Professional Documents

Culture Documents

Stal Nierdzewna 02 en

Stal Nierdzewna 02 en

Uploaded by

yorsh robert ramos jaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stal Nierdzewna 02 en

Stal Nierdzewna 02 en

Uploaded by

yorsh robert ramos jaraCopyright:

Available Formats

STAINLESS STEEL

IN RADWAG PRODUCTS

STANDARD AND SPECIAL APPLICATIONS

Characteristics Resistance

Stainless steel, also known as waterproof The degree of corrosion resistance is highly

steel, is popularly associated with higher resistance dependent on the quantity of chromium added

to external conditions and corrosion. In fact, to the steel. A protective passivation layer, i.e. a thin

the term „stainless steel” covers the whole family oxide film, forms on the surface of the steel, invisible

of quality steels differing from each other in chemical to the naked eye. It is formed naturally as a result

composition, degree of resistance and properties. of a chemical reaction between the chromium

In practice, this means that one type of stainless contained in stainless steel and the oxygen contained

steel can have several times the corrosion resistance in the air. It prevents corrosion of steel and influences

of another. its resistance. Increased chromium content and

the addition of other alloying elements, such as nickel

and molybdenum, further increase the resistance

of steel.

Two stainless steel grades are used in RADWAG scales: 304 and 316.

AISI 304 AISI 316

AISI 304 is the most commonly used AISI 316 steel is used to manufacture

steel grade in RADWAG products, mainly used for 1-load-cell platforms of increased resistance, marked

the majority of weighing panes. It is also used for as „HR”. It is used to design weighing pans and

the manufacture of structural elements in products structural elements of HR platforms. AISI 316 steel

marked ‚stainless’ or ‚waterproof’. AISI 304 steel is also is also used in some models of checkweighers.

used for indicators and weighing terminals housings.

AISI 304 AISI 316

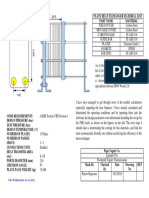

Stainless steel in RADWAG balances and scales:

LABORATORY BALANCES AISI 304 AISI 316

Weighing pan

Weighing chamber

component

Ultra-microbalances Microbalances Analytical balances

Weighing pan

Precision balances

Weighing pan

Weighing chamber

component

Moisture analyzers

INDUSTRIAL SCALES: HIGH RESOLUTION SCALES / 1-LOAD-CELL SCALES AISI 304 AISI 316

Weighing pan

Mechanical design

Post

High resolution scales Platform scales Multifunctional scales Postal scales Indicator / terminal

Weighing pan

Mechanical design

Post

Stainless steel Waterproof Stainless steel

high resolution scales platform scales multifunctional scales Indicator / terminal

Weighing pan

Mechanical design

Post

Waterproof and acid Waterproof and acid

resitant platform scales resistant multifunctional scales Indicator / terminal

4-LOAD-CELL INDUSTRIAL SCALES AISI 304 AISI 316

Platforma

Mechanical design

Indicator / terminal

Platform scales Pallet scales Beam scales

Platforma

Mechanical design

Indicator / terminal

Stainless steel platform scales Stainless steel embedded scales Stainless steel pallet scales Stainless steel beam scales

Platforma

Mechanical design

Stainless steel ramp scales Indicator / terminal

Stainless steel ramp scales with lifted platform

WEIGHING INDICATORS AND TERMINALS AISI 304 AISI 316

Housing

Weighing indicators Weighing terminals

At the customer’s request, it is possible to design any product or selected element

(e.g. weighing pan) using AISI 316 steel instead of the standard AISI 304. This is a special

design and as such requires individual arrangements.

Exemplary stainless steel applications:

GRADE AISI 304 AISI 316

Symbol AISI 304 AISI 316

1.4301 1.4401

0H18N9 0H17N12M2T

X5CrNi18-10 X5CrNiMo17-12-2

Intended use Corrosion neutral environment Highly corrosive environment

– Highly saline environment (e.g. coastal areas)

Food industry Food industry

without direct contact with corrosive substances with direct contact with corrosive substances

Meat industry Meat industry

without direct contact with brine and corrosive with direct contact with brine and corrosive

substances substances

Fish industry Fish industry

without direct contact with products with with direct contact with products with high salt

high salt content content

Pharmaceutical industry Pharmaceutical industry

without direct contact with aggressive substances with direct contact with aggressive substances

Chemical industry Chemical industry

without direct contact with aggressive substances with direct contact with aggressive substances

Maintenance Warranty

The user of products made of stainless steel For detailed warranty conditions read the

is obliged to observe the rules of their use, resulting warranty certificate that comes with the product.

from the characteristics of a given steel grade, and With regard to stainless steel components, the warranty

to keep them clean and systematically maintained. does not cover mechanical damage, natural wear

or misuse.

