Professional Documents

Culture Documents

SDS 20920 Penguard HSP ZP Comp A Eng KR

Uploaded by

Daniel SinagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SDS 20920 Penguard HSP ZP Comp A Eng KR

Uploaded by

Daniel SinagaCopyright:

Available Formats

SAFETY DATA SHEET

SDS Number: AA003190000000289

Penguard HSP ZP Comp A

In accordance with the Standard for Classification and Labeling of Chemical Substance and Safety Data Sheet,

Article 10 Paragraph 1

Section 1. Chemical product and company identification

A. Product name : Penguard HSP ZP Comp A

Product code : 20920

Product description : Paint.

B. Relevant identified uses of the substance or mixture and uses advised against

C. Manufacturer : Chokwang Jotun Ltd.

96, Gwahaksandan 1-ro

Gangseo-gu, Busan

South Korea

Tel: +82 51 797 6000

Fax: +82 51 711 7735

SDSJotun@jotun.com

Emergency telephone : H.G.LEE Chokwang Jotun Ltd.

number Tel: +82 51 797 6000

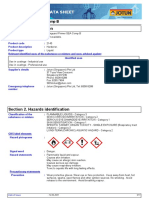

Section 2. Hazards identification

A. Hazard classification : FLAMMABLE LIQUIDS - Category 3

SKIN IRRITATION - Category 2

SERIOUS EYE DAMAGE - Category 1

SKIN SENSITIZATION - Category 1

AQUATIC HAZARD (LONG-TERM) - Category 2

This product is classified in accordance with the Industrial Safety and Health Act

and the Chemical Control Act.

B. GHS label elements, including precautionary statements

Symbol :

Signal word : Danger.

Hazard statements : H226 - Flammable liquid and vapor.

H315 - Causes skin irritation.

H317 - May cause an allergic skin reaction.

H318 - Causes serious eye damage.

H411 - Toxic to aquatic life with long lasting effects.

Precautionary statements

Prevention : P280 - Wear protective gloves, protective clothing and eye or face protection.

P210 - Keep away from heat, hot surfaces, sparks, open flames and other ignition

sources. No smoking.

P273 - Avoid release to the environment.

P261 - Avoid breathing vapor.

P264 - Wash hands thoroughly after handling.

P272 - Contaminated work clothing should not be allowed out of the workplace.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 2/13

Section 2. Hazards identification

Response : P391 - Collect spillage.

P303 + P361 + P353 - IF ON SKIN (or hair): Take off immediately all contaminated

clothing. Rinse skin with water.

P302 + P352 - IF ON SKIN: Wash with plenty of water.

P333 + P313 - If skin irritation or rash occurs: Get medical advice or attention.

P305 + P351 + P338, P310 - IF IN EYES: Rinse cautiously with water for several

minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

Immediately call a POISON CENTER or doctor.

Storage : Not applicable.

Disposal : P501 - Dispose of contents and container in accordance with all local, regional,

national and international regulations.

C.

Other hazards which do : None known.

not result in

classification

Section 3. Composition/information on ingredients

Substance/mixture : Mixture

Other means of : Not available.

identification

Ingredient name Common name Identifiers %

epoxy resin (MW ≤ 700) epoxy resin (MW ≤ 700) CAS: 1675-54-3 ≥15 - ≤20

titanium dioxide titanium dioxide CAS: 13463-67-7 ≥10 - ≤15

xylene xylene CAS: 1330-20-7 ≤10

2-methylpropan-1-ol 2-methylpropan-1-ol CAS: 78-83-1 ≤5

hydrocarbons, c9-unsatd., polymd. hydrocarbons, CAS: 71302-83-5 ≤5

C9-unsaturated,

polymerized

trizinc bis(orthophosphate) trizinc bis(orthophosphate) CAS: 7779-90-0 ≤5

ethylbenzene ethylbenzene CAS: 100-41-4 ≤5

1-methoxy-2-propanol 1-methoxy-2-propanol CAS: 107-98-2 ≤5

lead Inorganic lead compounds CAS: 7439-92-1 ≤5

There are no additional ingredients present which, within the current knowledge of the supplier and in the

concentrations applicable, are classified as hazardous to health or the environment and hence require

reporting in this section.

Occupational exposure limits, if available, are listed in Section 8.

Section 4. First aid measures

A. Eye contact : Get medical attention immediately. Call a poison center or physician. Immediately

flush eyes with plenty of water, occasionally lifting the upper and lower eyelids.

Check for and remove any contact lenses. Continue to rinse for at least 10 minutes.

Chemical burns must be treated promptly by a physician.

B. Skin contact : Get medical attention immediately. Call a poison center or physician. Wash with

plenty of soap and water. Remove contaminated clothing and shoes. Wash

contaminated clothing thoroughly with water before removing it, or wear gloves.

Continue to rinse for at least 10 minutes. Chemical burns must be treated promptly

by a physician. In the event of any complaints or symptoms, avoid further exposure.

Wash clothing before reuse. Clean shoes thoroughly before reuse.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 3/13

Section 4. First aid measures

C. Inhalation : Get medical attention immediately. Call a poison center or physician. Remove

victim to fresh air and keep at rest in a position comfortable for breathing. If it is

suspected that fumes are still present, the rescuer should wear an appropriate mask

or self-contained breathing apparatus. If not breathing, if breathing is irregular or if

respiratory arrest occurs, provide artificial respiration or oxygen by trained personnel.

It may be dangerous to the person providing aid to give mouth-to-mouth

resuscitation. If unconscious, place in recovery position and get medical attention

immediately. Maintain an open airway. Loosen tight clothing such as a collar, tie,

belt or waistband.

D. Ingestion : Get medical attention immediately. Call a poison center or physician. Wash out

mouth with water. Remove dentures if any. If material has been swallowed and the

exposed person is conscious, give small quantities of water to drink. Stop if the

exposed person feels sick as vomiting may be dangerous. Do not induce vomiting

unless directed to do so by medical personnel. If vomiting occurs, the head should

be kept low so that vomit does not enter the lungs. Chemical burns must be treated

promptly by a physician. Never give anything by mouth to an unconscious person.

