Professional Documents

Culture Documents

Sr. No Parameter Value Specified Observations Remark: Industrial Services

Uploaded by

Raghvendra Singh YadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sr. No Parameter Value Specified Observations Remark: Industrial Services

Uploaded by

Raghvendra Singh YadavCopyright:

Available Formats

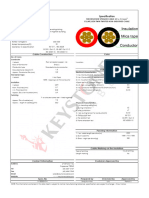

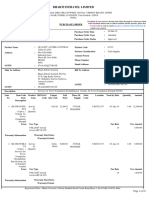

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Sr. No Parameter Value Specified Observations Remark

All pipes shall be clearly finished &

reasonably free from injurious

defects.

The ends shall be free from sharp

edges & burrs of the pipe.

Tubes should be reasonably

(a) Visual straight, in case of GI pips.

Zinc coating shall be reasonably Also see Appendix ‘A’ IS

smooth, free from imperfections 2629 for guidance

like flux, ash dross inclusion, bare

patches, black spots, pimples,

lumpiness, rust stains, runs, bulky

white deposits, blisters.

(b)

Dimensional As per drawing

For seamless pipes

C‐0.20 max +0.02

Mn‐1.30 max +0.04

Material S ‐0.040 max +0.005

(c) composition P‐0.04 max +0.005

Ii) Welded tubes shall be manufactured

from hot roll steel strip conforming to

IS 10478 or cold rolled steels/strips to Obtain test record

IS 513

For tubes of any thickness, a tubular

test piece of 100mm long shall be

taken from both ends after discarding

300mm in length. Dip the test piece in

freshly prepared solution of 32 g m of

Antimony chloride in 1000ml of

Concentrate Hydroelectric acid

(Specific gravity 1.6) for about 15‐30 IS 4736/1986 Amdt.

(d) Galvanizing (Coating sec. (till violent evaluation of Hydrogen No. 3 of May 2022

for GI pipe) gas) subject to max of 1 minute

Calculate mass of coating:(M=M1‐ IS 6745/1972

M2/M2XtX3930 CI.5.2.3

For tubes of any thickness, the

minimum mass of zinc coating, when

determined on a 100mm long test

piece in accordance with IS 6745:1972

shall be 360 gm/m2

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

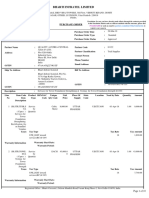

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Sr. No Parameter Value Specified Observations Remark

Dissolved about 36 grams of technical

gr. Copper Sulphate crystals in 100 ml

of distilled water. Specified gravity of

solution to be 1.186 at 18+‐2℃. Test IS 4736/1986

Uniformity of piece shall be subjected to 5 one ‐ Amdt.No.3

(e) Galvanized coating minute dips. After each clip, rinse the IS 2633/1986

test piece in running water. There

should not be red deposit of copper to

base metal.

GI tubes up to & including 50m, Normal

Bore when bent cold through 90ͦ round

grooved for having radius at bottom of

grooved equal to 8‐time pipe OD shall

(f) Adhesion test not develop any crack in the coating. CI.6.4 of IS 26.29/1985

GI tube of OD above 50mm shall be

checked pivoted hammer. Three

hammer blows shall be made at spacing

of 6mm each removal/lifting of the

coating in the area between the

impressions shall constitute failure.

Tensile 320 MPa

Strength % IS 1239(Pt‐1)/2004

Elongation for CI.14.1

steam/gas For ERW pipe

services specimen shall not

contain Weld.

For other 20% For GI tube, GI

(h) service coating to be

Up to 25mm removed before

bore 12% test

Over25mm up

to & including

150mm bore 20%

No fracture or failure when bend cold IS 2329‐1963 Welded

Bend Test ( to be at pipes shall be bent with

done for tubes up to (i) 180ͦ at a radius of 6XOD for un weld at 90ͦ to the plane

(i) 50mm bore only) galvanized of bending. Tubes shall

(ii) 90ͦ at radius of 8X OD of the not be filled with any

galvanized tubes media

No crack or break in metal.

