Professional Documents

Culture Documents

Criteria For Estimation of The Diameter and The Number of Inletoutlet Nozzle

Criteria For Estimation of The Diameter and The Number of Inletoutlet Nozzle

Uploaded by

shakil ahmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Criteria For Estimation of The Diameter and The Number of Inletoutlet Nozzle

Criteria For Estimation of The Diameter and The Number of Inletoutlet Nozzle

Uploaded by

shakil ahmadCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/274648427

Criteria for the vapor space design in kettle reboilers

Article · December 2008

CITATION READS

1 9,684

4 authors:

Branislav Milenko Jacimovic Srbislav Genic

University of Belgrade University of Belgrade - Faculty of Mechanical Engineering

61 PUBLICATIONS 452 CITATIONS 66 PUBLICATIONS 573 CITATIONS

SEE PROFILE SEE PROFILE

Nikola J. Budimir Marko S. Jarić

University of Belgrade 41 PUBLICATIONS 257 CITATIONS

51 PUBLICATIONS 269 CITATIONS

SEE PROFILE

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Heat exchangers View project

Improvement of system for process and storage heating in plant for margarine production View project

All content following this page was uploaded by Marko S. Jarić on 08 April 2015.

The user has requested enhancement of the downloaded file.

297

SCIENTIFIC BULLETIN OF

THE „POLITEHNICA” UNIVERSITY OF TIMISOARA, ROMANIA

TRANSACTIONS ON MECHANICS

BULETINUL ŞTIINŢIFIC AL

UNIVERSITĂŢII „POLITEHNICA” DIN TIMIŞOARA, ROMÂNIA

SERIA MECANICĂ

Tom 53 (67) ISSN 1224 - 6077 Fasc. S2, 2008

CRITERIA FOR THE VAPOR SPACE DESIGN IN

KETTLE REBOILERS

Branislav JACIMOVIC*, Srbislav GENIC*, Nikola BUDIMIR**, Marko JARIC**

*Department of Process Engineering, Faculty of Mechanical Engineering, University of Belgrade, Kraljice Marije 16,

11000 Beograd, Serbia, bjacimovic@mas.bg.ac.yu, sgenic@mas.bg.ac.yu

**Innovation Center of the Faculty of Mechanical Engineering, University of Belgrade, Kraljice Marije 16, 11000

Beograd, Serbia, nbudimir@mas.bg.ac.yu, mjaric@mas.bg.ac.yu

Abstract. There are several design criteria concerning the dimensions of the vapor space in kettle reboilers. These

criteria are listed and commented in this article. An numeric example illustrates the usage of this criteria.

Keywords: kettle reboiler, vapor space, liquid entrainment

1. Introduction 2 Design criteria

The most commonly used type of evaporator Two phase flow of vapor/liquid mixture in

in refining industry is a kettle reboiler. disengagement space in kettle reboilers is

This kind of reboiler is often used in many complex. Although several authors tried to

other industries (refrigeration systems, distilled develop the adequate mathematical model, it can

water production, desorption systems, etc.). Kettle be said that nowadays the design is still based on

reboiler consists of either a U-tube bundle or the empirically gathered information. Design

floating head tube bundle inserted into an criteria can be grouped in the following manner.

enlarged shell.

The shell provides disengaging space 2.1 Criteria based on the simple geometry

(volume) for the vapor separation of liquid ratios

droplets. Liquid level in shell is usually controlled Palen [2] suggests that the distance from the

by level controller or simply held by the weir. The centerline of the uppermost tube in a horizontal

hot fluid in this kind of apparatus flows inside the bundle to the top of the shell should not be less

tubes. Generally speaking the size (diameter) of than 40% of the kettle shell diameter

the kettle reboiler shell depends on the vapor and Ds / Db ≥ 1.4 .

liquid flow rates, their physical properties and the The freeboard between the liquid level and shell

exchanger geometry. It must be noted that if dry should be at least H s = 250 mm [1], [9].

vapor is really required, as in the case of a

compressor feed, additional protection, such as For practical reasons (better separations of

mechanical mist eliminators, is needed. entrainment) liquid level at kettle horizontal

There are several design criteria that can be reboilers settings that one or two upper rows of

found in the open literature sources. Further on tubes does not in liquid [2]. In these cases the

these criteria are listed and commented. height of the vapor space should be at least

H s = 300 mm .

