Professional Documents

Culture Documents

Environmental Plan

Uploaded by

Sakthi Kasi RajanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Plan

Uploaded by

Sakthi Kasi RajanCopyright:

Available Formats

ENVIRONMENT MANAGEMENT

PLAN

(TYPICAL)

0 Issued for Review / Comments

Approved

Date Rev Description Prepared by Checked by Approved by

by Client

Document No. XXXXXXXXXXXXXX Sheet 1 of 18 Rev 0

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

TABLE OF CONTENTS

1. SCOPE AND PURPOSE ............................................................................................ 4

2. POLICY .................................................................................................................. 4

3. ABBREVIATIONS AND DEFINITIONS ........................................................................ 4

4. REFERENCE............................................................................................................ 4

5. PROJECT OBJECTIVES ............................................................................................. 5

6. PROJECT ORGANIZATION AND RESPONSIBILITIES ................................................... 6

7. COMMUNICATION ................................................................................................ 8

8. MEETING PROGRAM ............................................................................................. 9

9. ENVIRONMENTAL INDUCTION / TRAINING ............................................................. 9

10. TOOLBOX MEETINGS ........................................................................................... 10

11. ENVIRONMENTAL PROCEDURES .......................................................................... 10

12. ENVIRONMENTAL PERMIT ................................................................................... 11

13. PPE REQUIREMENTS ............................................................................................ 11

14. EMERGENCY PREPAREDNESS AND RESPONSE....................................................... 12

14.1 EMERGENCY RESPONSE TEAM ........................................................................12

14.2 RESPONSIBILITIES OF EMERGENCY RESPONSE TEAM .....................................12

14.3 EMERGENCY PREPAREDNESS FACILITIES .........................................................13

14.4 EMERGENCY RESPONSE PROCEDURE..............................................................14

14.5 ASSEMBLY POINT .............................................................................................14

14.6 EMERGENCY EVACUATION DRILL ....................................................................14

14.7 EMERGENCY CONTACT NUMBERS ..................................................................15

15. EQUIPMENT INSPECTION ..................................................................................... 15

16. WASTE MANAGEMENT ........................................................................................ 15

Doc. No.: GS-EMP-REV00 Page 2 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

17. ACCIDENT / INCIDENT MANANGEMENT ...............................................................16

18. AUDITS AND INSPECTION .................................................................................... 16

19. PERFORMANCE MONITORING AND MEASUREMENT ............................................ 17

20. ENVIRONMENTAL RISK ASSESSMENT ................................................................... 17

21. ATTACHMENTS.................................................................................................... 17

Doc. No.: GS-EMP-REV00 Page 3 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

1. SCOPE AND PURPOSE

The prime purpose of this plan is to provide the Client with a comprehensive document that describes the

implementation of responsibilities, standards, and correct working practices for the management of the

Environmental risks associated with all GAS SOLUTIONS activities.

GAS SOLUTIONS site activities shall be executed in complete compliance with this plan and as per the

guidelines mentioned in the procedures attached after approval from the Client. As evidence of compliance

all relevant checklists, formats, and reports shall be visible, retained, and made available upon Client

request.

The plan makes use of KSA laws, Client Environmental regulations, and existing GAS SOLUTIONS Working

Procedures.

2. POLICY

It is the policy of the GAS SOLUTIONS team to develop a safe and healthy working environment, not only to

comply with health and safety legislation but also to act responsibly in preventing injury, ill health, damage,

losses, and environmental pollutions arising from its activities during all phases of the project.

QUALITY, HEALTH, SAFETY, AND ENVIRONMENT POLICY

Note: A formal copy of this policy signed by top management is attached as ATTACHMENT 2.

3. ABBREVIATIONS AND DEFINITIONS

EMP-Environment Management Plan

IMS-Integrated Management System

QHSE-Quality, Health, Safety, and Environment

HSE- Health, Safety, and Environment

4. REFERENCE

GAS SOLUTIONS is fully committed to ensuring the health & safety of all site personnel & the preservation of

the environment & natural resources. For this project, GAS SOLUTIONS shall ensure compliance with the

Kingdom of Saudi Arabia and Client specifications, guidelines, and permit-to-work system.

GAS SOLUTIONS shall adhere to the following:

Doc. No.: GS-EMP-REV00 Page 4 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

1) CLIENT Specific documents

2) Contractual documents

3) Legal documents

4) I S O -14001:2004

5) The requirement of the Supreme Council of Environment KSA

6) GAS SOLUTIONS IMS Manual

5. PROJECT OBJECTIVES

GAS SOLUTIONS' project objectives are to provide Environment-friendly working conditions for all

employees and the surrounding community and to maintain the highest environmental standards

concerning work and equipment operations.

