Professional Documents

Culture Documents

Design (Metric) 5 (1) .37

Uploaded by

Huy NguyenmbvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design (Metric) 5 (1) .37

Uploaded by

Huy NguyenmbvCopyright:

Available Formats

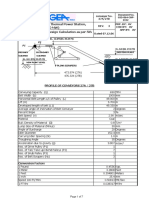

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.

37

This is a worksheet only. It is to be hidden from view.

Customer Name

Conveyor Number

Conveyor Length (m) 1000

Load (T/hour) 700 86.8 kW

Belt Speed (m/s) 2.5 1050 mm

Material Lift Height (m) 0 RECOMMENDED DRUM MOTOR

Ambient temperature (deg C) Mi -10 90 kW

Ambient temperature (deg C) Ma 40 2.5 m/s

Initial Velocity of Material (m/s) 0 JOKI Model(s):

Number of Belt Cleaners 2 800

Number of Belt Ploughs 1 $0

Length of Skirt Zone (m) 3

Depth of Mat'l in skirt zone (mm) 25

Number of Non-driven Pulleys 4 ALTERNATE DUAL DRIVE OPTION

0 Kg/m 0 55 kW/ea

2.5 m/s

JOKI Model(s):

Elevation (Km above sea level) 1.0 630, 800

Type of Material Sand, dry bank $0

Belt Width (mm) 1000 0

Belt Carcass Type Fabric

Idler Roll diam (mm) 108

CEMA Type (A,B,C,D,E) C RECOMMENDED OPTIONS: Tmax (degF)

Troughing (carrying) Idler Spaci 1.2

Skrt Lnth (ft)

Required Belt Pull, Te = 33209 N SPECIAL NOTES:

Engineering Design Data:

Ai 10.2304 N Tm 0N Calculated power to drive co 83.02 kW

Cs 0.1378 Tp 999 N Drive pulley bearing friction: 1.07 kW

H 0m Tpl 876 N Power at motor: 84.10 kW

Kt 1.06 Tsb 269 N Gear loss in motorized pulle 2.69 kW

Kx 0.93kg/m Ttr 0N Calculated power for JOKI 86.79 kW

Ky 0.019 Tx 9654 N Derate for high elevation 0.00 kW

L 1000 m Tyb 4671 N Required Power for motorize 86.79 kW

Q 700 mtph Tyc 2611 N

Si 1.2 m Tym 14504 N (Note: JOKI models above are based on 50 Hz power.)

Tac 2895 N Tyr 2059 N

Tam 486 N V 3 m/s Power savings for 3 shift/day, 50 week/yr operation

Tb 0N Wb 13 kg/m (JOKI pulley compared to gearmotor & V-belt drive)

Tbc 1751 N Wm 78 kg/m Save: 23876 Kw-Hrs/Yr, 1 shift/day or 71629

Te 33209 N Save: 2077 €/Yr, 1 shift/day or 6232 €/Yr, 3

638191938.xlsx 01/12/2023 03:25:26

Specifier

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.37

Specifier Sheet and Recommendation Summary

01/12/23

Date

www.rulmecacorp.com

www.rulmeca.com

© Copyright - Rulmeca Group

Telephone Telefax e-mail

Go to Design Parameters

Project Name Conveyor Reference Go to Trajectory Sheet

Standard Loading Conditions:

Conveyor Length (m) 1000 REQUIRED POWER: 86.8 kW

Tonnage Rate (metric tons/hour) 700

Belt Speed (m/s) 2.5 BELT PULL SUMMARY: Force (N)

Material Lift Height (m) 0.0 Standard Loading Belt Pull 33,209

Ambient temperature (°C) Min -10 Extra pull for Hopper (if any) 0 ###

Ambient temperature (°C) Max 40 Extra pull for Slider Bed (if any) 0 Sand, dry, bank,

Initial Velocity of Material (m/s) 0 Extra pull for Diverter or Tripper (if any) 0

Number of Belt Cleaners 2 TOTAL Required Belt Pull (Te): 33,209 Ashes, coal, dry, 0

