Professional Documents

Culture Documents

Super Welding Cables

Uploaded by

Narasimha Rao Jaggarapu0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

super-welding-cables

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageSuper Welding Cables

Uploaded by

Narasimha Rao JaggarapuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

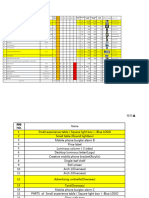

SUPER WELDING CABLES

TO SPECIFICATIONS SABS – VDE – BS – NOMINAL VOLTAGE UP TO 1000 V

RUGGED WELDING CONDITIONS

CA20+21, CC09

CONSTRUCTION OF TYPE TW TO VDE 0282

Extra fine wire stranding of plain copper, synthetic film or fibre separator, PCP sheath, oil and flame resis-

tant to VDE 0472, working voltage 100 V, test voltage 2000 V, max. conductor temperature 85 °C.

Core cross Colour Nominal Radial Diameter Copper Mass

Section number of thickness of in mm weight

strands insulation (max)

mm2 x Ø mm mm kg/km kg/km

10 black 320 x 0,21 2,0 9,5 96,0 171

16 black 510 x 0,21 2,0 11,5 154,0 198

25 black 760 x 0,21 2,0 13,0 240,0 305

35 black 1083 x 0,21 2,0 14,5 336,0 415

50 black 1517 x 0,21 2,2 17,0 480,0 555

70 black 2146 x 0,21 2,4 19,5 672,0 765

95 black 2223 x 0,21 2,6 22,0 912,0 1010

120 black 1665 x 0,31 2,8 24,0 1152,0 1262

CONSTRUCTION OF TYPE TW-E TO SANS 1576/93

Extra fine wire stranding of plain copper, synthetic film separator, elastomeric or CR sheath, oil-petrol-

grease-flame resistant, working voltage 100 V, scan voltage 3000 V, max. conductor temp. 85 °C

Core cross Colour Nominal Radial Diameter Copper Mass

Section number of thickness of in mm weight

strands insulation (max)

mm2 x Ø mm mm kg/km kg/km

*016 green 490 x 0,21 2,0 11,5 154 240

*025 blue 735 x 0,21 2,6 13,0 240 340

*035 grey 1050 x 0,21 2,0 14,5 336 450

*050 red 680 x 0,31 2,2 17,0 480 620

*070 brown 935 x 0,31 2,4 19,5 672 830

*095 yellow 1280 x 0,31 2,6 22,0 912 1130

*120 black 1614 x 0,31 2,8 24,0 1152 1310

*150 black 2080 x 0,31 3,0 27,0 1440 1609

*185 black 1450 x 0,41 3,2 29,0 1876 2200

CONSTRUCTION OF TYPE TFXW TO SANS 1574/1507

Extra fine wire stranding of plain copper, flexible grade PVC insulated and/or tightly bonded Nitrile sheath,

1000 V, test voltage 2000 V, max. conductor temperature 70 °C

Core cross Colour Nominal Diameter Copper Mass

Section number of in mm weight

strands (max)

mm2 x Ø mm kg/km kg/km

*012 black 230 x 0,26 8,1 115 159

*016 green 200 x 0,31 8,7 154 198

*025 blue 308 x 0,31 9,9 240 300

*035 grey 438 x 0,31 11,0 336 395

*050 red 624 x 0,31 13,4 480 561

*070 brown 893 x 0,31 15,4 672 790

*095 yellow 672 x 0,41 18,6 912 1070

*120 black 860 x 0,41 21,2 1152 1370

*150 black 1152 x 0,41 24,4 1440 1793

*240 black 1824 x 0,41 32,5 2304 2756

POWERMITE CURRENT RATING TABLE FOR WELDING AT MAXIMUM DUTY CYCLE

Nominal area of Colour 100% 85% 60% 30% 20%

copper conductor

A A A A A

*012 mm2 black 100 110 130 180 225

*016 mm2 green 135 145 175 245 300

*025 mm2 blue 180 195 230 330 395

*035 mm2 grey 225 245 290 410 500

*050 mm2 red 285 310 370 520 635

*070 mm2 brown 355 385 460 650 785

*095 mm2 yellow 430 470 560 790 965

*120 mm2 500 540 650 910 1115

*150 mm2 580 630 743 1047 1256

*185 mm2 660 715 850 1200 1450

* Special applications only – normally two small cables of equal length in tandem. For derating factors consult page 52

If cable length exceeds 15 metres, check voltage drop to maintain correct welding currents.