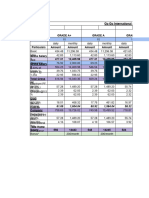

GAS SOLUTIONS Corporate-level Objectives and Targets are as follows:

Objectives Targets Performance Indicators

Legal Compliance 100 % Legal compliance Legal Compliance Register

5 % reduction in electricity

consumption in offices compared Monitoring Data

to 2021

5 % reduction in Paper

Resource Conservation consumption in offices compared Monitoring Data

to 2021

5 % reduction in Paper

consumption in offices compared Millage & Fuel Consumption

to 2021 Report

Training in environmental

awareness of engineers / Workshop to cover

supervisors at construction engineers/supervisors across the Record of personnel trained

sites company during 2021

Project-specific Objectives and Targets are as follows:

Objective:

• To Conserve Resources and Reduce Waste Generation.

Targets:

• 100 % Provision of secondary containment for diesel and lubricant/chemical storage.

Doc. No.: GS-EMP-REV00 Page 5 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

• 100% PUC for vehicles and equipment directly engaged by GAS SOLUTIONS

• 5 % reduction in diesel consumption compared to rated consumption

• 100 %Waste Segregation

6. PROJECT ORGANIZATION AND RESPONSIBILITIES

To ensure the success of the Environmental requirement implementation, GAS SOLUTIONS has a structure,

which ensures that:

• The Senior Management supports the formal Environment management of the project;

• There are sufficient managerial resources to support the Project’s Environmental processes;

• There are sufficient specialist resources to coordinate the implementation of the EMP;

• All members of Project Management have clearly defined responsibilities in terms of the

implementation of the EMP; and

• All workers play an active role in the Environmental process.

A generic project organization chart is given in Attachment no: 1

The responsibilities of the Project key figures involved in implementing the Environment Management

System are described below.

Project manager:

The Project Manager is delegated with the responsibility to ensure that the Environmental policies,

objectives, and activities incorporated or inferred in the project EMP are carried out and that any related

procedures are fully implemented.

It is his / her responsibility to continually review the effectiveness of the EMP/procedures and that the

operation under his / her control to whom Environment matters have been assigned.

Specifically, he shall:

• Be familiar with and demonstrate his commitment to the implementation of the Company QHSE

policy and promote continual improvement in Environment performance.

• Ensure that all personnel for whom he is responsible are aware of this Policy and implement

relevant procedures as per requirement

• Manage the effective implementation of the Project EMP and ensure corrective action is taken

where found necessary.

• Ensure that Environmental Risk Assessments are carried out at the earliest practicable opportunity.

• Ensure that all potential incidents involving damage to the environment, damage to property, or

the health of the personnel are thoroughly considered to identify causes and propose mitigation

measures;

• Monitor the Environmental performance of the activities under his control.

• Establish a consultation and communication system with all employees and

subcontractors.

Doc. No.: GS-EMP-REV00 Page 6 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

• Ensure sufficient induction training for all employees and workers before the

commencement of work at the site and subsequently for new inductees.

• Formulate an HSE committee.

• Arrange and chair HSE meetings.

• Participate in the investigation of the accident; incident and implementation of enforcing

corrective action.

Project Engineer:

The Project Engineer is responsible for ensuring that the activities under the contractual work scope are

completed by following the relevant approved criteria, standards, and procedures.

Specifically, he shall:

• Ensure that work under his control is conducted with due regard to safety considerations.

• Be familiar with the Company GAS SOLUTIONS IMS policy and the Project Environmental

Management Plan.

• Liaise and cooperate with HSE Engineer and ensure that defects brought to attention are

corrected.

• Establish and maintain proper communication with all workers concerning safety aspects.

• Provide proper supervision for the work.

Environmental Engineer / Officer:

Accountable to the Project Manager for fulfilling the duties assigned to him in the QHSE policy and

ensuring implementation of EMP. The Environmental Engineer / Officer is also responsible to the Project

Manager for the provision of Environmental advice and reporting on the environmental performance of the

project. Besides, his duties will include: -

• Monitor the implementation of Environmental Procedures at worksites

• Communicate with Line Management (Supervisors and Foremen) in Environment related matters

on their work sites

• Carry out inspections and issue reports on unsafe conditions/actions.

• Ensure that routine inspections are carried out on firefighting equipment, first aid facilities, and

other emergency equipment and take necessary action when required.

• Attend and participate in site HSE committee meetings, management HSE review meetings, and

periodic HSE meetings.

• Identify the training needs of project personnel.

• Generate and submit all necessary Environmental reports as required by the Client.

• Assist in conducting additional Toolbox Talks on new activities

• Assist in the investigation of accidents/incidentsWork supervisor:

The worksite supervisor’s responsibility includes:-

• Identifying the project’s Environmental requirements relevant to all operations under his

accountability.

• Communicate the Environmental aspects related to specific jobs to his workforce and ensure that

mitigation measures are met.

Doc. No.: GS-EMP-REV00 Page 7 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

• Ensure all the workforce under his accountability complies with the minimum required and task-

specific PPE requirements.

• Report any Environmental issues to the site Environmental engineer.

• Carry out site Environmental inspections and correct unsafe acts and conditions if any.

• Motivate workforce on compliance with project Environmental rules.

• Raise necessary work permits from the area authorities before commencing any activity.