Number of Return Belt Scrapers 1 Bauxite, ground,

Length of Skirt Zone (m) 3 RECOMMENDED OPTIONS: Cement, Portland, Dry

Depth of Mat'l in skirt zone (mm) 25 Cement clinker,

Number of Non-driven Pulleys 4 Clay,

Coal, ceramic, dry fines,0

bitum. mined,

Elevation Above Sea Level 1.0 Km SPECIAL NOTES (if any): Coke, ground fine,

Cullet (broken glass),

Material, fric coeff 2.5 Grains,wheat,corn,etc,

Gravel, bank run, 00

Belt Width 1000 mm Go to Design Parameters Iron Ore, pulv.,dry,

Limestone, 0

Belt Carcass Type Fabric RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY: Phosphate

Salt, rock, dry,

dry fine,

Idler Roll diameter 108 mm Power: 90 kW Models Available: Sand, dry,

Wood bank,

chips,

CEMA Type C Belt Speed: 2.5 m/s 800

Troughing Idler Spacing 1.2 meters Face Width: 1050 mm

Angle of Wrap** 420 degrees (dual) RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Type of Lagging Full Lagging Power: 55 kW/ea Models Available:

Type of Take-up Manual Belt Speed: 2.5 m/s 630, 800

Type of Belt 4 ply, 440 piw Face Width: 1050 mm

Bulk Density (Kg/m3) Sand, bank, dry, Power savings - 1 shift and 3 shift per day:

1,760

Condition of Idlers & Pulley (Motorized Pulley compared to exposed conveyor belt drives) Condition of Idlers & Pulleys

well maintained

Save: 23876 Kw-Hrs/Yr, 1 shift/day or 71629 Kw-Hrs/Yr, 3 shifts/d

** This parameter is for either single or dual drive arrangement. Save: 2077 €/Yr, 1 shift/day or 6232 €/Yr, 3 shifts/day @ 0.087 €/K

Minimum Acceptable Diameter is 610 mm

*A smaller pulley diameter may cause belt carcass or fastener damage.

This calculation does not check pulley/belt traction. Theoretical Belt Strength

Belt Strength (lbs)= belt wid

Special Loading Conditions: Go to Design Parameters Belt Width=

1. For hopper feeder specify opening dimensions below. 3. Sidewall & Cleated Belt Parameters: piw =

2. For slider bed, specify bed length and type of bed mater Sidewall & cleat height (mm) 0 Belt Strength=

3. If belt has cleats and/or sidewalls show dimensions below. Thickness of sidewall (mm) 0 ###

4. If conveyor has a tripper, define tripper below. Distance between cleats (mm) 0 420 degrees (dual)

5. If conveyor has diverter(s), define below. Thickness of cleats (mm) 0 180 degrees

1. Hopper Feeder Design Parameters Extra Sidewall & Cleat Wt (incl above) 0 Kg/m 200 degrees

Hopper opening width (mm) 0 210 degrees

Hopper opening length (mm) 0 4. Tripper Design Parameters 220 degrees

Tripper length (m) 0 240 degrees

Material lift height on tripper (m) 0 360 degrees (dual)

2. Slider Bed Design Parameters No. of belt cleaners on tripper 0 420 degrees (dual)

Slider Bed Length (m) 0 Length of tripper skirt zone (m) 0

Type of Slider Bed Material None Depth of material in skirt zone (mm) 0

Slider Bed Frictional Coefficient 0 No. of non-driven pulleys on tripper 0

Estimated belt tension, Te (N) 0

Estimated factor, Ky 0.03

Bulk Density Chart Imp

638191938.xlsx, Specifier, Page 2 of 7 01/12/2023 03:25:26

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.37

Model Selector

0 01/12/23

0 Date

0 www.rulmecacorp.com

www.rulmeca.com

© Copyright - Rulmeca Group

0 0 0

Telephone Telefax e-mail

0 0

Project Name Conveyor Reference

800M

REQUIRED POWER: 86.8 kW 220M

Select Model

220H

BELT PULL SUMMARY: Force (N) 320L

Standard Loading Belt Pull 33,209 320M

Extra pull for Hopper (if any) 0 Check Radial Load (to prevent 320H

Extra pull for Slider Bed (if any) 0 internal damage to pulley) Force (N) 400L

Extra pull for Diverter or Tripper (if a 0 Maximum Allowable Radial Load 73,600 400M

TOTAL Required Belt Pull (Te): 33,209 Estimated Maximum Radial Load 53,134 400H

Selected model is appropriate for estimated radial load. 500L

0 500M

Check Pulley Diameter

500H

(to prevent belt

RECOMMENDED OPTIONS (if any): damage.) 630M

Minimum Acceptable Diameter is 610 mm 630H

Selected Diameter is 800 mm 800M

Selected diameter is appropriate for specified belt. 800H

SPECIAL NOTES (if any (This calculation does not check pulley/belt traction.)

