Professional Documents

Culture Documents

ESLHT Centrifugal Pump for High Temp Water

Uploaded by

SRI MOTHISHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESLHT Centrifugal Pump for High Temp Water

Uploaded by

SRI MOTHISHCopyright:

Available Formats

ESLHT

DESMI ESLHT horizontal end suction centrifugal pump designed for high media temperatures for

water application up to 180o C.

ESLHT is a high efficiency and compact designed centrifugal

pump. The pump is developed for high temperature liquid

transportation and circulation in marine and offshore market

mainly, e.g., marine boiler water circulation, hot water supply

or other heat transfer applications.

The pump has been approved by main marine classification

societies in terms of design review, casting sampling and/

or final product witness inspection.

The pump and its prime mover are mounted on a common

base plate by the manufacturer before shipment for easy

installation on site.

Various pump materials are available as flexible customized

solutions.

Concept Features Application areas

• Duplex stainless steel shaft. • High temperature water circulation.

• Closed impeller design to achieve high efficiency

even in small capacity pumps.

• Carbon sleeve bearing as main bearing to obtain

optimal performance in self-lubrication and heat Norminal Diameter (DN) 25 to 65

resistance. Flow rate - 50 Hz Up to 100 m3/h (440 US gpm)

• Balanced mechanical shaft seal to increase Flow rate - 60 Hz Up to 120 m3/h (530 US gpm)

sealing reliability by its less seal face wear / heat Head Up to 65m (220 ft)

development. Pressure Up to 30 bar (435 psi)

• Separate shaft seal chamber with cooling fins

Temperature Up to 180°C (356 °F)

located away from main pump casing to protect

Motor Standard and Ex motor

shaft seals from heat transfer.

• Back pull design without disturbing pump casings VFD Direct or Bulkead/Wall-mounted

and external pipes during maintenance.

• Automatic air vent valve on top of shaft seal

chamber to prevent dry run and/or overheating

seal.

• Air fan on flexible coupling for cooling of bearing

and shaft seal arrangement.

For more information on Marine & Offshore solutions, please visit www.desmi.com

MARINE & OFFSHORE INDUSTRY ENVIRO-CLEAN DEFENCE & FUEL UTILITY

ESLHT

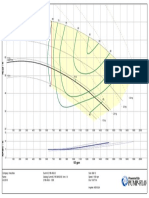

MLC ESLHT 2950 RPM

ESLHT 2950 RPM MLC

MLC ESLHT 3450 RPM

ESLHT 3540 RPM MLC

70 70 80 80

60 60 70 70

50 50 60 60

40 40

50 50

65

30 30

40 40

-1

40

50

25

32

40

50

65

25

32

8

-1

-1

0

-1

-1

-1

-1

-1

-1

-1

8

8

8

0

0

8

0

0

0

20 20 30 30

20 20

10 10

5 5

1 2 3 4 5 7 10 13 15 20 30 40 50 60 80 100 130 M3/H 10 10

2 3 4 5 7 10 13 15 20 30 40 50 60 80 100 130 M3/H

Capacity: 1 m3/h = 4.4 USGPM /Total

CAPACITY: 1 M3/H = 4.4 USGPM Head: 1 m = 3.28 feet / MaxMAX EFFICIENCY

TOTAL HEAD: 1 M = 3.28 FEET Efficiency

Capacity: 1 m3/h = 4.4 USGPM /Total Head: 1 m = 3.28 feet / Max Efficiency

CAPACITY: 1 M3/H = 4.4 USGPM TOTAL HEAD: 1 M = 3.28 FEET MAX EFFICIENCY

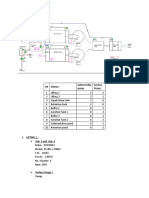

Material specification Delivery

Shaft seal

Code* Casing Impeller Shaft

cover

EN-

EN-GIS-400-15 1.4436 1.4460

GIS-400-15

A Ductile cast Stainless Stainless

Ductile cast

iron steel steel

iron

1.4410 1.4410

1.4410 1.4410

S Stainless Stainless

Stainless steel Stainless steel

steel steel

*The material can be customized according to individual applications or demands.

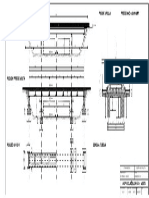

Dimension drawing / table

Suction

ESLHT Motor L L1* L2 L3 L4 L5 B B1 B1 H H1 H2 K Ds DNs DLs Ks Dd DNd DLd Kd

Size

112 720 763 520

100 700 738 500

ESLHT

25-180N/ 90L 700 693 500

80 21 579 242 160 150 40 110 115 25 14 85

A17 90S 650 663 450

W180

80 630 633 430

71 600 578 400

100 420 300 360 18 19

132 850 829 600

112 800 798 600

ESLHT

40-180N 100 780 773 580

100 35 632 270 180 185 65 145 150 40 18 110

/A17 90L 750 728 550

W180

90S 750 698 550

80 680 668

*L1 might vary slightly from different motor manufacturers.