• Ensure that the crafts under him have the necessary skills/undergone the necessary pieces of

training to perform the task assigned to them.

All personnel:

All personnel who are a part of the project directly or indirectly shall:

• Have attended Environmental induction briefing before commencing work on site.

• Comply with PPE requirements whenever present on the worksite according to their

respective job.

• Take all necessary precautions to ensure that their activities do not affect adversely other

working personnel involved in other activities.

• Work according to the instructions of their supervisors and always comply with Project EMP

and procedures.

• All personnel shall act as per the instruction of the main controller/incident controller in the

event of an emergency.

• Maintain the workplace properly with good housekeeping, free of Environmental Aspects.

• Report any accident/incident or near miss to his immediate supervisor or

Environmental representative.

7. COMMUNICATION

Effective communication is essential for the development of a good Environmental culture within the

organization, as well as to ensure that the objectives, Environmental performance requirements, and

responsibilities are clearly understood. This will be implemented through:

• Dissemination of GAS SOLUTIONS QHSE Policy to all personnel, and instruction on its use;

• Distribution of Memos, periodic Environmental briefing notes, Environmental alerts, etc. regularly;

• Promoting open communications between project management and the workforce on

Environmental matters.

• Ensuring Environmental issues are included on the top of the agenda at management meetings;

• Promoting hygiene, Environmental awareness by disseminating information such as accident and

injury statistics, and articles that have a direct impact on the environment; sharing Environmental

experience and best practices;

• On-the-job instructions (toolbox meeting);

• Effective signs indicating hazards and escape routes;

• Management visits to the site.

Doc. No.: GS-EMP-REV00 Page 8 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

8. MEETING PROGRAM

HSE Meetings Programme is convened to ensure that health, safety, and environmental issues are formally

presented and discussed collectively at all construction sites, which will be convened and chaired by the

Project Manager. All safety committee members shall also attend the meetings. GAS SOLUTIONS will report

all types of HSE Meetings to the Client representative who will be invited to the meeting.

9. ENVIRONMENTAL INDUCTION / TRAINING

Immediately after the employment of all new personnel or assignment of personnel to a project, he/she

will attend an environmental Induction training organized by the GAS SOLUTIONS site Environmental

representative.

GAS SOLUTIONS shall keep records showing that each employee has attended an environmental induction

session.

As required, all project personnel shall undergo Client induction before site deployment.

Good environmental awareness training will arrange for all employees, especially for those learning a new

trade. It is also essential to keep Supervisors and skilled Operators up-to-date with current Environmental

technology and practices. In addition to Environmental Induction, GAS SOLUTIONS will ensure specialized

training to all necessary employees during the project as per Client training requirements.

10. TOOLBOX MEETINGS

The supervisors and foremen are accountable to lead the daily toolbox talks to the working crews. This is to

ensure that every worker is quite conscious of his duties and hazards thereon, answer any questions, and

initiates discussions. The supervisors/foremen inspect the conditions of all tools and equipment, PPEs;

materials stored, and proposed work procedures. They shall also discuss the accidents and deficiencies if

any that occurred in the previous days.

The details of the Job safety analysis shall be cascaded to the workforce before work commences through

the toolbox talks.

The toolbox talks will be recorded in the template as given in Attachment no: 3

11. ENVIRONMENTAL PROCEDURES

A set of environmental Procedures are developed for the construction activities associated with installation

operations and environmental personnel shall be employed for the project who will ensure the relevant

implementation.

Doc. No.: GS-EMP-REV00 Page 9 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

The environmental Construction Procedures represent good working practices to be implemented at the

site level by the supervisors and the workforce. They are formulated in a way that may be also used as

training tools for the personnel and as references for Tool Box meetings.

The environmental Procedures apply to all site activities directly performed or supervised by GAS

SOLUTIONS Project Management.

The environmental procedures relevant to GAS SOLUTIONS operations are identified as per GAS

SOLUTIONS IMS and listed below:

• Environment aspect, impact Identification & control

• Improvement Program

• Accident, incident, investigation, and reporting

• Emergency preparedness and response

• Waste management

• Air pollution and control

• Minimization of ecological disturbance

• Issue and use of PPE

• Fire Prevention

• Housekeeping

12. ENVIRONMENTAL PERMIT

GAS SOLUTIONS ensures that all Environmental related permit approvals shall be obtained from the Ministry of

Environment KSA before proceeding with any such work which requires the above permits.

A work permit authorizes specific works to be conducted in a specific area. This serves as a record that

establishes steps that have been taken to ensure safe working conditions in the area.

GAS SOLUTIONS shall strictly follow the Client Work Permit System and other relevant procedures when

working on the site.

When required, an application for Work Permit shall be made in advance (as per Client requirement) before

the commencement of the work activity.

Any activity will not start until all conditions on a work permit are completely met.

13. PPE REQUIREMENTS

PPE includes protective clothing with high visibility, head protection, eye protection, and foot protection.

PPE is considered only as a last line of defense and as a means of supporting other more effective controls.