If unconscious, place in recovery position and get medical attention immediately.

Maintain an open airway. Loosen tight clothing such as a collar, tie, belt or

waistband.

E. Notes to physician : Treat symptomatically. Contact poison treatment specialist immediately if large

quantities have been ingested or inhaled.

Specific treatments : No specific treatment.

Protection of first-aiders : No action shall be taken involving any personal risk or without suitable training. If it

is suspected that fumes are still present, the rescuer should wear an appropriate

mask or self-contained breathing apparatus. It may be dangerous to the person

providing aid to give mouth-to-mouth resuscitation. Wash contaminated clothing

thoroughly with water before removing it, or wear gloves.

See toxicological information (Section 11)

Section 5. Fire-fighting measures

A. Extinguishing media

Suitable extinguishing : Use dry chemical, CO₂, water spray (fog) or foam.

media

Unsuitable : Do not use water jet.

extinguishing media

B. Specific hazards arising

: Flammable liquid and vapor. Runoff to sewer may create fire or explosion hazard.

from the chemical In a fire or if heated, a pressure increase will occur and the container may burst, with

the risk of a subsequent explosion. This material is toxic to aquatic life with long

lasting effects. Fire water contaminated with this material must be contained and

prevented from being discharged to any waterway, sewer or drain.

Hazardous thermal : Decomposition products may include the following materials:

decomposition products carbon dioxide

carbon monoxide

phosphorus oxides

metal oxide/oxides

C. Special protective : Fire-fighters should wear appropriate protective equipment and self-contained

equipment for fire- breathing apparatus (SCBA) with a full face-piece operated in positive pressure

fighters mode.

Special precautions for : Promptly isolate the scene by removing all persons from the vicinity of the incident if

fire-fighters there is a fire. No action shall be taken involving any personal risk or without

suitable training. Move containers from fire area if this can be done without risk.

Use water spray to keep fire-exposed containers cool.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 4/13

Section 6. Accidental release measures

A. Personal precautions, : No action shall be taken involving any personal risk or without suitable training.

protective equipment Evacuate surrounding areas. Keep unnecessary and unprotected personnel from

and emergency entering. Do not touch or walk through spilled material. Shut off all ignition sources.

procedures No flares, smoking or flames in hazard area. Do not breathe vapor or mist. Provide

adequate ventilation. Wear appropriate respirator when ventilation is inadequate.

Put on appropriate personal protective equipment.

B. Environmental : Avoid dispersal of spilled material and runoff and contact with soil, waterways,

precautions drains and sewers. Inform the relevant authorities if the product has caused

environmental pollution (sewers, waterways, soil or air). Water polluting material.

May be harmful to the environment if released in large quantities. Collect spillage.

C. Methods and materials for containment and cleaning up

Small spill : Stop leak if without risk. Move containers from spill area. Use spark-proof tools and

explosion-proof equipment. Dilute with water and mop up if water-soluble.

Alternatively, or if water-insoluble, absorb with an inert dry material and place in an

appropriate waste disposal container. Dispose of via a licensed waste disposal

contractor.

Large spill : Stop leak if without risk. Move containers from spill area. Use spark-proof tools and

explosion-proof equipment. Approach release from upwind. Prevent entry into

sewers, water courses, basements or confined areas. Wash spillages into an

effluent treatment plant or proceed as follows. Contain and collect spillage with non-

combustible, absorbent material e.g. sand, earth, vermiculite or diatomaceous earth

and place in container for disposal according to local regulations (see Section 13).

Dispose of via a licensed waste disposal contractor. Contaminated absorbent

material may pose the same hazard as the spilled product. Note: see Section 1 for

emergency contact information and Section 13 for waste disposal.

Section 7. Handling and storage

A. Precautions for safe handling

Protective measures : Put on appropriate personal protective equipment (see Section 8). Persons with a

history of skin sensitization problems should not be employed in any process in

which this product is used. Do not get in eyes or on skin or clothing. Do not breathe

vapor or mist. Do not ingest. Avoid release to the environment. Use only with

adequate ventilation. Wear appropriate respirator when ventilation is inadequate.

Do not enter storage areas and confined spaces unless adequately ventilated.

Keep in the original container or an approved alternative made from a compatible

material, kept tightly closed when not in use. Store and use away from heat, sparks,

open flame or any other ignition source. Use explosion-proof electrical (ventilating,

lighting and material handling) equipment. Use only non-sparking tools. Take

precautionary measures against electrostatic discharges. Empty containers retain

product residue and can be hazardous. Do not reuse container.

Advice on general : Eating, drinking and smoking should be prohibited in areas where this material is

occupational hygiene handled, stored and processed. Workers should wash hands and face before

eating, drinking and smoking. Remove contaminated clothing and protective

equipment before entering eating areas. See also Section 8 for additional

information on hygiene measures.

B. Conditions for safe : Store in accordance with local regulations. Store in a segregated and approved

storage, including any area. Store in original container protected from direct sunlight in a dry, cool and well-

incompatibilities ventilated area, away from incompatible materials (see Section 10) and food and

drink. Store locked up. Eliminate all ignition sources. Separate from oxidizing

materials. Keep container tightly closed and sealed until ready for use. Containers

that have been opened must be carefully resealed and kept upright to prevent

leakage. Do not store in unlabeled containers. Use appropriate containment to

avoid environmental contamination. See Section 10 for incompatible materials

before handling or use.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 5/13

Section 8. Exposure controls/personal protection

A. Control parameters

Occupational exposure limits

Ingredient name Exposure limits

titanium dioxide Ministry of Employment and Labor

(Republic of Korea, 1/2020).

TWA: 10 mg/m³ 8 hours. Form: total dust

with less than 1% of free SiO2

xylene Ministry of Employment and Labor

(Republic of Korea, 1/2020).

STEL: 150 ppm 15 minutes.

TWA: 100 ppm 8 hours.

2-methylpropan-1-ol Ministry of Employment and Labor

(Republic of Korea, 1/2020).

