Professional Documents

Culture Documents

LPG Installation Periodic Inspection & Testing Schedule

Uploaded by

Sakthi Kasi Rajan0 ratings0% found this document useful (0 votes)

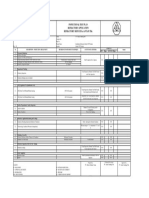

12 views1 pageThis document outlines the periodic inspection and testing requirements for an LPG installation according to various standards. It specifies that components like tanks, valves, regulators, meters and gauges should be inspected visually for leaks every 1 to 5 years, and undergo more thorough tests like pressure testing or replacement every 5 to 10 years. Pipe work and fill lines should also undergo wall thickness testing using ultrasonic sensors every 10 years to check for corrosion. Safety systems, electrical equipment, and other components require operational and functionality tests on a regular basis.

Original Description:

Original Title

Inspections & Tests

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the periodic inspection and testing requirements for an LPG installation according to various standards. It specifies that components like tanks, valves, regulators, meters and gauges should be inspected visually for leaks every 1 to 5 years, and undergo more thorough tests like pressure testing or replacement every 5 to 10 years. Pipe work and fill lines should also undergo wall thickness testing using ultrasonic sensors every 10 years to check for corrosion. Safety systems, electrical equipment, and other components require operational and functionality tests on a regular basis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageLPG Installation Periodic Inspection & Testing Schedule

Uploaded by

Sakthi Kasi RajanThis document outlines the periodic inspection and testing requirements for an LPG installation according to various standards. It specifies that components like tanks, valves, regulators, meters and gauges should be inspected visually for leaks every 1 to 5 years, and undergo more thorough tests like pressure testing or replacement every 5 to 10 years. Pipe work and fill lines should also undergo wall thickness testing using ultrasonic sensors every 10 years to check for corrosion. Safety systems, electrical equipment, and other components require operational and functionality tests on a regular basis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

PERIODIC INSPECTION & TESTING

LPG INSTALLATION

ACCORDING TO : NFPA 54, NPA 58, API-510

PART OF L.P.G SYSTEM TO PERIODIC YEARS

BE INSPECTED

1 5 10

HYDRO OR THICKNESS

TANKS LEAK VISUAL TEST

GAUGING TEST

REPLACE COVER

SAFETY RELIEF VALVES VISUAL TEST REPLACED AS PER NFPA 58

OF PRV

HYDROSTATIC VALVES LEAK - REPLACED

SHUT OFF VALVES OPERTIONAL TEST OPERTIONAL TEST OPERTIONAL TEST

EXCESS FLOW VALVES LEAK TEST LEAK TEST OPERTIONAL TEST

NON-RETURN VALVES LEAK TEST LEAK TEST OPERTIONAL TEST

FIRST STAGE REGULATOR LEAK & OPERTIONAL TEST LEAK TEST REPLACEMENT

SECOND STAGE REGULTOR LEAK & OPERTIONAL TEST LEAK TEST REPLACEMENT

GAS METERS LEAK TEST LEAK TEST REPLACEMENT

LEVEL GAUGES LEAK TEST LEAK TEST REPLACEMENT

LEAK TEST &

TEMP.GAUGES LEAK TEST REPLACEMENT

CALIBERATION

LEAK TEST &

PRESS.GAUGES LEAK TEST REPLACEMENT

CALIBERATION

HYDROSTATIC OR WALL

LEAK TEST AND INSPECTION

FILLING LINE LEAK TEST THICNESS USING ULTRASONIC

FOR CORROSION / DAMAGE

SENSORS

HYDROSTATIC OR WALL

LEAK TEST & INSPECTION

PIPE WORK LEAK TEST THICNESS USING ULTRASONIC

FOR CORROSION / DAMAGE

SENSORS

ALARM SYSTEM OPERTIONAL / FUNCTIONAL TEST

ELECTRICAL EQUIPMENT OPERTIONAL / FUNCTIONAL TEST

SPRINKLERS DEVICES OPERTIONAL / FUNCTIONAL TEST

SPRINKLER SYSTEM OPERTIONAL / FUNCTIONAL TEST

FIRE PRECAUTION REGULARLY

THERMAL INSUL VISUAL TEST

HYDROSTATIC OR WALL

VAPORIZERS LEAK TEST VISUAL TEST THICNESS USING ULTRASONIC

SENSORS

PUMPS, COMPRESSORS LEAK TEST ACCORDING TO SUPPLIER RECOMMENDATION

GAS SOLUTIONS GS-EO&M-INSP-001

REV00

You might also like

- Experimental Fluid Mechanics: Thermodynamics and Fluid Mechanics DivisionFrom EverandExperimental Fluid Mechanics: Thermodynamics and Fluid Mechanics DivisionRating: 4.5 out of 5 stars4.5/5 (5)