0

Check Belt Tension Force (N)

Maximum Belt Tension (T1) 43,171

Go to Design Parameters Allowable Belt Tension 77,606

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY: 0

Power: 90 kW Models Available:

Belt Speed: 2.5 m/s 800

Face Width: 1050 mm

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Power: 55 kW/ea Models Available:

Belt Speed: 2.5 m/s 630, 800

Face Width: 1050 mm

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.37

Design Parameter Summary

0 01/12/23

0 Date

0 www.rulmecacorp.com

www.rulmeca.com

© Copyright - Rulmeca Group

0 0 0

Telephone Telefax e-mail

0 0

Project Name Conveyor Reference

Power Calculation Summary Return to Specifier Sheet

Calculated power to drive conveyor belt: 83.0 kW

Drive pulley bearing friction: 1.1 kW

Power at motor: 84.1 kW

Gear loss in motorized pulley: 2.7 kW

Calculated power 86.8 kW

Derate for high elevation 0.0 kW

Derate for high temperature 0.0 kW

Required Power for motorized pulley: 86.8 kW

Symbol Value Definition of Terms Return to Specifier Sheet

Te 33209 N Te = effective belt tension at drive.

ang 420 degrees ang = angle of belt wrap around drive pulley(s).

Cw 0.3

T2 9963 N T2 = estimated "slack-side tension" required to keep belt from slipping on pulley surface.

T1 43171 N T1 = Te + T2

T1 + T2 53134 N T1 + T2 = Sum of belt forces on drive pulley. NOTE: This is not a vector sum.

T_L Full Lagging T_L = type of lagging specified for drive pulley(s).

Tatype Manual Tatype = type of take-up specified to apply "slack-side tension".

Beltype 4 ply Beltype = type of belt carsass specified.

w 1000 mm w = belt width

str 17323 N str = tensile strength of specified belt.

pstr 56 % pstr = percentage of available belt tensile strength used.

btr 14 to 21 mm btr = thickness range of specified belt

Ai 10.2304 N Ai = belt tension required to overcome frictional resistance and rotate idlers.

Cs 0.1378 Cs = skirtboard friction factor.

H 0m H = vertical distance that material is lifted or lowered.

Kt 1.06 Kt = ambient temperature correction factor.

Kx 0.93kg/m Kx = factor to calculate frictional resistance of the idlers and the sliding resistance

between belt and idler rolls.

Ky 0.02 Ky = factor to calculate resistance of belt and resistance of load to flexure as they move over idlers.

L 1000 m L = length of conveyor.

Q 700 mtph Q = tons per hour conveyed. Return to Specifier Sheet

Si 1.2 m Si = troughing idler spacing.

Tac 2895 N Tac = total of the tensions from conveyor accessories.

Tam 486 N Tam = tension required to accelerate the material continuously as it is fed onto belt.

Tb 0N Tb = tension required to lift or lower the belt.

Tbc 1751 N Tbc = tension required to overcome belt cleaner drag.

Te 33209 N Te = effective belt tension at drive.

Tm 0N Tm = tension required to lift or lower conveyed material.

Tp 999 N Tp = tension required to overcome resistance of belt to flexure around pulleys and

resistance of pulleys to rotate on their bearings.

Tpl 876 N Tpl = tension required to overcome belt plow drag.

Tsb 269 N Tsb = tension required to overcome skirtboard drag.

Ttr 0N Ttr = tension required to overcome special loading condition(s.)

Tx 9654 N Tx = tension required to overcome carrying and return idler friction.

Tyb 4671 N Tyb = total of tensions due to resistance of belt to flexure as it rides over carrying and return idlers.

Tyc 2611 N Tyc = tension due to resistance of belt to flexure as it rides over carrying idlers.

Tym 14504 N Tym = tension due to resistance of material to flexure as it rides over carrying idlers.

Tyr 2059 N Tyr = tension due to resistance of belt to flexure as it rides over return idlers.

V 3 m/s V = design belt speed.

Wb 13 kg/m Wb = weight of belt per unit of length of conveyor. Return to Specifier Sheet

Wm 78 kg/m Wm = weight of material per unit of length of conveyor.

