Professional Documents

Culture Documents

Adobe Scan 19 Nov 2022

Adobe Scan 19 Nov 2022

Uploaded by

Sunitha SasiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adobe Scan 19 Nov 2022

Adobe Scan 19 Nov 2022

Uploaded by

Sunitha SasiCopyright:

Available Formats

ion Process: In this process, the metal powders are

produced

a lR e d u c t i o n

ical

6Chemica Re ores oxides in a current of

or oxidesi

ores or hydrogen gas at a temperature

refinet Tungsten

byredtucing?

elting point. oxide, when heated

in a current of

below

the melthngen DOwder. Iron and copper powder can

fine tungsten powder

also be

hydrogen,

by

this

method.

produced

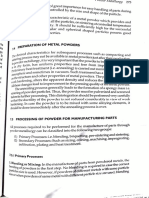

Atomisation: In this

Ta thi process, the molten metal is forced through a nozzle into

Atomnmpressed air or water as shown in Fig. 7.1.

Astream

Molten melal

. ***

*.. * * .

Air or

water

Automization

chamber

a

st

- Metal powder

is

Fig. 7.1:Automisation

Oncooling, the metal solidifies into small particles of various sizes, sometimes

dfimegular shapes. The nozzle size rate of flow of metal, temperature and pressure

water and the airstreamare the parameters affecting the size of theseparticles

ne Pwders of metals having low melting point such as zinc, aluminium and tin are

iS

widely produced by using this technique. A stream of inert gas may also be

SS umlized in automisation of metal

powders. The powders so produced are usually

herical or pear

shaped, coated with a thin oxide layer.

te

he 73

CHARACTERISTICS OF METAL POWDERS

gh

es Principal characteristics of metal powders upon which the properties of

on Ned

product depends are as follows:

or

of

POwdeComposition: It is outstanding characteristic of the metal

an

ly. nemical composition usually reveals the type and percentage of

You might also like

- Mocom Basic PlusDocument148 pagesMocom Basic PlusIvan50% (2)

- Bett Process 2Document14 pagesBett Process 2Ade SatriaNo ratings yet

- Powder Metallurgy - Wikipedia, The Free EncyclopediaDocument11 pagesPowder Metallurgy - Wikipedia, The Free EncyclopediazidaaanNo ratings yet

- Astm A764 PDFDocument5 pagesAstm A764 PDFCristian OtivoNo ratings yet

- Forensic Analysis of FingerprintsDocument27 pagesForensic Analysis of Fingerprints509ch044No ratings yet

- Blown To Atoms How To Make A Metal PowderDocument2 pagesBlown To Atoms How To Make A Metal PowderXax Xax XaxNo ratings yet

- L3L4L5-Metal Powder ProductionDocument10 pagesL3L4L5-Metal Powder ProductionAthlur Sai KiranNo ratings yet

- CopperDocument6 pagesCopperTahir AbbasNo ratings yet

- Powder Metallurgy Part I StudentsDocument16 pagesPowder Metallurgy Part I StudentsGrovn MannNo ratings yet

- Lecture 2 Chemical and Mechanical Methods of Powder ProcessingDocument31 pagesLecture 2 Chemical and Mechanical Methods of Powder ProcessingguruNo ratings yet

- Powder Metallurgy 1Document25 pagesPowder Metallurgy 1Aditya KoutharapuNo ratings yet

- Abdul Mahmood Aircraft Materials and HardwareDocument11 pagesAbdul Mahmood Aircraft Materials and HardwareAbdul MuizzNo ratings yet

- AOD Chapter12Document4 pagesAOD Chapter12Nguyễn Văn ThanhNo ratings yet

- BiomaterialDocument15 pagesBiomaterialNathalia AmeldaNo ratings yet

- Lecture 3 Phyical Methods For Powder ProcessingDocument23 pagesLecture 3 Phyical Methods For Powder ProcessingguruNo ratings yet

