Professional Documents

Culture Documents

Fluid Mechanics Lab Project Report

Uploaded by

Muhammad AbdullahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid Mechanics Lab Project Report

Uploaded by

Muhammad AbdullahCopyright:

Available Formats

12/21/2022 Pump With Flow Sensor

Fluid Mechanics Lab

ME-322L

Submitted By Received By

Name: Muhammad Imran Name: Engr. M. Waseem Akram

Reg #: 936-FET/BSME/F20

Name: Muhammad Sulaiman

Reg #: 937-FET/BSME/F20

Name: Muhammad Abdullah Signature: ___________________

Reg #: 938-FET/BSME/F20

Name: Muhammad Aqeel Anjum

Reg #: 939-FET/BSME/F20

Date: ____________________ Date: _______________________

Contents

Abstract........................................................................................................................................................ 2

Introduction ................................................................................................................................................. 3

Problem Statement...................................................................................................................................... 4

Background & Working ............................................................................................................................. 4

Objectives..................................................................................................................................................... 4

Calculation ................................................................................................................................................... 5

Significance of project ................................................................................................................................ 8

Advantages................................................................................................................................................... 8

Disadvantages .............................................................................................................................................. 8

References .................................................................................................................................................... 8

Mechanical Engineering & Technology

December 21, 2022 1

Abstract

In this report we are discussing the screw pump that what is screw pump? And it types then we do

analysis on the screw pump on the basis of the three main parts of the screw pump 1. Pump motor 2.

Pump screw or rotor 3. Suction and discharge pressure and its size, the main purpose of this analysis to

get more flow rate, high head pressure and low cost of electricity. In this report we do all the analysis and

at the end we manufacture the screw pump which run on the DC Voltage and gives 50ft head pressure,

30ft suction, water flow rate 2200L/H and at the we connect the flow rate sensor which takes value from

the sensor and give the data to Software through Arduino which is microcontroller.

Mechanical Engineering & Technology

December 21, 2022 2

Introduction

A Screw Pump is a type of rotary pump, and it is a type of Mechanical devices used for different

types of fluid pumping e.g, water, oil, gases etc.

A screw pump is a positive-displacement pump that use one or several screws to move fluid

solids or liquids along the screw(s) axis. [1]

Positive Displacement Pump

A positive displacement pump is a type of pump that transfers the liquid through the action of

gears, screws, vanes, plunger, piston.

In a positive displacement pump, a specific amount of the liquid is enclosed in the compression

chamber. [2]

Types of Positive Displacement Pumps

There are three major types of positive displacement pumps

1. Linear Pump

2. Reciprocating Pump

3. Rotary Pump

But we are interested in rotary pump, so the rotary pumps are divided into following three major

types

1. Gear pump

2. Rotary vane pump

3. Screw pump

In the above types we also interested in screw pump which our goal to write a proposal on it

Flow Rate Sensor

This type of sensor measures the flow rate of fluid using Arduino program

Mechanical Engineering & Technology

December 21, 2022 3

The water flow sensor consists of a plastic valve body, a water rotor and a hall-effect sensor.

When the water flows through the rotor, rotor rolls and the speed of it changes with a different

rate of flow. The hall-effect sensor outputs the corresponding pulse signal.

This type of sensor can be found on different diameters, water pressure (MPa) and flow rate

(L/m) ranges. Make sure to select one that will cover your needs. The sensor that I have it has

20mm diameter, <1.75Mpa water pressure and ~30 L/m flow rate range.

Problem Statement

We have a screw pump in which we will change the hub size, rotor or screw size and motor

voltages. We will observe the flow rate using flow rate sensor that in which case the flow rate of

the pump increase we will note it and will manufacture it through casting etc.

Background & Working

The screw pump is the oldest positive displacement pump. The first records of a water screw, or

screw pump, dates back to Ancient Egypt before the 3rd century BC.

