Professional Documents

Culture Documents

Mig Mag Welding Procedure

Uploaded by

burak cikirkan0 ratings0% found this document useful (0 votes)

17 views4 pagesMIG-MAG welding is a semi-automated welding process that uses an electric arc between metals to be joined and a filler wire to melt and fuse the metals. The arc and weld pool are protected from contamination by an inert gas shield. SAF-FRO provides a wide range of MIG-MAG welding power sources and filler wires suitable for demanding applications in industries like shipbuilding and machinery production. The MIG-MAG process involves melting the filler wire as it is fed into the arc and weld pool at the same rate to form part of the weld.

Original Description:

Shielded arc welding

Original Title

MIG MAG WELDING PROCEDURE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMIG-MAG welding is a semi-automated welding process that uses an electric arc between metals to be joined and a filler wire to melt and fuse the metals. The arc and weld pool are protected from contamination by an inert gas shield. SAF-FRO provides a wide range of MIG-MAG welding power sources and filler wires suitable for demanding applications in industries like shipbuilding and machinery production. The MIG-MAG process involves melting the filler wire as it is fed into the arc and weld pool at the same rate to form part of the weld.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views4 pagesMig Mag Welding Procedure

Uploaded by

burak cikirkanMIG-MAG welding is a semi-automated welding process that uses an electric arc between metals to be joined and a filler wire to melt and fuse the metals. The arc and weld pool are protected from contamination by an inert gas shield. SAF-FRO provides a wide range of MIG-MAG welding power sources and filler wires suitable for demanding applications in industries like shipbuilding and machinery production. The MIG-MAG process involves melting the filler wire as it is fed into the arc and weld pool at the same rate to form part of the weld.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

MIG-MAG

Welding

Shielded arc welding

The Metal Inert Gas (MIG) or Metal Active Gas (MAG)

welding is a semi-automated process, widely used in

many sectors of industry, such as shipbuilding, railroad

construction and the production of heavy plants and

machinery.

SAF-FRO can provide a wide range of MIG-MAG welding inverter and step

controlled power sources (DIGIWAVE, DIGISTEEL, FILCORD…). Our offer of

non alloyed (FILCORD...) or high alloyed steel solid wires (FILINOX 316L), as

our wide range of non-alloyed steel flux cored wires (STEELCORD 14HD,

SAFDUAL 100...) will surely answer your most demanding applications.

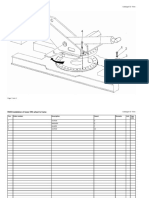

Principle of the process

The process melts and fuses metals using the intense heat generated by an electric

arc between the metals to be joined and a filler wire (solid or flux cored). The wire

is progressively melted at the same speed at which it is being fed by the wire feeder

and forms part of the weld pool.

Both the arc and the weld pool are protected against atmospheric contamination by

a shield of inert (non-reactive) gas.

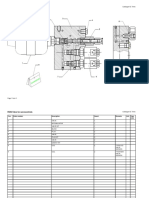

The metal transfer

Transfer modes

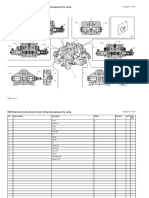

Scheme of a manual installation for

MIG-MAG welding

You might also like

- Tig Welding ProcedureDocument3 pagesTig Welding Procedureburak cikirkanNo ratings yet

- 9 Welding Processes Cwip 3.1Document12 pages9 Welding Processes Cwip 3.1Jawed AkhterNo ratings yet

- Introduction To Welding - 1 GCDocument66 pagesIntroduction To Welding - 1 GCkr_abhijeet72356587No ratings yet

- Weilding TechnologyDocument15 pagesWeilding TechnologyRAMALAKSHMI SUDALAIKANNANNo ratings yet

- Section 8 - Arc Equipment & Processes266 - 27344Document36 pagesSection 8 - Arc Equipment & Processes266 - 27344dbircs2010No ratings yet

- Training Report November MD Zeeshan Khalid-T1264Document5 pagesTraining Report November MD Zeeshan Khalid-T1264PANKAJ KUMARNo ratings yet

- Stick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)Document3 pagesStick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)senthil4youNo ratings yet

- Arc Welding Processes w3Document73 pagesArc Welding Processes w3snananrNo ratings yet

- SAIF - Weldinng Health and Safety PDFDocument25 pagesSAIF - Weldinng Health and Safety PDFskay4dekovNo ratings yet