Ring not less than 40mm long cut from ends

of selected tubes shall be flattened cold

below parallel plates with weld ,if any ,at 90ͦ

(j) Flattening Test ( For

(Point of maximum bending).No opening

tubes above 50 mm IS 2328/1963

shall occur by fracture in weld area till the

NB ) distance between plates in less than 75%

of OD of tube.

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

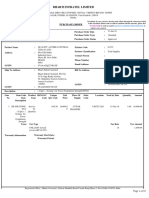

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Sr. No Parameter Value Specified Observations Remark

Firm’s name

Trade mark,

IS Number

Marking Colour band as per class of tube, Yellow ‐For Light

(m) ISI mark, Blue‐For medium

Tubes having length 4‐7 meter Red‐For Heavy

shall have two 75mm bands, one

near each end.

All other lengths shall have one 75

mm band.

Black tube shall be protected by

varnish or suitable painted

throughout length unless ordered

unpainted or unvarnished in order. Yellow ‐For Light

(n) Packing Tube shall be packed in bundle to Blue‐For medium

protect end of tube during Red‐For Heavy

transport.

Plastic tag or metal to be fix at last

in one end

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

QACA‐AIRTEL PDI

Product Specification for Tower & pole material with hardware

Specification Sub‐Spec Inspection Method

Conforming to Indian Standard IS 1239

Visual

(Part 1) latest

Specification Product ISI Marked Visual

Manufacturing Process of Pipe, Angel Visual & Metal inert gas(MIG) & Arc

General

& plate welding used for welding

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

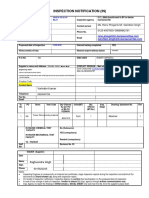

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Dimension As per drawing with Vernier

Material of Pipe , Angel & plate

caliper & measuring tap

Material Category of Steel Pipes Visual check of grade

Steel Pipe Galvanized Elcometer & Adherence Test

Dimension Nominal Bore of Steel Pipe (mm) Vernier calliper & measuring tap

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Length of Pipe, Angel & plate (Meter) Vernier calliper & measuring tap

Thickness of Pipe, Angel & plate in mm Vernier calliper & measuring tap

Tolerance in Pipe , Angel & plate

Vernier calliper & measuring tap

Length (mm)

Weight of material Weighing Scale

Weight

Marking on the Pipe, Angel & plate as

Visual

for IS specification

Marking

QACA PDI Marking of ok material Hard & soft stamp

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Availability of Test Report from NABL/ ILAC

accredited or Central Government Lab to

Documents verification

prove conformity of products to the

specification.

Calibration certificate Calibration certificate

Test Report

Witness by PDI engineer

Galvanizing Test Report

Tensile Strength Test Report Witness by PDI engineer

Bend Test Report Witness by PDI engineer

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

INDUSTRY DIVISION

QACA JOB NO.: IND.N.3.13.0222

RN NO. QACA/

Date -

PAGE 1 of 1

Flattening Test Report Witness by PDI engineer

Witness by PDI engineer

Adhesion test

Industrial Services

This Note is issued further to inspection whose duration and scope were limited by the terms and conditions of the contract with

QACA. This note is NOT an indication that the item(s) is (are)fit for any specific purpose and does not release the manufacturer,

supplier and any party from their respective duty, guarantee, obligation and /or indemnity relating to, without limitation, patents

workmanship, materials, safety, performance in operation and/or reliability.

