Professional Documents

Culture Documents

BSVITEL001

BSVITEL001

Uploaded by

Rajeev Kumar0 ratings0% found this document useful (0 votes)

14 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageBSVITEL001

BSVITEL001

Uploaded by

Rajeev KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

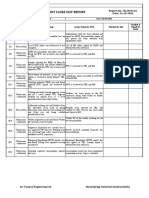

Sy Document No: JOCLIBSVUQC/O01

ti thyssenkrupp

Rey, 0, November 5, 2015

Page I of 1

‘QUALITY DEFICIENCY REPORT

Project Location? —] Contractor: Dates Fin Inprosess | Report No.

Toctrocinngvn | ns remntnetticonpsey | xezane | a TEL

Inspection Checklist, Specification, Or Drawing Used As Reference: _ Specification No:-PDRP-8440-SP-010

Location: Piping Fabrication Vard

" Description OF Discrepancy: _tkIS noticed the following observations:

1. Piping joint welding has been done without baking electrodes for

joint No: J-62,Line No: 150-P-212-BS4164M,SH.3/6,SP-17.

2. Electrodes baking has not been done as per electrode manufacturer

recommendations and contol register has not maintained, also not

reviewed by M/s.TEL QC Engineers.

3. Joint was not traceable

4 Portable oven was not power connected.

™ Surveillance/Deficiency:

See attached photograph:-

TKIS Surveillance Personnel: MrSushil Dey

‘Name Title

Person Notified Of Deficiency: MrNandakisor _ __ 26.02.2020

TIL Quality Control Date

T Recommended Corrective Action by KIS

Joint to be cutout and re weld.

Electrodes shall be baked as per manufacturer recommendations prior to welding.

Baking register shall be well maintained and monitored by TEL Engineer.

TOOL-Box Talk to be conducted among all welders, store assistance and supervisors.

'Y Corrective Actions Implemented/‘Accepted: a = ames

O56 Zoe) 2 ih020

WIS Quality PersonnelDate TEL FEL Quality Controt Date

‘KIS Site Constfucon Manager/Date

You might also like

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- INCDEX1Document2 pagesINCDEX1Rajeev KumarNo ratings yet

- Itp For MechDocument5 pagesItp For MechRajeev KumarNo ratings yet

- Hydro TestDocument2 pagesHydro TestRajeev KumarNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- LHS Rev-1Document29 pagesLHS Rev-1Rajeev KumarNo ratings yet

- L-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteDocument4 pagesL-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteRajeev KumarNo ratings yet

- Sect 11a P Welding DocumDocument31 pagesSect 11a P Welding DocumRajeev KumarNo ratings yet

- Hardness Ins ReportDocument2 pagesHardness Ins ReportRajeev KumarNo ratings yet

- Astm A217-2007Document6 pagesAstm A217-2007Rajeev KumarNo ratings yet

- Walk Through - TEL-COMPO.22.12..2021Document3 pagesWalk Through - TEL-COMPO.22.12..2021Rajeev KumarNo ratings yet

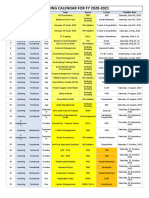

- Training Calender 2020-21Document2 pagesTraining Calender 2020-21Rajeev KumarNo ratings yet

- Acr 002Document1 pageAcr 002Rajeev KumarNo ratings yet

- MCF Testing of PWHTDocument21 pagesMCF Testing of PWHTRajeev KumarNo ratings yet

- QDR Tel-04Document2 pagesQDR Tel-04Rajeev KumarNo ratings yet

- Acr-001 (Draft)Document2 pagesAcr-001 (Draft)Rajeev KumarNo ratings yet

- HCDS Loop ListDocument20 pagesHCDS Loop ListRajeev KumarNo ratings yet

- H2 Balance Month Turn Over Plan - 11.11.2022Document4 pagesH2 Balance Month Turn Over Plan - 11.11.2022Rajeev KumarNo ratings yet

- Qly Walkthrough 09-11-2022Document4 pagesQly Walkthrough 09-11-2022Rajeev KumarNo ratings yet

- Jsa IndexDocument6 pagesJsa IndexRajeev KumarNo ratings yet

- Qwt-Tel-Compo-03 03 2022Document5 pagesQwt-Tel-Compo-03 03 2022Rajeev KumarNo ratings yet

- FINAL - Audit Report - Shailesh DongareDocument7 pagesFINAL - Audit Report - Shailesh DongareRajeev KumarNo ratings yet

- U#2 W.V.Document52 pagesU#2 W.V.Rajeev KumarNo ratings yet

- Day Wise TO Plan For The Month of DEC.22Document56 pagesDay Wise TO Plan For The Month of DEC.22Rajeev KumarNo ratings yet

- Practice ExerciseDocument7 pagesPractice ExerciseRajeev KumarNo ratings yet

- U-2 PWHT Charts SubmissionDocument102 pagesU-2 PWHT Charts SubmissionRajeev KumarNo ratings yet

- Structural Steel Received DetailsDocument16 pagesStructural Steel Received DetailsRajeev KumarNo ratings yet

- Activity 016Document2 pagesActivity 016Rajeev KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)