Professional Documents

Culture Documents

Tig Welding Procedure

Uploaded by

burak cikirkan0 ratings0% found this document useful (0 votes)

15 views3 pagesThe document discusses TIG (Tungsten Inert Gas) welding, a type of shielded arc welding. TIG welding produces very high quality welds suitable for demanding industries like pressure vessels and aviation. It uses a non-consumable tungsten electrode to generate an arc under an inert gas shield to melt and join metal workpieces. A filler rod can be manually added to the weld pool for thicker materials up to around 8-10 mm. TIG welding provides a clean weld and precise control suitable for many metal fabrication applications.

Original Description:

Shielded arc welding

Original Title

TIG WELDING PROCEDURE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses TIG (Tungsten Inert Gas) welding, a type of shielded arc welding. TIG welding produces very high quality welds suitable for demanding industries like pressure vessels and aviation. It uses a non-consumable tungsten electrode to generate an arc under an inert gas shield to melt and join metal workpieces. A filler rod can be manually added to the weld pool for thicker materials up to around 8-10 mm. TIG welding provides a clean weld and precise control suitable for many metal fabrication applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views3 pagesTig Welding Procedure

Uploaded by

burak cikirkanThe document discusses TIG (Tungsten Inert Gas) welding, a type of shielded arc welding. TIG welding produces very high quality welds suitable for demanding industries like pressure vessels and aviation. It uses a non-consumable tungsten electrode to generate an arc under an inert gas shield to melt and join metal workpieces. A filler rod can be manually added to the weld pool for thicker materials up to around 8-10 mm. TIG welding provides a clean weld and precise control suitable for many metal fabrication applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

TIG Welding

Shielded arc welding

The TIG welding process enables you to obtain very high

quality welding especially for demanding sectors of

application, such as pressure vessels, pipelines, food

industry containers and aviation.

SAF-FRO can provide a wide range of TIG AC/DC and DC power sources

(SAXOTIG, PRESTOTIG II…). Our TIG rods offer covers non alloy steels

(ALTIG SG1 & ALTIG SG2...), high alloy steels (ALTIG 316L...), and also

other materials.

Principle of the process

The TIG process uses the heat generated by an electric arc between the metals to be

joined and an infusible tungsten-based electrode, located in the welding torch. The

arc area is shrouded in an inert or reducing gas shield to protect the weld pool and

the tungsten electrode.

The filler metal as a rod is applied manually by the welder into the weld pool.

TIG welding is especially suited to sheet materials with thicknesses up to about 8

or 10 mm.

The metal transfer

Manual installation diagram for TIG

welding

You might also like

- Weilding TechnologyDocument15 pagesWeilding TechnologyRAMALAKSHMI SUDALAIKANNANNo ratings yet

- Chapter-3 General Information of WeldingDocument5 pagesChapter-3 General Information of WeldingKumar DneshNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Engineering Welding Handbook99 PDF TigDocument48 pagesEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- Welding Process SeminarDocument14 pagesWelding Process Seminartemporary hNo ratings yet

- Tig MigDocument15 pagesTig Migsatish448No ratings yet

- WeldingDocument27 pagesWeldingankit4565No ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- 3 Major Types of Welding Machines & Their FeaturesDocument2 pages3 Major Types of Welding Machines & Their FeaturesPratibha MauryaNo ratings yet

- Arc Welding Process PDFDocument12 pagesArc Welding Process PDFBiswanath RoulNo ratings yet

- Welder's Handbook PDFDocument48 pagesWelder's Handbook PDFdoanhbk20000100% (1)

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Manufacturing Technology: Tig Welding - Process AnalysisDocument8 pagesManufacturing Technology: Tig Welding - Process AnalysisshubhamNo ratings yet

- 13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)Document5 pages13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)IJAERS JOURNAL100% (1)

- Welder's Handbook (Air Products Co.)Document48 pagesWelder's Handbook (Air Products Co.)Patrick DominguezNo ratings yet

- Classification of Welding ProcessesDocument25 pagesClassification of Welding ProcessesvelavansuNo ratings yet

- Types of WeldingDocument66 pagesTypes of WeldingLee Shi HongNo ratings yet

- Orbital-Welding Facts enDocument52 pagesOrbital-Welding Facts ene.vicente.caballeroNo ratings yet

- Tungsten Inert Gas WeldingDocument2 pagesTungsten Inert Gas WeldingJacques SauNo ratings yet