298

In [1] and [9] the required shell diameter is column the entrainment coefficient ( K ) is

defined as the function of the heat flux. estimated by the relation from [5]

Summarizing the data from both references the 0.25

0.33 ⎛ σ ⎞

following equation can be formed K = 3.14 ⋅ e ⋅ ⎜⎜ ⎟⎟ (6)

Ds ⎝ ρ − ρ ⎠

= 1 + (0.015 ÷ 0.025 ) ⋅ q

L G

(1)

Db Specific entrainment (carryover of the liquid with

vapor phase) shouldn’t be above 2%, or can be

where q is in kW/m 2 . found by the

⎛ 1 ⎞ m& 1

2.2 Criteria based on the volume of the vapor e = ⎜⎜ − 1⎟⎟ ⋅ L ⋅ (7)

=0

⎝1 − fe ⎠ m& G E

e

space

The role of the vapor space is to separate the where

mixture of liquid and vapor. E e =0 − E a

In [11] for steam boilers at the atmospheric fe = (8)

pressure, the following equation is given E e=0

V&G 0.011

= 0.14 + (2) 2.3 Criteria for estimation of the diameter and

V 0.01 + H 1sep

,5

the number of inlet/outlet nozzles

In [10] this equation is recommended for kettle According to [8] an impingement plate, or other

reboilers with drop eliminators (figure 1). For means to protect the tube bundle against

pressures other than 1 bar the right side of impinging fluids, shall be provided when entrance

equation should be multiplied with line values of ρ L ⋅ w L2 exceed the following: non-

p corrosive, nonabrasive, single phase fluids, 2250

f = (3)

1,22 ⋅ p − 0,22 Pa; all other fluids including the liquids at its

for absolute pressure in range 0.5÷5 bar. boiling point, 750 Pa.

On the other hand, according to [12] the

Vapor recommended diameter of the feed nozzle is

2

determined using ρ mix ⋅ wmix < 1000 Pa .

In kettle reboilers design it’s necessary to keep the

vapor velocity below 30 m/s [3] in the outlet

nozzle. According to [4] the outlet nozzle is

Hsep

designed using

ρ G ⋅ wG2 ,out < 3750 Pa (9)

For both kettle and horizontal thermosyphon

reboilers, steps should be taken to adequate

longitudinal flow distribution. Above a certain

Figure 1 Cross section of the vapor space bundle length-to-diameter ratio, the number of

inlet and outlet nozzles should be increased. As a

According to Palen [2] the minimal vapor volume rule of thumb, the number of pairs of nozzles

should be (liquid and vapor) is given by [6]

V&G σ Lb

= 80,5 ⋅ (4) NN = (10)

V ρ L − ρG 5 ⋅ Db

The calculated value should be rounded up.

2.3 Criteria based on the Souders - Brown

equation 3 Example

The most commonly cited reference is based on Kettle reboiler (shown in figure 2) is used for the

Souders-Brown equation in the form condensation of the process stream inside tubes

ρL (CO2 - O2 mixture). Cold fluid is ammonia at 0.9

wG,max = K ⋅ −1 (5) bar absolute pressure (-35.91°C). Liquid ammonia

ρG

enters the bottom of the shell. After vaporization

In [1] and [9] it is said that the entrainment the vapor is sucked by the compressor.

coefficient K ranges between 0.03 m/s and 0.09 Tube bundle diameter is Db = 440 mm and the

m/s.

shell diameter is Ds = 700 mm , so the ratio is

If the kettle reboiler is connected with distillation

299

Ds / Db =1.59 and the height of the separation e = 0.0013 , which is way beyond usually adopted

space is H sep = 260 mm e = 0.02 .

