Professional Documents

Culture Documents

368480863-NW-Plant-Rev1-En PART

Uploaded by

Zoran DjurdjevicOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

368480863-NW-Plant-Rev1-En PART

Uploaded by

Zoran DjurdjevicCopyright:

Available Formats

TECHNICAL SPECIFICATION

3.3.1 FEED HOPPER

The feed hopper enables the use of dump truck loading and also ensures even and continuous material

flow to the feeder. There are two feed hoppers available with different capacities.

1 5

7

2

Callout Description

1 Gap plate

2 Columns

3 Bracings

4 Skid

5 Bed plates

6 Side plates

7 Top frame

8 Chain curtain

Figure 3.2 Feed hopper components

• Feed hopper

– weight: 9000 kg

– 23 m3

3-4 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

TECHNICAL SPECIFICATION

1 5

7

2

Callout Description

1 Gap plate

2 Columns

3 Bracings

4 Skid

5 Bed plates

6 Side plates

7 Top frame

8 Chain curtain

Figure 3.3 Feed hopper components

• Feed hopper

– weight: 12 950 kg

– capacity: 30 m3

05/2017 MM0430841-EN NW PLANT INSTRUCTION MANUAL 3-5

OPERATION

5.3.3 FEED HOPPER ASSEMBLY

1. Start the hopper assembly by preparing the support structure. Ensure that the support structure is

levelled and fits properly on the foundations.

Figure 5.9 Feed hopper foundation details

5-14 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

OPERATION

2. Assemble vertical columns.

3. Complete the bracing assembly.

05/2017 MM0430841-EN NW PLANT INSTRUCTION MANUAL 5-15

OPERATION

4. Install the bracings to the columns.

5. Install one of the side bracings to the columns.

5-16 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

OPERATION

6. Assemble the top frame.

7. Install taper plates on the top frame.

8. Install the bed plates over the top frame.

05/2017 MM0430841-EN NW PLANT INSTRUCTION MANUAL 5-17

OPERATION

9. Assemble the top box side plates on the ground.

10.Lift the top box over the top frame.

5-18 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

OPERATION

11.Fasten the top box on the top frame.

12.Install the top part on the columns.

05/2017 MM0430841-EN NW PLANT INSTRUCTION MANUAL 5-19

OPERATION

13.Assemble the remaining bracings.

5-20 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

OPERATION

14.Install the chain curtain.

05/2017 MM0430841-EN NW PLANT INSTRUCTION MANUAL 5-21

OPERATION

15.Install the gap plate.

16.Once the conveyors and the NW unit have been installed, check that there is enough clearance.

After the run-in period tighten all bolts and nuts.

5-22 NW PLANT INSTRUCTION MANUAL MM0430841-EN 05/2017

You might also like

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 2 out of 5 stars2/5 (1)

- Adjustment of Extensions HIABDocument4 pagesAdjustment of Extensions HIABEDUARDO VEGANo ratings yet

- 447 Series Tray / Wrap Organizers: Tools RequiredDocument8 pages447 Series Tray / Wrap Organizers: Tools Requiredrqkpwzjh54No ratings yet

- Coach Agitator CA Design and OperationDocument65 pagesCoach Agitator CA Design and OperationmiguelamenozaNo ratings yet

- Victaulic AlarmCheckValve751Document17 pagesVictaulic AlarmCheckValve751Bhaumik DaveNo ratings yet

- Chitarra ClassicaDocument6 pagesChitarra ClassicaGasparin GiancarloNo ratings yet

- Notice Potence 901A FRDocument18 pagesNotice Potence 901A FRMohamed Seghir BenzemraneNo ratings yet

- PF 206SMEngDocument29 pagesPF 206SMEngnelson.salgueroNo ratings yet

- Микро кэтботDocument18 pagesМикро кэтботJoão Pedro de SousaNo ratings yet

- Grounding Prerequisites and DescriptionsDocument3 pagesGrounding Prerequisites and DescriptionsNijad NasrNo ratings yet

- ChainDriveVise 1-25-19 WebDocument14 pagesChainDriveVise 1-25-19 WebEliseu ChereneNo ratings yet

- Install Snow Cab Kit on SnowthrowerDocument4 pagesInstall Snow Cab Kit on SnowthrowerBJ DixNo ratings yet

- Service Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitDocument24 pagesService Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitErissonNo ratings yet

- Parts Manual 10 MT Fixed Crane On Phooltas UTVDocument13 pagesParts Manual 10 MT Fixed Crane On Phooltas UTVAmit B ChauhanNo ratings yet