Industrial Services 003 rev. 00

You might also like

- Energy Efficiency in Motor Systems Proceedings of The 11th International ConferenceDocument748 pagesEnergy Efficiency in Motor Systems Proceedings of The 11th International Conferencedelta_scopeNo ratings yet

- Sample Letter of IntentDocument4 pagesSample Letter of IntentKaloyana Georgieva100% (2)

- CASE 1850K TIER 2 CRAWLER DOZER Service Parts Catalog ManualDocument70 pagesCASE 1850K TIER 2 CRAWLER DOZER Service Parts Catalog ManualAleksandar Vidinov100% (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- RC Tie Beam DesignDocument8 pagesRC Tie Beam DesignArfel BartianaNo ratings yet

- Elecrama ExhDocument44 pagesElecrama ExhMayank Dixit100% (1)

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsLim BoraNo ratings yet

- ME 205 ThermodynamicsDocument3 pagesME 205 Thermodynamicsnandan144No ratings yet

- Oes 25aDocument6 pagesOes 25aBOBNo ratings yet

- Is 1367 - 13 PDFDocument4 pagesIs 1367 - 13 PDFsat palNo ratings yet

- E-402 CalcDocument5 pagesE-402 Calcbiren shahNo ratings yet

- Data Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Document2 pagesData Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Murali KrishnaNo ratings yet

- Ts4040 Double Walled Brazed TubesDocument3 pagesTs4040 Double Walled Brazed TubesFCP PUNEKARNo ratings yet

- Project 2 ScrewedDocument7 pagesProject 2 ScrewedDjuro SavkinNo ratings yet

- T300 R6 - 04132018Document2 pagesT300 R6 - 04132018Suraj_73No ratings yet

- 7.01-7.03 Pipe Draind, Pipe Culvert, Concrete ChannelDocument2 pages7.01-7.03 Pipe Draind, Pipe Culvert, Concrete ChannelRam Prasad AwasthiNo ratings yet

- D Red-Dot Rigid Fittings enDocument9 pagesD Red-Dot Rigid Fittings enSam ANo ratings yet

- Piping Work 5Document17 pagesPiping Work 5Sastra WinataNo ratings yet

- T300 Technical Data Sheet 1 PDFDocument2 pagesT300 Technical Data Sheet 1 PDFmaraNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNo ratings yet

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- Technical Specification Rabbit ACSR ConductorDocument5 pagesTechnical Specification Rabbit ACSR ConductorRiyasKadappayilNo ratings yet

- Comments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Document2 pagesComments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Pritam MitraNo ratings yet

- Twisted Wire Gabion BasketsDocument3 pagesTwisted Wire Gabion Basketsthink padNo ratings yet

- DPIS Condura - Prime AMB-Si3N4Document4 pagesDPIS Condura - Prime AMB-Si3N4masonNo ratings yet

- Welding Processes Summary 2016 ImranDocument6 pagesWelding Processes Summary 2016 ImranEngr. Imran Hasan PathanNo ratings yet

- Zinc-Coated Steel Wire Rope and Fittings For Highway GuardrailDocument4 pagesZinc-Coated Steel Wire Rope and Fittings For Highway GuardrailCPA BTKNo ratings yet

- GTP 240Document2 pagesGTP 240er.manishnhpcNo ratings yet

- Coding System of Strain Gauges-AGS-TECH VersionDocument8 pagesCoding System of Strain Gauges-AGS-TECH VersionsergiojgsNo ratings yet

- Westermann Table 7Document1 pageWestermann Table 7muhd.qasimNo ratings yet

- B 172 - 01 - Qje3mi1sruqDocument5 pagesB 172 - 01 - Qje3mi1sruqCarlos LiceaNo ratings yet

- HELUKABLE F-CY-JZ - Catalog PDFDocument2 pagesHELUKABLE F-CY-JZ - Catalog PDFRhey NaturalNo ratings yet

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xNo ratings yet

- 0102-Tl-C-Tqu-101 - Technical Particular Guarantee For Lattice Tower1Document5 pages0102-Tl-C-Tqu-101 - Technical Particular Guarantee For Lattice Tower1ashadiamirNo ratings yet

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDocument2 pagesHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledAshishkekreNo ratings yet

- Fixed Attenuators (SMA Type) : AT-100, AT-200, and AT-300 SeriesDocument3 pagesFixed Attenuators (SMA Type) : AT-100, AT-200, and AT-300 SeriesSebastian ChaileNo ratings yet