PROVEN TECHNOLOGY

You might also like

- Alfa Laval LKH Centrifugal PumpDocument4 pagesAlfa Laval LKH Centrifugal PumpJosé Carlos DrodowskiNo ratings yet

- Bulk HP: Achieve MoreDocument4 pagesBulk HP: Achieve MoreTangguh JayaNo ratings yet

- AL-RED EN 60HzDocument8 pagesAL-RED EN 60HzAlejandro ReynoldsNo ratings yet

- ITM Nterruptor 400 EATONDocument1 pageITM Nterruptor 400 EATONjosseNo ratings yet

- Use of Inverters Stream Compressors Technical Information enDocument9 pagesUse of Inverters Stream Compressors Technical Information enIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Lowara LNE 50Hz EN LDocument136 pagesLowara LNE 50Hz EN LBringo BoyNo ratings yet

- Martin Hurricane Air Cannon: Technical Data SheetDocument2 pagesMartin Hurricane Air Cannon: Technical Data Sheettacosanchezbrayan100% (1)

- Tembreak 2 S250-GE MCCB Data SheetDocument4 pagesTembreak 2 S250-GE MCCB Data SheetBanupriya BalasubramanianNo ratings yet

- Japanese Technology Pumps Since 1912Document4 pagesJapanese Technology Pumps Since 1912FilipNo ratings yet

- PD Sheet - LKH Centrifugal Pump - ENDocument3 pagesPD Sheet - LKH Centrifugal Pump - ENdhenis imam FaujiNo ratings yet

- Internal Deposits Fact SheetDocument2 pagesInternal Deposits Fact SheetMario RodeznoNo ratings yet

- E-Sh Series: Erp 2009/125/ceDocument124 pagesE-Sh Series: Erp 2009/125/ceabedzNo ratings yet

- General CatalogueDocument6 pagesGeneral Cataloguemasoud mjNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- Multi-stage centrifugal pumps for clean water applicationsDocument6 pagesMulti-stage centrifugal pumps for clean water applicationsazze bouzNo ratings yet

- Beton IVAN ModelDocument1 pageBeton IVAN ModelIvan MileticNo ratings yet

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- Chemistry Heating Curve WorksheetDocument6 pagesChemistry Heating Curve WorksheetArlyn Pong Pling PioNo ratings yet

- Evoplus Ts EngDocument96 pagesEvoplus Ts EnggabitermoinstalNo ratings yet

- CR 313 AfgjaehqqeDocument10 pagesCR 313 AfgjaehqqeTatiana Mejías SeguraNo ratings yet

- Curva Disjuntor EATON - 5721B10Document1 pageCurva Disjuntor EATON - 5721B10Davi SalvatoreNo ratings yet

- Centrifugal Pumps: Installation and Use Performance RangeDocument4 pagesCentrifugal Pumps: Installation and Use Performance Rangewilliam.r.bastosNo ratings yet

- 12 01 0192 PDFDocument9 pages12 01 0192 PDFangelomarinilliNo ratings yet

- Liberty Series Progressive Cavity Curve 1LL8Document1 pageLiberty Series Progressive Cavity Curve 1LL8karthikNo ratings yet

- 12 Boosters LBDocument2 pages12 Boosters LBMauricio Andrés MontenegroNo ratings yet

- Full CatalogDocument397 pagesFull CatalogMatiusBiuSarraNo ratings yet

- Vertical Multi-Stage Pumps: Installation and Use Performance RangeDocument4 pagesVertical Multi-Stage Pumps: Installation and Use Performance RangeCARLOS EZEQUIEL FARINANo ratings yet

- Technical FlowpakDocument3 pagesTechnical FlowpakAmjad HussainNo ratings yet

- Etech EH SeriesDocument16 pagesEtech EH SeriesZeina FarhatNo ratings yet

- Compact End-Suction Booster PumpsDocument5 pagesCompact End-Suction Booster PumpsShofchatin MardiyahNo ratings yet

- Flygt Hydroturbine BrochureDocument8 pagesFlygt Hydroturbine BrochureTogaroNo ratings yet

- Ingersoll Rand Compressor - 2545 Engineering DataDocument4 pagesIngersoll Rand Compressor - 2545 Engineering DataJNo ratings yet