Do not use powders or other abrasive

substances and agents containing chlorine, salt

or bleach to clean stainless steel products. Even a small

amount of chlorine in the cleaning products can cause The main causes of corrosion precluding

permanent damage to the chromium oxide coating the manufacturer’s warranty:

responsible for the anti-corrosion properties and lead

• Working in an aggressive environment,

to corrosion.

exceeding the resistance of the steel used.

Dirty elements can be cleaned with a soft • No systematic maintenance, no removal

cloth slightly moistened with a solution of water of heavy contamination.

and a mild detergent (e.g. soap or dishwashing liquid)

• Contamination during operation (e.g. foreign

and then rinsed with clean water and wiped dry

metallic pits caused by the use of angle

grinders in the vicinity).

• Contact of stainless steel with carbon steel.

RADWAG Balances and Scales

Toruńska 5, 26-600 Radom, Poland www.radwag.com

e-mail: radom@radwag.pl

You might also like

- SBV-SBVD Eng 120724 1Document6 pagesSBV-SBVD Eng 120724 1SeresdfrtNo ratings yet

- Hot Rolled Structural Steel Products 2019 PDFDocument35 pagesHot Rolled Structural Steel Products 2019 PDFRavinduNo ratings yet

- TECVALDocument8 pagesTECVALRamaswamy Neelakantan NNo ratings yet

- Ancon Stainless Steel Reinforcement Round Bars Australia EditionDocument12 pagesAncon Stainless Steel Reinforcement Round Bars Australia EditionBrad MannNo ratings yet

- Bench ScalesDocument2 pagesBench ScalesbarkahNo ratings yet

- Breather ValveDocument2 pagesBreather ValveSalsa Bila MaisaNo ratings yet

- Stainless Steel Tube and Fittings: Photography Courtesy of Outokumpu, Arcelor and New Zealand Tube MillsDocument13 pagesStainless Steel Tube and Fittings: Photography Courtesy of Outokumpu, Arcelor and New Zealand Tube MillsAwang PannyNo ratings yet

- Safety and Relief Valve Products Product OverviewDocument15 pagesSafety and Relief Valve Products Product Overviewفؤاد ابوزيدNo ratings yet

- Preview AWS+D10.4-86RDocument7 pagesPreview AWS+D10.4-86RأبومحمدالزياتNo ratings yet

- Dual-Plate High Performance Wafer Check Valves, API 594: CatalogueDocument11 pagesDual-Plate High Performance Wafer Check Valves, API 594: Cataloguejun dongNo ratings yet

- Asme enDocument2 pagesAsme endaudtarampak.dtNo ratings yet

- CA6NMDocument2 pagesCA6NMJoshua WalkerNo ratings yet

- Basket Strainer 2022-CMPDocument7 pagesBasket Strainer 2022-CMPMohanrajaNo ratings yet

- Basket Strainers HFSDocument15 pagesBasket Strainers HFSAme NatureNo ratings yet

- On-Off Valves Ball Side-Entry TopsideDocument2 pagesOn-Off Valves Ball Side-Entry TopsideshamekhalmaamariNo ratings yet

- Carbon Steel Pipe Standards 1Document1 pageCarbon Steel Pipe Standards 1phoneme79No ratings yet

- Screen Abc ExtraDocument2 pagesScreen Abc ExtraSoldequipo Cia LtdaNo ratings yet

- B10M Dry Powder Fire ExtinguisherDocument2 pagesB10M Dry Powder Fire ExtinguisherMajaz AhmedNo ratings yet

- MTADocument25 pagesMTAMoh NassNo ratings yet

- Apollo Safety Valves Serie 19Document5 pagesApollo Safety Valves Serie 19Daniel SanNo ratings yet

- High Precision Tubes For Critical Medical ApplicationsDocument5 pagesHigh Precision Tubes For Critical Medical ApplicationsZhu DanielNo ratings yet

- Plate Heat Exchanger PRDocument1 pagePlate Heat Exchanger PRRenzo BagacinaNo ratings yet

- Hot-Rolled-Cat Edition8 Rebrand2019Document35 pagesHot-Rolled-Cat Edition8 Rebrand2019Sherin ShajiNo ratings yet

- Heavy Plates CapabilitiesDocument26 pagesHeavy Plates Capabilitieswindsurferke007No ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- Sa 20 PDFDocument46 pagesSa 20 PDFmr.aghelNo ratings yet

- Micro Motion R-Series General Purpose Coriolis Flow and Density MetersDocument6 pagesMicro Motion R-Series General Purpose Coriolis Flow and Density MeterskEWQ 865kNo ratings yet