638191938.xlsx, Design Parameters, Page 4 of 7 01/12/2023 03:25:26

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.37

Conveyor Height Calculator

Inclined conveyor length (m) 0

Angle of inclination (degrees) 0

Material lift height (m) 0.0 www.rulmecacorp.com

www.rulmeca.com

© Copyright - Rulmeca Group

Return to Specifier Sheet

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5

Bulk Handling Belt Conveyor Terminology

www.rulmeca.com

www.rulmecacorp.com Return to Specifier Sheet © Copyright - Rulmeca Group

Conveyor Profile Return to Specifier

Initial Velocity of Material Return to Specifier

Conveyor Cross Section in Skirt Zone Return to Specifier

Belt Conveyor with Tripper Return to Specifier

Hopper Feeder Conveyor Return to Specifier

Cleated Belt with Sidewalls Return to Specifier

Belt Conveyor with Two Diverter(s)

"CEMA" Idler Type Definitions Return to Specifier

(Based on Conveyor Equipment Manufacurters Association Manual)

Belt Width Idler Load Ratings* (kg)

Idler Type > A B C D E

Idler (deg) > 20 35 45 20 35 45 20 35 45 20 35 45 20 35 45

460 136 136 136 186 186 186 408 408 408 - - - - - -

610 136 136 131 186 186 186 408 408 408 544 544 544 816 816 816

760 136 127 122 186 186 186 408 408 408 544 544 544 816 816 816

915 125 116 112 186 186 180 408 380 367 544 544 544 816 816 816

1070 - - - 177 165 159 386 359 347 544 544 544 816 816 816

1220 - - - 172 160 155 363 337 327 544 544 544 816 816 816

1370 - - - - - - 340 317 306 544 506 490 816 816 816

1525 - - - - - - 318 295 286 522 485 469 816 816 816

1830 - - - - - - - - - 476 443 429 816 816 816

2130 - - - - - - - - - - - - 816 759 735

2440 - - - - - - - - - - - - 794 738 714

*These ratings are for three-equal-roll idlers and are based on a 30,000 hour minimum

BU bearing life at 500 RPM. BU bearing life represents the statistical point in hours where Return to Specifier

a minimum of 90% of the bearings will still be functional with no increase in torque or noise. Return to Trajectory Sheet

Material Surcharge Angle Guide

(Based on Conveyor Equipment Manufacurters Association Manual)

Surcharge Angle of

Description of Material

Angle Repose

Uniform size, very small rounded particles, either very wet or very dry;

5 0 to 19

such as dry silica sand, cement, and wet concrete.

Rounded, dry polished particles, of medium weight, such as whole grain

10 20 to 29

and beans.

Irregular, granular or lumpy materials of medium weight, such as

20 30 to 34

anthracite coal, cottonseed meal, and clay.

25 35 to 39 Typical common materials such as bituminous coal, stone, and most ores.

Irregular, stringy, fibrous, interlocking material, such as wood chips,

30 40+

bagasse, and tempered foundry sand.

638191938.xlsx, Terminology, Page 6 of 7 01/12/2023 03:25:26

Rulmeca Motorized Pulley Power Calculation Program - Metric Version 5.37

Bulk Handling Trajectory Calculator and Plotter

(based on CEMA 5th Edition)

0

0

0

www.rulmecacorp.com

www.rulmeca.com

0 0 © Copyright - Rulmeca Group

Phone Fax

Project Name 0 Return to Specifier

Conveyor Ref. 0

System Design Parameters: Belt Width (mm

Material Trajectory:

Belt Width 1000 mm

Small Pulley (scale: 75 mm/in-

Troughing Idler Angle 35° crement)

Pulley Lagged D

Diameter Pulley (mm) 516 mm

500 Lagging Thickn

Lagging Thickness (MM) 8 mm

8

Belt Speed 2.58 m/s

Actual Belt Spe

Surcharge Angle (degrees) 25 25

deg.

Tonnage Rate (MTPH) 700

Material Density (Kg/m3) 1,760

Belt Thickness (mm) 8

Distance to Chute Plate (mm) 700

Angle of Conv. Inclination (deg) 0 Surcharge angle (deg)

Alternate Belt Speed (m/s) 1.4 Tonnage Rate (metric tph)=

Belt Speed (fpm)

Print This Sheet

Material Density (kg/cu m)=

Go to Large Pulley Sheet Area A (sq ft)

Design Trajectory - solid red line; Alternate speed - dotted blue.

