning Fungal

Chronic: Biological dusts (flour, hardwood)

- asthma

Contact Cuts, abrasions Swarf

Rough timber

Concrete blocks

Burns, frostbite Molten metal

Frozen food

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 23 of 35

HAZARD CHECKLIST - 3

Hazards Associated with Place of Work

Category Type of Harm Examples of Hazards

Access/Egress Tripping Damaged floors

Slipping Trailing cables

Falls Oil spills

Water on floors

Ice

Debris

Sloping surface

Uneven steps

Changes in floor level

Work at height Falls Fragile roof

Edge of roof

Edge of mezzanine floor

Work on ladder

Erecting scaffold

Hole in floor

Obstructions Striking against Low headroom

Sharp projections

Work over/near Fall into substances: Tank

liquids - Drowning Sump

- poisoning Work over sea

- suffocation

Emergencies Entrapment during escape, eg from fire Locked exits

Obstructed egresses

Long exit route

Transport Fatality, injury Motor vehicle

Air

Marine

Rail

Pedestrian

Natural Hazards Injury Lightning

Illness Flash flood

Earthquake

HAZARD CHECKLIST - 4

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 24 of 35

Hazards Associated with the Working Environment

Category Type of Harm Examples of Hazards

Light Eye strain Glare

Arc eye Poor lighting

(NB : also increases Cataracts Stroboscopic effect

risk of contact with Arc welding

other hazards) Molten metal

Temperature Heat stress Cold room

Hypothermia Outdoor work

Sunburn Hot weather

Melanoma Cold weather

Hypothermia Wind chill factor

Work in rain, snow, etc.

Noise Hearing loss Ambient Noise > 85 dB(A)

Deafness Machinery noise

Tinnitus Relief valve noise

Confined space Asphyxiation Work in tank

Chimney

Unventilated room

Vessel

Silo

Ventilation Nausea Fumes

Tiredness Odours

Tobacco smoke

Extreme (high/low) humidity

HAZARD CHECKLIST - 5

Hazards Associated with the Method of Work

Category Type of Harm Examples of Hazards

Manual Handling Back injury Lifting

Hernia Lowering

Carrying

Pushing

Pulling

Hot / Cold Loads

Rough Loads

Live Loads - Animal / Person

Repetitive Work related upper Keyboard work

Movement limb disorders Using screwdriver

Using hammer and chisel

Production line tasks

Posture Muscle strains/ sprains Seated work

Back pains Work above head height

Work related upper Work with display screen equipment

limb disorders Work at floor level

Stress

HAZARD CHECKLIST - 6

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 25 of 35

Hazards Associated with Work Organisation

Category Type of Harm Examples of Hazards

Contractors

Injuries and ill health to employees by Work above employees

contractors. Use of harmful substances

Work Injuries and ill health to contractors' Contractors welding

employees by work in premises Process fumes

Stored hazardous materials

Organisation of Injuries to employees Monotonous work

work Stress

Too much work

Lack of control of job:

- lack of supervision

- lack of information

- lack of instruction

- lack of training

- inadequate monitoring

Work too demanding/high work rate

Communication

Provision of unsuitable equipment

Work in public Injuries and ill health of public Trailing cables

areas Traffic/plant movement

Obstructions to pedestrians

Work above public

HAZARD CHECKLIST - 7

Hazards - Other Types

Category Type of Harm Examples of Hazards

Attack by animal or Bite Bees

insect Sting Dog

Crushing Horse

Kick Camel

Ill health Scorpion

Fleas

Mosquito

Snake

Attack by people Injury Criminal attack

Illness Angry customer

Post trauma stress Drunken person

Disorder Drug abuser

Mentally ill person

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 26 of 35

APPENDIX 3 CONTROL MEASURES GUIDANCE

Control measures should be applied as described in Section 5.4, using the

hierarchy:

Elimination or Substitution

Eliminate the hazard; e.g. use of sodium hypochlorite solution instead of

free chlorine gas for disinfectant purposes.

Hazard Reduction

Reduce the hazard with an alternative; e.g. use flame retardant scaffold

boards where hot work may be taking place.

Segregation

Isolate the hazard from people; e.g. machine guards.