According to Palens equation (4) minimal volume

Heat power of the apparatus is 472 kW (ammonia

flow rate is 1194 kg/h), and the heat transfer of the vapor space is V = 0.798 m 3 , and this value

surface is S = 63.9 m 2 , that provides heat flux is by 8% lesser than the real V = 0.858 m 3 .

Since the bundle length is Lb = 5500 mm , the

q = 7.39 kW/m 2 . Using equation (1) the

minimal number of nozzle pairs is N N = 2.5 .

diameter ratio should be Ds / Db = 1.11 ÷ 1.18 or

The outlet vapor velocity is wG ,out = 26.5 m/s

according to Palen Ds / Db = 1.4 .

2

Accordingly to (5) using K = 0.03 m/s the and the ρG ⋅ wG ,out = 549 Pa

maximal vapor velocity should be wG ,max =0,889 It can be concluded that all of the design

m/s. Real vapor velocity is wG =0,110 m/s, so criteria noted in the this article are satisfied.

wG / wG ,max = 12,4% . If the equation (6) is used

to obtain the entrainment factor is K = 0.03 m/s ,

the corresponding value of specific entrainment is

Figure 2 Kettle horizontal reboiler (all dimensions in millimeters) A- inlet of process fluid, B-outlet of

process fluid, C-inlet of ammonia, D-outlet of vapor ammonia

4. Conclusion K , m/s , the entrainment coefficient

There are several design criteria in open literature Lb , m , length of tube bundle

concerning the dimensions of the vapor space in m& , kg/s , mass flow rate

kettle reboilers. These criteria (recommendations)

are listed in this article, so the design procedure N N , number of pairs (inlet plus outlet) of nozzles

can be easily formed. The procedure is p, bar , pressure in vapor space

demonstrated on kettle reboiler that condenses Q, W , heat power

CO2 at the tube side, using ammonia as a cold

fluid. q, W/m 2 , heat flux

S , m 2 , heat transfer surface

5. Nomenclature

Ds , m , diameter

V , m 3 , vapor volume

w, m/s , velocity

Db , m , tube bundle diameter

E e=0 , tray efficiency at zero entrainment Greek

E a , apparent tray efficiency ρ , kg/m 3 density

H sep , mm , the height of the separation zone σ , N/m surface tension

H sep = D s − Db

Indexes

300

max, maximal 8. ***Standards of Tubular Excangers

min, minimal Manufactures Association, Sixth Edition, New

mix, mixture York 1978.

G, gas (vapor) 9. Ernest L.: Applied Process Design for Chemical

L, liquid and Petrohemical Plants, Volume 3, Third

out, outlet Edition, Gulf Professional Publishing, Boston

1999.

10. Billet, R.: Evaporation Technology, VCH

6. References Verlagsgesellscahft mbH, Weinheim, 1989.

1. Sinnott R. K.: Chemical Engineering Volume 6: 11. Vorkauf, H., Forschung auf dem Gebiet des

Chemical Engineering Design, Pergamon Press, Ingenieurwesens, VDI Forschungsheft B341,

Oxford, 1983. 1931.

2. Palen J. W. Small W. M.: A New Way to Design 12. ***Engineering standard for process design of

Kettle and Internal Reboilers, Hydrocarbon gas (vapour)-liquid separators, original edition

Processing, V. 43, No. 11, p. 199 1964. May 1997. Iranian Petroleum Standard IPS-E-

3. Vujic, S..: Colling Devices [in Serbian], Faculty PR-880.

of Mechanical Engineering, Belgrade, 1997.

4. *** Iranian Petroleum Standards IPS-E-PR-880,

Engineering Standard For Process Design Of RELAŢIA CRITERIALĂ PENTRU

Gas (Vapor)-Liquid Separators, May 1997. DIMENSIONAREA SPAŢIULUI DE VAPORI

5. Tammami B., Simplifying reboiler entrainment DIN CAZANUL DE ABUR TIP KETTLE

calculations, Oil Gas Journal, June 1985.