- Fig6 PipeguideDocument1 pageFig6 PipeguideMPNo ratings yet

- Hammer Select: Parts ManualDocument15 pagesHammer Select: Parts Manualhegang liuNo ratings yet

- ST334 - Electric Lift CombinationDocument273 pagesST334 - Electric Lift Combinationefrain.hilario.86No ratings yet

- 6E822B 6E826B Owners Manual PDFDocument4 pages6E822B 6E826B Owners Manual PDFAlan SCNo ratings yet

- 45-02263Document8 pages45-02263khans.martinNo ratings yet

- Victaulic Alarm Check ValveDocument14 pagesVictaulic Alarm Check ValveEdward Chan AcostaNo ratings yet

- Undercarriage Tools Caterpillar C10509674 PDFDocument102 pagesUndercarriage Tools Caterpillar C10509674 PDFAgus Yulfizar100% (1)

- Remove Engine and Transmission in 14 StepsDocument12 pagesRemove Engine and Transmission in 14 StepsRamon CasillasNo ratings yet

- Theory Book ME Sample PDFDocument33 pagesTheory Book ME Sample PDFabhishek bsNo ratings yet

- Duo Check Valve MaintenanceDocument2 pagesDuo Check Valve Maintenanceddoyle1351100% (1)

- Nhom 8 - V184 Engine 2.4LDocument9 pagesNhom 8 - V184 Engine 2.4LTrương Ngọc ThắngNo ratings yet

- Remove Traction Batteries from Lift TruckDocument76 pagesRemove Traction Batteries from Lift TruckRenzo De Pisis100% (1)

- BS5352 1981Document27 pagesBS5352 1981rajuhaveriNo ratings yet

- 11 Lab Table Assembly InstructionsDocument8 pages11 Lab Table Assembly InstructionsCesar BandaNo ratings yet

- Operation Manual: Dual Plate Wafer Check ValvesDocument3 pagesOperation Manual: Dual Plate Wafer Check ValvesDhim131267No ratings yet

- Blass Tray 3&4 Front Panel Locator Bracket Repair Kit V2 SFSDocument2 pagesBlass Tray 3&4 Front Panel Locator Bracket Repair Kit V2 SFSSdb EirlNo ratings yet

- Operating Instructions 9901X0070 - 5Document6 pagesOperating Instructions 9901X0070 - 5Olatunde MakindeNo ratings yet

- TSB201801001Document2 pagesTSB201801001Víctor FaríasNo ratings yet

- Twister User ManualDocument17 pagesTwister User ManuallucioNo ratings yet

- Hobie Tiger Assembly ManualDocument23 pagesHobie Tiger Assembly ManualSigens WindestNo ratings yet

- MeArm Assembly ManualDocument11 pagesMeArm Assembly ManualjpradeebanNo ratings yet

- ELME 817 Manual PDFDocument20 pagesELME 817 Manual PDFniko67% (3)

- Team E User Manual 1Document12 pagesTeam E User Manual 1Luis IgnacoNo ratings yet

- Assembly InstructionsDocument41 pagesAssembly InstructionsCHUPA CABRANo ratings yet

- WheelHorse Cultivator 7-1723 - 803965Document4 pagesWheelHorse Cultivator 7-1723 - 803965Kevins Small Engine and Tractor ServiceNo ratings yet

- EXPLORER II 75-85-95 Special 1 Section 10Document66 pagesEXPLORER II 75-85-95 Special 1 Section 10dimos KARAMATZIARISNo ratings yet

- User Guide: Height Adjustable TableDocument24 pagesUser Guide: Height Adjustable TableАлина ВладиславовнаNo ratings yet

- EN36492 Bolting Quick Reference GuideDocument7 pagesEN36492 Bolting Quick Reference GuidemohdfirdausNo ratings yet

- Fluid Mechanics SampleDocument16 pagesFluid Mechanics SampleAdaitaChowdhuryNo ratings yet

- Typical TW3-P335 Parts and Instruction ManualDocument41 pagesTypical TW3-P335 Parts and Instruction ManualJanos KornfeldNo ratings yet

- EN - Instruction Manual Cranes 2015Document30 pagesEN - Instruction Manual Cranes 2015bursztyn76No ratings yet

- Series 63 Round Bottom BoatsDocument54 pagesSeries 63 Round Bottom BoatsBozidar SaricNo ratings yet