Control

Control the hazard by introducing suitable measures, which may be in

either or both of the following two categories;

Personal controls - competence based (e.g. well trained staff)

Organisational controls - rule based (e.g. adherence to work

procedures)

Controls should be introduced using the following preferred sequence:

(a) procedures, such as permit to work, emergency response, etc.

(b) training and instruction

(c) supervision

(d) maintenance

Mitigation

Provide personal protective equipment (PPE) as necessary, e.g. hard

hats, boots, gloves, harnesses to prevent falls from height, etc.

The following tables describe typical control measures and are not

exhaustive.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 27 of 35

Appendix 3 Control Measures Guidance

Contents

1. Health Hazards

2. Falling/Swinging/Dropping objects

3. Electricity

4. Noise/Vibration

5. Emergency

6. Equipment Failure

7. Machinery/Equipment

8. Explosion

9. Fire

10. Human Error

11. Entry into Confined Space

12. Pressure

13. Ionising Radiation

14. Slip/Trip/Fall

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 28 of 35

1. Control Measures for Health Hazards

1) Atmospheric Monitoring

2) Barrier Cream

3) Breathing Apparatus

4) Detailed COSHH Assessment

5) Enclosure/Segregation of Contaminant

6) Ergonomic Assessment

7) Forced Extract Ventilation

8) Information

9) Instruction

10) Local Exhaust Ventilation

11) Manual Handling Assessment

12) Medical Surveillance/Screening

13) Minimised Fume/Dust/Vapour Production

14) Natural Ventilation

15) Protective Clothing

16) Regular Cleaning/Decontamination

17) Respiratory Protective Equipment

18) Restricted Workplace Eating / Drinking / Smoking

19) Restricted/Controlled Access to Workplace

20) Substituted Safer Material

21) Supervision

22) Training

2. Control Measures for Falling/Swinging/Dropping Loads

1) Additional Suspension/Support Devices

2) Adequate Lighting

3) Banksman

4) Bumper Protection

5) Competent Lifting Operation

6) Competent Rigging

7) Failure Mode Effect Analysis (FMEA)

8) Fall Restraint Device

9) Load Monitoring

10) Maintenance Programme

11) Movement Restraint Device

12) Overhead Protection

13) Overload Warning System

14) Periodic Examination/Testing/Inspection

15) General Issue Personal Protective Equipment

16) Relocation of Vulnerable Equipment / Depressurisation

17) Restricted Access to Safe Distances

18) Safety Watch

19) Warning Notices

3. Control Measures for Electricity

1) Anti-static

2) Classification of Hazardous Areas (Flammable Gases and Vapours) (Ref BS5345)

3) Earth Monitoring

4) Equipment & Fittings Constructed, Installed & Maintained for use in Potentially Explosive

Atmospheres

5) Fusing

6) Insulation

7) Isolating Transformer

8) Isolation

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 29 of 35

9) Phase Separation

10) Residual Current Device

11) Permit to Work/Limitation of Access

12) Shielding

13) Voltage Reduction

14) Work Carried Out by Competent Person/s

4. Control Measures for Noise/Vibration

1) Audiometry

2) Design Out Noise/Vibration from Equipment

3) Design Out Noise/Vibration from Task

4) Detailed Noise/Vibration Assessment

5) Enclose Noisy/Vibrating Equipment

6) Engineering Controls

7) Hearing Protection Zone

8) Noise/Vibration Exposure Monitoring

9) Noise/Vibration Survey

10) Restricted Access to Noisy/Vibrating Areas

11) Selection and use of Appropriate Hearing Protectors

12) Warning Signs

13) Work Patterns e.g.: Defined Spells of Exposure

5. Control Measures for Emergency

1) Adequate Planning

2) Competent Person/s in Charge

3) Platform PA and Alarm System

4) Emergency Response Procedures

5) Drills/Exercises/Training

6) Provision of Adequate EER Facilities

6. Control Measures for Equipment Failure

1) Appropriate Materials (Fit for Purpose)