- SA Advanced NDT.36130258Document16 pagesSA Advanced NDT.36130258aun.muhd2No ratings yet

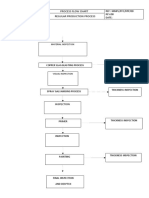

- Process Flow Chart Regular Production Process: Ref: Mmpl/Pfc/Rpp/00 REV:00 DateDocument1 pageProcess Flow Chart Regular Production Process: Ref: Mmpl/Pfc/Rpp/00 REV:00 DateCorrosion FactoryNo ratings yet

- Ervices AIM Control Provide... : The Viet-Nhan Agriculture - Industry - Marine Control Inspection CorporationDocument9 pagesErvices AIM Control Provide... : The Viet-Nhan Agriculture - Industry - Marine Control Inspection CorporationInspection0% (2)

- Electrical Site Tests ProceduresDocument105 pagesElectrical Site Tests ProceduresMohd SalehNo ratings yet

- RBI Solutions Linesheet 1705078286Document2 pagesRBI Solutions Linesheet 1705078286Faiz HussainNo ratings yet

- Report UT CS From 21Document112 pagesReport UT CS From 21daemsalNo ratings yet

- Test ProcedureDocument106 pagesTest ProcedureAdetunji TaiwoNo ratings yet

- Qap - Iso - TankDocument2 pagesQap - Iso - TankMani MaNo ratings yet

- Site Test Procedure for Electrical InstallationsDocument110 pagesSite Test Procedure for Electrical Installationsmkarimilolo50% (2)

- VW Turbine Bypass ValvesDocument12 pagesVW Turbine Bypass ValvesWahyu TryNo ratings yet

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- Inspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegDocument1 pageInspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegRamzi Zoghlami100% (1)

- Seacom Skills University B.Tech Course Laboratory Details (CIVIL Dept.)Document3 pagesSeacom Skills University B.Tech Course Laboratory Details (CIVIL Dept.)RAVI BARTIANo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- Ultrasonic Examination ReportDocument2 pagesUltrasonic Examination ReportdaemsalNo ratings yet

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul RajNo ratings yet

- Fire protection inspection planDocument4 pagesFire protection inspection planRM ENTERPRISESNo ratings yet

- Hyundai InspDocument1 pageHyundai InspJoseph Emmanuel ParedesNo ratings yet

- 062-063 Passive Samplers - ULTRA Passive SamplersDocument2 pages062-063 Passive Samplers - ULTRA Passive SamplersLuiz Rubens Souza CantelliNo ratings yet

- Inspeksi Trafo - Sabtu SiangDocument24 pagesInspeksi Trafo - Sabtu SiangJAN OJANNo ratings yet

- Neatecha 1Document20 pagesNeatecha 1cram retselNo ratings yet

- Repport UT CS - 11Document4 pagesRepport UT CS - 11daemsalNo ratings yet

- Company Product SuciraDocument10 pagesCompany Product SuciraPejuang TPP Musola TajurNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Test Report RV1061 281022Document1 pageTest Report RV1061 281022vilashni prasadNo ratings yet

- CmosDocument5 pagesCmosAnonymous uiHyyZpBiNo ratings yet

- RAAH Product CategoriesDocument8 pagesRAAH Product Categoriesraah indiaNo ratings yet

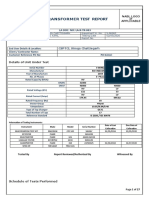

- Transformer Test Report: LA DOC. NO: LA-R-TR-003Document27 pagesTransformer Test Report: LA DOC. NO: LA-R-TR-003mayur dhandeNo ratings yet

- AIM Diving Surveying Tallying Inspection ServicesDocument35 pagesAIM Diving Surveying Tallying Inspection ServicesInspectionNo ratings yet