TWA: 50 ppm 8 hours.

ethylbenzene Ministry of Employment and Labor

(Republic of Korea, 1/2020).

STEL: 125 ppm 15 minutes.

TWA: 100 ppm 8 hours.

1-methoxy-2-propanol Ministry of Employment and Labor

(Republic of Korea, 1/2020).

STEL: 150 ppm 15 minutes.

TWA: 100 ppm 8 hours.

Inorganic lead compounds Ministry of Employment and Labor

(Republic of Korea, 1/2020).

TWA: 0.05 mg/m³, (as Pb) 8 hours.

B. Appropriate engineering : Use only with adequate ventilation. Use process enclosures, local exhaust

controls ventilation or other engineering controls to keep worker exposure to airborne

contaminants below any recommended or statutory limits. The engineering controls

also need to keep gas, vapor or dust concentrations below any lower explosive

limits. Use explosion-proof ventilation equipment.

Environmental : Emissions from ventilation or work process equipment should be checked to ensure

exposure controls they comply with the requirements of environmental protection legislation. In some

cases, fume scrubbers, filters or engineering modifications to the process

equipment will be necessary to reduce emissions to acceptable levels.

C. Personal protective equipment

Respiratory protection : If workers are exposed to concentrations above the exposure limit, they must use

appropriate, certified respirators. Use respiratory mask with charcoal and dust filter

when spraying this product(as filter combination A2-P2 or NIOSH-approved P95). In

confined spaces, use compressed-air or fresh-air respiratory equipment. When use

of roller or brush, consider use of charcoalfilter.

Eye protection : Use safety eyewear designed to protect against splash of liquids.

Hand protection : There is no one glove material or combination of materials that will give unlimited

resistance to any individual or combination of chemicals.

The breakthrough time must be greater than the end use time of the product.

The instructions and information provided by the glove manufacturer on use,

storage, maintenance and replacement must be followed.

Gloves should be replaced regularly and if there is any sign of damage to the glove

material.

Always ensure that gloves are free from defects and that they are stored and used

correctly.

The performance or effectiveness of the glove may be reduced by physical/chemical

damage and poor maintenance.

Barrier creams may help to protect the exposed areas of the skin but should not be

applied once exposure has occurred.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 6/13

Section 8. Exposure controls/personal protection

Wear suitable gloves tested to EN374.

Recommended, gloves(breakthrough time) > 8 hours: Teflon, Viton®, Responder,

nitrile rubber, neoprene, butyl rubber, fluor rubber

May be used, gloves(breakthrough time) 4 - 8 hours: PVC, polyvinyl alcohol (PVA),

4H

For right choice of glove materials, with focus on chemical resistance and time of

penetration, seek advice by the supplier of chemical resistant gloves.

The user must check that the final choice of type of glove selected for handling this

product is the most appropriate and takes into account the particular conditions of

use, as included in the user's risk assessment.

Body protection : Personal protective equipment for the body should be selected based on the task

being performed and the risks involved and should be approved by a specialist

before handling this product. When there is a risk of ignition from static electricity,

wear anti-static protective clothing. For the greatest protection from static

discharges, clothing should include anti-static overalls, boots and gloves.

Hygiene measures : Wash hands, forearms and face thoroughly after handling chemical products, before

eating, smoking and using the lavatory and at the end of the working period.

Appropriate techniques should be used to remove potentially contaminated clothing.

Contaminated work clothing should not be allowed out of the workplace. Wash

contaminated clothing before reusing. Ensure that eyewash stations and safety

showers are close to the workstation location.

Section 9. Physical and chemical properties

The conditions of measurement of all properties are at standard temperature and pressure unless otherwise indicated.

A. Appearance

Physical state : Liquid.

Color : Black. , Grey, Red, Off-white., Red, Yellowish-brown.

B. Odor : Characteristic.

C. Odor threshold : Not available.

D. pH : Not applicable.

E. Melting/freezing point : Not applicable.

F. Boiling point, initial : Lowest known value: 108°C (226.4°F) (2-methylpropan-1-ol). Weighted average:

boiling point, and 224.24°C (435.6°F)

boiling range

G. Flash point : Closed cup: 29°C (84.2°F)

Fire point : Not available.

H. Evaporation rate : Highest known value: 0.84 (ethylbenzene) Weighted average: 0.75compared with

butyl acetate

I. Flammability (solid, gas) : Not available.

J. Lower and upper : Not available.

explosive (flammable)

limits

K. Vapor pressure : Highest known value: <1.6 kPa (<12 mm Hg) (at 20°C) (2-methylpropan-1-ol).

Weighted average: 0.44 kPa (3.3 mm Hg) (at 20°C)

L. Solubility : Insoluble in the following materials: cold water and hot water.

Solubility in water : Not available.

M. Vapor density : Highest known value: 11.7 (Air = 1) (epoxy resin (MW ≤ 700)). Weighted average:

8.09 (Air = 1)

N. Relative density : 1.688 to 1.786 g/cm³

O. Partition coefficient: n- : Not available.

octanol/water

P. Auto-ignition : Lowest known value: 270°C (518°F) (1-methoxy-2-propanol).

temperature

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 7/13

Section 9. Physical and chemical properties

Q. Decomposition : Not available.

temperature

R. Viscosity : Kinematic (40°C (104°F)): >20.5 mm2/s (>20.5 cSt)

Flow time (ISO 2431) : Not available.

S. Molecular weight : Not applicable.

Particle characteristics

Median particle size : Not applicable.

Section 10. Stability and reactivity

A. Chemical stability : The product is stable.

Possibility of hazardous : Under normal conditions of storage and use, hazardous reactions will not occur.

reactions

B. Conditions to avoid : Avoid all possible sources of ignition (spark or flame). Do not pressurize, cut, weld,

braze, solder, drill, grind or expose containers to heat or sources of ignition.

C. Incompatible materials : Keep away from the following materials to prevent strong exothermic reactions:

oxidizing agents, strong alkalis, strong acids.

D. Hazardous : Under normal conditions of storage and use, hazardous decomposition products

decomposition products should not be produced.