- TIG-welding Gases PDFDocument2 pagesTIG-welding Gases PDFwenigmaNo ratings yet

- Book of Welding 2007Document80 pagesBook of Welding 2007Gangadhar Yeddala50% (2)

- Mig Mag Welding ProcedureDocument4 pagesMig Mag Welding Procedureburak cikirkanNo ratings yet

- C042011020 With Cover Page v2Document11 pagesC042011020 With Cover Page v2Weses narniaNo ratings yet

- Presentation On: Applications of and Welding in ManufacturingDocument27 pagesPresentation On: Applications of and Welding in ManufacturingHope ThemNo ratings yet

- Description of Tig Welding Final 1Document4 pagesDescription of Tig Welding Final 1api-355092514No ratings yet

- 9 Welding Processes Cwip 3.1Document12 pages9 Welding Processes Cwip 3.1Jawed AkhterNo ratings yet

- A TIG Unit Consists ofDocument5 pagesA TIG Unit Consists ofZaky MuzaffarNo ratings yet

- Applying Tig Techniques Hand-OutDocument12 pagesApplying Tig Techniques Hand-Outjuvy may esbanNo ratings yet

- Adyapeath Annada Polytechnic CollegeDocument5 pagesAdyapeath Annada Polytechnic CollegeArunavaNo ratings yet

- WeldingDocument2 pagesWeldingNeuza Flora UacheNo ratings yet

- Study of Electric Arc Welding Process and Various Types of JointDocument12 pagesStudy of Electric Arc Welding Process and Various Types of JointMohammed RakibNo ratings yet

- WELDINGDocument21 pagesWELDINGCabildo, Neil Andrei T.No ratings yet

- Workshop Case StudyDocument13 pagesWorkshop Case Study1071Vishal kumarNo ratings yet

- Welding Is A Fabrication or Sculptural Process That Joins Materials, Usually Metals. This Is OftenDocument3 pagesWelding Is A Fabrication or Sculptural Process That Joins Materials, Usually Metals. This Is OftenrifkywijayaNo ratings yet

- FabricationDocument6 pagesFabricationRushabhNo ratings yet

- Experiment No 3 Tungsten Inert Gas (TIG) Welding: ObjectiveDocument7 pagesExperiment No 3 Tungsten Inert Gas (TIG) Welding: ObjectiveUsman Saeed KianiNo ratings yet

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDocument115 pagesAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyNo ratings yet

- Proc.-02 GTAW - PAWDocument37 pagesProc.-02 GTAW - PAWRaghu vamshiNo ratings yet

- Experiment - TIGDocument5 pagesExperiment - TIGAl Anood Al AmeriNo ratings yet

- Training Report November MD Zeeshan Khalid-T1264Document5 pagesTraining Report November MD Zeeshan Khalid-T1264PANKAJ KUMARNo ratings yet

- RaghavDocument9 pagesRaghavommkarNo ratings yet

- Midalloy ER70S-2Document1 pageMidalloy ER70S-2nasirfahimNo ratings yet

- Case Study YayaDocument6 pagesCase Study YayaYayaNo ratings yet

- Welding 8Document3 pagesWelding 8রিপন মন্ডলNo ratings yet

- Arc Welding: Putra Perdana BandiDocument66 pagesArc Welding: Putra Perdana BandiJuniorYanaNo ratings yet

- HSE PAPER (Soldagem)Document9 pagesHSE PAPER (Soldagem)Wyllton CandidoNo ratings yet

- OK Tigrod 308LDocument1 pageOK Tigrod 308LslowmosquitoNo ratings yet

- Catalogo Nickel Alloys - Techalloy PDFDocument12 pagesCatalogo Nickel Alloys - Techalloy PDFCebrac ItatibaNo ratings yet

- Experiment-1: Study of Grinding Machine and It's OperationsDocument15 pagesExperiment-1: Study of Grinding Machine and It's OperationsMohammed RakibNo ratings yet

- Lecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyDocument24 pagesLecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyNavneet KumarNo ratings yet

- Experiment-1: Study of Grinding Machine and It's OperationsDocument15 pagesExperiment-1: Study of Grinding Machine and It's OperationsMohammed RakibNo ratings yet

- WOWLibrary TIG WeldingDocument3 pagesWOWLibrary TIG Weldingisaac2408No ratings yet

- Welding Technology Unit 1 NotesDocument58 pagesWelding Technology Unit 1 NotesVasanthakumar B.E;No ratings yet

- The Principle of Tungsten Inert Gas TIG Welding ProcessDocument7 pagesThe Principle of Tungsten Inert Gas TIG Welding ProcessWill TohallinoNo ratings yet