PPE is supplied free of charge to those identified as at risk.

Doc. No.: GS-EMP-REV00 Page 10 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

GAS SOLUTIONS ensures that PPE is:

• Suitable for the intended use.

• Maintained fit for purpose, cleaned, and replaced when damaged or no longer effective.

• Properly used by staff and sub-contractors and visitors.

• Complying with Client Requirements.

GAS SOLUTIONS identifies the following listed PPE as the minimum required for site entry for all personnel

• Helmet

• Safety goggles

• Safety shoes

• Long sleeve cover-all

• Reflective Vest

Additional job-specific PPE shall be enforced based on the nature of the activity, work location, and the

level of hazards.

14. EMERGENCY PREPAREDNESS AND RESPONSE

GAS SOLUTIONS shall fully comply with the Client’s emergency procedure while working at the site and

shall ensure that all its employees are fully aware of the procedure through induction and training.

However, GAS SOLUTIONS shall have an emergency response plan, procedures, and arrangements, specific

to the location and activities carried out, which shall be applied when working in a remote area where

Client monitoring is not practicable.

The objective of the Emergency Procedures is to ensure that any emergency affecting the place of

operational activities is dealt with efficiently and professionally so that the safety of personnel is not

compromised in any way. The environmental pollution risks are prevented or minimized and all other

losses which may arise from emergencies are prevented.

A site-specific emergency response plan will be developed in line with Client procedures, to detail the

arrangements and measures, which specify the actions to be taken in the event of an emergency that may

occur during operational activities.

Each Section of the Specific Emergency Response Plan provides instructions and relevant checklists, which

should be utilized to assist in incident management. Emergency plans cover most operations, i.e.

• Fire Explosions.

• Spillage

• Structural/equipment failure.

• Escape of gas.

• Medical emergency.

Doc. No.: GS-EMP-REV00 Page 11 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

14.1 EMERGENCY RESPONSE TEAM

GAS SOLUTIONS has identified emergency response team members who will be responsible for the

project group and responding to an emergency.

• The main controller (Project Manager);

• Incident controller(Project Engineer);

• Incident action team members (Supervisor & Engineers)

14.2 RESPONSIBILITIES OF THE EMERGENCY RESPONSE TEAM

Main controller:

• Control and direct the overall situation from the incident control center

• Inform the Client and explain the type of emergency & location of the emergency;

• Coordinate action with the Incident Controller

• Call out and brief the public emergency services if required

• Direct the evacuation of people and stop all activities if required

• Call in key operational personnel

• Continually review and assess possible developments

• Ensure casualties are receiving appropriate attention

• Issue statements to employees and the public media

• Control the return to normal operations after the emergency

Incident controller:

• Control the initial situation

• Assess the level of response required

• Call out the senior manager if required, who will become the Main Controller

• Call out and brief the public emergency services if required

• Direct operations at the scene of the incident

• Set up communication between the scene of the incident and the incident control center

• Brief the Main Controller on arrival

Incident action team members:

• Inform the incident controller immediately

• If possible Fight and control emergency

• Check for rescue & provide first aid

• Shut down equipment, isolate materials, and if required move equipment

• Organize for emergency power and lighting

• Manage assembly points and escape routes and direct personnel

Doc. No.: GS-EMP-REV00 Page 12 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

14.3 EMERGENCY PREPAREDNESS FACILITIES

GAS SOLUTIONS has taken proactive measures in the form of emergency preparedness facilities to

ensure that potential emergencies are handled efficiently and the project team is in a state of

readiness to respond to any emergency that may arise.

GAS SOLUTIONS shall provide the following emergency preparedness facilities at the project site and

office.

• A sufficient number of fire extinguishers shall be positioned throughout the project site.

• Quick and efficient transport and communication facilities shall be available.Smoking will be restricted

throughout the premises except in designated areas.

• A sufficient number of project personnel shall be trained for firefighting and first aid.

• A sufficient quantity of first aid kits shall be available.

• All key personnel shall be provided with communication means like land phones/ mobile Phones

to ease communication during an emergency.

• A periodic emergency response drill shall be conducted.

14.4 EMERGENCY RESPONSE PROCEDURE

The main controller shall consider the following points before evacuation:

• The severity of the incident;

• The likelihood of escalation;

• The incident becomes uncontrollable beyond the resources available.

The generic process of evacuation is shown below;

• Reason for evacuation realized.

• The main controller and incident controller assess the situation.

• Notification is given to staff and others concerned to evacuate to assembly points.

• Incident action team members render assistance as required, under the direction of the main

controller.

• Client emergency Services were notified of the emergency.

• Incident action team members to ensure the venue is vacated (public areas, toilets, etc).

• A roll call shall be initiated at the assembly point to account for the missing members.

• Await Emergency Services Assessment.

14.5 ASSEMBLY POINT

The Assembly point is an area at which all personnel assembles during an emergency after evacuation.

This shall be identified at a suitable location near t GAS SOLUTIONS operating area. The area shall be

suitably large to occupy all the project team members and displayed with standard signage for easy

identification.