- 143XU Globe CraneFS DS 1021 p121Document1 page143XU Globe CraneFS DS 1021 p121Cesar PlataNo ratings yet

- Dimenzije - Buttweld FittingsDocument4 pagesDimenzije - Buttweld Fittingspetrus erectusNo ratings yet

- ControlValves Datasheet PDFDocument60 pagesControlValves Datasheet PDFBsd FareedNo ratings yet

- A 283a 283m-03-Standard Specification For Low & Intermediate Strength Carbon Steel PlatesDocument2 pagesA 283a 283m-03-Standard Specification For Low & Intermediate Strength Carbon Steel PlatesAgni MalekuNo ratings yet

- Standard Product Catalog MontanstahlDocument51 pagesStandard Product Catalog MontanstahlÁguila OccidenteNo ratings yet

- Sa 283Document3 pagesSa 283ismaelarchilacastilloNo ratings yet

- L&T - Triple OffsetDocument16 pagesL&T - Triple OffsetTasneemNo ratings yet

- High Flow Dry Chemical Models: Ultimate Performance For Class B HazardsDocument2 pagesHigh Flow Dry Chemical Models: Ultimate Performance For Class B HazardsAnonymous 8RFzObvNo ratings yet

- Catálogo Cadenas PIAZ 2017Document256 pagesCatálogo Cadenas PIAZ 2017Eduardo Mario NuñezNo ratings yet

- Wilo 497649Document24 pagesWilo 497649Gustavo AmezquitaNo ratings yet

- NOR - Steel Sucker Rods and Pony Rods - V2Document8 pagesNOR - Steel Sucker Rods and Pony Rods - V2Cosersum Int C ANo ratings yet

- Specification For General Requirements For Steel Plates For Pressure VesselsDocument34 pagesSpecification For General Requirements For Steel Plates For Pressure Vesselsedisson_barreraNo ratings yet

- Catalog 79352ENG HOKE Needle Valves 10.15.13Document38 pagesCatalog 79352ENG HOKE Needle Valves 10.15.13lamosy78No ratings yet

- Bial 3 MLD STP Load Calculation Sheet For Cable Tray in Plant RoomDocument4 pagesBial 3 MLD STP Load Calculation Sheet For Cable Tray in Plant RoomRUPESH KUMARNo ratings yet

- NOR Steel Sucker Rods and Pony Rods BR 062122Document8 pagesNOR Steel Sucker Rods and Pony Rods BR 062122Pedro GilNo ratings yet

- DBS Sinker Bars PDFDocument17 pagesDBS Sinker Bars PDFJose Manuel Piñeros NavasNo ratings yet

- Ultrahigh-Purity (UHP) and High-Purity Stainless Steel TubingDocument6 pagesUltrahigh-Purity (UHP) and High-Purity Stainless Steel Tubingatnkpr_vn9368No ratings yet

- Hoke 1700 SeriesDocument38 pagesHoke 1700 SeriesOceanexNo ratings yet

- Bleed Valves and Purge ValvesDocument2 pagesBleed Valves and Purge ValvesdeckyirawansusantoNo ratings yet

- Astm A608 PDFDocument1 pageAstm A608 PDFgaminNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- Tube Fittings CatalogueDocument69 pagesTube Fittings Cataloguerejoy HealyNo ratings yet

- Section II A SA-20 - SA-20M PDFDocument45 pagesSection II A SA-20 - SA-20M PDFSocrates MoralesNo ratings yet

- Stud WeldingDocument33 pagesStud WeldingMurugesan ElaiyappanNo ratings yet

- Ebsray Pumps: G SeriesDocument4 pagesEbsray Pumps: G Seriesmartin.rubenNo ratings yet

- Corporate Presentation Ambica Steels LimitedDocument27 pagesCorporate Presentation Ambica Steels Limitedkuldeep SinghNo ratings yet

- NSK-Linear Guides Standard Items PDFDocument62 pagesNSK-Linear Guides Standard Items PDFBrian ThompsonNo ratings yet

- Spirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Document4 pagesSpirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Nestor LozanoNo ratings yet

- Stock Guide: Stainless SteelDocument43 pagesStock Guide: Stainless SteeljigsNo ratings yet

- 410 QDT Stainless Steel Bar - AISI 410 StandardDocument7 pages410 QDT Stainless Steel Bar - AISI 410 StandardchamaljsNo ratings yet

- Catalogue Seal Oil CoolerDocument28 pagesCatalogue Seal Oil CoolerSharad KokateNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Tutorial 2Document2 pagesTutorial 2Angelina PutriNo ratings yet

- 10th CBSE Holiday HW DoneDocument35 pages10th CBSE Holiday HW Donepomkumar193No ratings yet

- (Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationDocument8 pages(Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationPSirotinNo ratings yet