6. Heat Exchanger Design Handbook (HEDH)

Rezumat

Volume 3, Hemisphere Publishing Company,

In literatura de specialitate există o serie de relaţii

Washington, 1986.

criteriale cu care se dimensionează spaţiul de vapori

7. Jacimovic B., Genic S.: The Study Of The

din cazanul de abur tip Kettle. In lucrarea de faţă aceste

Revitalization Of The CO2 Production Fascility relaţii sunt analizate şi comentate. Compararea lor s-a

In Becej Serbia [in Serbian], Belgrade 2007. realizat pe baza unui exemplu numeric.

Scientific reviewers: Prof. Dr. Ing. Habil Ioana IONEL

Prof. Dr. Ing. Mihai NAGI

View publication stats

You might also like

- Book Shop Management (Final)Document59 pagesBook Shop Management (Final)Sarowar Kumar100% (2)

- Economic Optimization of A CO - Based EGS Power Plant: Aleks D. Atrens, Hal Gurgenci, and Victor RudolphDocument11 pagesEconomic Optimization of A CO - Based EGS Power Plant: Aleks D. Atrens, Hal Gurgenci, and Victor RudolphyasharNo ratings yet

- 20 OPTIMIZATIONOnDocument9 pages20 OPTIMIZATIONOnDavid AlejandroNo ratings yet

- Airlift Simulation CFDDocument10 pagesAirlift Simulation CFDlrodriguez_892566No ratings yet

- Ja-Imovi - Et Al-2019-Chemical Engineering Technology-1Document10 pagesJa-Imovi - Et Al-2019-Chemical Engineering Technology-1lekesam918No ratings yet

- zyaseen,+KBES Paper 4Document8 pageszyaseen,+KBES Paper 4Eduardo Antonio Burgos RuidíasNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- 2-D Numerical Simulation of Hydrogen Combustion in DLR SCRAMJET Combustion ChamberDocument10 pages2-D Numerical Simulation of Hydrogen Combustion in DLR SCRAMJET Combustion ChamberArnalt StalinNo ratings yet

- 1 s2.0 S1876610211005960 MainDocument8 pages1 s2.0 S1876610211005960 MainRenalyn TorioNo ratings yet

- 65 FAC-Calculation Model EngelsDocument10 pages65 FAC-Calculation Model EngelsAdriano Dorneles de OliveiraNo ratings yet

- RD On Spoke-Type CryomoduleDocument4 pagesRD On Spoke-Type CryomodulevladimirNo ratings yet

- Pressure Drop Constraints in Sludge Double-Pipe Heat Exchanger DesignDocument11 pagesPressure Drop Constraints in Sludge Double-Pipe Heat Exchanger Designwatersoul.nNo ratings yet

- Me307 2016 11Document5 pagesMe307 2016 11Kelvin Kindice MapurisaNo ratings yet

- Performance Analysis of Economizer Using Journal 4Document3 pagesPerformance Analysis of Economizer Using Journal 4adventius S.SNo ratings yet

- Modeling and Simulation of A Hydrocracking UnitDocument18 pagesModeling and Simulation of A Hydrocracking UnitAnnu RawatNo ratings yet

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoNo ratings yet

- Applied Energy: Su Guo, Deyou Liu, Xingying Chen, Yinghao Chu, Chang Xu, Qunming Liu, Ling ZhouDocument15 pagesApplied Energy: Su Guo, Deyou Liu, Xingying Chen, Yinghao Chu, Chang Xu, Qunming Liu, Ling ZhouHafiz Ghulam NabiNo ratings yet

- Dreyer Analysis 1988Document349 pagesDreyer Analysis 1988Yutt WattNo ratings yet