Working in the Client operation area, the Client Assembly point shall be identified for assembling in

Doc. No.: GS-EMP-REV00 Page 13 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

emergencies.

14.6 EMERGENCY EVACUATION DRILL

Emergency evacuation drills shall be conducted within the project members to verify the effectiveness

of emergency preparedness and to monitor the readiness of the members to respond to a real

emergency. GAS SOLUTIONS shall conduct this drill once every six months. The outcome of the drill

shall be documented in the Mock drill report form as given in Attachment no: 4 and recorded.

14.7 EMERGENCY CONTACT NUMBERS

The Client's emergency contact numbers shall be identified and displayed at relevant locations at the

project site.

15. EQUIPMENT INSPECTION

GAS SOLUTIONS is strongly committed to ensuring the safe condition of the equipment to be used in the

worksite and those maintained for emergency preparedness. It applies to all equipment used by GAS

SOLUTIONS and covers safe handling, maintenance, storage, and use.

All equipment shall be used only after Client Safety inspection and approval where applicable.

Following is the list of equipment, tools, and instruments for which the requirements apply but are not

limited,

• Fire extinguisher

• First aid kit

• PPE

• Vehicles / Equipment

The inspection and reporting system for the project is primarily designed to ensure that all tools and

equipment are maintained in a safe condition and to minimize any downtime. All the tools and equipment

used by GAS SOLUTIONS shall be inspected by a competent person against the Cliessss requirement before

putting into operation.

16. WASTE MANAGEMENT

GAS SOLUTIONS confirms its commitment to performing the Project scope of works with the least possible

impact on the environment and in absolute compliance with all Client requirements,

GAS SOLUTIONS shall pay due regard to the environment by acting to minimize any impact, which may

arise from construction activities. This includes assessing the types of materials and substances that are

currently in use and substituting them with more environmentally friendly materials.

Doc. No.: GS-EMP-REV00 Page 14 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

Environmental objectives are set and improvement programs are running, at the GAS SOLUTIONS

corporate level as a part of ISO 14001 compliance which includes a reduction in fuel, electricity, and paper

consumption.

GAS SOLUTIONS shall ensure that all the waste produced as a result of GAS SOLUTIONS operations at the

site is identified as hazardous and domestic wastes and shall be handled and disposed of by following the

Client Specifications for Waste Management and all related KSA regulatory standards related to waste

management.

Sewage waste shall be handled by the authorized waste management agency and documented proof shall

be made available

GAS SOLUTIONS shall always comply with the Client waste management procedure if available.

However, GAS SOLUTIONS has developed a waste management procedure specific to its operations which

shall be applied in line with Client procedures. The procedure is given in Attachment no: 10E

17. ACCIDENT / INCIDENT MANANGEMENT

All accidents, incidents, and near-misses shall be classified, investigated, and reported systematically by

following the established Client Accident / Incident Reporting and Investigation System.

The Site Environmental representative shall be the focal point for the administration of the system and will

compile it in the monthly HSE statistics report.

The Site Environmental representative shall ensure the system is in operation by:

• Ensuring immediate notification is made to the authorities.

• Ensuring all accident /incident near misses are reported immediately and a written report

submitted to the Client within 24 hrs.

• Initiating investigation of all Environmental incidents beyond the immediate cause to identify the

root cause.

The written incident investigation report shall contain the root causes of the incident and a corrective

action plan to prevent the recurrence of similar incidents.

Besides GAS SOLUTIONS shall invite the Client’s Environmental advisor to be present while investigating

the incident that occurred within GAS SOLUTIONS’ activities while on Client premises.

The GAS SOLUTIONS accident/incident investigation report and Incident notification report form is given in

Attachment no: 5 and 6

18. AUDITS AND INSPECTION

Doc. No.: GS-EMP-REV00 Page 15 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

The project operations shall be audited half-yearly by GAS SOLUTIONS’ internal auditors. The aim of the

audit will be the identification of non-conformity in compliance with the integrated management system,

Environmental plan, and Client Environmental regulations. Corrective and preventive action will be

initiated by the project manager to correct the deficiencies and improve the management system.

GAS SOLUTIONS will also subject itself to inspections and audits conducted by Client personnel and take

necessary steps to initiate corrective action.

GAS SOLUTIONS shall allow client representatives to access any time to its operational areas, personnel,

and records when requested to make a formal investigation of compliance with regulations, procedures,

and safe work practices.

The corrective and preventive action report (CPAR) template is given in Attachment no: 7

19. PERFORMANCE MONITORING AND MEASUREMENT

GAS SOLUTIONS shall be responsible for recording and reporting all work-related accident incidents near

misses, and damages, during the project duration, to Client and Local authorities where applicable.

GAS SOLUTIONS shall submit periodic Environmental performance reports weekly / monthly / quarterly

and yearly as appropriate. These reports shall consist of both proactive indicators such as the number of

HSE meetings, Environmental toolbox talks, pieces of training, and induction as well as reactive indicators

which include man-hours worked, number of lost time incidents, near misses, medical treatment cases,

Environmental incidents, motor vehicle incidents, occupational illness, etc.