2) Certified Equipment/Materials

3) Design Diversity

4) Design Redundancy

5) Failure Mode Effects Analysis

6) Fault Tree Analysis

7) HAZOP

8) Planned Preventative Maintenance Programme

9) Operational Monitoring

10) Regular Inspection/Testing

7. Control Measures for Machinery/Equipment

1) Control System Interlocked Guarding

2) Emergency Stop Device

3) Fixed Guarding

4) Planned Preventative Maintenance Programme

5) Mechanical and Electrical Isolation

6) Permit to Work System

7) General Issue Protective Equipment

8) Warning Signs/Notices

8. Control Measures for Explosion

1) Electrical Equipment and Fittings Constructed, Installed and Maintained in Accordance

with BS5345

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 30 of 35

2) Blast Wall/Enclosure

3) Deluge on Confirmed Gas Detection

4) Earthing/Earth Monitoring

5) Exclusion of Ignition Sources

6) Explosion Venting/Relief

7) Inert Gas Blanketing

8) Leak/Spillage Detection - Portable Gas Monitor

9) Leak/Spillage Detection - Gas Detection System

10) Purging

11) Security of Access to Explosive Materials

12) Permit to Work System

13) Use of Non-Sparking Tools

14) Safety/Fire Watch

15) Pressure Relief Panels

16)

9. Control Measures for Fire

1) Automatic Fire Doors

2) Classification of Hazardous Areas Ref. BS5345

3) Containment/Segregation of Flammable Materials

4) Emergency Shut Down System

5) Exclusion of Ignition Sources

6) Exclusion of Oxygen Sources

7) Fire Extinguishing Protection Systems - Fire, Water, CO2, Halon

8) Passive Fire Protection

9) Fire Watch

10) Fire and Gas Detection System

11) Depressurisation/Blowdown System

12) Inspection/Certification of Premises

13) Self-Closing Fire Doors

14) Portable Fire Extinguishers

15) Portable Gas Monitors

16) Use of Fire Blankets

17) Permit to Work System

10. Control Measures for Human Error

1) Adequate Rest Periods

2) Audit Performance

3) Defined Competence Level

4) Defined Performance Standard

5) Defined Responsibilities

6) Adequate Information

7) Adequate Instruction

8) Adequate Supervision

9) Adequate Training

11. Control Measures for Entry into Confined Space

1) Atmospheric Monitoring of Confined Space

2) Breathing Apparatus

3) Lifeline

4) Safety Watch

5) Forced Ventilation

6) Natural Ventilation

7) Equipment Positively Isolated (Mechanical/Electrical)

8) Adequate Lighting

9) Safe Access/Egress

10) Permit-To-Work System

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 31 of 35

12. Control Measures for Pressure

1) Appropriate Design/Construction Materials

2) Barriers at Safe Distance

3) Certified Equipment/Materials

4) Periodic Inspection/Testing Examination

5) Pressure Monitoring

6) Overpressure Protection e.g.: PSV, Bursting Disc, Pressure Relief Panels

7) Safe Working Pressure Specification

13. Control Measures for Ionising Radiation

1) Competent Personnel

2) Dose Monitoring

3) Health Surveillance

4) Local Rules

5) Personal Protective Equipment

6) Adequate Training

7) Appointed Radiation Protection Supervisor

8) Permit to Work System

9) Warning Signs

10) Area Cordoned Off (Three Dimensionally)

11) Non-essential Personnel Cleared

12) PA Announcements

14. Control Measures for Slip/Trip/Fall

1) Adequate Lighting

2) Appropriate Footwear

3) Openings Covered

4) Edge Protection/Rails/Barriers

5) Fixed Platform/Ladder

6) Good Housekeeping

7) Harness, Line and Attachment

8) Non-slip Surface

9) Periodic Cleaning

10) Periodic Inspection

11) General Issue Personal Protective Equipment

12) Warning Notices

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 32 of 35

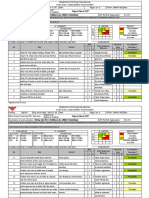

APPENDIX 4 RISK ASSESSMENT EXAMPLE

NO. HAZARD CONSEQUENCE EXISTING RISK ANALYSIS REQUIRED RISK ANALYSIS EVALUATION

CONTROL ADDITIONAL

(EXISTING CONTROL (WITH EXTRA

CONTROLS) MEASURES ONTROLS)

C

SEVE LIKE- RISK SEVE LIKE- RISK

RITY LIHOO RITY LIHOO

D D

Fire of oil Major damage to Reliable ESD 10 4 40 Conduct more 10 2 20 The control

producing assets, potential system, frequent measures must

well for multiple Reliable fire firewater tests be fully

1 fatalities and maintained to

detection system

serious injuries keep them as

Reliable FF system Ensure ESD reliable as

Operating procedure systems possible and

in place as Permit to regularly tested reduce human

Work System in accordance error

with

specification

Extensive

2 Fire of Preventive 10 4 40 Increase 10 2 20 Full

damage (the fuel Maintenance frequency of implementation

fuel tank

tank can blow) System inspections of of Existing and

and possibility of and inspections of equipment Additional

multiple tank and its area Control

fatalities) and Measures

Conduct more Required

equipment (PSV,

frequent

, instruments etc.)