Go to Overview Sheet 0

Calculated Results: Pulley Diam Lagged (in)

Calc'd mat'l height at centerline 113 mm Mat'l Cross Section at Pulley Face:

Pulley radius Lagged (in)

Calc'd actual height of C.O.G.* 46 mm Small Pulley (scale: 75 mm/incre- Belt Thickness (in)

Calc'd actual mat'l cross section 4.3 sq m ment) Radius to Belt Top (in)

CEMA Max Allow. height at center 198 mm

CEMA Max Height of C.O.G.* 79 mm

CEMA Max Allow. cross section 13.7 sq m

Note:

This program uses actual C.O.G.* height above

top of belt (based on actual cross section) to plot

trajectory. Height of C.O.G. for CEMA

max. allow. cross section is given for ref. only. Design Cross Section - dotted red line; CEMA max allow. - solid black line.

*C.O.G. = center of gravity of material, shown as ∆ and ∆

638191938.xlsx, Page 7 of 7 01/12/2023 03:25:27

You might also like

- 1 Vdocuments - MX - Conveyor-Design-CalcDocument7 pages1 Vdocuments - MX - Conveyor-Design-CalcPascal CustonNo ratings yet

- System Information Idler Set DataDocument98 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- 12 (B 100) Metre KonveyörDocument30 pages12 (B 100) Metre KonveyörHasan arif KısaalioğluNo ratings yet

- Conveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectDocument62 pagesConveyor design for EUROCHEM KOVDORSKIY GOK M-2 projectHasan arif KısaalioğluNo ratings yet

- 6 KM 2 BoosterDocument62 pages6 KM 2 BoosterHasan arif KısaalioğluNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- Conveyor Power - Rulmeca BasedDocument1 pageConveyor Power - Rulmeca Basednm_rangaNo ratings yet

- System Information Idler Set DataDocument48 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- 3100 CV 0001Document11 pages3100 CV 0001tranceinttNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- Rubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDDocument8 pagesRubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDmah moudNo ratings yet

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- Helix Delta-T6 Sample Report01Document29 pagesHelix Delta-T6 Sample Report01Khaleel PashaNo ratings yet

- Conveyor Design Summary for PT Indonesia PowerDocument34 pagesConveyor Design Summary for PT Indonesia Powerdeni prastikoNo ratings yet

- Electric Rope Shovel - 9001XR7: Mining Solutions Mech3100 Group 32Document1 pageElectric Rope Shovel - 9001XR7: Mining Solutions Mech3100 Group 32JamesNo ratings yet

- Technical Data Titan 525: Engine (Diesel)Document2 pagesTechnical Data Titan 525: Engine (Diesel)dmh cargoNo ratings yet

- Conveyor design analysis reportDocument10 pagesConveyor design analysis reportRafael FerreiraNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- DX300LCA Hydraulic Excavator Specifications and DetailsDocument31 pagesDX300LCA Hydraulic Excavator Specifications and DetailsOmar Diaz Segura100% (1)

- 005-Mek-Cal-Nk - Pkt-Design Calculation Tripper Car. r1 - AfDocument10 pages005-Mek-Cal-Nk - Pkt-Design Calculation Tripper Car. r1 - AfAhmad FaujiNo ratings yet

- Cor-695 450tph - A AtolloDocument10 pagesCor-695 450tph - A AtolloCristobal JimenezNo ratings yet

- Design of Booster Pump Foundation AnalysisDocument20 pagesDesign of Booster Pump Foundation AnalysisSuresh nathanNo ratings yet

- DX210WA Spec SheetDocument46 pagesDX210WA Spec SheetAkbarNo ratings yet

- Datasheet Kleemann MOBIBELT MBT 20Document2 pagesDatasheet Kleemann MOBIBELT MBT 20Kevin GuoNo ratings yet

- ZC01CV001 DriveDocument3 pagesZC01CV001 Drivedhiny.andrianiNo ratings yet

- Conveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMDocument20 pagesConveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMiman zareieNo ratings yet

- Design Data-Conductor ACSR 240 40Document3 pagesDesign Data-Conductor ACSR 240 40Sara RamliNo ratings yet

- 28.4kW Yanmar Engine Mini Excavator SpecsDocument2 pages28.4kW Yanmar Engine Mini Excavator Specsrizky alfaNo ratings yet