- Cesium and Cesium Compounds: 1. Physical and Chemical PropertiesDocument5 pagesCesium and Cesium Compounds: 1. Physical and Chemical PropertiesjaimeNo ratings yet

- Powder ManufacturingDocument5 pagesPowder ManufacturingJyoti SharmaNo ratings yet

- Production of Copper and Copper Alloy Powders: AtomizationDocument38 pagesProduction of Copper and Copper Alloy Powders: AtomizationdaffaNo ratings yet

- Banhart 1998Document12 pagesBanhart 1998Jose SotoNo ratings yet

- Precious Metals Refining PracticeDocument16 pagesPrecious Metals Refining Practicerichipc100% (1)

- AOD Chapter12 PDFDocument4 pagesAOD Chapter12 PDFNguyễn Văn ThanhNo ratings yet

- Abhishek Gupta Research PaperDocument9 pagesAbhishek Gupta Research PaperalwaysbestcricketNo ratings yet

- Metals 11 01108Document12 pagesMetals 11 01108John TorrezNo ratings yet

- (EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Document9 pages(EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Juan Diego AlvarezNo ratings yet

- Dorfman 2002Document10 pagesDorfman 2002zidan ojaNo ratings yet

- Chapter 9: Manufactured Substances in Industry: UsesDocument9 pagesChapter 9: Manufactured Substances in Industry: Useseyeda2000No ratings yet

- Types of Methods of Powder Production:: Physico Chemical Processes Are As UnderDocument11 pagesTypes of Methods of Powder Production:: Physico Chemical Processes Are As UnderDevashish JoshiNo ratings yet

- Steel Slag. Conversion of An Industrial Waste Material Into A Value Adding Asphalt IngredientDocument8 pagesSteel Slag. Conversion of An Industrial Waste Material Into A Value Adding Asphalt IngredientMehdi FarrokhiNo ratings yet

- Aluminum Foaming For Lighter StructureDocument5 pagesAluminum Foaming For Lighter StructureInternational Journal of computational Engineering research (IJCER)No ratings yet

- James 1931Document3 pagesJames 1931alirezayusufyarNo ratings yet

- Steel and Other Alloying ElementDocument62 pagesSteel and Other Alloying ElementJoby Jobzz SebellinoNo ratings yet

- Operation in Extractive MetallurgyDocument25 pagesOperation in Extractive Metallurgybt19108055 Amarjeet KumarNo ratings yet

- The Rhodium: StructureDocument3 pagesThe Rhodium: StructureWaskito BudiawanNo ratings yet

- Ojebuoboh 1992Document4 pagesOjebuoboh 1992Dereck FosterNo ratings yet

- SAP in Aluminum Industry Overview 27 AprDocument47 pagesSAP in Aluminum Industry Overview 27 AprGanesh sNo ratings yet

- Charecterization of Silver Particles Used For Low Temp Joining TechnDocument5 pagesCharecterization of Silver Particles Used For Low Temp Joining TechnTecnoserv Ingenieros S.A:No ratings yet

- Chemistry Folio Manufacture Substance in IndustryDocument23 pagesChemistry Folio Manufacture Substance in Industryseela gunalanNo ratings yet

- Inoculation of Ductile Iron Why and WhenDocument4 pagesInoculation of Ductile Iron Why and WhenKarthiKeyan SNo ratings yet

- Powder MetallurgyDocument7 pagesPowder MetallurgyAnkur KumarNo ratings yet

- Metallurgy (Notes) (13th)Document12 pagesMetallurgy (Notes) (13th)Raju SinghNo ratings yet

- Foundry Technology: Reference BooksDocument34 pagesFoundry Technology: Reference BooksGowtham VishvakarmaNo ratings yet

- Metallurgical Class OverviewDocument59 pagesMetallurgical Class OverviewsyedfarazshafeeqNo ratings yet

- Introduction To Powder Metallurgy 1Document75 pagesIntroduction To Powder Metallurgy 1ramuNo ratings yet

