Professional Documents

Culture Documents

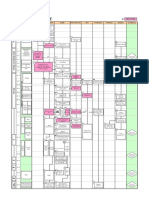

Aravindh's Resume - GOC

Uploaded by

Aravindh Nagaraj0 ratings0% found this document useful (0 votes)

8 views1 pageAravindh is seeking a technical position that offers professional growth through being innovative and flexible. He has over 3 years of experience in quality management, failure analysis, and project management. His skills include Six Sigma, APQP, PPAP, supplier quality assurance, and data analytics tools like Tableau and Data Studio. He has led quality improvement projects, improved supplier performance, and actively solved over 75 quality problems using tools like 8D, RCA, and FMEA. Aravindh holds a Lean Six Sigma Black Belt certification and has experience in quality system implementation, auditing, and cost reduction.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAravindh is seeking a technical position that offers professional growth through being innovative and flexible. He has over 3 years of experience in quality management, failure analysis, and project management. His skills include Six Sigma, APQP, PPAP, supplier quality assurance, and data analytics tools like Tableau and Data Studio. He has led quality improvement projects, improved supplier performance, and actively solved over 75 quality problems using tools like 8D, RCA, and FMEA. Aravindh holds a Lean Six Sigma Black Belt certification and has experience in quality system implementation, auditing, and cost reduction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageAravindh's Resume - GOC

Uploaded by

Aravindh NagarajAravindh is seeking a technical position that offers professional growth through being innovative and flexible. He has over 3 years of experience in quality management, failure analysis, and project management. His skills include Six Sigma, APQP, PPAP, supplier quality assurance, and data analytics tools like Tableau and Data Studio. He has led quality improvement projects, improved supplier performance, and actively solved over 75 quality problems using tools like 8D, RCA, and FMEA. Aravindh holds a Lean Six Sigma Black Belt certification and has experience in quality system implementation, auditing, and cost reduction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

aravindhnagaraj@gmail.

com

Aravindh S 7667660500 / 8838307284

Coimbatore, India

Seeking a position to utilize my skills and abilities in a technical industry that offers professional growth while being resourceful,

innovative and flexible. Experienced in Quality Management, Failure Analysis, Project Management, Data & Analytics for reaching goals

using prescribed as well as innovative methods.

WORK EXPERIENCE SKILLS

Senior Engineer Six Sigma APQP PPAP

Lakshmi Machine Works Limited

07/2018 - Present, Coimbatore, India Supplier Quality Assurance QRQC RCA

Achievements/Tasks

Deploy APQP activities to determine appropriate use of 8D Lean Continuous Improvement FMEA

process controls, FMEA, Control plan, MSA with process

during pilot & mass production CAPA First Time Right QMS

Sets up or participates in continuous improvement Process Excellence Process Optimization

teams related to establishing a process or process

improvement Project Management Risk Analysis

Work closely with the business and Risk Management to

assess risk and develop controls and mitigation Cost Reduction Supplier Audit 5S TQM

strategies for risk areas

Tableau Data Studio PDCA

Improved supplier performance (both quality & delivery)

through various projects, audits, TWSR (Top worst

5 Why Analysis

supplier review), VQR dashboard monitoring system

Define and drive the execution of standard operating

procedures, best practices, including standardization

and centralization, within the end to end supply chain

accounting team and Global Controlling’s Community of KEY DELIVERABLES

Excellence

Involved in FMEA cluster, infrastructure creation, Lead of 8 Six sigma & 15 QC story projects

process evaluation, Poka-Yoke creation, Measurement

Improved Vendor Quality Rating through Supplier

system upgradation, Process capability validation, QMS

implementation at supplier end

partnership, TWSR (Top worst supplier review), VQR

dashboard monitoring system

Experienced in quality tools like APQP, PPAP, 8D, SICR,

FAI, VQR, MSA, Gauge R&R, Cp, Cpk, SPC, DMAIC, DOE Actively solved 75+ quality problems through 8D &