Above sizes may require minimum quantities. All quoted data is approximate and not binding

6

You might also like

- H01N2-D / H01N2-E: 100 V, VDE Approved, Welding CableDocument1 pageH01N2-D / H01N2-E: 100 V, VDE Approved, Welding Cablemaxlnw888888No ratings yet

- Page 312Document1 pagePage 312jorgedode7No ratings yet

- VCC CD Series DATASHEETDocument4 pagesVCC CD Series DATASHEETKaiNo ratings yet

- PTFE Single Core: BS 3G 210 Type ADocument1 pagePTFE Single Core: BS 3G 210 Type ASKYhabiaNo ratings yet

- Eq KZDocument1 pageEq KZSKYhabiaNo ratings yet

- TC - WIRE Type KDocument1 pageTC - WIRE Type KHou YangfanNo ratings yet

- Price 1Document4 pagesPrice 1leslieNo ratings yet

- C29-JE-Y (ST) Y BD PDFDocument1 pageC29-JE-Y (ST) Y BD PDFNarendra Reddy BhumaNo ratings yet

- c29 Je y (ST) y BDDocument1 pagec29 Je y (ST) y BDNarendra Reddy BhumaNo ratings yet

- JE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Document1 pageJE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Narendra Reddy BhumaNo ratings yet

- Toxfree ZH: ES05Z1-K & H07Z1-K (AS)Document3 pagesToxfree ZH: ES05Z1-K & H07Z1-K (AS)Stefano EsmNo ratings yet

- Cooper - Heyman PreviousDocument2 pagesCooper - Heyman PreviousMd SafwanNo ratings yet

- SV GB Zubh 104-123 PDFDocument20 pagesSV GB Zubh 104-123 PDFTiti Mulat KusumaningrumNo ratings yet

- Atasheet Liycy Electronic Control Cable With Tinned Copper BraidingDocument3 pagesAtasheet Liycy Electronic Control Cable With Tinned Copper Braidingandy175No ratings yet

- PTFE Single Core: BS 3G 210 Type BDocument1 pagePTFE Single Core: BS 3G 210 Type BSKYhabiaNo ratings yet

- BS 6862 - Auto CablesDocument5 pagesBS 6862 - Auto CablesBrandon BroNo ratings yet

- Brochure KuterlexDocument8 pagesBrochure KuterlexT KelvinNo ratings yet

- Technical DataDocument19 pagesTechnical Datamustafa nasihNo ratings yet

- Teamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689Document6 pagesTeamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689leslieNo ratings yet

- H05V-K / H07V-K: Low Voltage - Energy and CablingDocument2 pagesH05V-K / H07V-K: Low Voltage - Energy and CablingMuhamad YasrinNo ratings yet

- Galvanized Specification: Home Profile Processing Advantages Applications Handling & Storages Projects ContactDocument4 pagesGalvanized Specification: Home Profile Processing Advantages Applications Handling & Storages Projects ContactEwo50 NewNo ratings yet

- Indoor Cable GlandDocument1 pageIndoor Cable GlandChandra Sekhar BoyinaNo ratings yet

- A. Extention of Rooms On Top of Tallyn's Bedroom: (Option 1)Document4 pagesA. Extention of Rooms On Top of Tallyn's Bedroom: (Option 1)Bj AfanteNo ratings yet

- GPT Automotive CablesDocument1 pageGPT Automotive CablesVandana SethiNo ratings yet

- Sterner Infranor 891 & 895 Series Brochure 1987Document4 pagesSterner Infranor 891 & 895 Series Brochure 1987Alan MastersNo ratings yet

- Eq atDocument1 pageEq atSKYhabiaNo ratings yet

- Chain & Accessories: 161 All Rights ReservedDocument50 pagesChain & Accessories: 161 All Rights ReservedsetyaadikurniawanNo ratings yet

- Eq KuDocument1 pageEq KuSKYhabiaNo ratings yet

- Cable para Servo-Motores PE - PVC Con Pantalla de Cobre General 0.6 - 1 KVDocument1 pageCable para Servo-Motores PE - PVC Con Pantalla de Cobre General 0.6 - 1 KVmpochet6661No ratings yet