- Alfa Laval Sanitary Centrifugal PumpDocument4 pagesAlfa Laval Sanitary Centrifugal PumpHarwin ChowNo ratings yet

- Acid viscosity recipes comparison under different conditionsDocument1 pageAcid viscosity recipes comparison under different conditionsOleg KokorynetsNo ratings yet

- PartisiDocument1 pagePartisiIman Influential PlaymakerNo ratings yet

- gsd-c-single-stage-end-suction-general-service-pumpDocument4 pagesgsd-c-single-stage-end-suction-general-service-pumprafaelberaldiNo ratings yet

- MPU Brochure ZF TRWDocument4 pagesMPU Brochure ZF TRWWong DaNo ratings yet

- 88HST (12.5) Pump Curve PDFDocument1 page88HST (12.5) Pump Curve PDFDaylis GonzalezNo ratings yet

- Technical Specs for Split Core Current TransformersDocument9 pagesTechnical Specs for Split Core Current TransformersAndy MezetaNo ratings yet

- Fundamentals of Centrifugal Pumps PDFDocument7 pagesFundamentals of Centrifugal Pumps PDFÁlvaro Martínez FernándezNo ratings yet

- HHB Stal EngDocument2 pagesHHB Stal EngrafaelNo ratings yet

- KBL Pump GADocument11 pagesKBL Pump GAudgeetNo ratings yet

- 641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

- Gea Hilge TP Centrifugal Pumps Us 170792Document6 pagesGea Hilge TP Centrifugal Pumps Us 170792German TchiliNo ratings yet

- Centrifugal Pumps With Open Impeller: Installation and Use Performance RangeDocument4 pagesCentrifugal Pumps With Open Impeller: Installation and Use Performance RangekhusnulNo ratings yet

- Regulators Edge 3 Series Regulators: Slam™Document1 pageRegulators Edge 3 Series Regulators: Slam™Dries VandezandeNo ratings yet

- DP16003-YR05-90BAK-144410-Rev-04 General Arrangement Drawings of 11KV SPBDDocument12 pagesDP16003-YR05-90BAK-144410-Rev-04 General Arrangement Drawings of 11KV SPBDsanjayprakash1979No ratings yet

- Pump specification and performance dataDocument3 pagesPump specification and performance dataRachmad PascalNo ratings yet

- GS Brochure A4!20!09 CDocument4 pagesGS Brochure A4!20!09 CFilipNo ratings yet

- ReportDocument1 pageReportMauro RuaNo ratings yet

- 350 MM LBV GraphDocument1 page350 MM LBV GraphVishal ShivaNo ratings yet

- Diagrama de Molière R134a: RefrigerantesDocument1 pageDiagrama de Molière R134a: RefrigerantesHumnerNo ratings yet

- MISSION 2500 AG Centrifugal Slurry Pump FlyerDocument2 pagesMISSION 2500 AG Centrifugal Slurry Pump FlyerFaroukNo ratings yet

- Compact centrifugal pumps for clean liquidsDocument3 pagesCompact centrifugal pumps for clean liquidsJose Ricardo Sarco BaluarteNo ratings yet

- Curvas Hidraulicas KSB MegaCPK 125 - 100 - 400Document1 pageCurvas Hidraulicas KSB MegaCPK 125 - 100 - 400Agustín TorresNo ratings yet

- Unit 3 - 5 - Unit HydrographDocument8 pagesUnit 3 - 5 - Unit Hydrographtom meeteiNo ratings yet

- Curva de Bombas SummitDocument1 pageCurva de Bombas SummitMagali OsorioNo ratings yet

- Centrifugal Pumps With Open Impeller: Installation and Use Performance RangeDocument4 pagesCentrifugal Pumps With Open Impeller: Installation and Use Performance RangemahmudNo ratings yet

- Centrifugal Twin-Impeller Pumps for Clean Water ApplicationsDocument10 pagesCentrifugal Twin-Impeller Pumps for Clean Water ApplicationsMoutaz IsmailNo ratings yet

- Eslv and Eslh Monobloc - Assembly DrawingsDocument5 pagesEslv and Eslh Monobloc - Assembly DrawingsSRI MOTHISHNo ratings yet

- DESMI End Suction Centrifugal Pump: NSLH and NSLV SpacerDocument31 pagesDESMI End Suction Centrifugal Pump: NSLH and NSLV SpacerSRI MOTHISHNo ratings yet

- Assembly-Drawing TSLHDocument1 pageAssembly-Drawing TSLHSRI MOTHISHNo ratings yet

- DESMI End Suction Centrifugal Pump NSLV and NSLH Compact SpacerDocument21 pagesDESMI End Suction Centrifugal Pump NSLV and NSLH Compact SpacerSRI MOTHISHNo ratings yet