- Repport UT CS - 7Document1 pageRepport UT CS - 7daemsalNo ratings yet

- Bicmos Process FlowchartDocument8 pagesBicmos Process FlowchartNaveed AhmedNo ratings yet

- Brochure ! PrabhiDocument2 pagesBrochure ! PrabhichandchauNo ratings yet

- 1645400A05 - QAP For Compressor ZR450 - R01 - 20170109Document4 pages1645400A05 - QAP For Compressor ZR450 - R01 - 20170109shahkunal11No ratings yet

- Sign: Assistant: Sign: Assistant: SignDocument1 pageSign: Assistant: Sign: Assistant: SignBelal Alrwadieh100% (1)

- ITP RefractoryDocument1 pageITP RefractoryADOFSLNo ratings yet

- Catalogo Ultraprobe ES-UP100Document2 pagesCatalogo Ultraprobe ES-UP100Rodolfo ParraNo ratings yet

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- 2019 Time Schedule InstallationsDocument6 pages2019 Time Schedule InstallationsTria HikmaNo ratings yet

- Inspection Request Roughing InsDocument1 pageInspection Request Roughing InsJhuzel colisNo ratings yet

- Maintenance PlanDocument7 pagesMaintenance PlanAris Bagoes MaladhiNo ratings yet

- Precision Accurate: Empowering With SolutionsDocument8 pagesPrecision Accurate: Empowering With SolutionsMohammed KhalidNo ratings yet

- PSV Operation - Maintenance & Calibration-09!02!2011Document1 pagePSV Operation - Maintenance & Calibration-09!02!2011Aftab Ahmed MazariNo ratings yet

- Pre-Concrete Inspection Checklist:: 13 Oktober 2023: CCMSPHR/SPK/3700132652Document1 pagePre-Concrete Inspection Checklist:: 13 Oktober 2023: CCMSPHR/SPK/3700132652yazitNo ratings yet

- Generator inspection checklistDocument2 pagesGenerator inspection checklistban-mrw CompaniesNo ratings yet

- UTS General Brochure 2020 (OVERSEAS) - 1Document7 pagesUTS General Brochure 2020 (OVERSEAS) - 1Hanaw MohammadNo ratings yet

- Switchgear ChecklistDocument2 pagesSwitchgear ChecklistAnonymous IeFbdsfCo100% (1)

- Pre-Commissioning Check Sheet: InstrumentsDocument1 pagePre-Commissioning Check Sheet: InstrumentshrimklimNo ratings yet

- Test and Calibrate Control Valves with this PM SheetDocument1 pageTest and Calibrate Control Valves with this PM SheetazitaggNo ratings yet

- DS-1 Training-Drill Pipe InspectionDocument180 pagesDS-1 Training-Drill Pipe InspectionSara Marzouk83% (6)

- Clark - Calibration Report (Nexzus 3) 2Document1 pageClark - Calibration Report (Nexzus 3) 2PNEUMOVENTNo ratings yet

- S. No. Name of Lab Parameter Name Equipment Approx Cost: Electrical Stability TesterDocument2 pagesS. No. Name of Lab Parameter Name Equipment Approx Cost: Electrical Stability TesterArshad Noor SiddiqueeNo ratings yet

- Surface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Document29 pagesSurface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Nilesh Pathare100% (1)

- IEEE Std.43-2000Document27 pagesIEEE Std.43-2000arrongaNo ratings yet

- Ieee std43 2000 PDFDocument27 pagesIeee std43 2000 PDFGheorghe BogdanNo ratings yet

- Wet Dry CorrosionDocument2 pagesWet Dry CorrosionIng. José Antonio Ortiz LopezNo ratings yet

- ASME Liquid Penetrant Standard for General Industry ExamsDocument20 pagesASME Liquid Penetrant Standard for General Industry ExamsfabioNo ratings yet

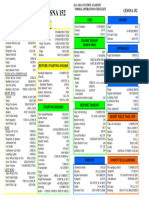

- 152 flight checklist revised pg. 1Document1 page152 flight checklist revised pg. 1King SolomonNo ratings yet

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveNo ratings yet

- Inspection ReportDocument9 pagesInspection ReportSakthi Kasi RajanNo ratings yet