Section 11. Toxicological information

There are no data available on the mixture itself. See Sections 2 and 3 for details.

Exposure to component solvent vapor concentrations in excess of the stated occupational exposure limit may

result in adverse health effects such as mucous membrane and respiratory system irritation and adverse effects on

the kidneys, liver and central nervous system. Solvents may cause some of the above effects by absorption

through the skin. Repeated or prolonged contact with the mixture may cause removal of natural fat from the skin,

resulting in non-allergic contact dermatitis and absorption through the skin. Ingestion may cause nausea, diarrhea

and vomiting.

A. Information on the likely : Not available.

routes of exposure

Potential acute health effects

Inhalation : No known significant effects or critical hazards.

Ingestion : No known significant effects or critical hazards.

Skin contact : Causes skin irritation. May cause an allergic skin reaction.

Eye contact : Causes serious eye damage.

Over-exposure signs/symptoms

Inhalation : No specific data.

Ingestion : Adverse symptoms may include the following:

stomach pains

Skin contact : Adverse symptoms may include the following:

pain or irritation

redness

blistering may occur

Eye contact : Adverse symptoms may include the following:

pain

watering

redness

B. Health hazards

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 8/13

Section 11. Toxicological information

Acute toxicity

Product/ingredient name Result Species Dose Exposure

epoxy resin (MW ≤ 700) LD50 Dermal Rabbit 20 g/kg -

LD50 Oral Mouse 15600 mg/kg -

xylene LC50 Inhalation Vapor Rat 20 mg/l 4 hours

LD50 Oral Rat 4300 mg/kg -

TDLo Dermal Rabbit 4300 mg/kg -

2-methylpropan-1-ol LC50 Inhalation Vapor Rat 19200 mg/m³ 4 hours

LD50 Dermal Rabbit 3400 mg/kg -

LD50 Oral Rat 2460 mg/kg -

hydrocarbons, LD50 Dermal Rat >2000 mg/kg -

C9-unsaturated,

polymerized

LD50 Oral Rat >2000 mg/kg -

ethylbenzene LC50 Inhalation Vapor Rat - Male 17.8 mg/l 4 hours

LD50 Dermal Rabbit >5000 mg/kg -

LD50 Oral Rat 3500 mg/kg -

1-methoxy-2-propanol LD50 Dermal Rabbit 13 g/kg -

LD50 Oral Rat 6600 mg/kg -

Irritation/Corrosion

Product/ingredient name Result Species Score Exposure Observation

epoxy resin (MW ≤ 700) Eyes - Severe irritant Rabbit - 24 hours 2 -

milligrams

Skin - Mild irritant Rabbit - 500 -

milligrams

titanium dioxide Skin - Mild irritant Human - 72 hours -

xylene Eyes - Mild irritant Rabbit - 87 milligrams -

Skin - Mild irritant Rat - 8 hours 60 -

microliters

2-methylpropan-1-ol Eyes - Irritant Mammal - - - -

species

unspecified

Skin - Mild irritant Mammal - - - -

species

unspecified

1-methoxy-2-propanol Eyes - Mild irritant Rabbit - 24 hours -

500 mg

Skin - Mild irritant Rabbit - 500 mg -

Sensitization

Product/ingredient name Route of Species Result

exposure

epoxy resin (MW ≤ 700) skin Mammal - species Sensitizing

unspecified

hydrocarbons, skin Mouse Sensitizing

C9-unsaturated,

polymerized

CMR - ISHA Article 42 Occupational Exposure Limits

Product/ingredient name Identifiers Classification

Titanium dioxide CAS: 13463-67-7 CARCINOGENICITY - Category 2

Ethyl benzene CAS: 100-41-4 CARCINOGENICITY - Category 2

Lead and Inorganic compounds CAS: 7439-92-1 CARCINOGENICITY - Category 1B

TOXIC TO REPRODUCTION -

Category 1A

Mutagenicity

Conclusion/Summary : No known significant effects or critical hazards.

Carcinogenicity

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 9/13

Section 11. Toxicological information

Conclusion/Summary : No known significant effects or critical hazards.

Classification

Product/ingredient name OSHA IARC NTP ACGIH

epoxy resin (MW ≤ 700) - 3 - -

1-methoxy-2-propanol - - - A4

Inorganic lead compounds - 2B Reasonably anticipated to be a human A3

carcinogen.

Reproductive toxicity

Not available.

Teratogenicity

Conclusion/Summary : No known significant effects or critical hazards.

Specific target organ toxicity (single exposure)

Product/ingredient name Category Route of Target organs

exposure

xylene Category 3 - Respiratory tract

irritation

2-methylpropan-1-ol Category 3 - Respiratory tract

irritation

Category 3 Narcotic effects

1-methoxy-2-propanol Category 3 - Narcotic effects

Specific target organ toxicity (repeated exposure)

Product/ingredient name Category Route of Target organs

exposure

ethylbenzene Category 2 - hearing organs

Inorganic lead compounds Category 2 - -

Aspiration hazard

Product/ingredient name Result

xylene ASPIRATION HAZARD - Category 1

ethylbenzene ASPIRATION HAZARD - Category 1

Potential chronic health effects

Chronic toxicity

General : Once sensitized, a severe allergic reaction may occur when subsequently exposed

to very low levels.

Carcinogenicity : No known significant effects or critical hazards.

Mutagenicity : No known significant effects or critical hazards.

Reproductive toxicity : No known significant effects or critical hazards.

Numerical measures of toxicity

Acute toxicity estimates

Product/ingredient name Oral (mg/ Dermal Inhalation Inhalation Inhalation

kg) (mg/kg) (gases) (vapors) (dusts

(ppm) (mg/l) and mists)

(mg/l)

Penguard HSP ZP Comp A (MM-WCSE) N/A 19247.6 N/A 254.6 N/A

xylene 4300 1100 N/A 20 N/A

2-methylpropan-1-ol 2460 3400 N/A N/A N/A

hydrocarbons, C9-unsaturated, polymerized 2500 2500 N/A N/A N/A

ethylbenzene 3500 N/A N/A 17.8 N/A

1-methoxy-2-propanol 6600 13000 N/A N/A N/A

Inorganic lead compounds 500 N/A N/A N/A N/A

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 10/13

Section 12. Ecological information

A. Ecotoxicity

This material is toxic to aquatic life with long lasting effects.