- Experiment-1: Study of Grinding Machine and It's OperationsDocument15 pagesExperiment-1: Study of Grinding Machine and It's OperationsMohammed RakibNo ratings yet

- About Welding Process 21Document1 pageAbout Welding Process 21XerexNo ratings yet

- Welding Presentation609Document10 pagesWelding Presentation609cfcshakerNo ratings yet

- R977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R189 Hydrocontrol Valve Block For WinchDocument2 pagesR189 Hydrocontrol Valve Block For Winchburak cikirkanNo ratings yet

- R822 Configuration For Hydraulic Control UnitDocument2 pagesR822 Configuration For Hydraulic Control Unitburak cikirkanNo ratings yet

- R335 Components Mounted On Swing Drive Speed ReducerDocument2 pagesR335 Components Mounted On Swing Drive Speed Reducerburak cikirkanNo ratings yet

- R1364 Front Axle - KatalogDocument3 pagesR1364 Front Axle - Katalogburak cikirkanNo ratings yet

- R1462 Installation of Pumps On ConverterDocument1 pageR1462 Installation of Pumps On Converterburak cikirkanNo ratings yet

- R585 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR585 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R333 Gearbox MT306L200A01 - Brake 4Document2 pagesR333 Gearbox MT306L200A01 - Brake 4burak cikirkanNo ratings yet

- rc40 GobekDocument4 pagesrc40 Gobekburak cikirkanNo ratings yet

- R977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For SwingDocument2 pagesR977 Hydrocontrol Valve Block For Boom Luffing-Telescoping and For Swingburak cikirkanNo ratings yet

- R334 Trasmital Speed Reducer (Danfoss OMSU 80 Hydraulic Motor)Document2 pagesR334 Trasmital Speed Reducer (Danfoss OMSU 80 Hydraulic Motor)burak cikirkanNo ratings yet

- R331 Gearbox MT306L200A01 - Reduction Stage 306Document2 pagesR331 Gearbox MT306L200A01 - Reduction Stage 306burak cikirkanNo ratings yet

- rc40 Spare PartsDocument32 pagesrc40 Spare Partsburak cikirkanNo ratings yet

- R189 Hydrocontrol Valve Block For WinchDocument2 pagesR189 Hydrocontrol Valve Block For Winchburak cikirkanNo ratings yet

- R329 Gearbox MT306L200A01 - Output Version 306 HC-HZDocument2 pagesR329 Gearbox MT306L200A01 - Output Version 306 HC-HZburak cikirkanNo ratings yet

- R246 Valve For ServocontrolsDocument2 pagesR246 Valve For Servocontrolsburak cikirkanNo ratings yet

- R330 Gearbox MT306L200A01 - Output Fittings 306Document2 pagesR330 Gearbox MT306L200A01 - Output Fittings 306burak cikirkanNo ratings yet

- Securitex Sena Parani Manual Parani sd-v1.1.7.1Document50 pagesSecuritex Sena Parani Manual Parani sd-v1.1.7.1burak cikirkanNo ratings yet

- R191 Hydrocontrol Valve For ServocontrolsDocument2 pagesR191 Hydrocontrol Valve For Servocontrolsburak cikirkanNo ratings yet

- ZFinGradersERGOPOWER 71461Document2 pagesZFinGradersERGOPOWER 71461burak cikirkanNo ratings yet

- 714-1178Document1 page714-1178burak cikirkanNo ratings yet

- R247 Valve Block For WinchDocument2 pagesR247 Valve Block For Winchburak cikirkanNo ratings yet

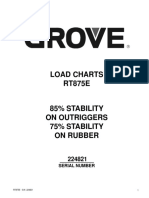

- Grove LOADDocument20 pagesGrove LOADburak cikirkanNo ratings yet

- Filcordrange en NewDocument4 pagesFilcordrange en Newburak cikirkanNo ratings yet

- How To Use This CD: Viewing DocumentsDocument1 pageHow To Use This CD: Viewing Documentsburak cikirkanNo ratings yet

- Filcord C OzelliklerDocument3 pagesFilcord C Ozelliklerburak cikirkanNo ratings yet

- Grove AT700BE OPCARDocument98 pagesGrove AT700BE OPCARburak cikirkanNo ratings yet

- Engine CodesDocument6 pagesEngine Codesburak cikirkanNo ratings yet

- Grove Rt530e-2 Load ChartDocument16 pagesGrove Rt530e-2 Load Chartburak cikirkanNo ratings yet