- 734 Part2 EmulsionDocument28 pages734 Part2 EmulsionRabiya KhanNo ratings yet

- Group 13 The Boron FamilyDocument130 pagesGroup 13 The Boron Familystella jovita0% (1)

- MSL Brochure Compressor-Vacuum-Pump-Fluids20p ENG V1.2 LRDocument11 pagesMSL Brochure Compressor-Vacuum-Pump-Fluids20p ENG V1.2 LRbagaswidyadanaNo ratings yet

- 3.10. Flash, Thermit, FrictionDocument14 pages3.10. Flash, Thermit, FrictionVINAY BHASKARNo ratings yet

- CHCHCHBR X Y Z: Cbse Test Paper-04 CLASS - XII CHEMISTRY (Haloalkanes and Haloarenes)Document1 pageCHCHCHBR X Y Z: Cbse Test Paper-04 CLASS - XII CHEMISTRY (Haloalkanes and Haloarenes)Shreyash KolekarNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingDocument6 pagesSafety Data Sheet: 1. Identification of The Substance/Mixture and of The Company/UndertakingzhangNo ratings yet

- Plastic Limit TestDocument11 pagesPlastic Limit TestAh Gus78% (9)

- IB Chemistry Online EQ - Ans - 001 020 PDFDocument20 pagesIB Chemistry Online EQ - Ans - 001 020 PDFVanessa PilayNo ratings yet

- Desmodur E21: Aromatic PolyisocyanateDocument2 pagesDesmodur E21: Aromatic PolyisocyanateSergiu TaralaNo ratings yet

- Dependence of Refractive Index On Concentration AnDocument7 pagesDependence of Refractive Index On Concentration AnTegar Ari WidiantoNo ratings yet

- Circular Plates On Elastic Foundations Modelled With Annular PlatesDocument10 pagesCircular Plates On Elastic Foundations Modelled With Annular PlatesYoun Seok ChoiNo ratings yet

- Forging ProcessDocument32 pagesForging Processaman prasadNo ratings yet

- Various Nano Catalysts For Biodiesel Production-A Review: Corresponding Author: EmailDocument6 pagesVarious Nano Catalysts For Biodiesel Production-A Review: Corresponding Author: EmailMech HoD DAITNo ratings yet

- Mole Sample Problems With AnswersDocument11 pagesMole Sample Problems With AnswersRaymario NascimentoNo ratings yet

- Technical Data Sheet For Hot Dipped Galvanized Hex NutDocument1 pageTechnical Data Sheet For Hot Dipped Galvanized Hex NutKABIR CHOPRANo ratings yet

- Mounting System For Photovoltaic and Solar Cells 2012Document136 pagesMounting System For Photovoltaic and Solar Cells 2012salkan_rahmanovic810No ratings yet

- Is 432 2 1982 PDFDocument14 pagesIs 432 2 1982 PDFAnil Daniel HansNo ratings yet

- Kepala Teknik: Struktur Organisasi K-3 Ubp Nikel Operasi PomalaaDocument4 pagesKepala Teknik: Struktur Organisasi K-3 Ubp Nikel Operasi PomalaaAnjhar AspandyNo ratings yet

- CHM11-3 Balancing EquationsDocument35 pagesCHM11-3 Balancing EquationsBenmar N. OcolNo ratings yet

- CHEMISTRY Practical Ppt. MMDocument10 pagesCHEMISTRY Practical Ppt. MMmanikmaurya227No ratings yet

- OTC-6076-MS A New Approach To Designing Repair Clamps For Offshore StructuresDocument14 pagesOTC-6076-MS A New Approach To Designing Repair Clamps For Offshore StructuresAnil Chanana100% (1)

- Pebax Product Range BrochureDocument14 pagesPebax Product Range BrochureVictor CastrejonNo ratings yet

- ASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995Document6 pagesASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995ecsuperalNo ratings yet

- Biotower 001 PDFDocument3 pagesBiotower 001 PDFIsmael KhalilNo ratings yet

- Strain Specificity in Antimicrobial Activity of Silver and Copper NanoparticlesDocument10 pagesStrain Specificity in Antimicrobial Activity of Silver and Copper Nanoparticlesdebashish sarkarNo ratings yet

- Technical Data Sheet: 18F (1802-1808) ., King International, No. 345 South Huancheng West Road, Ningbo China 315000Document1 pageTechnical Data Sheet: 18F (1802-1808) ., King International, No. 345 South Huancheng West Road, Ningbo China 315000medo.k016No ratings yet

- Metallurgical Thermo Dynamics9 R H TupkaryDocument208 pagesMetallurgical Thermo Dynamics9 R H TupkaryRahul Pandey100% (7)