- Advantages of Sco2 in Small Water ReactorDocument10 pagesAdvantages of Sco2 in Small Water Reactortevin sessaNo ratings yet

- Heat Exchanger DesignDocument8 pagesHeat Exchanger DesignWilliam KearNo ratings yet

- Modification and Analysis of Globe Valve Using Computational Fluid DynamicsDocument5 pagesModification and Analysis of Globe Valve Using Computational Fluid Dynamicsnguyenhuutan91No ratings yet

- Preliminary Study of Printed Circuit Heat Exchanger (PCHE) For Various Power Conversion Systems For SMARTDocument3 pagesPreliminary Study of Printed Circuit Heat Exchanger (PCHE) For Various Power Conversion Systems For SMARTSyed Anas SohailNo ratings yet

- Ejector DesignDocument49 pagesEjector DesignMohamed KadhimNo ratings yet

- Dra1713 Fluid Mechanics Past Year 2223i - 240129 - 213154Document25 pagesDra1713 Fluid Mechanics Past Year 2223i - 240129 - 213154ila nabilaNo ratings yet

- Comparative Study Between SST, and K-Viscous Model Used For The Analysis of Uid Behavior in A Jet Pump Oil SystemDocument7 pagesComparative Study Between SST, and K-Viscous Model Used For The Analysis of Uid Behavior in A Jet Pump Oil SystemAnonymous AtAGVssJNo ratings yet

- Temperature Drop Calculation Design of Hot Oil Pipeline: B. Current Status of Experimental ResearchDocument6 pagesTemperature Drop Calculation Design of Hot Oil Pipeline: B. Current Status of Experimental ResearchTrần ElvinNo ratings yet

- 1 s2.0 S0360544221002620 MainDocument10 pages1 s2.0 S0360544221002620 MainHugo CostaNo ratings yet

- Chemical Engineering s7 & s8Document337 pagesChemical Engineering s7 & s8MaryamNo ratings yet

- 1983 Fire Tech Pool FiresDocument12 pages1983 Fire Tech Pool FiresJuan PulgarNo ratings yet

- Geothermal Plant Design Optimization by Genetic Algorithms: Mohamad Ridwan SuronoDocument8 pagesGeothermal Plant Design Optimization by Genetic Algorithms: Mohamad Ridwan SuronoridwansuronoNo ratings yet

- ETD Final Exam 4Document4 pagesETD Final Exam 4Bhargav Srinivas PadamataNo ratings yet

- REPORT - Well Modelling With Gas LiftDocument24 pagesREPORT - Well Modelling With Gas LiftNavneet KaurNo ratings yet

- Heat Exchanger Design Algorithm: Report 2Document9 pagesHeat Exchanger Design Algorithm: Report 2lulaNo ratings yet

- S e N S o R S & T R A N S D U C e R SDocument6 pagesS e N S o R S & T R A N S D U C e R SPCezzzNo ratings yet

- IEEE PWRD PrintedApr2012Document9 pagesIEEE PWRD PrintedApr2012FREDY ALEXIS SALAS VELASQUEZNo ratings yet

- Modelling of Combustion and Calcination in A CemenDocument7 pagesModelling of Combustion and Calcination in A CemengldiasNo ratings yet

- Cross Flow Tower FBDocument9 pagesCross Flow Tower FBHafizh tarunaNo ratings yet

- Optimal Shell and Tube Heat Exchangers Design: September 2011Document31 pagesOptimal Shell and Tube Heat Exchangers Design: September 2011jeremytoh89No ratings yet

- Winter 17Document2 pagesWinter 17Bala DuttNo ratings yet

- The Effect of Geometric Parameters On The Head Loss Factor in HeadersDocument9 pagesThe Effect of Geometric Parameters On The Head Loss Factor in HeadersSudarshan GNo ratings yet

- Mathematical Modelling of Engineering Problems: Received: 24 April 2018 Accepted: 26 May 2018Document7 pagesMathematical Modelling of Engineering Problems: Received: 24 April 2018 Accepted: 26 May 2018yanan.camarazaNo ratings yet