Types of Screw Pumps

The major types of screw pump are given bellow.

1. Single Screw Pump

2. Two Screw Pump

3. Three Screw Pump

4. Four Screw Pump

5. Five Screw Pump

In this level we are interested in in single screw pump.

This screw pump works on the principle of positive displacement and in this pump, the water or

other fluids enters into the pump through the inlet valve and flows linearly toward the outlet side

of the pump along with the interlocking screws. The small gap between the screw and the cavity

increases the fluid pressure when fluid flows through the pump.

Objectives

In this project our objective is given bellow

1. Changing hub size

2. Changing rotor or screw size

3. Changing motor voltage

4. Measuring the flow rate using flow rate sensor

We will change all theses in pump and will note the flow rate of the fluid on each case and at the

end will manufacture the pump.

Mechanical Engineering & Technology

December 21, 2022 4

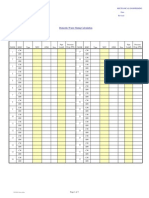

Calculation

Motor Watt Change

Modified Screw Pump Calculation

Discharge Pressure

Size PD (N/m2) 100000 Discharge Q (m3/s) 0.00033

Max. Working Head Preasure H 13.8028765

Series Preasure 185 (m) 2

Hydraulic Power Ph

Serial No. Motor Input Pa (W) 90 (W) 44.55

Density ρwater Break Horsepower

Model (kg/m3) 997 BHP 2.1326E-08

10.2 Suction Pressure

Roter 4 g (m/s2) 9.81 (N/m2) -35000

Motor Specific Gravity 0.9975 Pump Efficiency 53.8043478

Efficiency ɳmotor 0.92 SGwater 6 ɳpump (%) 3

Mechanical Engineering & Technology

December 21, 2022 5

Suction Pressure Change

Modified Centrifugal Pump Calculation

RPM : 1800rev/m

Discharge Pressure

Size PD (N/m2) 100000 Discharge Q (m3/s) 0.00033

Max. Working Head Preasure H 13.2916588

Series Preasure 185 (m) 7

Hydraulic Power Ph

Serial No. Motor Input Pa (W) 108 (W) 42.9

Density ρwater Break Horsepower 2.55912E-

Model (kg/m3) 997 BHP 08

10.2 Suction Pressure

2

Roter 4 g (m/s ) 9.81 (N/m2) -30000

Motor Specific Gravity 0.9975 Pump Efficiency

Efficiency ɳmotor 0.92 SGwater 6 ɳpump (%) 43.1763285

Discharge Pressure Change

Modified Screw Pump Calculation

RPM : 1800rev/m

Discharge Pressure

Size PD (N/m2) 10000 Discharge Q (m3/s) 0.00033

Max. Working Head Preasure H

Series Preasure 185 (m) 4.60095884

Hydraulic Power Ph

Serial No. Motor Input Pa (W) 190 (W) 14.85

Density ρwater Break Horsepower 4.50216E-

Model (kg/m3) 997 BHP 08

10.2 Suction Pressure

Roter 4 g (m/s2) 9.81 (N/m2) -35000

Motor Specific Gravity 0.9975 Pump Efficiency 8.49542334

Efficiency ɳmotor 0.92 SGwater 6 ɳpump (%) 1

Mechanical Engineering & Technology

December 21, 2022 6

RPM Change

Modified Screw Pump Calculation

Discharge Pressure

Size PD (N/m2) 10000 Discharge Q (m3/s) 0.00033

Max. Working Head Preasure H

Series Preasure 185 (m) 10

Hydraulic Power Ph

Serial No. Motor Input Pa (W) 60 (W) 32.275881

Density ρwater Break Horsepower 1.42174E-

Model (kg/m3) 997 BHP 08

10.2 Suction Pressure

Roter 4 g (m/s2) 9.81 (N/m2) -35000