Product/ingredient name Result Species Exposure

epoxy resin (MW ≤ 700) Acute EC50 1.4 mg/l Daphnia 48 hours

Acute LC50 3.1 mg/l Fish - pimephales promelas 96 hours

Chronic NOEC 0.3 mg/l Fish 21 days

titanium dioxide Acute LC50 3 mg/l Fresh water Crustaceans - Ceriodaphnia 48 hours

dubia - Neonate

Acute LC50 6.5 mg/l Fresh water Daphnia - Daphnia pulex - 48 hours

Neonate

Acute LC50 >1000000 µg/l Marine Fish - Fundulus heteroclitus 96 hours

water

xylene Acute LC50 8500 µg/l Marine water Crustaceans - Palaemonetes 48 hours

pugio

Acute LC50 13400 µg/l Fresh water Fish - Pimephales promelas 96 hours

2-methylpropan-1-ol Chronic NOEC 4000 µg/l Fresh water Daphnia - Daphnia magna 21 days

trizinc bis(orthophosphate) Acute LC50 0.14 mg/l Fish - Oncorhynchus mykiss 96 hours

Chronic NOEC 0.1 mg/l Micro-organism 4 hours

ethylbenzene Acute EC50 7700 µg/l Marine water Algae - Skeletonema costatum 96 hours

Acute EC50 2.93 mg/l Daphnia 48 hours

Acute LC50 4.2 mg/l Fish 96 hours

B. Persistence and degradability

Product/ingredient name Aquatic half-life Photolysis Biodegradability

epoxy resin (MW ≤ 700) - - Not readily

xylene - - Readily

trizinc bis(orthophosphate) - - Not readily

ethylbenzene - - Readily

C. Bioaccumulative potential

Product/ingredient name LogPow BCF Potential

epoxy resin (MW ≤ 700) 2.64 to 3.78 31 low

xylene 3.12 8.1 to 25.9 low

2-methylpropan-1-ol 1 - low

hydrocarbons, 3.627 - low

C9-unsaturated,

polymerized

trizinc bis(orthophosphate) - 60960 high

ethylbenzene 3.6 - low

1-methoxy-2-propanol <1 - low

D. Mobility in soil

Soil/water partition : Not available.

coefficient (KOC)

E. Other adverse effects : No known significant effects or critical hazards.

Section 13. Disposal considerations

A. Disposal methods : The generation of waste should be avoided or minimized wherever possible.

Disposal of this product, solutions and any by-products should at all times comply

with the requirements of environmental protection and waste disposal legislation

and any regional local authority requirements. Dispose of surplus and non-

recyclable products via a licensed waste disposal contractor. Waste should not be

disposed of untreated to the sewer unless fully compliant with the requirements of

all authorities with jurisdiction. Waste packaging should be recycled. Incineration or

landfill should only be considered when recycling is not feasible.

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 11/13

Section 13. Disposal considerations

B. Disposal precautions : This material and its container must be disposed of in a safe way. Care should be

taken when handling emptied containers that have not been cleaned or rinsed out.

Empty containers or liners may retain some product residues. Vapor from product

residues may create a highly flammable or explosive atmosphere inside the

container. Do not cut, weld or grind used containers unless they have been cleaned

thoroughly internally. Avoid dispersal of spilled material and runoff and contact with

soil, waterways, drains and sewers.

Section 14. Transport information

UN IMDG IATA

A. UN number UN1263 UN1263 UN1263

B. UN proper Paint Paint. Marine pollutant (trizinc Paint

shipping name bis(orthophosphate), epoxy

resin (MW ≤ 700))

C. Transport 3 3 3

hazard class(es)

D. Packing group III III III

E. Environmental Yes. The environmentally Yes. Yes. The environmentally

hazards hazardous substance mark is hazardous substance mark is

not required. not required.

Additional information

UN : Tunnel restriction code: (D/E)

Hazard identification number: 30

IMDG : The marine pollutant mark is not required when transported in sizes of ≤5 L or ≤5 kg.

Emergency schedules F-E, S-E

IATA : The environmentally hazardous substance mark may appear if required by other

transportation regulations.

F. Special precautions for : Transport within user’s premises: always transport in closed containers that are

user upright and secure. Ensure that persons transporting the product know what to do in

the event of an accident or spillage.

Transport in bulk according : Not available.

to IMO instruments

Transport in accordance with ADR/RID, IMDG/IMO and ICAO/IATA and national regulation.

Section 15. Regulatory information

A. Regulation according to ISHA

ISHA article 117 : None of the components are listed.

(Harmful substances

prohibited from

manufacture)

ISHA article 118 : None of the components are listed.

(Harmful substances

requiring permission)

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 12/13

Section 15. Regulatory information

Article 2 of Youth : Not applicable.

Protection Act on

Substances Hazardous

to Youth

Exposure Limits of Chemical Substances and Physical Factors

The following components have an OEL:

titanium dioxide

xylene

2-methylpropan-1-ol

ethylbenzene

1-methoxy-2-propanol

Inorganic lead compounds

ISHA Enforcement Regs : The following components are listed: Lead and its inorganic compounds

Annex 19 (Exposure

standards established

for harmful factors)

ISHA Enforcement Regs : The following components are listed: titanium dioxide, xylene, isobutyl alcohol, ethyl

Annex 21 (Harmful benzene

factors subject to Work

Environment

Measurement)

ISHA Enforcement Regs : The following components are listed: Xylene, Isobutyl alcohol, Ethyl benzene

Annex 22 (Harmful

Factors Subject to

Special Health Check-

up)

Standard of Industrial : The following components are listed: titanium dioxide, xylene, isobutyl alcohol, zinc

Safety and Health and its compounds, ethyl benzene

Annex 12 (Hazardous

substances subject to

control)

B. Regulation according to Chemicals Control Act

CCA Article 11 (TRI) : The following components are listed: Xylene including o-,m-,p- isomer, Zinc and its

compounds, Ethylbenzene

Article 18 Prohibited (K- : None of the components are listed.