- Aux Boilers - Change Over ProcedureDocument22 pagesAux Boilers - Change Over ProcedurezacharioudakisNo ratings yet

- FLUID MECHANICS D203 Otazky PDFDocument87 pagesFLUID MECHANICS D203 Otazky PDFKhoa NguyễnNo ratings yet

- Etanorm: Standardised Water PumpDocument124 pagesEtanorm: Standardised Water Pumpricelles1No ratings yet

- Load-Sensing Control Block in Sandwich Plate Design: ContentDocument52 pagesLoad-Sensing Control Block in Sandwich Plate Design: Contenteaglego00No ratings yet

- Parts List FAS-SC7 37Document45 pagesParts List FAS-SC7 37Magoga MagoutNo ratings yet

- Calculation Data Sheet for Flow Element FE-7151Document1 pageCalculation Data Sheet for Flow Element FE-7151SureshNo ratings yet

- How Does Variable Turbine Geometry WorkDocument20 pagesHow Does Variable Turbine Geometry Workkasibhatta100% (2)

- DHT Question Answer BankDocument41 pagesDHT Question Answer BankBikas Saha100% (3)

- Transport To VenezuelaDocument75 pagesTransport To Venezuelaimron rosyadiNo ratings yet

- Active Learning Power Actuated Safety Relief ValveDocument2 pagesActive Learning Power Actuated Safety Relief ValveNur Syazwani KhalidNo ratings yet

- Cent PumpDocument4 pagesCent Pumpahmedabdelaziz851647No ratings yet

- ATA 36 - PNEUMATIC-Diff-R25Document86 pagesATA 36 - PNEUMATIC-Diff-R25NadirNo ratings yet

- Valves DatasheetDocument1 pageValves DatasheetLuis Acevedo AyalaNo ratings yet

- 256-Article Text-594-1-10-20180302Document5 pages256-Article Text-594-1-10-20180302Hery PurnawantNo ratings yet

- SN Station Submersible Pump Surface PumpDocument8 pagesSN Station Submersible Pump Surface PumpraizoNo ratings yet

- JSD Engineering Products: Vane PumpDocument3 pagesJSD Engineering Products: Vane PumptanveerNo ratings yet

- KOSO General CatalogDocument52 pagesKOSO General Catalogनिखिल बायवार100% (3)

- Existing Corrosion Inhibitor Skid DetailsDocument1 pageExisting Corrosion Inhibitor Skid DetailsMohamed Wasim ShaikhNo ratings yet

- Folga de VálvulasDocument3 pagesFolga de VálvulasTatiano BrolloNo ratings yet

- 3.9S Excavator - HydDocument85 pages3.9S Excavator - HydJorge Rojas100% (1)

- EH HEX Cat 320D (Ing) PDFDocument13 pagesEH HEX Cat 320D (Ing) PDFPercy Vilca QuispeNo ratings yet

- Mass and Energy Analysis of Control VolumesDocument37 pagesMass and Energy Analysis of Control VolumesReafe Carla Bustamante MabalotNo ratings yet

- University of Zakho College of Engineering Mechanical DepartmentDocument9 pagesUniversity of Zakho College of Engineering Mechanical DepartmentDler SabryNo ratings yet

- Mechanical Permit (FRONT)Document1 pageMechanical Permit (FRONT)Ricardo DalisayNo ratings yet

- Becoming An ExpertDocument71 pagesBecoming An ExpertHIDRUCOL SASNo ratings yet

- Centrifugal Compressor Axial Thrust: Hassan Mohamed A. M. HassanDocument12 pagesCentrifugal Compressor Axial Thrust: Hassan Mohamed A. M. HassanMosab AmmarNo ratings yet

- Bladder-Type Accumulator HAB: RE 50170/03.2014, Bosch Rexroth AGDocument20 pagesBladder-Type Accumulator HAB: RE 50170/03.2014, Bosch Rexroth AGShariq KhanNo ratings yet

- FiltersDocument7 pagesFiltersDenisNo ratings yet

- Fuderer, A. and Rudelstorfer, E. Selective Adsorption Process. U.S. Patent 3,986,849Document27 pagesFuderer, A. and Rudelstorfer, E. Selective Adsorption Process. U.S. Patent 3,986,849kay LauNo ratings yet

- Mass and Energy Analysis of Control Volumes: Thermodynamics: An Engineering Approach, 6 EditionDocument20 pagesMass and Energy Analysis of Control Volumes: Thermodynamics: An Engineering Approach, 6 EditionAhmad SiddiqNo ratings yet