Coordinate work effort in partnership with a team of RCA

local or remote SMEs (functional / operations) and Lean

Six Sigma trained resources to support the delivery of

projects

Active participation in development of Process

ACHIEVEMENTS

Excellence Community and culture through active

involvement in a variety of workshops, forums and Lean Six Sigma Black Belt

TUV SUD - South Asia

training sessions related to Lean Six Sigma and other

Process Excellence concepts and practices Key member of cost reduction project of around 8

crores

ASNT SNT TC 1A Level 2 - UT, PT, RT, MT

EDUCATION ISO 9001:2015 Internal Auditor

M.S in Non Destructive Testing

National Institute of Technology, NIT

Tiruchirappalli LANGUAGES

08/2016 - 06/2018, Tiruchirappalli, Tamil Nadu, India

8/10 English Tamil

Full Professional Proficiency Native or Bilingual Proficiency

AMIE Mechanical Engineering

The Institution of Engineers INDIA

06/2011 - 03/2014, India 7.2/10

You might also like

- AravindhDocument1 pageAravindhAravindh NagarajNo ratings yet

- Resume AjeetGuptaDocument4 pagesResume AjeetGuptaphani_ssNo ratings yet

- Operations Management With Six Sigma : Executive Development inDocument12 pagesOperations Management With Six Sigma : Executive Development inParth MundhwaNo ratings yet

- Rajiv Ranjan Raja - CVDocument2 pagesRajiv Ranjan Raja - CVShashank SrivastavaNo ratings yet

- Extensive Experience in Quality Assurance and Manufacturing ExcellenceDocument4 pagesExtensive Experience in Quality Assurance and Manufacturing ExcellenceVarinder Pal SinghNo ratings yet

- Vijay Pathak: Core Competencies Profile SummaryDocument3 pagesVijay Pathak: Core Competencies Profile SummaryVijay PathakNo ratings yet

- Career Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressDocument5 pagesCareer Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressvivekNo ratings yet

- QA Leader Seeking Operational ExcellenceDocument4 pagesQA Leader Seeking Operational ExcellenceumeshjmangroliyaNo ratings yet

- Pavan KonkaDocument2 pagesPavan Konkacrazy admirerNo ratings yet

- Shrikant R S - Quality ManagerDocument2 pagesShrikant R S - Quality ManagerParag WadekarNo ratings yet

- Sandipkumar Arjun ShindeDocument3 pagesSandipkumar Arjun ShindeAditya NaikNo ratings yet

- Senior QA Analyst resume with 6.5+ years experienceDocument1 pageSenior QA Analyst resume with 6.5+ years experienceSrz CreationsNo ratings yet

- Latest Resume Yogesh CharatkarDocument4 pagesLatest Resume Yogesh CharatkarYogesh CharatkarNo ratings yet

- Rateek Awhney E Q: EY KillsDocument2 pagesRateek Awhney E Q: EY KillsMeer Hassan FarhadNo ratings yet

- Key Skills Profile Summary: Manish KumarDocument3 pagesKey Skills Profile Summary: Manish KumarobvertNo ratings yet

- Sriteja Lanka ResumeDocument5 pagesSriteja Lanka ResumeMasum PatthakNo ratings yet

- UPASANA PATTNAIK---APMDocument2 pagesUPASANA PATTNAIK---APMUpasana PattnaikNo ratings yet

- Abhimanyu CV1608 QMSDocument2 pagesAbhimanyu CV1608 QMSabhimanyu mishraNo ratings yet

- Expert Quality Manager with 14+ Years of Experience Driving Operational ExcellenceDocument3 pagesExpert Quality Manager with 14+ Years of Experience Driving Operational ExcellenceobvertNo ratings yet

- Mariela Paunescu ResumeDocument5 pagesMariela Paunescu ResumeMihai GabrielNo ratings yet

- Naukri RAJESHMAKWANA (12y 0m)Document4 pagesNaukri RAJESHMAKWANA (12y 0m)Piyush SinghalNo ratings yet

- Nagaraja H M ResumeDocument4 pagesNagaraja H M ResumeMNR SolutionsNo ratings yet