- Standards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsDocument1 pageStandards Approvals & Certificates: Rutil-Bazik Örtülü Elektrod - Non Alloyed SteelsBeshoy RedaNo ratings yet

- Eq EtDocument1 pageEq EtSKYhabiaNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Je-Liycy: BD Si Industry-Elektronic Cable According To DIN VDE 0815Document1 pageJe-Liycy: BD Si Industry-Elektronic Cable According To DIN VDE 0815fuermiguelNo ratings yet

- FEP Single Core: NEMA HP-4Document1 pageFEP Single Core: NEMA HP-4SKYhabiaNo ratings yet

- Vinyl Insulated Double Crimp: Female Quick DisconnectsDocument2 pagesVinyl Insulated Double Crimp: Female Quick DisconnectsErasmo Franco SNo ratings yet

- FT Câble PCDocument2 pagesFT Câble PCM AMRNo ratings yet

- Light/Extra Light Pipe To Australian Standards: Specification GalvanizingDocument1 pageLight/Extra Light Pipe To Australian Standards: Specification GalvanizingMohamed amine El mtalakNo ratings yet

- V I P Price List Dated 01.12.2014Document1 pageV I P Price List Dated 01.12.2014raviNo ratings yet

- Mars240 GBDocument4 pagesMars240 GBJose Luis FulledaNo ratings yet

- Lista de Precios General en $ y Bs 24.08.2020Document16 pagesLista de Precios General en $ y Bs 24.08.2020Alejandra RamirezNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- SD 960 CP enDocument1 pageSD 960 CP enJuanNo ratings yet

- Firekab Je H ST H BD Fe180 ph120Document2 pagesFirekab Je H ST H BD Fe180 ph120Azzeddine ZerroukNo ratings yet

- Weight of G.I.Strip Flat KG MT.: X X X X X X X X XDocument2 pagesWeight of G.I.Strip Flat KG MT.: X X X X X X X X XHiral SolankiNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- UTP Category 6 Cables V1.0Document2 pagesUTP Category 6 Cables V1.0Maham MansoorNo ratings yet

- (Shipping List) Indonesia (For Warehouse Use)Document3 pages(Shipping List) Indonesia (For Warehouse Use)Deni SaputraNo ratings yet

- Price ListDocument2 pagesPrice ListAshan Udaya PushpakumaraNo ratings yet

- Pex/Al/Pex Multilayer Pipes: R999 Versions and Product CodesDocument10 pagesPex/Al/Pex Multilayer Pipes: R999 Versions and Product Codesonga yaaNo ratings yet

- Helukabel Solarflex - X H1Z2Z2-K: 1500 V DC, EN 50618 APPROVALDocument2 pagesHelukabel Solarflex - X H1Z2Z2-K: 1500 V DC, EN 50618 APPROVALkuan sim angNo ratings yet

- Bs 6231 / Tri Rated Panel Wiring Wire Heat Resistant PVC Insulated Single Core Flexible WireDocument1 pageBs 6231 / Tri Rated Panel Wiring Wire Heat Resistant PVC Insulated Single Core Flexible WireryoNo ratings yet

- Report StrutsDocument15 pagesReport Strutsfazlin natasyaNo ratings yet

- Product Sheet ALON PDFDocument3 pagesProduct Sheet ALON PDFMauricio FriedrichNo ratings yet

- Na2xy-O/ (J) : Din Vde 0276-603 (5G-2)Document3 pagesNa2xy-O/ (J) : Din Vde 0276-603 (5G-2)Asad Ali100% (1)

- Eq AaDocument1 pageEq AaSKYhabiaNo ratings yet

- Ov Erhea D Ca Bles Hi GH Vo Ltage: Crocus (ACSR)Document1 pageOv Erhea D Ca Bles Hi GH Vo Ltage: Crocus (ACSR)Siul VegaNo ratings yet

- TCKT Day TK ACSR - AAACDocument6 pagesTCKT Day TK ACSR - AAACDang DoNo ratings yet

- 4037 PDFDocument10 pages4037 PDFasfaruk2556No ratings yet

- 1 Starting Time Calculation 2Document15 pages1 Starting Time Calculation 2Sankalp MittalNo ratings yet