Reliable fire firewater tests

detection system

Reliable FF system Enhance

Operating procedure training of

In place as Permit to firefighting

Work System personnel

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 33 of 35

APPENDIX 5 HSE WORK PLAN EXAMPLE

1 Description of Activity

This generic risk assessment and control arrangements covers the erection and dismantling of

scaffolding on a construction site for work at heights carried out by employees and contractors.

2 Persons at Risk

Personnel erecting and/or dismantling the scaffolding will be especially at risk from the following

hazards. Any other person in the area could also be at risk from falling objects or scaffolding

collapse.

3 Hazards

The significant hazards associated with the erection/dismantling of scaffolding are :-

a) Scaffolding Collapse

b) Adverse Weather (High Wind, Rain, Snow)

c) Falling Objects

d) Person(s) Falling from Scaffolding

e) Inadequate Lighting

f) Open Grating (if applicable)

g) Access/Egress

h) Trapping of Body Parts Between Scaffolding Components or Between Components and

Surfaces

i) Striking People or Equipment with Scaffolding Components

j) Striking/Obstructions

k) Contact with Hot/Cold Surfaces

Others hazards include, but are not restricted to :-

- Particles (Dust from Board Cutting, Debris in Tubing)

- Cuts/abrasions from Sharp Edges, Swarf, Contact with Hand Saws

- Extreme Ambient Temperature

- Stacking/Storing of Scaffolding Components

4 Risk Analysis and Evaluation

The following arrangements should eliminate or reduce the risk from the above hazards to a

tolerable level. The risk assessment on which these are based (identification of the hazards,

analysis of severity and likelihood of the hazards and identification and evaluation of control

measures) is filed in the Site Office. Additional risk assessments must be conducted and

appended to this assessment with details of the appropriate arrangements, if any other hazards

are identified not included above.

5 Arrangements

5.1 Planning and Organising

The (responsible person) shall ensure that scaffolding can be erected and dismantled safely and

efficiently at the work site taking into account specific area hazards, other persons and activities

within the area. Where there is any doubt, the HSE Adviser shall be consulted for advice.

Competent supervisors shall be employed to carry out inspections. All scaffolding shall be

erected, altered or dismantled by competent Scaffolders or under the direct supervision of a

competent person.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 34 of 35

The Site Construction Supervisor shall ensure that the following equipment is provided and

maintained:-

- Safety harness for use when working above 2m.

- Protective clothing (including safety helmet, safety footwear, gloves, warm weather during

extreme cold weather).

- Eye protection.

- Hearing protection (if required by the Workplace Noise Assessment).

- Communication (safety watch to control room), if hot work is involved.

The work plan shall allow for sufficient rest periods during periods of extreme hot/cold weather.

5.2 Management Control

No person shall erect, alter or dismantle any scaffolding unless authorised by the (appropriate

senior person as above) or appointed representative. The supervisor must ensure the following

when scaffolding is to be erected, altered or dismantled:-

- Conformance with BS 5973 : 1993 Code of Practice for Access and Working Scaffolds

and Special Scaffold Structures in Steel.

- Inspection and subsequent tagging of approved scaffolding.

- Compliance with load bearing capacity.

- Work is suspended and the site made safe during extreme weather conditions.

- Inspection of scaffolding prior to continuing work following extreme weather conditions.

- Standby vessel is on location, safety watch posted and overboard discharges noted, if

work over the sea.

- Compliance with manual handling assessment.

- Guard rails and toe / kicker boards are fitted.

- Scaffolding area is barrier off, warning tape/notices are posted and restricted access

imposed.

- Vulnerable/fragile equipment within the area are noted.

- Secure means for lifting/handling/storing of scaffold components are employed.

- High standard of housekeeping.

- Materials and tools are removed from or secured to the scaffolding when not in use.

- Suitable fall arrestors to be worn when working above 1.8 m.