- Anjali Verma: Senior Quality ConsultantDocument3 pagesAnjali Verma: Senior Quality ConsultantKuldeep vermaNo ratings yet

- G. Siva Durga Pawan: ContactDocument2 pagesG. Siva Durga Pawan: ContactPS AdityaNo ratings yet

- Expert Quality Manager with 13+ years experience in manufacturingDocument3 pagesExpert Quality Manager with 13+ years experience in manufacturingobvertNo ratings yet

- Song ListDocument3 pagesSong ListUjjal MishraNo ratings yet

- Agastine Paul Raja J: Quality ExecutiveDocument2 pagesAgastine Paul Raja J: Quality ExecutiveA.P. RajaNo ratings yet

- Resume - Mahesh Kumbhare - SQE - 5yearsDocument2 pagesResume - Mahesh Kumbhare - SQE - 5yearser.kumbhareNo ratings yet

- Six Sigma - Green Belt 3-Day WorkshopDocument2 pagesSix Sigma - Green Belt 3-Day WorkshoptetrahedronNo ratings yet

- Supply Chain Intern Resume for Industrial EngineerDocument2 pagesSupply Chain Intern Resume for Industrial EngineersatyajitlNo ratings yet

- Management Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceDocument2 pagesManagement Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceHeart Touching VideosNo ratings yet

- Naukri SharathA (7y 0m)Document2 pagesNaukri SharathA (7y 0m)RaghuNo ratings yet

- Resume RahulDocument3 pagesResume RahulIndian MHNo ratings yet

- Sample MGRDocument3 pagesSample MGRMottu2003No ratings yet

- Sankalp CurriculumVitaeDocument2 pagesSankalp CurriculumVitaeashutoshpal21No ratings yet

- Resume-Love Kumar-1Document4 pagesResume-Love Kumar-1Yâśhïkā BhãtìåNo ratings yet

- CV Praveen PDFDocument6 pagesCV Praveen PDFPraveen KumarNo ratings yet

- Key Skills: Sunil Kumar DalalDocument3 pagesKey Skills: Sunil Kumar DalalAvinashBatraNo ratings yet

- Gauravcv (2) (2)Document1 pageGauravcv (2) (2)gauravkumar787093No ratings yet

- AbhishekChopra CV 2023Document4 pagesAbhishekChopra CV 2023Abhishek ChopraNo ratings yet

- 05 - Training Insert - Global 8D & 7QC ToolsDocument3 pages05 - Training Insert - Global 8D & 7QC ToolsssqiindiapvtltdNo ratings yet

- General CV-Naveenan PDocument1 pageGeneral CV-Naveenan PP.NAVEENANNo ratings yet

- AbhijitBarik 12 0Document3 pagesAbhijitBarik 12 0almamunmolla96No ratings yet

- Karen - Perez - Cazares - CV Eng 2018Document3 pagesKaren - Perez - Cazares - CV Eng 2018roccomtzsegoviaNo ratings yet

- CV ExampleDocument2 pagesCV Examplefanicaii.iacobNo ratings yet

- Dharmendra CVDocument6 pagesDharmendra CVAmandeep SharmaNo ratings yet

- Functional QA LeadDocument4 pagesFunctional QA LeadSrikant PandaNo ratings yet

- Resume Summary for Quality ProfessionalDocument5 pagesResume Summary for Quality ProfessionalneerajrdxNo ratings yet

- Abhishek Dhaka - QADocument5 pagesAbhishek Dhaka - QAAsif ShaikhNo ratings yet

- Muzammil Khan ResumeDocument2 pagesMuzammil Khan ResumeMuzammil KhanNo ratings yet

- Quality Assurance VinothDocument3 pagesQuality Assurance VinothThanh TranNo ratings yet

- Thaarinisudhakaran (4 3)Document1 pageThaarinisudhakaran (4 3)vineeth rockstar1999No ratings yet

- WAHID HUSSAIN - CV - Doc-1Document2 pagesWAHID HUSSAIN - CV - Doc-1Mubi MalikNo ratings yet