- Environmental PlanDocument17 pagesEnvironmental PlanSakthi Kasi RajanNo ratings yet

- Quality PlanDocument40 pagesQuality PlanSakthi Kasi RajanNo ratings yet

- HSE PlanDocument20 pagesHSE PlanSakthi Kasi RajanNo ratings yet

- Manual Instructivo CO 407Document34 pagesManual Instructivo CO 407Juan RafaelNo ratings yet

- A&F Tank Chemical Feed System BrochureDocument4 pagesA&F Tank Chemical Feed System BrochurePromagEnviro.comNo ratings yet

- Compressor Discharge Check 1Document9 pagesCompressor Discharge Check 1rajeshbharatNo ratings yet

- A Manual Valve 4 02Document11 pagesA Manual Valve 4 02Robbi FerdianNo ratings yet

- Monnet - Recommended Scheme and Write Up of Auto ControlsDocument34 pagesMonnet - Recommended Scheme and Write Up of Auto ControlsDipti BhanjaNo ratings yet

- 10 SOP of CEP PumpDocument4 pages10 SOP of CEP Pumppriyanka singhNo ratings yet

- 2-Ton Hydraulic Engine Crane: Owner'S ManualDocument55 pages2-Ton Hydraulic Engine Crane: Owner'S Manualenio10No ratings yet

- Catepilar ParameterDocument3 pagesCatepilar ParameterHAriantonoNo ratings yet

- 02-Crown Intstacker MDocument4 pages02-Crown Intstacker MJacob GrechNo ratings yet

- Transformer assembly diagramDocument3 pagesTransformer assembly diagramdineshNo ratings yet

- Hydraulic Basic LevelDocument286 pagesHydraulic Basic LevelMariaJose Hwa Ha HanNo ratings yet

- B30D 2Document150 pagesB30D 2Teknik MakinaNo ratings yet

- Heatec: Tec-NoteDocument11 pagesHeatec: Tec-Notepowerslave123No ratings yet

- Operation Manual: Pile Driver DPD 350Document31 pagesOperation Manual: Pile Driver DPD 350Joseph Emmanuel ParedesNo ratings yet

- 5000 Series Brochure - V1.1Document12 pages5000 Series Brochure - V1.1Yelena ObyazovaNo ratings yet

- Muller Stoppling MachinesDocument8 pagesMuller Stoppling MachinesSyed Faisal HassanNo ratings yet

- 21 Cargo Ventilation & Heating Sys Pres PDFDocument14 pages21 Cargo Ventilation & Heating Sys Pres PDFlsthanhlsthanhNo ratings yet

- 114E Series: EngineDocument320 pages114E Series: Enginesu quoc100% (1)

- Drifter Yh70 e Yh70rpDocument68 pagesDrifter Yh70 e Yh70rpDipper Tellez100% (1)

- Chlorine HandbookDocument32 pagesChlorine Handbooknimm1962100% (4)

- Flow Control January 2015Document45 pagesFlow Control January 2015Tiffany Johnson100% (1)

- 7032 - Data SheetDocument9 pages7032 - Data SheetÁlvaro Martínez FernándezNo ratings yet

- Type: Bulker Model: Serial NumberDocument14 pagesType: Bulker Model: Serial NumberManikantaSumanthNo ratings yet

- C9 Injection Actuation Pressure TestDocument18 pagesC9 Injection Actuation Pressure Testharikrishnanpd3327100% (1)

- FDGDFGFDDocument12 pagesFDGDFGFDWency JavateNo ratings yet

- UK 2536 Revision 1Document39 pagesUK 2536 Revision 1JaviNo ratings yet

- Catalogo Seko Tekna EvoDocument12 pagesCatalogo Seko Tekna EvoJonathan VillagraNo ratings yet

- Manual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarDocument36 pagesManual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarWilson BuenoNo ratings yet

- 50cc (LT50 2003) Suzuki ATV Parts ListDocument27 pages50cc (LT50 2003) Suzuki ATV Parts ListMark100% (1)

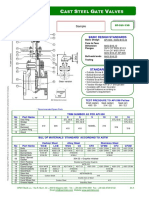

- Cast Steel Gate ValvesDocument2 pagesCast Steel Gate ValvesMohamed SalehNo ratings yet