- Ladders are secured.

- Adequate lighting is provided.

- Open areas in floors to be barriered off/hand railed.

- Access/egress routes are unobstructed and alternative escape routes are available.

- Obstructions, protrusions, hot/cold surfaces are noted.

- boards are protected from hot surfaces.

- protection is provided on cut surfaces.

- compliance with workplace noise assessment and confined space risk assessment,

where appropriate.

5.3 Procedures for Serious or Imminent Danger

Any defect noted in the scaffolding equipment must be reported and attended to immediately.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

HAZARD/ ASPECT IDENTIFICATION, RISK/ IMPACTS ASSESSMENT AND

CONTROL

IDC HSEP - 1 PAGE 35 of 35

6. Monitoring and Review

6.1 Inspections

The Site Supervisor (Rig Manager) shall ensure that the equipment and working practices are

maintained to these standards by arranging regular inspections by a competent person(s).

6.2 Risk Assessment Review

This risk assessment and arrangements shall be reviewed at intervals annually or after any

reported complaint, incident or accident, or whenever the activity changes.

ISSUE A Revision 1 ISSUE DATE : Nov, 2015

Prepared by OIL & GAS SKILLS "OGS"

You might also like

- SLB LiftingDocument98 pagesSLB Liftingbilo1984100% (7)

- Appendix E - Monthly Meeting, Kick Off and HSE WorkshopDocument2 pagesAppendix E - Monthly Meeting, Kick Off and HSE WorkshopNaba majeadNo ratings yet

- ISO 45001 Case Study Risk Management INTLDocument2 pagesISO 45001 Case Study Risk Management INTLGlenn MalloNo ratings yet

- Confined Space Rescue PlanDocument4 pagesConfined Space Rescue PlanFranscois Van RooyenNo ratings yet

- Behavior Based SafetyDocument27 pagesBehavior Based SafetySuresh KumarNo ratings yet

- Shell Emergency Preparedness and Office Closure ProceduresDocument6 pagesShell Emergency Preparedness and Office Closure Proceduresbilo1984No ratings yet

- Emergency ResponseDocument32 pagesEmergency ResponseMizerNo ratings yet

- Fsims Opspec PDFDocument398 pagesFsims Opspec PDFBum Joo KimNo ratings yet

- Certified Fire Protection Specialist Exam Questions (230Document4 pagesCertified Fire Protection Specialist Exam Questions (230RajendraNo ratings yet

- Bloodborn Pathogen ProgramDocument22 pagesBloodborn Pathogen Programsitimaezyaroh100% (1)

- SWMS Bored PilingDocument17 pagesSWMS Bored PilingnaraNo ratings yet

- Fatigue Management ProcedureDocument12 pagesFatigue Management ProcedureWakarusa CoNo ratings yet

- Crisis ManagementDocument19 pagesCrisis Managementsssr3103No ratings yet

- Incident Report FormDocument2 pagesIncident Report FormUnachukwu Sopulu SopsyNo ratings yet

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Crisis Management Plan: Revised - March 7, 2012Document214 pagesCrisis Management Plan: Revised - March 7, 2012Exa HeydemansNo ratings yet

- Hazard Report Form: Workplace South Brisbane InstituteDocument3 pagesHazard Report Form: Workplace South Brisbane InstituteAnderson OlivierNo ratings yet

- Employers LiabilityDocument43 pagesEmployers LiabilitysaifulmuslimzNo ratings yet

- Production Risk AssessmentDocument4 pagesProduction Risk AssessmentEmilyNo ratings yet

- Jurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Document3 pagesJurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Anonymous kWfNFb100% (1)

- UPEI Emergency Plan SummaryDocument17 pagesUPEI Emergency Plan SummarySankaranarayanan Chandresekar100% (2)

- Zero HarmDocument2 pagesZero Harmtnsv222No ratings yet

- Inherent V Residual RiskDocument2 pagesInherent V Residual RiskAlephNo ratings yet

- Health and Safety Risk AssessmentDocument2 pagesHealth and Safety Risk AssessmentShahil IslamNo ratings yet

- Chelston Decorators Health and Safety PolicyDocument13 pagesChelston Decorators Health and Safety PolicySam MurrayNo ratings yet