- Yash Resume 2 2Document2 pagesYash Resume 2 2BaljeetNo ratings yet

- Senior Test Analyst with 6+ Years of Experience in Automation and Manual TestingDocument1 pageSenior Test Analyst with 6+ Years of Experience in Automation and Manual TestingDEV DNo ratings yet

- Service Delivery Professional: Core CompetenciesDocument1 pageService Delivery Professional: Core CompetenciesGuru KguruNo ratings yet

- Yatender Sharma ResumeDocument4 pagesYatender Sharma ResumeMNR SolutionsNo ratings yet

- Paritosh Kumar_Dr Reddys_NITIEDocument1 pageParitosh Kumar_Dr Reddys_NITIEparitosh kumarNo ratings yet

- Mahesh K: Areas of ExpertiseDocument4 pagesMahesh K: Areas of ExpertiseMAHESH NAGANo ratings yet

- APQP Guidelines & FormatDocument36 pagesAPQP Guidelines & FormatAravindh NagarajNo ratings yet

- Indian Statistical Institute 203 B.T. ROAD, KOLKATA - 108Document1 pageIndian Statistical Institute 203 B.T. ROAD, KOLKATA - 108Aravindh NagarajNo ratings yet

- APQP4Wind E-Manual Version 1.2 - Partial PreviewDocument12 pagesAPQP4Wind E-Manual Version 1.2 - Partial PreviewGüner Güvenç0% (1)

- ISO Standards Pneumatic Cylinders ExplainedDocument1 pageISO Standards Pneumatic Cylinders ExplainedAravindh NagarajNo ratings yet

- Aravindh CV PDFDocument3 pagesAravindh CV PDFAravindh NagarajNo ratings yet

- Vendor Contact List TemplateDocument6 pagesVendor Contact List TemplateAravindh NagarajNo ratings yet

- SR 12615Document1 pageSR 12615Aravindh NagarajNo ratings yet

- Advt 312Document6 pagesAdvt 312aonysonNo ratings yet

- Supplier FPI SOP for Eaton FSDDocument4 pagesSupplier FPI SOP for Eaton FSDAravindh NagarajNo ratings yet

- ClutshesDocument15 pagesClutshesAmr Abd ElrahmanNo ratings yet

- AbaqusDocument18 pagesAbaqusAravindh NagarajNo ratings yet

- 10 1016@j Corsci 2009 11 005 PDFDocument8 pages10 1016@j Corsci 2009 11 005 PDFAravindh NagarajNo ratings yet

- 10 1016@j Corsci 2009 11 005 PDFDocument8 pages10 1016@j Corsci 2009 11 005 PDFAravindh NagarajNo ratings yet

- ME1302 Machine Elements Design Q&ADocument14 pagesME1302 Machine Elements Design Q&AProf. Avinash MahaleNo ratings yet

- TIERRA - REIJEN - S - Ass2 - The 3D Wheel of Architect's Services - Module2Document4 pagesTIERRA - REIJEN - S - Ass2 - The 3D Wheel of Architect's Services - Module2Reijen Canary S TierraNo ratings yet

- MBA Project Proposal On Effective Brand Management - 237200326Document6 pagesMBA Project Proposal On Effective Brand Management - 237200326Murtaza GolwalaNo ratings yet

- ISO 14001.2015 Environmental Management System Implementation GuideDocument14 pagesISO 14001.2015 Environmental Management System Implementation GuideCandice0% (1)

- Saep 3101Document7 pagesSaep 3101Anonymous 4IpmN7OnNo ratings yet

- SAHARA INDIA PARIWAR Summer Training ReportDocument116 pagesSAHARA INDIA PARIWAR Summer Training ReportUjjawalpratap Singh100% (1)

- Board Governance For Early Stage Technology Companies Complete2Document147 pagesBoard Governance For Early Stage Technology Companies Complete2Ghulam Murtaza KoraiNo ratings yet