Motor Specific Gravity 0.9975 Pump Efficiency 58.4707989

Efficiency ɳmotor 0.92 SGwater 6 ɳpump (%) 1

Roter Change

Modified Screw Pump Calculation

RPM : 1800rev/m

Discharge Pressure PD 0.00027777

Size (N/m2) 1000 Discharge Q (m3/s) 8

Max. Working Head Preasure H

Series Preasure 185 (m) 8

Hydraulic Power Ph 21.7346173

Serial No. Motor Input Pa (W) 190 (W) 9

Density ρwater Break Horsepower 4.50216E-

Model (kg/m3) 997 BHP 08

Suction Pressure

Roter 6 g (m/s2) 9.81 (N/m2) -350

Motor Efficiency 0.9 Specific Gravity 0.9975 Pump Efficiency 12.4339916

ɳmotor 2 SGwater 6 ɳpump (%) 4

Mechanical Engineering & Technology

December 21, 2022 7

Conclusion

Orignal Screw Pump Calculation

RPM : 1800rev/m

Discharge Pressure

Size PD (N/m2) 100000 Discharge Q (m3/s) 0.0006111

Max. Working Head Preasure H

Series Preasure 185 (m) 15.24

Hydraulic Power Ph 91.0880524

Serial No. Motor Input Pa (W) 108 (W) 2

Density ρwater Break Horsepower 2.55912E-

3

Model (kg/m ) 997 BHP 08

10.2 Suction Pressure

2

Roter 4 g (m/s ) 9.81 (N/m2) -49055.8868

Motor

Efficiency Specific Gravity 0.9975 Pump Efficiency 91.6747709

ɳmotor 0.92 SGwater 6 ɳpump (%) 6

Significance of project

Significance of the project is making such a pump which give more flow rate with low cast

Advantages

1. Simple in structure.

2. These pumps are easy to maintain.

3. Progressive cavity pumps can be used for all fluids

4. Very high pumping speed

5. Noiseless

Disadvantages

The main disadvantage of this pump is that that it locks due to fraction of the rubber when it run

dry.

References

[1] market@haoshpump.com

[2] instrumentationtools.com

Mechanical Engineering & Technology

December 21, 2022 8

You might also like

- Progressive Cavity Pump (PCP) : Mohamed ElbadriDocument46 pagesProgressive Cavity Pump (PCP) : Mohamed Elbadrimohanned salah100% (3)

- Fluid Machinery HandoutDocument19 pagesFluid Machinery Handoutأحمد صلاح الدينNo ratings yet

- 4V158TIDocument2 pages4V158TIEduardo Uquiza HuamanNo ratings yet

- V 222 TiDocument2 pagesV 222 TiTrupp2785No ratings yet

- V222TIDocument2 pagesV222TIDEEPAK GOYALNo ratings yet

- V222ti PDFDocument2 pagesV222ti PDFcmendezNo ratings yet

- V222TI Marine Engine Specs & RatingsDocument2 pagesV222TI Marine Engine Specs & RatingscmendezNo ratings yet

- CH1 3a2017Document41 pagesCH1 3a2017Kadie EdwardsNo ratings yet

- Paddle Powered Water PumpDocument35 pagesPaddle Powered Water PumpJahanzaib Khan100% (1)

- Improving The Head and Efficiency of A PumpDocument7 pagesImproving The Head and Efficiency of A PumpPandeyNo ratings yet

- V180TI Marine Engine Power Ratings and SpecificationsDocument2 pagesV180TI Marine Engine Power Ratings and SpecificationsJohn MartinNo ratings yet

- V222TIDocument2 pagesV222TILisandroNo ratings yet

- Spec - V158TI - Heavy DutyDocument2 pagesSpec - V158TI - Heavy DutyIsmar EdgardoNo ratings yet

- Technical Specs Model 69ug15-050s Carrier Um A6015b9eDocument8 pagesTechnical Specs Model 69ug15-050s Carrier Um A6015b9eodethNo ratings yet