- Data Sheet Ship Design Ahts Vs482 4307Document2 pagesData Sheet Ship Design Ahts Vs482 4307pj4hv79yspNo ratings yet

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument2 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliNo ratings yet

- M.T. EAGLE PETROLINA - VESSEL SPECS AND CAPACITIESDocument1 pageM.T. EAGLE PETROLINA - VESSEL SPECS AND CAPACITIESCapital Shipping Services0% (1)

- Doosan SD310 Compact Wheel Loader SpecificationsDocument9 pagesDoosan SD310 Compact Wheel Loader SpecificationsAndrea T FilottoNo ratings yet

- 400/220kV Mandar SS: Sag Tension Calculation For 220Kv Jack Bus - TacsrDocument9 pages400/220kV Mandar SS: Sag Tension Calculation For 220Kv Jack Bus - TacsrVijai PrasathNo ratings yet

- PILE FDN DESIGN For NMD TOWERDocument12 pagesPILE FDN DESIGN For NMD TOWERraj mNo ratings yet

- Bond Mill ThroughputDocument5 pagesBond Mill ThroughputAnonymous TsKN7XZBNo ratings yet

- Transportador B01 R2 OADocument19 pagesTransportador B01 R2 OAmacbolNo ratings yet

- Thyssenkrupp Fördertechnik GMBH: Organic Growth Project 1 (Ogp1) Execution PhaseDocument11 pagesThyssenkrupp Fördertechnik GMBH: Organic Growth Project 1 (Ogp1) Execution PhasedavidusachNo ratings yet

- Mill Performance CalculationsDocument9 pagesMill Performance Calculationssafwat hassanNo ratings yet

- DX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Document46 pagesDX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Andrea T Filotto50% (2)

- 20230912-Thesis-Rekap Data Thesis - Rev14-2Document45 pages20230912-Thesis-Rekap Data Thesis - Rev14-2taufiqadwNo ratings yet

- Tameer Consulting Associates: Design of PurlinDocument8 pagesTameer Consulting Associates: Design of PurlinSabrina ImloulNo ratings yet

- IS FormDocument43 pagesIS FormShivkumar VijapureNo ratings yet

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADxFxNo ratings yet

- Crawler Crane SpecificationsDocument44 pagesCrawler Crane SpecificationsДмитрий БакайNo ratings yet

- 40tph LB500 Batch Mixing Asphalt Plant Quotation (Baghouse Dust Collector)Document8 pages40tph LB500 Batch Mixing Asphalt Plant Quotation (Baghouse Dust Collector)Michael Forrest100% (1)

- GR/KWH, KG/HR or Tons/Month.: ScopeDocument5 pagesGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementNo ratings yet

- BK 4 (CC 51400)Document9 pagesBK 4 (CC 51400)hasan arifNo ratings yet

- Ball - Screw - Calculations - As Per THK and PmiDocument5 pagesBall - Screw - Calculations - As Per THK and PmiDharmeshPatelNo ratings yet

- Catalogue of European Urban Wind Turbine ManufacturersDocument61 pagesCatalogue of European Urban Wind Turbine ManufacturersRoxana G. MantaNo ratings yet

- Telescopic Crawler Crane: S P E C I F I C A T I O N SDocument4 pagesTelescopic Crawler Crane: S P E C I F I C A T I O N SMuhaiminNo ratings yet

- 40t Rope Drum Hoist220512Document37 pages40t Rope Drum Hoist220512Anonymous sfkedkymNo ratings yet

- 40t Rope Drum Hoist220512Document37 pages40t Rope Drum Hoist220512Anonymous sfkedkymNo ratings yet

- IT6468 0911gbDocument24 pagesIT6468 0911gbmarcos lemosNo ratings yet

- Mukkkkk 2Document28 pagesMukkkkk 2Joshi ChumbaleNo ratings yet

- Unlike Charges Attract and Coulomb's LawDocument6 pagesUnlike Charges Attract and Coulomb's LawnovaNo ratings yet

- (Mai 1.6) Geometric SequencesDocument22 pages(Mai 1.6) Geometric SequencesShivSantosh JhaNo ratings yet

- Advanced Lithium-Ion Battery Failure Analysis - Thought Leadership - Knowledge - ExponentDocument10 pagesAdvanced Lithium-Ion Battery Failure Analysis - Thought Leadership - Knowledge - ExponentAndyNo ratings yet