- Types of WeldingDocument66 pagesTypes of WeldingLee Shi HongNo ratings yet

- Welding: From Wikipedia, The Free EncyclopediaDocument2 pagesWelding: From Wikipedia, The Free EncyclopediaNgro Quinapaxi GonzalezNo ratings yet

- Submerged Arc Welding (SAW) Is A Common Arc Welding Process. The First Patent On The Submerged-Arc WeldingDocument31 pagesSubmerged Arc Welding (SAW) Is A Common Arc Welding Process. The First Patent On The Submerged-Arc Weldingankit gargNo ratings yet

- Welding ProcessDocument31 pagesWelding ProcessMohamad TaufikNo ratings yet

- WELDINGDocument21 pagesWELDINGCabildo, Neil Andrei T.No ratings yet

- Metal Inert Gas WeldingDocument4 pagesMetal Inert Gas WeldingINfo WTCSNo ratings yet

- Mig Gmaw Welding 1Document26 pagesMig Gmaw Welding 1HAZEL BELLONo ratings yet

- Welding and GmawDocument14 pagesWelding and GmawAl-hadi AliakbarNo ratings yet

- WL TIG & MIG Welding NotesDocument14 pagesWL TIG & MIG Welding NotesGanesh JadhavNo ratings yet

- MIG - Gas Metal Arc Welding (GMAW)Document3 pagesMIG - Gas Metal Arc Welding (GMAW)Koya ThangalNo ratings yet

- Welding Types and Their Applications - 1Document18 pagesWelding Types and Their Applications - 1tgu1eramos100% (3)

- WeldingDocument2 pagesWeldingNeuza Flora UacheNo ratings yet

- Welding TechnologyDocument26 pagesWelding TechnologyHiren Kumar100% (1)

- Common Welding ProcessDocument4 pagesCommon Welding ProcessLalit Bom MallaNo ratings yet

- Manufacturing - WeldingDocument8 pagesManufacturing - WeldingKhalid EwigNo ratings yet

- Presentation On: Applications of and Welding in ManufacturingDocument27 pagesPresentation On: Applications of and Welding in ManufacturingHope ThemNo ratings yet

- Study of Electric Arc Welding Process and Various Types of JointDocument12 pagesStudy of Electric Arc Welding Process and Various Types of JointMohammed RakibNo ratings yet

- Tig MigDocument15 pagesTig Migsatish448No ratings yet

- Henry Welding UpdatedDocument11 pagesHenry Welding UpdatedJoshua Espanto MorenNo ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- Electric WeldingDocument28 pagesElectric WeldingmayankNo ratings yet

- Principle of Arc WeldingDocument60 pagesPrinciple of Arc Weldingsamurai7_7786% (7)

- Arc WeldingDocument7 pagesArc WeldingMay FadlNo ratings yet

- MigDocument2 pagesMigAriyant dopeNo ratings yet

- Welding Short NotesDocument3 pagesWelding Short NotesMidhun K Chandrabose100% (1)

- About Welding Process 19Document1 pageAbout Welding Process 19XerexNo ratings yet

- Welder's Handbook (Air Products Co.)Document48 pagesWelder's Handbook (Air Products Co.)Patrick DominguezNo ratings yet

- Engineering Welding Handbook99 PDF TigDocument48 pagesEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- MRT-10-2 Arc Welding Principle and SSWDocument27 pagesMRT-10-2 Arc Welding Principle and SSW1026Aniket TankNo ratings yet

- What Are The Types of WeldingDocument11 pagesWhat Are The Types of WeldingLeslie AnasNo ratings yet

- Welding Process SeminarDocument14 pagesWelding Process Seminartemporary hNo ratings yet

- Welding Is ADocument19 pagesWelding Is AAnthony ValinNo ratings yet

- Welding (WorkShop) Assig # 1Document7 pagesWelding (WorkShop) Assig # 1Muhammad Talha ZaroonNo ratings yet

- Q. What Are The Processes Included in Metal Joining Process?Document2 pagesQ. What Are The Processes Included in Metal Joining Process?Saumil ShahNo ratings yet

- MIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesDocument8 pagesMIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesCalvin YeohNo ratings yet

- RCF KapurthallaDocument18 pagesRCF KapurthallaSudhir Kumar50% (2)

- WeldingDocument93 pagesWeldingPradeepNo ratings yet

- EML 2322L - Welding - MAE Design and Manufacturing LabDocument21 pagesEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59No ratings yet

- Welding: Welding Is A Fabrication or Sculptural Process That Joins Materials, Usually MetalsDocument21 pagesWelding: Welding Is A Fabrication or Sculptural Process That Joins Materials, Usually Metalsvishnu0751No ratings yet