- 8ex10ft RCC Reamer ManualDocument14 pages8ex10ft RCC Reamer ManualIng del PeleNo ratings yet

- Assignment 2 Dama Eng'gDocument2 pagesAssignment 2 Dama Eng'gselemonchanie345No ratings yet

- Transmission Tubing Installation InstructionsDocument2 pagesTransmission Tubing Installation InstructionsabhijitNo ratings yet

- AT520CT Users ManualDocument14 pagesAT520CT Users ManualAlbert SomendraNo ratings yet

- B246 Detailed DescriptionDocument143 pagesB246 Detailed DescriptionJeferson ferreiraNo ratings yet

- Modification and Evaluation of A Reciprocating Machine For Shelling PeanutDocument16 pagesModification and Evaluation of A Reciprocating Machine For Shelling PeanutFiraol GudisaNo ratings yet

- Technical Service Information: Chrysler 45Rfe/55RfeDocument3 pagesTechnical Service Information: Chrysler 45Rfe/55RfeMario MastronardiNo ratings yet

- WHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualDocument9 pagesWHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualWill Freddy MartinezNo ratings yet

- Section 8 Cil. Boom, Linde C4230TL PDFDocument53 pagesSection 8 Cil. Boom, Linde C4230TL PDFrodrigo belardyNo ratings yet

- HS400 Series Single Full Height Turnstile: Service & Installation ManualDocument40 pagesHS400 Series Single Full Height Turnstile: Service & Installation Manualmaqsood ahmadNo ratings yet

- HS400 Series Single Full Height Turnstile Installation ManualDocument40 pagesHS400 Series Single Full Height Turnstile Installation Manualmaqsood ahmadNo ratings yet

- AARBK48 User-ManualDocument8 pagesAARBK48 User-ManualChris HeNo ratings yet

- Cameron t31 Iom SpecialDocument20 pagesCameron t31 Iom SpecialJuan Carlos Sua SuaNo ratings yet

- NW-FH NW106 GA Drawing R002-1Document2 pagesNW-FH NW106 GA Drawing R002-1Zoran Djurdjevic100% (1)

- PNEUMAX CatalogueDocument980 pagesPNEUMAX CatalogueZoran DjurdjevicNo ratings yet

- 2016-2017 General Catalogue KyoceraDocument992 pages2016-2017 General Catalogue KyoceraZoran DjurdjevicNo ratings yet

- General Catalogue (Metric)Document908 pagesGeneral Catalogue (Metric)Zoran DjurdjevicNo ratings yet

- Dimenzije i težine pločaDocument9 pagesDimenzije i težine pločaarchpavlovicNo ratings yet

- Pester Pewo PacksDocument16 pagesPester Pewo PacksZoran DjurdjevicNo ratings yet

- Catalogue AC Cast IRON Gearmotors 50 HZ 0121Document111 pagesCatalogue AC Cast IRON Gearmotors 50 HZ 0121Zoran DjurdjevicNo ratings yet

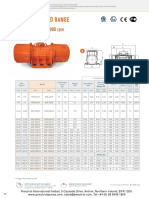

- Oli - MVE - Standard - 4 - Pole - Three - Phase - Opt 500 - 15Document2 pagesOli - MVE - Standard - 4 - Pole - Three - Phase - Opt 500 - 15Zoran DjurdjevicNo ratings yet

- Masine I Njihove KarakteristikeDocument21 pagesMasine I Njihove Karakteristikekrivipotok880% (1)

- Gear Boxes and MotorsDocument170 pagesGear Boxes and MotorsAshish MishraNo ratings yet

- Chapter 19 Membrane FiltrationDocument12 pagesChapter 19 Membrane FiltrationDheeraj ShuklaNo ratings yet

- Rotare Vane PumpsDocument10 pagesRotare Vane PumpsZoran DjurdjevicNo ratings yet

- Ka MatsuDocument10 pagesKa MatsuZoran DjurdjevicNo ratings yet

- Masine I Njihove Karakteristike PDFDocument21 pagesMasine I Njihove Karakteristike PDFZoran DjurdjevicNo ratings yet

- 04 - TočkoviDocument36 pages04 - TočkoviZoran DjurdjevicNo ratings yet

- X-Force NfoDocument2 pagesX-Force NfoZoran DjurdjevicNo ratings yet

- Read MeDocument21 pagesRead MeJosue MoralesNo ratings yet

- Wheat StoneDocument55 pagesWheat StoneZoran DjurdjevicNo ratings yet

- Hip 0707Document1 pageHip 0707Zoran DjurdjevicNo ratings yet

- APFDocument4 pagesAPFZoran DjurdjevicNo ratings yet

- Conair Product Profile PortfolioDocument12 pagesConair Product Profile PortfolioKosdila AprillianiNo ratings yet