- The Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - JcdaDocument10 pagesThe Endocrown - A Different Type of All-Ceramic Reconstruction For Molars - Jcdaabcder1234No ratings yet

- Stengers 'Shibbolet ForewordDocument12 pagesStengers 'Shibbolet ForewordAndreas LeyererNo ratings yet

- Mark Halverson PHD Data Scientist ResumeDocument1 pageMark Halverson PHD Data Scientist Resumeapi-269922428No ratings yet

- Solution 4Document3 pagesSolution 4Chen ShyanNo ratings yet

- 17 Differential Equations Ma102Document3 pages17 Differential Equations Ma102Salim ShahulNo ratings yet

- Probs in AMP PDFDocument3 pagesProbs in AMP PDFwilliam taloNo ratings yet

- UNI Engineering ManualDocument144 pagesUNI Engineering ManualJorch GalvanNo ratings yet

- Fractional Calculus For Scientis and Engineers - M. Duarte O. - SpringerDocument159 pagesFractional Calculus For Scientis and Engineers - M. Duarte O. - SpringerPuig123100% (1)

- BIOBASE Low Speed Centrifuge BKC-TL6III User ManualDocument15 pagesBIOBASE Low Speed Centrifuge BKC-TL6III User Manualsoporte03No ratings yet

- Measure Moment of Inertia FlywheelDocument8 pagesMeasure Moment of Inertia FlywheelSanil Khinchi100% (1)

- Alphabet LinesDocument7 pagesAlphabet LinesCristy RiveraNo ratings yet

- Taiwanese IMO 2014: A Brief Reflection on the Selection ProcessDocument25 pagesTaiwanese IMO 2014: A Brief Reflection on the Selection ProcessCường Nguyễn KhắcNo ratings yet

- Kunal Roy, Supratik Kar, Rudra Narayan Das - A Primer On QSAR - QSPR Modeling. Fundamental Concepts-Springer (2015)Document125 pagesKunal Roy, Supratik Kar, Rudra Narayan Das - A Primer On QSAR - QSPR Modeling. Fundamental Concepts-Springer (2015)Jayanta L CNo ratings yet

- Statics 213 Module 3.1 AND 3.2 HCCDocument12 pagesStatics 213 Module 3.1 AND 3.2 HCCMark MagcalasNo ratings yet

- An Intuitive Guide To Linear Algebra - BetterExplainedDocument25 pagesAn Intuitive Guide To Linear Algebra - BetterExplainedvkk intensiveNo ratings yet

- Manual Intended Use: Piinline Plus AQR/AQR Low PressureDocument5 pagesManual Intended Use: Piinline Plus AQR/AQR Low PressureMario PortillaNo ratings yet

- Quantum mechanical model explains atomic orbitalsDocument15 pagesQuantum mechanical model explains atomic orbitalsNatalia SadekNo ratings yet

- Errata For Modern Quantum Mechanics 2nd Ed by Sakurai and NapolitanoDocument16 pagesErrata For Modern Quantum Mechanics 2nd Ed by Sakurai and Napolitanokevinchu021195No ratings yet

- ETY155 Lab10 SuperpositionDocument4 pagesETY155 Lab10 SuperpositionprantiNo ratings yet

- Poly PhysicsDocument46 pagesPoly PhysicsSiva KumarNo ratings yet

- Corporatefed SpringerDocument8 pagesCorporatefed Springer109Sangeeta SinghNo ratings yet

- 02 05 21 SR CO SC Jee Adv 2016 P1 GTA 7 P I KEY & SOL 1Document12 pages02 05 21 SR CO SC Jee Adv 2016 P1 GTA 7 P I KEY & SOL 1T.n CharithNo ratings yet

- Chapter 1: Introduction To Vibration: DR Asif Israr, Hod (Mechanical Engineering) Institute of Space TechnologyDocument38 pagesChapter 1: Introduction To Vibration: DR Asif Israr, Hod (Mechanical Engineering) Institute of Space TechnologySahab HafeezNo ratings yet

- Critique PaperDocument2 pagesCritique PaperMariel CadayonaNo ratings yet

- Gravity MethodDocument38 pagesGravity Methodzain828No ratings yet

- GP2 Q3 Melc-6 Mod-2Document29 pagesGP2 Q3 Melc-6 Mod-2Diana AfableNo ratings yet