- MIG Welding ProcessDocument12 pagesMIG Welding ProcessHimanshu RaoNo ratings yet

- Types of WeldingDocument10 pagesTypes of WeldingMuhammad Tauseef ZafarNo ratings yet

- Book of Welding 2007Document80 pagesBook of Welding 2007Gangadhar Yeddala50% (2)

- Case Study YayaDocument6 pagesCase Study YayaYayaNo ratings yet

- Report Arc WeldingDocument4 pagesReport Arc WeldingFaris Kadesh50% (2)

- CO2 WeldingDocument3 pagesCO2 WeldingNisarg PatelNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- R977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R189 Hydrocontrol Valve Block For WinchDocument2 pagesR189 Hydrocontrol Valve Block For Winchburak cikirkanNo ratings yet

- R822 Configuration For Hydraulic Control UnitDocument2 pagesR822 Configuration For Hydraulic Control Unitburak cikirkanNo ratings yet

- R335 Components Mounted On Swing Drive Speed ReducerDocument2 pagesR335 Components Mounted On Swing Drive Speed Reducerburak cikirkanNo ratings yet

- R1364 Front Axle - KatalogDocument3 pagesR1364 Front Axle - Katalogburak cikirkanNo ratings yet

- R1462 Installation of Pumps On ConverterDocument1 pageR1462 Installation of Pumps On Converterburak cikirkanNo ratings yet

- R585 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR585 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R333 Gearbox MT306L200A01 - Brake 4Document2 pagesR333 Gearbox MT306L200A01 - Brake 4burak cikirkanNo ratings yet

- rc40 GobekDocument4 pagesrc40 Gobekburak cikirkanNo ratings yet

- R977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R334 Trasmital Speed Reducer (Danfoss OMSU 80 Hydraulic Motor)Document2 pagesR334 Trasmital Speed Reducer (Danfoss OMSU 80 Hydraulic Motor)burak cikirkanNo ratings yet

- R331 Gearbox MT306L200A01 - Reduction Stage 306Document2 pagesR331 Gearbox MT306L200A01 - Reduction Stage 306burak cikirkanNo ratings yet

- rc40 Spare PartsDocument32 pagesrc40 Spare Partsburak cikirkanNo ratings yet

- R189 Hydrocontrol Valve Block For WinchDocument2 pagesR189 Hydrocontrol Valve Block For Winchburak cikirkanNo ratings yet

- R329 Gearbox MT306L200A01 - Output Version 306 HC-HZDocument2 pagesR329 Gearbox MT306L200A01 - Output Version 306 HC-HZburak cikirkanNo ratings yet

- R246 Valve For ServocontrolsDocument2 pagesR246 Valve For Servocontrolsburak cikirkanNo ratings yet

- R330 Gearbox MT306L200A01 - Output Fittings 306Document2 pagesR330 Gearbox MT306L200A01 - Output Fittings 306burak cikirkanNo ratings yet

- Securitex Sena Parani Manual Parani sd-v1.1.7.1Document50 pagesSecuritex Sena Parani Manual Parani sd-v1.1.7.1burak cikirkanNo ratings yet

- R191 Hydrocontrol Valve For ServocontrolsDocument2 pagesR191 Hydrocontrol Valve For Servocontrolsburak cikirkanNo ratings yet

- ZFinGradersERGOPOWER 71461Document2 pagesZFinGradersERGOPOWER 71461burak cikirkanNo ratings yet

- 714-1178Document1 page714-1178burak cikirkanNo ratings yet

- R247 Valve Block For WinchDocument2 pagesR247 Valve Block For Winchburak cikirkanNo ratings yet

- Grove LOADDocument20 pagesGrove LOADburak cikirkanNo ratings yet

- Filcordrange en NewDocument4 pagesFilcordrange en Newburak cikirkanNo ratings yet

- How To Use This CD: Viewing DocumentsDocument1 pageHow To Use This CD: Viewing Documentsburak cikirkanNo ratings yet

- Filcord C OzelliklerDocument3 pagesFilcord C Ozelliklerburak cikirkanNo ratings yet

- Grove AT700BE OPCARDocument98 pagesGrove AT700BE OPCARburak cikirkanNo ratings yet

- Engine CodesDocument6 pagesEngine Codesburak cikirkanNo ratings yet

- Grove Rt530e-2 Load ChartDocument16 pagesGrove Rt530e-2 Load Chartburak cikirkanNo ratings yet