- Traditional Methods For The Design of Radial-Axial Hydraulic Turbines With Verification in CFD SimulationDocument15 pagesTraditional Methods For The Design of Radial-Axial Hydraulic Turbines With Verification in CFD SimulationЖивотаЛазаревићNo ratings yet

- Process Integration of A Steam TurbineDocument9 pagesProcess Integration of A Steam Turbineali.a.yahyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRîkèñ PâtélNo ratings yet

- The Potential of CO2 Gas Injection Application in Improving Oil RecoveryDocument8 pagesThe Potential of CO2 Gas Injection Application in Improving Oil RecoveryDanielNo ratings yet

- Rahmani Bookchapter 2021 BP 3174FDocument12 pagesRahmani Bookchapter 2021 BP 3174FVignesh AlagesanNo ratings yet

- CPB3B Test3b S2 2009Document7 pagesCPB3B Test3b S2 2009Muavha MadembeNo ratings yet

- Susanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 316 012002 PDFDocument8 pagesSusanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 316 012002 PDFEdy MesinNo ratings yet

- Characteristics Air Flow in Room Chamber Test Refrigerator Household Energy Consumption With Inlet Flow VariationDocument8 pagesCharacteristics Air Flow in Room Chamber Test Refrigerator Household Energy Consumption With Inlet Flow VariationEdy MesinNo ratings yet

- Simulationof Subcooled Boilingin Multiphase CFDCode CFXDocument18 pagesSimulationof Subcooled Boilingin Multiphase CFDCode CFXHuynhiemquoc80No ratings yet

- De Waard 1995Document16 pagesDe Waard 1995stadairNo ratings yet

- Applied Thermodynamics Kme401Document3 pagesApplied Thermodynamics Kme401RafelNo ratings yet

- Rahim I 2008Document5 pagesRahim I 2008samandondonNo ratings yet

- Exam 1Document34 pagesExam 1rshnaelNo ratings yet

- Zebian 2012Document21 pagesZebian 2012nejmiddin boughattasNo ratings yet

- Efacec2009 CFD Core TypeDocument10 pagesEfacec2009 CFD Core TypedgtzagaNo ratings yet

- Calcite Scaling in Well CasingsDocument12 pagesCalcite Scaling in Well CasingsVeronicaNo ratings yet

- 4447-Article Text-22162-1-10-20220206Document8 pages4447-Article Text-22162-1-10-20220206Eydi HadiNo ratings yet

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageFrom EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNo ratings yet

- Augmentation of Gas Performance Using Air Coolers: Applied Thermal Engineering February 2004Document16 pagesAugmentation of Gas Performance Using Air Coolers: Applied Thermal Engineering February 2004Sabba CabbaNo ratings yet

- Divided-Wall Distillation ColumnsDocument14 pagesDivided-Wall Distillation ColumnsSabba CabbaNo ratings yet

- Sofis - Product Sheet - EasiDrive - 01Document3 pagesSofis - Product Sheet - EasiDrive - 01Sabba CabbaNo ratings yet

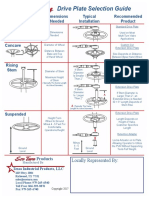

- Product Selection GuideDocument1 pageProduct Selection GuideSabba CabbaNo ratings yet

- Sofis - EasiDrive Portable ActuatorDocument5 pagesSofis - EasiDrive Portable ActuatorSabba CabbaNo ratings yet

- Reboiler Calculations Design Guide PDF FreeDocument12 pagesReboiler Calculations Design Guide PDF FreeSabba CabbaNo ratings yet

- A Classification of Techniques For The Compensation of Time DelayDocument13 pagesA Classification of Techniques For The Compensation of Time DelaySabba CabbaNo ratings yet

- Speed and Acceleration v1.0Document11 pagesSpeed and Acceleration v1.0Anonymous 2iv3uONo ratings yet