- Library of PD&T QMS Project HSE Moments: Presented By: On DateDocument8 pagesLibrary of PD&T QMS Project HSE Moments: Presented By: On DateSyahril Aizal AhmadNo ratings yet

- SWMS - Blind IstallationDocument12 pagesSWMS - Blind IstallationParasNo ratings yet

- Al Majal QMS - 2018Document19 pagesAl Majal QMS - 2018Adam DeviatteyNo ratings yet

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- Role of Safety OfficerDocument12 pagesRole of Safety OfficerChristian MeanaNo ratings yet

- Accident Causes, Prevention, and Control: NotesDocument7 pagesAccident Causes, Prevention, and Control: NotesGeorge John AmegashieNo ratings yet

- Confined Space Entry PlansDocument6 pagesConfined Space Entry Plansrichard100% (1)

- Covid 19 Emergency Handling ProcedureDocument9 pagesCovid 19 Emergency Handling ProcedureDhananjay PatilNo ratings yet

- Guide Lines For NSC HSE PlanDocument52 pagesGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംNo ratings yet

- NUS CN3135 SHE Management System EssentialsDocument99 pagesNUS CN3135 SHE Management System EssentialsNicklas ReusNo ratings yet

- Fire Risk Assessment FormDocument19 pagesFire Risk Assessment FormGopinath SekarNo ratings yet

- Safety Consulting by SlidesgoDocument42 pagesSafety Consulting by SlidesgoChavez Ordonez ManuelNo ratings yet

- Managing Hazards Through The Hierarchy of ControlsDocument6 pagesManaging Hazards Through The Hierarchy of ControlsAnonymous FmXEu2cHxKNo ratings yet

- 21.0 - Permit To Work Systems v3.1 EnglishDocument18 pages21.0 - Permit To Work Systems v3.1 EnglishjbdejhiuhwNo ratings yet

- 2.1 - Machine GuardingDocument6 pages2.1 - Machine Guardingkumar100% (1)

- Hot Work Program PDFDocument49 pagesHot Work Program PDFAnonymous wtK1AZBiNo ratings yet

- Measuring health and safety performanceDocument31 pagesMeasuring health and safety performancesohaibNo ratings yet

- Sharjah Waterfront City-Sector 2 & Sun IslandDocument2 pagesSharjah Waterfront City-Sector 2 & Sun IslandCaptainNo ratings yet

- HIRAC - Work at Height TemplateDocument8 pagesHIRAC - Work at Height Templateputra2azanNo ratings yet

- Mifa Safety Regulations UKDocument2 pagesMifa Safety Regulations UKnqh2009No ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- Risk and OpportunityDocument2 pagesRisk and OpportunityGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Causes & DefinitionsDocument11 pagesCauses & DefinitionsSayed DarwishNo ratings yet

- Loading & Lifting ProcedureDocument5 pagesLoading & Lifting Procedurekhurram shahzadNo ratings yet

- TBT 30 HousekeepingDocument2 pagesTBT 30 HousekeepingfrancisNo ratings yet

- 1 - ERP - CrisisDocument124 pages1 - ERP - Crisisamira_zainal92No ratings yet

- Location Risk Assessment Form-Part A: Basic Information &: Hazard ListDocument4 pagesLocation Risk Assessment Form-Part A: Basic Information &: Hazard Listapi-330575448No ratings yet

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahNo ratings yet

- Incident ReportDocument5 pagesIncident Reportrizal azizanNo ratings yet

- Presentation and Facilitation Skills Module 1: WorkshopDocument6 pagesPresentation and Facilitation Skills Module 1: WorkshopnoorhidayahismailNo ratings yet

- On-Site Emergency Plan and Reporting FlowchartDocument4 pagesOn-Site Emergency Plan and Reporting FlowchartMd Nurul IslamNo ratings yet

- Holcim OH S PolicyDocument2 pagesHolcim OH S Policykmas1612No ratings yet

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocument37 pagesFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongNo ratings yet

- Contact NoDocument3 pagesContact NovictorNo ratings yet

- Crisis Communication PlanDocument32 pagesCrisis Communication Planapi-507098917No ratings yet

- 09 - Accident InvestigationDocument24 pages09 - Accident InvestigationBert MunozNo ratings yet

- culture of safety A Complete Guide - 2019 EditionFrom Everandculture of safety A Complete Guide - 2019 EditionRating: 5 out of 5 stars5/5 (1)