- Material Specification SheetDocument2 pagesMaterial Specification Sheetcalvin.bloodaxe4478No ratings yet

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDocument2 pagesHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledbenoiNo ratings yet

- High Strength Steels For Cold Forming Thermomechanically Rolled QStE340TMDocument2 pagesHigh Strength Steels For Cold Forming Thermomechanically Rolled QStE340TMKrishnanNo ratings yet

- UDI Productcatalogue 2015Document4 pagesUDI Productcatalogue 2015Ryan TayNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- DIN 1628 ST 52.4Document2 pagesDIN 1628 ST 52.4Anonymous m1cSnEavoNo ratings yet

- Pure Epoxy Mortar For Anchoring Rebars & Threaded Rods To Concrete, Brick & RockDocument8 pagesPure Epoxy Mortar For Anchoring Rebars & Threaded Rods To Concrete, Brick & RockvuikhinNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- GRINNELL 577 Replacem. VICTAULIC STYLE 75Document4 pagesGRINNELL 577 Replacem. VICTAULIC STYLE 75Сергей КолесниковNo ratings yet

- Aluminum Conductors Carbon Fiber Core Reinforced-LAPWINGDocument6 pagesAluminum Conductors Carbon Fiber Core Reinforced-LAPWINGgabriel yair sanchez henandezNo ratings yet

- Shincoil CompressionDocument98 pagesShincoil CompressionVNK90No ratings yet

- Joint Welding Method PHC D600A-100Document2 pagesJoint Welding Method PHC D600A-100sochealaoNo ratings yet

- Astm F871M 1998Document7 pagesAstm F871M 1998Jesse ChenNo ratings yet

- Slotted Spring Pins Design GuideDocument8 pagesSlotted Spring Pins Design GuideHumor 101No ratings yet

- Final Standerization of All Committee 02062016Document6 pagesFinal Standerization of All Committee 02062016pramod_jvNo ratings yet

- GSP-0205 Partition ST60Document3 pagesGSP-0205 Partition ST60salvoNo ratings yet

- Tools - Earthing Design For LV SystemDocument37 pagesTools - Earthing Design For LV Systemosp005No ratings yet

- Appendix 1 Test Report of DWC PipeDocument2 pagesAppendix 1 Test Report of DWC Pipeprasun.tcelNo ratings yet

- Die Design B11 PDFDocument14 pagesDie Design B11 PDFநளின் கான்No ratings yet

- Soliani Emc Fingers CatalogueDocument25 pagesSoliani Emc Fingers Cataloguekrishna kumarNo ratings yet

- Bharti Infratel Limited: Purchase OrderDocument10 pagesBharti Infratel Limited: Purchase OrderRaghvendra Singh YadavNo ratings yet

- Bharti Infratel Limited: Purchase OrderDocument10 pagesBharti Infratel Limited: Purchase OrderRaghvendra Singh YadavNo ratings yet

- Bharti Infratel Limited: Purchase OrderDocument10 pagesBharti Infratel Limited: Purchase OrderRaghvendra Singh YadavNo ratings yet

- TLVA REPORT SHS01 (STR)Document43 pagesTLVA REPORT SHS01 (STR)Raghvendra Singh YadavNo ratings yet

- Inspection Notification format-MANAN METALDocument1 pageInspection Notification format-MANAN METALRaghvendra Singh YadavNo ratings yet

- Pages From 50m-170KMPH WTTIL - 3LHybridDocument1 pagePages From 50m-170KMPH WTTIL - 3LHybridRaghvendra Singh YadavNo ratings yet

- Shani Gupta Resume-1Document1 pageShani Gupta Resume-1Raghvendra Singh YadavNo ratings yet

- 7 - RCA - FormatDocument1 page7 - RCA - FormatRaghvendra Singh YadavNo ratings yet