- L136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146Document2 pagesL136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146RaymondNo ratings yet

- Md196T Marine Engine: Model Conditions Power RPM Base Engine MD196T Heavy Duty 280PS (206kW) 2,000 DE12TDocument2 pagesMd196T Marine Engine: Model Conditions Power RPM Base Engine MD196T Heavy Duty 280PS (206kW) 2,000 DE12TElton FloresNo ratings yet

- L136Ti Marine Engine: Model Conditions Power RPM Base Engine L136TI Heavy Duty 230PS (169kW) 2200 D1146TIDocument2 pagesL136Ti Marine Engine: Model Conditions Power RPM Base Engine L136TI Heavy Duty 230PS (169kW) 2200 D1146TIMohamed AbdelazimNo ratings yet

- Technical Manual MKTHDocument30 pagesTechnical Manual MKTHahmed abdoh0% (1)

- Presentasi BFPT Dhimas A.D.H (Variation Inlet Steam Temperature To BFPT Performance)Document24 pagesPresentasi BFPT Dhimas A.D.H (Variation Inlet Steam Temperature To BFPT Performance)Dicky harsonoNo ratings yet

- PN11 - Deluge PumpDocument2 pagesPN11 - Deluge PumpFayez Al-ahmadiNo ratings yet

- MD196T Marine Engine SpecsDocument2 pagesMD196T Marine Engine SpecsMaurice ConnorNo ratings yet

- MD196T Data SheetDocument2 pagesMD196T Data SheetElton FloresNo ratings yet

- V158Ti Marine EngineDocument2 pagesV158Ti Marine EngineVICROENo ratings yet

- Energy Integrated Systems Support and Services ConsultingDocument15 pagesEnergy Integrated Systems Support and Services ConsultingLucky Cham AguilaNo ratings yet

- L136TI Marine Engine SpecsDocument2 pagesL136TI Marine Engine SpecsJulio SanchezNo ratings yet

- HP Gearless Ball Mill Drive in Cement-Why Not! PDFDocument15 pagesHP Gearless Ball Mill Drive in Cement-Why Not! PDFRajuNo ratings yet

- Impeller SplitterDocument6 pagesImpeller SplitterBaskar SNo ratings yet

- HPD ProfileDocument25 pagesHPD Profilerasnawati762No ratings yet

- Dat V180tiDocument2 pagesDat V180tijorge luisNo ratings yet

- Cement Fluid Flow GuideDocument10 pagesCement Fluid Flow GuideHasnaoui SamirNo ratings yet

- MCWFHBM - CentrifugalDocument2 pagesMCWFHBM - CentrifugalmuhammaduzairNo ratings yet

- Centrifugal Pump Operating EnvelopeDocument9 pagesCentrifugal Pump Operating EnvelopeChang Chee HongNo ratings yet

- Lap Report 2Document20 pagesLap Report 2aidoo3045No ratings yet

- Sizing and Specifying Pumps R2Document27 pagesSizing and Specifying Pumps R2royNo ratings yet

- Reciprocating Pump Manual 1Document17 pagesReciprocating Pump Manual 1Youssef ChahlaNo ratings yet

- Modular&Packaged Air Cooled Water Chiller: Shandong Vicot Air Conditioning Co.,LtdDocument20 pagesModular&Packaged Air Cooled Water Chiller: Shandong Vicot Air Conditioning Co.,LtdLeman SihotangNo ratings yet

- Pump Hydralics TrainingDocument81 pagesPump Hydralics TrainingNai Bale100% (1)

- L086Ti Marine EngineDocument2 pagesL086Ti Marine EngineChâu TínNo ratings yet

- Centrifugal PumpsDocument7 pagesCentrifugal PumpsNhutNo ratings yet

- Examen 1er ParcialDocument6 pagesExamen 1er ParcialDylänReYsNo ratings yet

- Doosan Marine Diesel Engine Catalogue and SpecificationsDocument25 pagesDoosan Marine Diesel Engine Catalogue and SpecificationsJohn MartinNo ratings yet