Reach Article 27)

Article 19 Subject to : None of the components are listed.

authorization (K-Reach

Article 25)

Article 20 Toxic : Not applicable

Chemicals (K-Reach

Article 20)

Article 20 Restricted (K- : None of the components are listed.

Reach Article 27)

CCA Article 39 : None of the components are listed.

(Accident Precaution

Chemicals)

Existing Chemical : The following components are listed: Xylene; Dimethylbenzene, Trizinc bis

Substances Subject to (orthophosphate, Lead

Registration

C. Dangerous Materials : Class: Class 4 - Flammable Liquid

Safety Management Act Item: 4. Class 2 petroleums - Water-insoluble liquid

Threshold: 1000 L

Danger category: III

Signal word: Contact with sources of ignition prohibited

Date of revision : 25.01.2022

Penguard HSP ZP Comp A Page: 13/13

Section 15. Regulatory information

D. Wastes regulation : Dispose of contents and container in accordance with all local, regional, national

and international regulations.

E. Regulation according to other foreign laws

International regulations

Chemical Weapon Convention List Schedules I, II & III Chemicals

Not listed.

Montreal Protocol

Not listed.

Stockholm Convention on Persistent Organic Pollutants

Not listed.

Rotterdam Convention on Prior Informed Consent (PIC)

Not listed.

UNECE Aarhus Protocol on POPs and Heavy Metals

Not listed.

Section 16. Other information

A. References : - Registry of Toxic Effects of Chemical Substances

- United States Environmental Protection Agency ECOTOX

B. Date of issue : 25.01.2022

Date of revision : 25.01.2022

C. Version : 1

Date of printing : 25.01.2022

D. Other

Indicates information that has changed from previously issued version.

Key to abbreviations : ATE = Acute Toxicity Estimate

BCF = Bioconcentration Factor

GHS = Globally Harmonized System of Classification and Labelling of Chemicals

IATA = International Air Transport Association

IBC = Intermediate Bulk Container

IMDG = International Maritime Dangerous Goods

LogPow = logarithm of the octanol/water partition coefficient

MARPOL = International Convention for the Prevention of Pollution From Ships,

1973 as modified by the Protocol of 1978. ("Marpol" = marine pollution)

N/A = Not available

SGG = Segregation Group

UN = United Nations

Notice to reader

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are

often used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the

product itself. Minor product variations may be implemented in order to comply with local requirements.

Jotun reserves the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their

needs and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United

Kingdom) version will prevail.

Date of revision : 25.01.2022

You might also like

- SDS Penguard HB Comp ADocument13 pagesSDS Penguard HB Comp AK3L AJGNo ratings yet

- SDS Penguard Comp BDocument13 pagesSDS Penguard Comp BK3L AJGNo ratings yet

- Barrier 77 Comp ADocument13 pagesBarrier 77 Comp ATan Chen KiongNo ratings yet

- Msds P6Document14 pagesMsds P6Bansal Engineers Grain Milling Pvt LtdNo ratings yet

- SDS 35683 Jotamastic 70 Comp B Eng CADocument14 pagesSDS 35683 Jotamastic 70 Comp B Eng CATubagus DikaNo ratings yet

- Jotamastic 80 Comp ADocument15 pagesJotamastic 80 Comp AMohammad Imtiaz AliNo ratings yet

- SDS 574 Marathon Comp A Euk TH-TH THDocument11 pagesSDS 574 Marathon Comp A Euk TH-TH THsbry.anwrNo ratings yet

- SDS 1505 Epoxy HR Comp A Eng USDocument15 pagesSDS 1505 Epoxy HR Comp A Eng USsufizamaniNo ratings yet

- Msds F6 BDocument14 pagesMsds F6 BBansal Engineers Grain Milling Pvt LtdNo ratings yet

- Safety Data Sheet Hazard IdentificationDocument11 pagesSafety Data Sheet Hazard IdentificationPOKHTOON WORLDNo ratings yet

- 5062-8576 NAEnglishDocument12 pages5062-8576 NAEnglishYudha DorkzillaNo ratings yet

- Msds Aicd 2Document16 pagesMsds Aicd 2Kadek Ayang Cendana PrahayuNo ratings yet

- Cfas HbaicDocument18 pagesCfas HbaicKadek Ayang Cendana PrahayuNo ratings yet

- SDS 720 Solvalitt Euk AEDocument11 pagesSDS 720 Solvalitt Euk AEDebbie SaputraNo ratings yet

- SDS 14920 Woodshield Exterior Euk TH-TH KHDocument11 pagesSDS 14920 Woodshield Exterior Euk TH-TH KHTom RiddleNo ratings yet

- Hardtop Ultra Comp ADocument13 pagesHardtop Ultra Comp Anuryati jahariNo ratings yet

- Barrier 80 Comp BDocument12 pagesBarrier 80 Comp BColourNo ratings yet

- SDS 527 Jotamastic 87 Standard Comp B Eng USDocument12 pagesSDS 527 Jotamastic 87 Standard Comp B Eng USIan Czar E. BangcongNo ratings yet

- MSDS-jotomastıc 87 Comp-ADocument14 pagesMSDS-jotomastıc 87 Comp-AnestroyersNo ratings yet

- Sodium Hydroxide Solution 30 - 54 MX ENDocument15 pagesSodium Hydroxide Solution 30 - 54 MX ENChe RomeroNo ratings yet

- Sikafloor®-81 Epocem® New HC (C) : Safety Data SheetDocument8 pagesSikafloor®-81 Epocem® New HC (C) : Safety Data SheetHaris RisdianaNo ratings yet

- Safety Data Sheet for Pilot QD PrimerDocument13 pagesSafety Data Sheet for Pilot QD PrimerHarold JimenezNo ratings yet

- Jotamastic 80 Aluminium Comp A Euk Zho CNDocument12 pagesJotamastic 80 Aluminium Comp A Euk Zho CNDashzeveg DashkaaNo ratings yet