- Sulfatizing Roasting and Leaching of Cobalt Ores at Outokumpu OyDocument5 pagesSulfatizing Roasting and Leaching of Cobalt Ores at Outokumpu OyEduardo CandelaNo ratings yet

- Low-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionDocument7 pagesLow-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionJahidul IslamNo ratings yet

- Powder MtlrgyDocument6 pagesPowder Mtlrgyaditya rastogiNo ratings yet

- Department of Mechanical Department SSET 2014Document32 pagesDepartment of Mechanical Department SSET 2014HarshNo ratings yet

- Casting Porosity AnalysisDocument1 pageCasting Porosity AnalysisRahulNo ratings yet

- Thiemann2000 PDFDocument50 pagesThiemann2000 PDFLilisNo ratings yet

- Aluminum DrossDocument16 pagesAluminum DrossJamir JoNo ratings yet

- Remelting For Highest StandardsDocument12 pagesRemelting For Highest StandardsX800XLNo ratings yet

- Extractive Metallurgy Final Term NotesDocument19 pagesExtractive Metallurgy Final Term NotesWajid RaheemNo ratings yet

- Powder Metallurgy-Sayfa 85Document84 pagesPowder Metallurgy-Sayfa 85Naser MiriNo ratings yet

- Question BankSUBRATDocument55 pagesQuestion BankSUBRATमधु हांसदाNo ratings yet

- NON-FERROUS Extractive FinalDocument40 pagesNON-FERROUS Extractive FinalJaidevNo ratings yet

- 07 01 METALLURGY Principles and Methods of ExtractionDocument17 pages07 01 METALLURGY Principles and Methods of ExtractionrcraktimcNo ratings yet

- Silver Casting.Document3 pagesSilver Casting.Richard.nlNo ratings yet

- Advance Foundry TechnologyDocument34 pagesAdvance Foundry TechnologyPranav Pandey100% (1)

- Extraction MetallurgyDocument23 pagesExtraction MetallurgyChima C. UgwuegbuNo ratings yet

- Application Note Stainless SteelDocument6 pagesApplication Note Stainless SteelVictoria TechiNo ratings yet

- Metal Foams - Manufacture and Physics of FoamingDocument17 pagesMetal Foams - Manufacture and Physics of FoamingDaniela Silva MolinaNo ratings yet

- Reducing The Need For Subsequent Machining: Examples: Filters Oil-Impregnated Bearings and GearsDocument30 pagesReducing The Need For Subsequent Machining: Examples: Filters Oil-Impregnated Bearings and GearsPankaj VishwakarmaNo ratings yet

- Unit II - Sensors - MasterDocument44 pagesUnit II - Sensors - MasterSunitha SasiNo ratings yet

- Unit II - Signal Conditioning - MasterDocument33 pagesUnit II - Signal Conditioning - MasterSunitha SasiNo ratings yet

- Adobe Scan 19 Nov 2022Document1 pageAdobe Scan 19 Nov 2022Sunitha SasiNo ratings yet

- Sojourner Mars and Lessons Learned For Future Planetary Rovers. Brian Wilcox and Tam NguyenDocument10 pagesSojourner Mars and Lessons Learned For Future Planetary Rovers. Brian Wilcox and Tam NguyenSunitha SasiNo ratings yet

- Adobe Scan 19 Nov 2022Document1 pageAdobe Scan 19 Nov 2022Sunitha SasiNo ratings yet

- Adobe Scan 19 Nov 2022Document1 pageAdobe Scan 19 Nov 2022Sunitha SasiNo ratings yet

- Adobe Scan 19 Nov 2022Document1 pageAdobe Scan 19 Nov 2022Sunitha SasiNo ratings yet

- Belin 2013Document15 pagesBelin 2013Tecnología del HormigónNo ratings yet

- Reflections AcrylicDocument49 pagesReflections AcrylicananthNo ratings yet

- Figure 1.1: General Structure of Schiff BaseDocument15 pagesFigure 1.1: General Structure of Schiff Basedipto dasNo ratings yet