Monthly Environmental performance report shall be prepared as per the Environmental Monitoring Plan

given in Attachment No.:8 and submitted regularly.

20. ENVIRONMENTAL RISK ASSESSMENT

GAS SOLUTIONS has established a procedure for environmental aspect identification, assessment, and

control given in Attachment 10A; shall ensure that Aspect and its Impact relating to its work are identified,

risk assessed and control measures shall be put in place.

Aspect identification techniques and processes are used to identify the Aspects during the project

development stages. A generic Environmental Risk Assessment is given in Attachment 9.

Doc. No.: GS-EMP-REV00 Page 16 of 17

Document Title TYPICAL ENVIRONMENT MANAGEMENT PLAN

Document No. GS-EMP-REV00

Revision No. 0

Date 16th January 2022

21. ATTACHMENTS

Control of attachments:

The attachments of this document shall be updated whenever required during the project, and shall be

submitted for Client approval; however, this Environment Management Plan shall be of the same revision

status.

Attachment no: 1 – Project Organization Chart

Attachment no: 2 – QHSE Policy.

Attachment no: 3 – Toolbox talk record.

Attachment no: 4 – Mock drill report.

Attachment no: 5 – Accident/Incident investigation report.

Attachment no: 6 – HSE Incident notification form.

Attachment no: 7 – Corrective and preventive action report.

Attachment no: 8 – Environmental Monitoring Plan Attachment

Attachment no: 9 – Environmental Risk Assessment

*Attachment no: 10A – Environment Aspect, Impact Identification & control

*Attachment no: 10B – Improvement Program

*Attachment no: 10C – Accident, incident, investigation, and reporting

*Attachment no: 10D – Emergency preparedness and response

*Attachment no: 10E – Waste management

*Attachment no: 10F – Air pollution and control

*Attachment no: 10G – Minimization of ecological disturbance

*Attachment no: 10H – Issue and use of PPE

*Attachment no: 10I – Fire Prevention

*Attachment no: 10J – House Keeping

*This will be selectively included in the project-specific EMP as appropriate

Doc. No.: GS-EMP-REV00 Page 17 of 17

You might also like

- Contractor HSE Management ProgramDocument12 pagesContractor HSE Management ProgramAhmed IbrahimNo ratings yet

- Minutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftDocument5 pagesMinutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftMohammed Jai Sujiya KhanNo ratings yet

- Objectives and TargetsDocument2 pagesObjectives and TargetsZohaib TahirNo ratings yet

- Control of Substances Hazordous To HealthDocument16 pagesControl of Substances Hazordous To Healthnathan_roadNo ratings yet

- Environmental and Waste Management Plan (EMP) - 1Document31 pagesEnvironmental and Waste Management Plan (EMP) - 1Ekum EdunghuNo ratings yet

- Certi Ed Anti-Money Laundering Specialist (CAMS)Document2 pagesCerti Ed Anti-Money Laundering Specialist (CAMS)Alex ThomasNo ratings yet

- Oil India Limited: Onshore Emergency Response PlanDocument23 pagesOil India Limited: Onshore Emergency Response Planaji sathyanandanNo ratings yet

- BSP Contractor HSSE QuestionnaireDocument3 pagesBSP Contractor HSSE QuestionnaireMohamad HafizNo ratings yet

- HSE PlanDocument20 pagesHSE PlanSakthi Kasi RajanNo ratings yet

- Safety Audit PDFDocument11 pagesSafety Audit PDFaqibNo ratings yet

- Our ChallengeDocument198 pagesOur ChallengeZachary KleimanNo ratings yet

- ISO 45001 HSE Manual and Forms ListDocument5 pagesISO 45001 HSE Manual and Forms ListWAN NORASHIKIN WAN MUSANo ratings yet

- Saep 13Document25 pagesSaep 13Engg Shah Ather QuadriNo ratings yet

- TPF RAG Violation AnalysisDocument2 pagesTPF RAG Violation AnalysisImran KhanNo ratings yet

- COSHH Assessment FormDocument2 pagesCOSHH Assessment Formmohamed atefNo ratings yet

- Planned Parenthood HBCU Organizing Toolkit d07Document17 pagesPlanned Parenthood HBCU Organizing Toolkit d07Carole NovielliNo ratings yet

- HSE Manual Provides Guidance on Health, Safety & Environmental RequirementsDocument13 pagesHSE Manual Provides Guidance on Health, Safety & Environmental RequirementsNZ NZ100% (1)

- HSEMS & Manual Rev 02, May 2018Document419 pagesHSEMS & Manual Rev 02, May 2018isaacNo ratings yet

- HSE Safety AuditsDocument3 pagesHSE Safety Auditsvlad100% (1)

- STATCON - People v. Purisima, G.R. No. L-42050-66, 20 November 1978 - AMORILLO, D.Document4 pagesSTATCON - People v. Purisima, G.R. No. L-42050-66, 20 November 1978 - AMORILLO, D.Danica AmorilloNo ratings yet