- Operation Manual: BW1500/12 MUD PUMPDocument29 pagesOperation Manual: BW1500/12 MUD PUMPЕвгенийNo ratings yet

- Group 4 - F5 pumps performanceDocument16 pagesGroup 4 - F5 pumps performanceParag SinghNo ratings yet

- Evmsg10 6f5q1bege 2.2Document7 pagesEvmsg10 6f5q1bege 2.2sara jamalNo ratings yet

- 5806 - 110 P & M Doc For Effluent Disposal Pump REv 02Document16 pages5806 - 110 P & M Doc For Effluent Disposal Pump REv 02Gopala KrishnanNo ratings yet

- MD196T DMT136HDocument2 pagesMD196T DMT136HJulio SanchezNo ratings yet

- CPCDocument2 pagesCPCUok RitchieNo ratings yet

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- 6E - Group Assignment Fluid Mechanics IIDocument22 pages6E - Group Assignment Fluid Mechanics IIAfnan MazNo ratings yet

- Determining the Operation Point of a Centrifugal Pump Lab ReportDocument13 pagesDetermining the Operation Point of a Centrifugal Pump Lab ReportKenan GojayevNo ratings yet

- Technical Specification: General InformationDocument15 pagesTechnical Specification: General InformationPathy Gutierrez MoralesNo ratings yet

- Installation, Commissioning & Start-Up ProcedureDocument9 pagesInstallation, Commissioning & Start-Up ProcedureMudassir RafiqNo ratings yet

- Manual de Operacion de Grua Sany SCC1000Document40 pagesManual de Operacion de Grua Sany SCC1000gilberto isrrael roman saviñon100% (1)

- FM R22 R407C TOPAIRE WATER COOLED PACKAGED R1-HadiDocument39 pagesFM R22 R407C TOPAIRE WATER COOLED PACKAGED R1-HadiHasrul RosliNo ratings yet

- Technical System Data: Date/sign.: Rev. B: 24Aug06/KHE 1 01Apr11/KHEDocument5 pagesTechnical System Data: Date/sign.: Rev. B: 24Aug06/KHE 1 01Apr11/KHEapalakNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Lecture 3 and 4Document37 pagesLecture 3 and 4Muhammad AbdullahNo ratings yet

- Lecture 3 and 4Document37 pagesLecture 3 and 4Muhammad AbdullahNo ratings yet

- Mathematics IV Open Ended ActivityDocument7 pagesMathematics IV Open Ended ActivityMuhammad AbdullahNo ratings yet

- Cep FeaDocument60 pagesCep FeaMuhammad AbdullahNo ratings yet

- Machine Design Project ReportDocument11 pagesMachine Design Project ReportMuhammad Abdullah100% (1)

- Instrumentation & Measurement Project ReportDocument13 pagesInstrumentation & Measurement Project ReportMuhammad AbdullahNo ratings yet

- Fluid Mechanics Lab AssignmnentDocument8 pagesFluid Mechanics Lab AssignmnentMuhammad AbdullahNo ratings yet

- Kunal Patel: - Bi-Directional Cadworx 3D, Stress Analysis Solutions and Modeling SupportDocument6 pagesKunal Patel: - Bi-Directional Cadworx 3D, Stress Analysis Solutions and Modeling SupportYogiCadNo ratings yet

- Ficha-Tecnica-10500 10502 10504 All PMDocument1 pageFicha-Tecnica-10500 10502 10504 All PMJorge Luis Sánchez MuñozNo ratings yet

- Full download Fluid Mechanics 1St Edition Hibbeler Solutions Manual pdfDocument149 pagesFull download Fluid Mechanics 1St Edition Hibbeler Solutions Manual pdfpaul.martin924100% (11)