- Center For Advancing Research in Transportation Emissions, Energy, and HealthDocument25 pagesCenter For Advancing Research in Transportation Emissions, Energy, and HealthRoberttNo ratings yet

- 2015-5 - TechPresentation - Bentley ASME RTP 1Document71 pages2015-5 - TechPresentation - Bentley ASME RTP 1Christian Cobo100% (4)

- 06 KMA'15 SPM CHEMISTRY-ANALYSIS + ANS-Azie F.indd PDFDocument40 pages06 KMA'15 SPM CHEMISTRY-ANALYSIS + ANS-Azie F.indd PDFMd ZaidiNo ratings yet

- NEET Revision Notes For Chemistry Chemical Bonding and Molecular StructureDocument21 pagesNEET Revision Notes For Chemistry Chemical Bonding and Molecular StructureTanushree DeshmukhNo ratings yet

- Lee 2016Document31 pagesLee 2016Tatiana Gómez MoraNo ratings yet

- Sigmacover 280 Hardener MSDSDocument17 pagesSigmacover 280 Hardener MSDSJORGE MONCAYONo ratings yet

- AN-nir065Document4 pagesAN-nir065Mihaly JNo ratings yet

- Dry-Jet-Wet SpinningDocument16 pagesDry-Jet-Wet SpinningaadishNo ratings yet

- Organic ExperimentsDocument3 pagesOrganic ExperimentsVAIBHAW VAIBHAWNo ratings yet

- Artikel 23Document18 pagesArtikel 23M Ikhtiar Roza XII MIA 5No ratings yet

- 10 - SOT Question Paper End Sem 2012Document2 pages10 - SOT Question Paper End Sem 2012Harsh ThakurNo ratings yet

- Chemistry: Unit I. Chemistry and Us Factual KnowledgeDocument31 pagesChemistry: Unit I. Chemistry and Us Factual KnowledgeMARICEL MIRANDANo ratings yet

- AIATS-03 Open Mock Test @DefeatNEETDocument25 pagesAIATS-03 Open Mock Test @DefeatNEETDevendra SharmaNo ratings yet

- Activity CMT Glass Plactic BitumenDocument3 pagesActivity CMT Glass Plactic BitumenArif IzanyNo ratings yet

- MC MX 6-2960 Corrosion InhibitorDocument1 pageMC MX 6-2960 Corrosion InhibitorRicardo ValeraNo ratings yet

- G8010 2GR PREMIUM - Molykote - g8010Document2 pagesG8010 2GR PREMIUM - Molykote - g8010Dicky PratamaNo ratings yet

- Chapter 5 - Welding Joint Design and Welding SymbolsDocument43 pagesChapter 5 - Welding Joint Design and Welding Symbolsyves suarezNo ratings yet

- Chemistry Depth StudyDocument11 pagesChemistry Depth StudyAdyasree AlluruNo ratings yet

- Shear PumpDocument4 pagesShear PumpAnilNo ratings yet

- Samuchiwal Et Al. 2023 - Environ PollutDocument13 pagesSamuchiwal Et Al. 2023 - Environ PollutRahul KhandareNo ratings yet

- What Is A Hazardous Waste?Document4 pagesWhat Is A Hazardous Waste?Dali MondalNo ratings yet

- Processes 10 01041 v2Document23 pagesProcesses 10 01041 v2Maria AlvarezNo ratings yet

- ENERGY AND ENVIRONMENT - 18ME751 Module 4 - Dr. ShashikantDocument31 pagesENERGY AND ENVIRONMENT - 18ME751 Module 4 - Dr. Shashikant17druva MNo ratings yet

- Biology Chapter 3 Form 5 Presentation (Latest)Document28 pagesBiology Chapter 3 Form 5 Presentation (Latest)Alexander Yong Jin RongNo ratings yet