- 2 - Hse Legal and Other RequirmentDocument8 pages2 - Hse Legal and Other Requirmentbilo1984No ratings yet

- HSE-P-06 Monitoring and Measurement Issue 2.1Document4 pagesHSE-P-06 Monitoring and Measurement Issue 2.1eng20072007No ratings yet

- Quality PlanDocument40 pagesQuality PlanSakthi Kasi RajanNo ratings yet

- HSEQ-HQ-09-01-00 Incident and Accident Investigation PDFDocument13 pagesHSEQ-HQ-09-01-00 Incident and Accident Investigation PDFAHMED AMIRANo ratings yet

- 2.2 Driving PolicyDocument2 pages2.2 Driving Policyoussama_88100% (1)

- BAC Resolution - GOODS 15 13Document2 pagesBAC Resolution - GOODS 15 13Jerald MaglantayNo ratings yet

- Monthly Statistical Report #32 UP03, March, 2022Document4 pagesMonthly Statistical Report #32 UP03, March, 2022yasirali43No ratings yet

- Control of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Document24 pagesControl of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Tiago FerreiraNo ratings yet

- T&D-HSE-PRC-0061 Procurement ProcedureDocument12 pagesT&D-HSE-PRC-0061 Procurement ProcedureDamalieNo ratings yet

- Financial Model - Real Estate DevelopmentDocument7 pagesFinancial Model - Real Estate DevelopmentAdnan Ali100% (1)

- Fatigue Management ProcedureDocument12 pagesFatigue Management ProcedureWakarusa CoNo ratings yet

- Plaintiff-Appellee: Second DivisionDocument14 pagesPlaintiff-Appellee: Second DivisionAurora SolastaNo ratings yet

- Environment, Health & Safety Policy - PPT-rev3Document48 pagesEnvironment, Health & Safety Policy - PPT-rev3Isabel ImNo ratings yet

- Monitoring HSE PerformanceDocument2 pagesMonitoring HSE PerformanceYousaf RichuNo ratings yet

- CoP - 9.0 - Workplace WellnessDocument9 pagesCoP - 9.0 - Workplace WellnessAnonymous y1pIqcNo ratings yet

- Incident Report PDFDocument29 pagesIncident Report PDFMehdi MessNo ratings yet

- IMS-PRO-02 Hazard and Risk Assessment & Aspect ImpactDocument6 pagesIMS-PRO-02 Hazard and Risk Assessment & Aspect ImpactISO Consultancy100% (1)

- 04 Sop For Objectives, Targets & EnvtalDocument7 pages04 Sop For Objectives, Targets & EnvtalMusyoka UrbanusNo ratings yet

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- OHS-PR-02-07 Document ControlDocument14 pagesOHS-PR-02-07 Document ControlSn Ahsan100% (1)

- Daily HSSE Report TemplateDocument2 pagesDaily HSSE Report TemplateBadr JLASSI100% (1)

- Caubang VS People Title 4Document9 pagesCaubang VS People Title 4Michy De GuzmanNo ratings yet

- Environmental Aspects, Impacts and Its Evaluation: AuthorizationDocument7 pagesEnvironmental Aspects, Impacts and Its Evaluation: AuthorizationMukilan ThiruNo ratings yet

- Health Requirements for Labour AccommodationsDocument7 pagesHealth Requirements for Labour Accommodationsdemie figueroaNo ratings yet

- Sustainability Management Plan: Movenpick Hotel Ibn Battuta Gate DubaiDocument39 pagesSustainability Management Plan: Movenpick Hotel Ibn Battuta Gate DubaiEka Descartez0% (1)

- Guevarra V BanachDocument2 pagesGuevarra V BanachRishell Miral100% (2)

- VIivares v. ReyesDocument3 pagesVIivares v. ReyesJustineNo ratings yet

- Waste Management Procedure PDFDocument6 pagesWaste Management Procedure PDFASHIQ KOYITH VEETILNo ratings yet

- Environmental Policy TemplateDocument3 pagesEnvironmental Policy TemplateJahaziNo ratings yet

- ASMI-OSHMS-PR-02 - Targets and Objectives ProcedureDocument9 pagesASMI-OSHMS-PR-02 - Targets and Objectives ProcedureJHUPEL ABARIALNo ratings yet

- Guidelines For HO Staff Traveling To Site: Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesGuidelines For HO Staff Traveling To Site: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- Improvement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Document10 pagesImprovement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Ravi Shankar TurlapatiNo ratings yet

- PLN-1400-0000-013 Community Health and Safety Plan 4 October PDFDocument13 pagesPLN-1400-0000-013 Community Health and Safety Plan 4 October PDFrodman823No ratings yet

- AD EHSMS RF - Form E - Entity Quaterly Performance Report - V2.1Document3 pagesAD EHSMS RF - Form E - Entity Quaterly Performance Report - V2.1Suraj NairNo ratings yet