- Kia EV6 BrochureDocument11 pagesKia EV6 BrochureRaghvendra Singh YadavNo ratings yet

- Different Options That Can Be Used With Sapinst Command LineDocument5 pagesDifferent Options That Can Be Used With Sapinst Command Linesai_balaji_8No ratings yet

- EN - DR-ID300CL V10 - 0 Manufacturing ProcedureDocument13 pagesEN - DR-ID300CL V10 - 0 Manufacturing ProcedureSalvador CajasNo ratings yet

- CS 310-Algorithms-Imdad Ullah Khan-Arif ZamanDocument3 pagesCS 310-Algorithms-Imdad Ullah Khan-Arif ZamanAli ShahidNo ratings yet

- Steam Jet Refrigeration SystemDocument3 pagesSteam Jet Refrigeration Systematulyajyoti123100% (1)

- TXP Advanced ExplanationDocument109 pagesTXP Advanced ExplanationDaniel OrdoñezNo ratings yet

- Lattice Optimisation Tutorial PDFDocument16 pagesLattice Optimisation Tutorial PDFvovanpedenkoNo ratings yet

- Notice: Human Drugs: Prescription Drug User Fee Cover Sheet (FDA Form 3397) and User Fee Payment Identification Number Electronic AvailabilityDocument1 pageNotice: Human Drugs: Prescription Drug User Fee Cover Sheet (FDA Form 3397) and User Fee Payment Identification Number Electronic AvailabilityJustia.comNo ratings yet

- Trans-Asia Shipping Lines, Inc. vs. Court of AppealsDocument19 pagesTrans-Asia Shipping Lines, Inc. vs. Court of AppealsYeu GihNo ratings yet

- PROPOSALDocument62 pagesPROPOSALJam Dela CruzNo ratings yet

- URI Protocol Scheme For MatrixDocument6 pagesURI Protocol Scheme For MatrixDhanNo ratings yet

- Djimon Hounsou CADocument101 pagesDjimon Hounsou CAlolita damienNo ratings yet

- JS Quiz MergedDocument25 pagesJS Quiz Mergedabc abcNo ratings yet

- Exam 1Document4 pagesExam 1Abdisamad Muse HassanNo ratings yet

- DTS-X Vs Dolby AtmosDocument3 pagesDTS-X Vs Dolby Atmoskar_21182No ratings yet

- Week 1 QuizDocument20 pagesWeek 1 QuizEduardo GomezNo ratings yet

- Motion in A Straight Line PDFDocument26 pagesMotion in A Straight Line PDFsujit21in4376100% (1)

- Case Study #3Document4 pagesCase Study #3Annie Morrison AshtonNo ratings yet

- THE BLENDED LEARNING BOOK - Best Practices, Proven Methodologies, and Lessons Learned (#176368) - 156133Document4 pagesTHE BLENDED LEARNING BOOK - Best Practices, Proven Methodologies, and Lessons Learned (#176368) - 156133ghinasindiNo ratings yet

- Filipino Value SystemDocument2 pagesFilipino Value SystemJayvee Amoy AmolatoNo ratings yet

- 10.boot Strap SweepDocument3 pages10.boot Strap SweepBharadwaj MedapuramNo ratings yet

- 6 ஆண்டு பிரியாவிடை உரைDocument12 pages6 ஆண்டு பிரியாவிடை உரைKUHAN A/L TAMILCHELVAN MoeNo ratings yet

- YZF-R7 Owners Manual 2023sDocument100 pagesYZF-R7 Owners Manual 2023sSedatNo ratings yet

- ArticuloDocument11 pagesArticuloTaniaNo ratings yet

- Application For One Time Financial Assistance: Paste A Current Passport Size PhotoDocument2 pagesApplication For One Time Financial Assistance: Paste A Current Passport Size PhotoRAKTIM PUJARINo ratings yet

- Chapter 2. Processes and Process ManagementDocument54 pagesChapter 2. Processes and Process ManagementMinte DejeneNo ratings yet