- MGMT E-4000 Syllabus - 1-24-16Document11 pagesMGMT E-4000 Syllabus - 1-24-16Renato Barrientos La RosaNo ratings yet

- AMP Vol 171 - N°09 - September 2013Document89 pagesAMP Vol 171 - N°09 - September 2013bluecreteNo ratings yet

- How Cans Are MadeDocument4 pagesHow Cans Are MadeOkeyourying MayourNo ratings yet

- LMP AmmoniaDocument4 pagesLMP AmmoniaEli Elke GalindoNo ratings yet

- H893 V4 PDFDocument5 pagesH893 V4 PDFاحمد الدلالNo ratings yet

- Ahmed Ali (Database Design & Concepts)Document37 pagesAhmed Ali (Database Design & Concepts)Ahmed100% (1)

- Parikrama Polytechnic Mandatory Disclosure PDFDocument140 pagesParikrama Polytechnic Mandatory Disclosure PDFSonali MirajkarNo ratings yet

- Donation After Cardiac Death 3Document18 pagesDonation After Cardiac Death 3api-258141893No ratings yet

- Javascript Interview Questions and AnswersDocument5 pagesJavascript Interview Questions and AnswersNarendrareddy RamireddyNo ratings yet

- Analyzing A Propped Cantilever Beam Using FEMAP10 and ABAQUS6.11-2Document16 pagesAnalyzing A Propped Cantilever Beam Using FEMAP10 and ABAQUS6.11-2Lakshman ReddyNo ratings yet

- Walmart Value Chain AnalysisDocument21 pagesWalmart Value Chain AnalysisAnonymous lSeU8v2vQJ100% (2)

- Smardt Vs McQuay Less Than 400 TonsDocument15 pagesSmardt Vs McQuay Less Than 400 TonsLim YorkChuanNo ratings yet

- Gmk4080-1 para 80 Ton.Document22 pagesGmk4080-1 para 80 Ton.EdilsonNo ratings yet

- Edexcel IGCSE Chemistry Topic 4: Organic ChemistryDocument3 pagesEdexcel IGCSE Chemistry Topic 4: Organic ChemistryAli Hasan MaherNo ratings yet

- 6) Tender Specification DOLIYADocument262 pages6) Tender Specification DOLIYADwsc BharuchNo ratings yet

- Walter Drilling eDocument155 pagesWalter Drilling eAbdulrahman Al-sNo ratings yet

- Plant Disease Detection Using Deep Learning: Anjaneya Teja KalvakolanuDocument4 pagesPlant Disease Detection Using Deep Learning: Anjaneya Teja KalvakolanuCoffee pasteNo ratings yet

- COMSATS University Islamabad (Lahore Campus) : Department of Electrical & Computer EngineeringDocument4 pagesCOMSATS University Islamabad (Lahore Campus) : Department of Electrical & Computer EngineeringAsfand KhanNo ratings yet

- SVFDocument26 pagesSVFmalthesh08No ratings yet

- QRS Complex Detection and ECG Signal ProcessingDocument6 pagesQRS Complex Detection and ECG Signal ProcessingGoumas JimNo ratings yet

- Logistic in Online ShoppingDocument108 pagesLogistic in Online ShoppingSuhail FaridNo ratings yet

- VHDL Configurations TutorialDocument23 pagesVHDL Configurations TutorialKhadar BashaNo ratings yet

- CFMDocument13 pagesCFMaliNo ratings yet

- 803 14Document8 pages803 14Cesar AbarcaNo ratings yet

- TM-127 Collet Tube PullerDocument18 pagesTM-127 Collet Tube PullerKaruNo ratings yet

- Csss Scholarship AI 2009Document66 pagesCsss Scholarship AI 2009Anup RaikarNo ratings yet

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Document7 pagesInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Rohit AmareshNo ratings yet

- Com Statement (HT APFC22 - 02)Document2 pagesCom Statement (HT APFC22 - 02)SOUMENNo ratings yet