- Head LossDocument1 pageHead LossamrNo ratings yet

- Transport Phenomena 2 Vol 1 - CH 11 Pumps & CompressorsDocument9 pagesTransport Phenomena 2 Vol 1 - CH 11 Pumps & CompressorsDarryan DhanpatNo ratings yet

- Pumps PDFDocument22 pagesPumps PDFNewNo ratings yet

- 2.5-inch Automatic Resetting Deluge ValveDocument16 pages2.5-inch Automatic Resetting Deluge ValvelavascudoNo ratings yet

- T8 - Fluid Mechanics - CH8Document17 pagesT8 - Fluid Mechanics - CH8roi constantineNo ratings yet

- Importance of Wind Tunnel Test in Design Process of Micro Air VehiclesDocument9 pagesImportance of Wind Tunnel Test in Design Process of Micro Air VehiclesDhivaakar KrishnanNo ratings yet

- Xfoil Workshop Rev2Document2 pagesXfoil Workshop Rev2brandonNo ratings yet

- HSSRptr-Plus One Chapter10 PhysicsDocument24 pagesHSSRptr-Plus One Chapter10 PhysicsSPARTANo ratings yet

- Tutorial On Sediment Transport Mechanics: April, 2020Document15 pagesTutorial On Sediment Transport Mechanics: April, 2020zelalemniguse100% (1)

- How to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreDocument2 pagesHow to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreNo PersonNo ratings yet

- Jockey in NFPA20, 2007 Hand BookDocument3 pagesJockey in NFPA20, 2007 Hand BookVipul GandhiNo ratings yet

- Race Car Unit 2Document17 pagesRace Car Unit 2meetbalakumarNo ratings yet

- Hydraulic Services Commissioning Standard Version 4 - September 2019Document18 pagesHydraulic Services Commissioning Standard Version 4 - September 2019Mohamed Abou El hassanNo ratings yet

- New Hydraulic PowerMaster MotorDocument2 pagesNew Hydraulic PowerMaster MotorVictor Edy Facundo DelzoNo ratings yet

- Hydraulic Jump Energy DissipationDocument35 pagesHydraulic Jump Energy DissipationAhmad PshtiwanNo ratings yet

- 076BAS030 PritamDocument9 pages076BAS030 PritamPritam SahNo ratings yet

- A Hydrodynamic Comparisons of Two Different High Press - 2022 - Chemical EngineeDocument12 pagesA Hydrodynamic Comparisons of Two Different High Press - 2022 - Chemical EngineeJonathan SoeNo ratings yet

- Hydraulics 1Document47 pagesHydraulics 1Avaricious AndrewNo ratings yet

- CLASS 13620: DEP 31.38.01.14-Gen Class 13620, Rev. K Page 1 of 12Document12 pagesCLASS 13620: DEP 31.38.01.14-Gen Class 13620, Rev. K Page 1 of 12Bharuk MechNo ratings yet

- Pompa Transfer Mall 1 1000lpm@70m (Evo V 6403-1-18,5kw - 2pole)Document5 pagesPompa Transfer Mall 1 1000lpm@70m (Evo V 6403-1-18,5kw - 2pole)Rinaldy AkbarNo ratings yet

- Production PDFDocument78 pagesProduction PDFtibk_kktNo ratings yet

- Meson Gate Valve 620767Document1 pageMeson Gate Valve 620767syed aliNo ratings yet

- 5.a19a PMSDocument5 pages5.a19a PMSS.selvakumarNo ratings yet

- AccumulatorDocument5 pagesAccumulatorMohan CharanchathNo ratings yet

- Deliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00Document13 pagesDeliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00lightsonsNo ratings yet

- Project Name: Domestic Water Sizing CalculationDocument5 pagesProject Name: Domestic Water Sizing CalculationsitehabNo ratings yet

- Brochure - Jamal PIPEDocument20 pagesBrochure - Jamal PIPEMavia KhanNo ratings yet