- The Electrical Contractor Safety Program GuideDocument102 pagesThe Electrical Contractor Safety Program Guidefolake_ajayi100% (1)

- Hapter 19: © 2008 Prentice Hall Business Publishing Accounting Information Systems, 11/e Romney/SteinbartDocument159 pagesHapter 19: © 2008 Prentice Hall Business Publishing Accounting Information Systems, 11/e Romney/Steinbartp12400No ratings yet

- Pertemuan Ke 2, An Introduction To Cost Terms and Purposes Sampai Learning Objaective 6Document76 pagesPertemuan Ke 2, An Introduction To Cost Terms and Purposes Sampai Learning Objaective 6Erick JonathanNo ratings yet

- Apqp Workflow - EXAMPLEDocument1 pageApqp Workflow - EXAMPLEMiguel NetoNo ratings yet

- Standard Costing - Solutions To Home Work Problems: Question No: 19 Reconciliation With Finished Goods InventoryDocument7 pagesStandard Costing - Solutions To Home Work Problems: Question No: 19 Reconciliation With Finished Goods InventoryDevi ParameshNo ratings yet

- Pressures For Global IntegrationDocument16 pagesPressures For Global IntegrationMahpuja JulangNo ratings yet

- Good Governance Prelim ExamDocument4 pagesGood Governance Prelim ExamEt WatNo ratings yet

- Assessment of Learning 2: Dr. Alicia P. FranciscoDocument22 pagesAssessment of Learning 2: Dr. Alicia P. FranciscoAlicia Pangilinan FranciscoNo ratings yet

- Poem 2009: 2 Ifip WG 8.1 Working Conference OnDocument1 pagePoem 2009: 2 Ifip WG 8.1 Working Conference OnRitu SharmaNo ratings yet

- Case Study (Tesco)Document2 pagesCase Study (Tesco)Rachel Ann RazonableNo ratings yet

- Brand Management Unit 4Document13 pagesBrand Management Unit 4Sankalp JainNo ratings yet

- MC 2 Consulting BidDocument40 pagesMC 2 Consulting BidbenelovesNo ratings yet

- SCM-02 Performance of Supply ChainDocument16 pagesSCM-02 Performance of Supply Chainshivani radhu100% (1)

- Information Technology in Supply Chain Management: 2010 Slide 1 of 23 Role of IT in SCMDocument23 pagesInformation Technology in Supply Chain Management: 2010 Slide 1 of 23 Role of IT in SCMamitabhNo ratings yet

- CSCP QuestionsDocument16 pagesCSCP QuestionsNijiRajesh100% (4)

- Customer ServiceDocument14 pagesCustomer ServiceAnonymous 0HycR53No ratings yet

- Strategic Human Resource Management PDFDocument251 pagesStrategic Human Resource Management PDFkoshyligo100% (2)

- Test DocumentationDocument6 pagesTest DocumentationIrina ClaudiaNo ratings yet

- Task Evidence: Mdsap Audit Checklist (For Audit Model Version 2016, Reflecting ISO 13485:2016)Document14 pagesTask Evidence: Mdsap Audit Checklist (For Audit Model Version 2016, Reflecting ISO 13485:2016)Norah Al-ShamriNo ratings yet

- Internship presentation on inventory management at Kirloskar BrothersDocument9 pagesInternship presentation on inventory management at Kirloskar BrothersAyush Chopra100% (1)

- Task 1 - BCM Method - Guide V5e FinalDocument86 pagesTask 1 - BCM Method - Guide V5e Finalilumezianu100% (1)

- Human Resource Management-Chapter 1 Dr. Nisha RanaDocument27 pagesHuman Resource Management-Chapter 1 Dr. Nisha RanaPriyank GangwalNo ratings yet

- Laura Ann Rauen ResumeDocument3 pagesLaura Ann Rauen ResumeLauraNo ratings yet

- IBS Center For Management Reseorc H: HR Restructuring at NissanDocument3 pagesIBS Center For Management Reseorc H: HR Restructuring at NissanHuyền Oanh ĐinhNo ratings yet