- Tank Guard Storage MSDSDocument14 pagesTank Guard Storage MSDSPradip GhoshNo ratings yet

- SDS Jotafloor Topcoat Comp BDocument11 pagesSDS Jotafloor Topcoat Comp BSreejith MadhavanNo ratings yet

- SDS Penguard Midcoat Comp ADocument13 pagesSDS Penguard Midcoat Comp AK3L AJGNo ratings yet

- SDS MSDS 000030 Chain and Cable Lube L0135-063 2014 06-15 MSCDocument17 pagesSDS MSDS 000030 Chain and Cable Lube L0135-063 2014 06-15 MSCeadriesNo ratings yet

- Penguard Msds Comp ADocument12 pagesPenguard Msds Comp Apavan kumarNo ratings yet

- Protect Eyes from Flammable Aerosol SprayDocument11 pagesProtect Eyes from Flammable Aerosol Sprayabdulbaset alselwi100% (1)

- Section 1. Identification: Safety Data SheetDocument13 pagesSection 1. Identification: Safety Data SheetMohammad Imtiaz AliNo ratings yet

- SDS 4238 Jotacryl Euk QADocument11 pagesSDS 4238 Jotacryl Euk QAzubiahmadNo ratings yet

- CA1405 Partially Hydrogenated Coconut Fatty Acid SDSDocument10 pagesCA1405 Partially Hydrogenated Coconut Fatty Acid SDSJay LakhaniNo ratings yet

- Msds Penguard Midcoat B JotunDocument12 pagesMsds Penguard Midcoat B JotuncrysNo ratings yet

- Concentrated Cleaner SDSDocument7 pagesConcentrated Cleaner SDSmds9185No ratings yet

- Safety Data Sheet Solvalitt Paint Provides Important Safety InformationDocument12 pagesSafety Data Sheet Solvalitt Paint Provides Important Safety InformationcristinaNo ratings yet

- DownloadfebbDocument11 pagesDownloadfebbmohamed saadNo ratings yet

- Electric Isolation Peint DatasheetDocument15 pagesElectric Isolation Peint Datasheetsosorel10No ratings yet

- Sds - SDS 35982 Jotafix Epoxy Primer Comp A Euk OMDocument12 pagesSds - SDS 35982 Jotafix Epoxy Primer Comp A Euk OMPeshteenNo ratings yet

- B 8001 EdbfDocument24 pagesB 8001 EdbfDharmendra DubeyNo ratings yet

- Protect Yourself from Toxic Pesticide SDSDocument21 pagesProtect Yourself from Toxic Pesticide SDSAndi SupriyonoNo ratings yet

- MasterTop 1140 PART A SDS Safety Data SheetDocument10 pagesMasterTop 1140 PART A SDS Safety Data SheetYudhaNo ratings yet

- Caustic Soda 47 Sds5317 EnDocument12 pagesCaustic Soda 47 Sds5317 EnsonerNo ratings yet

- SDS 36902 Jotafix PU Topcoat Comp A Euk TH-TH THDocument11 pagesSDS 36902 Jotafix PU Topcoat Comp A Euk TH-TH THtebongedeNo ratings yet

- Pengard Comp B - Jotun - SDSDocument13 pagesPengard Comp B - Jotun - SDSmani nadarNo ratings yet

- SDS SikarugasolDocument9 pagesSDS SikarugasolIis InayahNo ratings yet

- Msds Jotamastic 80 A JotunDocument14 pagesMsds Jotamastic 80 A JotuncrysNo ratings yet

- SDS 2140 Penguard Primer SEA Comp B Euk SGDocument11 pagesSDS 2140 Penguard Primer SEA Comp B Euk SGMustafa GhuloomNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. Identificationj.saiyathNo ratings yet

- 1201 GlyptalDocument11 pages1201 GlyptalRonald CatacoraNo ratings yet

- MikroBac Forte-MsdsDocument10 pagesMikroBac Forte-MsdsDendi Pradeep ReddyNo ratings yet

- MSDS - Jotun JotamasticDocument27 pagesMSDS - Jotun Jotamasticfirstyan dhika aldaniNo ratings yet

- 1 PDFDocument14 pages1 PDFAndre YulianNo ratings yet

- Resina MEGAPOXY HICB-Part-B-Version-2.1 - Ficha Segurança - ENGDocument6 pagesResina MEGAPOXY HICB-Part-B-Version-2.1 - Ficha Segurança - ENGfernando.luis.mariaNo ratings yet

- Nitric AcidDocument12 pagesNitric AcidRichard StanleyNo ratings yet

- SDS 500 Jotafloor Solvent Free Primer Comp A Euk Zho CNDocument11 pagesSDS 500 Jotafloor Solvent Free Primer Comp A Euk Zho CNnuryati jahariNo ratings yet

- MSDS Aradur 2965 PDFDocument9 pagesMSDS Aradur 2965 PDFkamalnandreNo ratings yet

- MasterRoc HCA 10 safety data sheetDocument10 pagesMasterRoc HCA 10 safety data sheetabukayes.abdinNo ratings yet

- MSDS-jotomastıc 87 Comp-BDocument11 pagesMSDS-jotomastıc 87 Comp-BnestroyersNo ratings yet

- SDS 10540 Gardex Premium Gloss Euk SGDocument11 pagesSDS 10540 Gardex Premium Gloss Euk SGFadzil RofieNo ratings yet

- Contoh ITP Dan FlowchartDocument8 pagesContoh ITP Dan FlowchartDaniel SinagaNo ratings yet

- Line-000-Ca-4-0013 - Specification For Fencing - Rev. 0Document8 pagesLine-000-Ca-4-0013 - Specification For Fencing - Rev. 0Daniel SinagaNo ratings yet

- Tower 3 Daily Monitoring ProgressDocument1 pageTower 3 Daily Monitoring ProgressDaniel SinagaNo ratings yet

- Price ComparationDocument1 pagePrice ComparationDaniel SinagaNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- Tower 4 Daily Monitoring ProgressDocument1 pageTower 4 Daily Monitoring ProgressDaniel SinagaNo ratings yet