- Training Procedure for HSE CompetencyDocument11 pagesTraining Procedure for HSE Competencybilo1984100% (1)

- Idc Hsef 8.5 Company Rig & AreasDocument1 pageIdc Hsef 8.5 Company Rig & Areasbilo1984No ratings yet

- 5.4 Work Permit SystemDocument14 pages5.4 Work Permit Systembilo1984100% (1)

- Idc Hsef 8.4 External Aid & External AssistanceDocument1 pageIdc Hsef 8.4 External Aid & External Assistancebilo1984No ratings yet

- HSE Legal Requirements ProcedureDocument1 pageHSE Legal Requirements Procedurebilo1984No ratings yet

- IDC HSEF 8.2 Rig Emergency Response Team Organization .Document1 pageIDC HSEF 8.2 Rig Emergency Response Team Organization .bilo1984No ratings yet

- 2.2 - Legal Framework & Aspect FormDocument1 page2.2 - Legal Framework & Aspect Formbilo1984No ratings yet

- 8.1 Safety Equi8. 8.1 1pement Rig Lay Out 204Document2 pages8.1 Safety Equi8. 8.1 1pement Rig Lay Out 204bilo1984No ratings yet

- 2 - Hse Legal and Other RequirmentDocument8 pages2 - Hse Legal and Other Requirmentbilo1984No ratings yet

- HSE Aspect and Impact Assessment FormDocument2 pagesHSE Aspect and Impact Assessment Formbilo1984No ratings yet

- Human Factors Engineering HFEDocument22 pagesHuman Factors Engineering HFEbilo1984No ratings yet

- Hazid OperationDocument20 pagesHazid Operationbilo1984No ratings yet

- Near Miss Investigation Report Version 12-Nov-2019Document14 pagesNear Miss Investigation Report Version 12-Nov-2019bilo1984No ratings yet

- ATEX PosterDocument1 pageATEX Posterbilo1984No ratings yet

- IDC 58 30-Oct-2019 - Dropped Empty Bottle of WaterDocument18 pagesIDC 58 30-Oct-2019 - Dropped Empty Bottle of Waterbilo1984No ratings yet

- Safety 16 - Cause TreeDocument40 pagesSafety 16 - Cause Treebilo1984No ratings yet

- Emergency Blowout Response PlanDocument9 pagesEmergency Blowout Response Planbilo1984No ratings yet

- Monthly Lifting Audit 54 - 28-02-2020Document13 pagesMonthly Lifting Audit 54 - 28-02-2020bilo1984No ratings yet

- Process Safety Management (PSM) : Module Two - Overview of The PSM RuleDocument40 pagesProcess Safety Management (PSM) : Module Two - Overview of The PSM Rulebilo1984No ratings yet

- UCD Specific Evacuatio PlanDocument7 pagesUCD Specific Evacuatio Planbilo1984No ratings yet

- Monthly Lifting Audit 54 - 28-02-2020Document13 pagesMonthly Lifting Audit 54 - 28-02-2020bilo1984No ratings yet

- Causal Tree Analysis Root Cause 1208180054865499 8Document36 pagesCausal Tree Analysis Root Cause 1208180054865499 8bilo1984No ratings yet

- Identifying and Evaluating Hazards in Research Laboratories DraftDocument133 pagesIdentifying and Evaluating Hazards in Research Laboratories Draftbilo1984No ratings yet

- UCD-IMS-WI-04-23-P.01 Minutes of Meeting 16-3-2017-1Document1 pageUCD-IMS-WI-04-23-P.01 Minutes of Meeting 16-3-2017-1bilo1984No ratings yet

- HSE-BMS-011 Crane & Lifting SafetyDocument51 pagesHSE-BMS-011 Crane & Lifting Safetybilo1984100% (2)

- 2020 Draft HSE Plan Ucd CampDocument17 pages2020 Draft HSE Plan Ucd Campbilo198450% (2)

- Traffic Management AssignmentDocument2 pagesTraffic Management Assignmentaiman kanainNo ratings yet

- Mountain Accident Research ReportDocument223 pagesMountain Accident Research Reportdocco4748No ratings yet

- Smartrise Engineering Training ManualDocument300 pagesSmartrise Engineering Training ManualSazzad Hossan RaselNo ratings yet