- Brevity CodeDocument18 pagesBrevity CodeArash AziziNo ratings yet

- Euro Ncap Aeb Test Protocol v11 PDFDocument31 pagesEuro Ncap Aeb Test Protocol v11 PDFRTCNNo ratings yet

- Vale International Pellet Plant PDFDocument2 pagesVale International Pellet Plant PDFSrinivasanNo ratings yet

- Fibac 2017 ReportDocument68 pagesFibac 2017 ReportNitin KumarNo ratings yet

- Celsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayDocument6 pagesCelsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayJaspinder SinghNo ratings yet

- Prime Vision Security Solutions - Company ProfileDocument11 pagesPrime Vision Security Solutions - Company ProfileAbdul QayyumNo ratings yet

- Don Honorio Ventura Technological State University: Dr. Enrique G. BakingDocument1 pageDon Honorio Ventura Technological State University: Dr. Enrique G. BakingJulianne DucutNo ratings yet

- Adxrs610 Yaw Rate GyroDocument12 pagesAdxrs610 Yaw Rate GyroTarek Car MillaNo ratings yet

- Fpga Viva QuestionDocument4 pagesFpga Viva QuestionManila MathurNo ratings yet

- Design of Anchor Bolts Embedded in Concrete MasonryDocument9 pagesDesign of Anchor Bolts Embedded in Concrete MasonryYoesuf DecipherNo ratings yet

- C3704 2018 PDFDocument122 pagesC3704 2018 PDFHaileyesus Kahsay100% (1)

- ECE 551 Assignment 2: Ajit R Kanale, 200132821 January 25, 2017Document5 pagesECE 551 Assignment 2: Ajit R Kanale, 200132821 January 25, 2017Ajit KanaleNo ratings yet

- TMP 4341Document2 pagesTMP 4341nithiananthiNo ratings yet

- Prospectus 2019 20 PDFDocument76 pagesProspectus 2019 20 PDFDhruv goyalNo ratings yet

- Watershed SegmentationDocument19 pagesWatershed SegmentationSan DeepNo ratings yet

- Application Filed by The Industry / Organization OnDocument7 pagesApplication Filed by The Industry / Organization Onkrish659No ratings yet

- Skills, Techniques and Production in Contemporary Art HANDOUT PDFDocument4 pagesSkills, Techniques and Production in Contemporary Art HANDOUT PDFKeyy TaezaNo ratings yet

- Strategies To Avoid Communication Breakdown (Part Ii) : Oral Communication in Context For Grade 11Document19 pagesStrategies To Avoid Communication Breakdown (Part Ii) : Oral Communication in Context For Grade 11Elda Mae EsmaneNo ratings yet

- Patrick C Hall@yahoo - com-TruthfinderReportDocument13 pagesPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNo ratings yet

- BCA-529 Linux & Unix PDFDocument102 pagesBCA-529 Linux & Unix PDFmayur malviyaNo ratings yet

- A Framework For Reliability and Risk Centered MaintenanceDocument8 pagesA Framework For Reliability and Risk Centered MaintenanceIlham M Taufik100% (1)

- Hemi Spherical Vs Ellipsoidal Vs Tori SphericalDocument5 pagesHemi Spherical Vs Ellipsoidal Vs Tori SphericalkingstonNo ratings yet

- 13.2.2.13 Lab - Incident HandlingDocument3 pages13.2.2.13 Lab - Incident Handlingc583706No ratings yet

- Title Proposal Form For StudentsDocument3 pagesTitle Proposal Form For StudentsHelen AlalagNo ratings yet

- Trailler On JettyDocument4 pagesTrailler On JettyFuad Andaru BaskaraNo ratings yet

- Polymer and Web ComponentsDocument26 pagesPolymer and Web ComponentsAdjetey Adjei-laryeaNo ratings yet

- Production and Active Pharmaceutical Ingredients 5EEC Group 1Document10 pagesProduction and Active Pharmaceutical Ingredients 5EEC Group 1Derrick RamosNo ratings yet

- Product Data: 58GP, GS Upflow Natural-Draft Gas-Fired FurnaceDocument8 pagesProduct Data: 58GP, GS Upflow Natural-Draft Gas-Fired FurnaceMichael MartinNo ratings yet