- Tower 2 Daily Monitoring ProgressDocument1 pageTower 2 Daily Monitoring ProgressDaniel SinagaNo ratings yet

- Tower 4 Daily Monitoring ProgressDocument1 pageTower 4 Daily Monitoring ProgressDaniel SinagaNo ratings yet

- 5.ITP For Excavation and Back FillingDocument19 pages5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- 8.ITP For Painting KK3 - PR - 20 - 00002Document9 pages8.ITP For Painting KK3 - PR - 20 - 00002Daniel SinagaNo ratings yet

- Tower 4 Daily Monitoring ProgressDocument1 pageTower 4 Daily Monitoring ProgressDaniel SinagaNo ratings yet

- JIS G3131 Hot Roll Mild Steel Plates Sheet and StripDocument9 pagesJIS G3131 Hot Roll Mild Steel Plates Sheet and StripAnonymous uYGle1vucNo ratings yet

- 6.ITP For RebarDocument1 page6.ITP For RebarDaniel Sinaga100% (1)

- Gis G 3112-2010Document22 pagesGis G 3112-2010Tú TrầnNo ratings yet

- Calibration Certificate: #N/A #N/A #N/A #N/ADocument1 pageCalibration Certificate: #N/A #N/A #N/A #N/AMauricioNo ratings yet

- Dr. Derm CatalogDocument20 pagesDr. Derm CatalogCosmetics Bulgaria100% (1)

- Chapter-2 - Matter-and-EnergyDocument26 pagesChapter-2 - Matter-and-EnergyJam BermejoNo ratings yet

- Natural gas pipeline capacity calculationDocument3 pagesNatural gas pipeline capacity calculationMohamed SamyNo ratings yet

- Module 1 Unit 1Document12 pagesModule 1 Unit 1Mia Lorena JandocNo ratings yet

- Safety Data Sheet: (Helaian Data Keselamatan) P461-XXXX Revision No: 1Document10 pagesSafety Data Sheet: (Helaian Data Keselamatan) P461-XXXX Revision No: 1SerenitiNo ratings yet

- Organic Chemistry Test QuestionsDocument4 pagesOrganic Chemistry Test QuestionsAbaring KathrynaNo ratings yet

- What Is Compressive Strength: Compressive Strength Is The MaximumDocument2 pagesWhat Is Compressive Strength: Compressive Strength Is The MaximumLASA VADODARANo ratings yet

- Dr. Ahmad Nawaz: Lecture 02: Introduction To Engineering Materials and Their StructuresDocument34 pagesDr. Ahmad Nawaz: Lecture 02: Introduction To Engineering Materials and Their StructuresAhmad NawazNo ratings yet

- Bulk and Suspenshion Polynerization of MMA Into PMMADocument5 pagesBulk and Suspenshion Polynerization of MMA Into PMMADavid Meza CarbajalNo ratings yet

- Extension Module 6 of ChemistryDocument6 pagesExtension Module 6 of Chemistryangelo aquinoNo ratings yet

- Hitec 355 PdsDocument2 pagesHitec 355 PdsAlex CamposNo ratings yet

- An Air Compressor Is Tested and It Is Found That T...Document2 pagesAn Air Compressor Is Tested and It Is Found That T...Juan DiegoNo ratings yet

- Titration - FinalDocument2 pagesTitration - FinalHitesh SharmaNo ratings yet

- UEP (July2013) Paper 1Document4 pagesUEP (July2013) Paper 1Irfan AliNo ratings yet

- PM304 ch1Document6 pagesPM304 ch1何英奇No ratings yet

- HabaCHIAN Slat Conveyor ChainsDocument128 pagesHabaCHIAN Slat Conveyor Chainsjunico76No ratings yet

- Carbonyls, Carboxylic Acid and ChiralityDocument23 pagesCarbonyls, Carboxylic Acid and ChiralityAyshath MaaishaNo ratings yet

- Polymers: 1. Polymers 1.1 General Introduction and Its ScopeDocument7 pagesPolymers: 1. Polymers 1.1 General Introduction and Its ScopeJayvee MendozaNo ratings yet

- Journal of Cleaner Production: Amit Madhu, J.N. ChakrabortyDocument20 pagesJournal of Cleaner Production: Amit Madhu, J.N. ChakrabortyNagender SinghNo ratings yet

- Manufacturing of Acrylonitrile Internship ReportDocument33 pagesManufacturing of Acrylonitrile Internship ReportHirenNo ratings yet

- SS - AIATS - 01 (Adv) - P - 1 - A - 2020-06-21 - 2020 - QDocument23 pagesSS - AIATS - 01 (Adv) - P - 1 - A - 2020-06-21 - 2020 - Qyash chawliyaNo ratings yet

- Line Sizing Criteria As Per Different International StandardsDocument12 pagesLine Sizing Criteria As Per Different International StandardsbadelitamariusNo ratings yet

- Essentials of Chemical Reaction Engineering 1st Edition Fogler Solutions Manual Full Chapter PDFDocument42 pagesEssentials of Chemical Reaction Engineering 1st Edition Fogler Solutions Manual Full Chapter PDFJulieMorrisfazg100% (11)

- Alphawool 1600 Vacuum Formed Board Data SheetDocument2 pagesAlphawool 1600 Vacuum Formed Board Data SheetGurdeep Sungh AroraNo ratings yet

- Impacts On Marine Ecology 2016Document56 pagesImpacts On Marine Ecology 2016Kalyani C ChendilNo ratings yet

- Us3479310 PDFDocument7 pagesUs3479310 PDFKhoi Nguyen DangNo ratings yet

- Acs JPCC 1c02131Document9 pagesAcs JPCC 1c02131arkaphysicsNo ratings yet

- Photomultiplier Tube: FeaturesDocument2 pagesPhotomultiplier Tube: Featuresابو حميد ابو حميدNo ratings yet

- Squeeze Cement With Coiled TubingDocument60 pagesSqueeze Cement With Coiled TubingJose Leonardo Materano Perozo100% (1)