- 12 Ton Fixed Height Tripod Jack Business Jets: Model 7212BDocument4 pages12 Ton Fixed Height Tripod Jack Business Jets: Model 7212BGenaire LimitedNo ratings yet

- WoodweyDocument19 pagesWoodweyMichael PatrickNo ratings yet

- Seminar Report Rohit JainDocument49 pagesSeminar Report Rohit JainAshish Rawat25% (4)

- ISO Tolerances For Holes (ISO 286-2) - 400mm To 3150 MMDocument2 pagesISO Tolerances For Holes (ISO 286-2) - 400mm To 3150 MMchubee94No ratings yet

- Six Sigma Through Poka-Yoke: A Navigation Through Literature ArenaDocument13 pagesSix Sigma Through Poka-Yoke: A Navigation Through Literature Arenaprabhulean14No ratings yet

- Kristen's Cookie Production Process and Capacity AnalysisDocument33 pagesKristen's Cookie Production Process and Capacity AnalysisSamkit Kirti Shah100% (1)

- Mastercool Scule Dispozitive Accesorii FrigotehnieDocument88 pagesMastercool Scule Dispozitive Accesorii FrigotehnieraducelfrumosNo ratings yet

- 3.list of Abbreviations For StudentsDocument4 pages3.list of Abbreviations For Studentsjaved alamNo ratings yet

- 5 Erection Work of Balasinor-2 SDNDocument15 pages5 Erection Work of Balasinor-2 SDNPradeep jainNo ratings yet

- Catalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFDocument52 pagesCatalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFPedro MalpicaNo ratings yet

- 1338-Right Angle Gear Drives PDFDocument7 pages1338-Right Angle Gear Drives PDFdgkmurtiNo ratings yet

- S09723820 Xls-RevkDocument1 pageS09723820 Xls-RevkRinda ManuNo ratings yet

- BS en 12310-2Document12 pagesBS en 12310-2rajivr_ranjan_verma100% (1)

- Cloudera Connector For TableauDocument12 pagesCloudera Connector For Tableausoma1243No ratings yet

- Lippmann Jawmanual 07 03 08 Locked PDFDocument77 pagesLippmann Jawmanual 07 03 08 Locked PDFMarco Antonio Salcedo100% (7)

- CHAPTER 1.3 Prod PLanning SystemDocument5 pagesCHAPTER 1.3 Prod PLanning SystemSyrill CayetanoNo ratings yet

- ProjectCalcs KEYDocument72 pagesProjectCalcs KEYHaider Shadfan100% (1)

- Customer Satisfaction Hyundai MotorsDocument72 pagesCustomer Satisfaction Hyundai MotorshariharaNo ratings yet

- Iip Project On Cease FireDocument74 pagesIip Project On Cease FireSomraj Pathak100% (1)

- Komatsu D85EX-15 - D85PX-15 Shop ManualDocument924 pagesKomatsu D85EX-15 - D85PX-15 Shop ManualJovie GrohlNo ratings yet

- Purdue CS307 Software EngineeringDocument30 pagesPurdue CS307 Software EngineeringAlec GorgeNo ratings yet

- Analysis of Air BerlinDocument9 pagesAnalysis of Air BerlinDanny TsaiNo ratings yet

- Blast Effects Intro PDFDocument23 pagesBlast Effects Intro PDFAhmed TahaNo ratings yet

- New High-Performance, Low-Power STN2100 OBD Interpreter IC Now AvailableDocument3 pagesNew High-Performance, Low-Power STN2100 OBD Interpreter IC Now AvailablePR.comNo ratings yet

- BPMon Housekeeping JobsDocument13 pagesBPMon Housekeeping JobsDeepak SharmaNo ratings yet

- Ashby, Michael F. - Materials Selection in Mechanical Design-Elsevier (2011)Document22 pagesAshby, Michael F. - Materials Selection in Mechanical Design-Elsevier (2011)ritzky fachriNo ratings yet

- JDE Plant and EAMDocument2 pagesJDE Plant and EAMAang LudiNo ratings yet

- The Daimler-Chrysler MergerDocument24 pagesThe Daimler-Chrysler MergerSunil ShettyNo ratings yet

- 1Document9 pages1sureya smileyNo ratings yet