- Pt. Delta Multi Karya: HSE Management System ManualDocument20 pagesPt. Delta Multi Karya: HSE Management System Manualmedia trisna100% (1)

- Thermax Engineering HO staff travel guidelinesDocument2 pagesThermax Engineering HO staff travel guidelinesNagendra Kumar SinghNo ratings yet

- Ensure sufficient natural and artificial lightingDocument3 pagesEnsure sufficient natural and artificial lightingMohamed MounerNo ratings yet

- Monthly Safety Report SampleDocument2 pagesMonthly Safety Report SamplenagaaNo ratings yet

- N-MS-NTT-PRO-150 EHS Monitoring ProceduresDocument4 pagesN-MS-NTT-PRO-150 EHS Monitoring ProceduresZaid RNo ratings yet

- Communication, Participation & ConsulatationDocument7 pagesCommunication, Participation & ConsulatationSuresh MuruganNo ratings yet

- DMSG-12-4 Management System ReviewDocument6 pagesDMSG-12-4 Management System ReviewWilliam VazquezNo ratings yet

- Management Review Meeting MinutesDocument2 pagesManagement Review Meeting Minutesilayaraja MKNo ratings yet

- 7010 - Subcontractor Performance Assessment FormDocument4 pages7010 - Subcontractor Performance Assessment FormRifatRahmatullahNo ratings yet

- IH Plan GoalsDocument3 pagesIH Plan GoalsKukuh WidodoNo ratings yet

- HSE Procedure For Garbage DisposalDocument4 pagesHSE Procedure For Garbage DisposalKhuda BukshNo ratings yet

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtNo ratings yet

- EIA Registration FormDocument2 pagesEIA Registration FormOluwaseun Babs LawalNo ratings yet

- Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesThermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- BOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Document21 pagesBOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Jude EdohorNo ratings yet

- Business Process Re-engineering (BPR) A Clear and Concise ReferenceFrom EverandBusiness Process Re-engineering (BPR) A Clear and Concise ReferenceNo ratings yet

- LPG Installation Periodic Inspection & Testing ScheduleDocument1 pageLPG Installation Periodic Inspection & Testing ScheduleSakthi Kasi RajanNo ratings yet

- Inspection ReportDocument9 pagesInspection ReportSakthi Kasi RajanNo ratings yet

- Go Go International-3Document2 pagesGo Go International-3sahil.goelNo ratings yet

- 3.history Civics and Geography PDFDocument64 pages3.history Civics and Geography PDFloose manusyaNo ratings yet

- Iajuddin AhmedDocument6 pagesIajuddin AhmedMichael FelicianoNo ratings yet

- Quiño Essay PDFDocument2 pagesQuiño Essay PDFRyuusukeNo ratings yet

- Fraction 1Document5 pagesFraction 1Anjal NasheetNo ratings yet

- Zielonka, Dariusz JDocument318 pagesZielonka, Dariusz JBOMI YOONNo ratings yet

- Rizal and The Chinese ConnectionDocument12 pagesRizal and The Chinese ConnectionLee HoseokNo ratings yet

- GEPPC WEEK 4 ACTIVITY 2 March 4 2023Document4 pagesGEPPC WEEK 4 ACTIVITY 2 March 4 2023McRoovers NovelaNo ratings yet

- DBP Loan Dispute Over Interest Rates and ChargesDocument5 pagesDBP Loan Dispute Over Interest Rates and ChargesfrancisNo ratings yet

- Survival Guide For Undocumented Students Uc Berkeley EditionDocument24 pagesSurvival Guide For Undocumented Students Uc Berkeley EditionundocuresourcesNo ratings yet

- Regulations of The Occupational Health and Safety DepartmentDocument62 pagesRegulations of The Occupational Health and Safety DepartmentCruz CruzNo ratings yet

- Insurance Policy Automatically Cancelled for Unpaid PremiumDocument6 pagesInsurance Policy Automatically Cancelled for Unpaid PremiumMarkey MarqueeNo ratings yet

- The Lady or the Tiger? Summary and ThemesDocument12 pagesThe Lady or the Tiger? Summary and ThemesFarah ElmirNo ratings yet

- Sultan Ismail CollegeDocument3 pagesSultan Ismail CollegeAmin GorgonnNo ratings yet

- Final Exam Purposive CommunicationDocument2 pagesFinal Exam Purposive CommunicationReñer Aquino Bystander0% (1)

- Vander Nat and Keep - MLM 2002Document13 pagesVander Nat and Keep - MLM 2002Bill KeepNo ratings yet

- Sexual Harassment Case Studies ExplainedDocument20 pagesSexual Harassment Case Studies ExplainedMegumi ParkNo ratings yet

- Additional ClausesDocument13 pagesAdditional ClausesPankaj GuptaNo ratings yet

- Dr. Bhimrao Ambedkar University, AgraDocument2 pagesDr. Bhimrao Ambedkar University, Agraajay sharmaNo ratings yet

- Final Fresno County GP LetterDocument10 pagesFinal Fresno County GP LetterMelissa MontalvoNo ratings yet