- Coconut Water MsdsDocument7 pagesCoconut Water MsdsyulfanNo ratings yet

- Ergonomics Analysis Tools Used in IndustryDocument10 pagesErgonomics Analysis Tools Used in IndustryMyle26No ratings yet

- Biorisk Management and The AMP Model MT101Document3 pagesBiorisk Management and The AMP Model MT101Ryle KurtaNo ratings yet

- BDRRMC BunacanDocument1 pageBDRRMC BunacanAnna Lisa DaguinodNo ratings yet

- CODE of PRACTICE - COMPRESSED GAS CYLINDERSDocument5 pagesCODE of PRACTICE - COMPRESSED GAS CYLINDERSAkhilesh Kumar SinghNo ratings yet

- WA80 WA100M 7 Operation ManualDocument304 pagesWA80 WA100M 7 Operation Manualandres sanchez100% (1)

- Personal Protective Equipment at Work Regulations 1992Document3 pagesPersonal Protective Equipment at Work Regulations 1992Sue CoohNo ratings yet

- Basic Welding Techniques - Welding SafetyDocument26 pagesBasic Welding Techniques - Welding SafetyNoerfaizi Achmad NicdanatoNo ratings yet

- Kasco Safety Manual CurrentDocument171 pagesKasco Safety Manual CurrentLea Santos CidNo ratings yet

- TR - Masonry NC IIDocument67 pagesTR - Masonry NC IIjoselpalomaNo ratings yet

- English For Mechanical Engineering S-1 PDFDocument19 pagesEnglish For Mechanical Engineering S-1 PDFGinanjar Hadi SukmaNo ratings yet

- Implementation of PSM in Capital Projects DuPont 11 1Document11 pagesImplementation of PSM in Capital Projects DuPont 11 1rodrigo_domNo ratings yet

- Hanna Instruments SRL Safety Data Sheet for Zinc Reagent ADocument12 pagesHanna Instruments SRL Safety Data Sheet for Zinc Reagent AKatherine Palacios GonzalezNo ratings yet

- Proper Engineering and Management Decisions: Functions of Engineers and ManagersDocument5 pagesProper Engineering and Management Decisions: Functions of Engineers and ManagersNajmul Puda PappadamNo ratings yet

- DW-002 String Up New Drilling Line, Mast Up.Document4 pagesDW-002 String Up New Drilling Line, Mast Up.khurramNo ratings yet

- Safety Management Manual SMM Issue2-Rev.0-Eff - Date 21 MAY 2019 TR-10 OCT 2019Document284 pagesSafety Management Manual SMM Issue2-Rev.0-Eff - Date 21 MAY 2019 TR-10 OCT 2019itsadaporn rahaNo ratings yet

- Product Safety Data Sheet: According To Article 31 and Annex II of The EU REACH RegulationDocument7 pagesProduct Safety Data Sheet: According To Article 31 and Annex II of The EU REACH RegulationGustavo Alonso BerettaNo ratings yet

- Annex To Ed Decision 2020-021-r Amc GM For Ams - Issue 1 Amdt 4Document65 pagesAnnex To Ed Decision 2020-021-r Amc GM For Ams - Issue 1 Amdt 4Stathis BelosNo ratings yet

- Ansul - Mather Platt PDFDocument1 pageAnsul - Mather Platt PDFMikeNo ratings yet

- Siemens Line Reactor PDFDocument72 pagesSiemens Line Reactor PDFHitesh PanigrahiNo ratings yet

- Industrial Electrical Machines and Drives Servicing Level II Learning Guide-38Document34 pagesIndustrial Electrical Machines and Drives Servicing Level II Learning Guide-38kedirNo ratings yet

- STS ManualDocument8 pagesSTS ManualWalki Os100% (1)

- MULTIS EP 0 30875 Belgium English 20220721Document16 pagesMULTIS EP 0 30875 Belgium English 20220721Pierre-Olivier MouthuyNo ratings yet

- EP-HQ-GDL-008-00 Safety - Critical - Elements - Integrity - Management - GuidelineDocument57 pagesEP-HQ-GDL-008-00 Safety - Critical - Elements - Integrity - Management - GuidelineAHMED AMIRA100% (5)

- Total 2003 HSEQ Charter en PDFDocument1 pageTotal 2003 HSEQ Charter en PDFTheresiaVickaaNo ratings yet